Introduction: Navigating the Global Market for stylecnc laser

In today’s competitive landscape, sourcing the right CNC laser equipment can be a daunting task for B2B buyers, particularly for those in emerging markets like Africa and South America, as well as established regions such as Europe and the Middle East. The stylecnc laser technology has revolutionized manufacturing and crafting across various sectors, but with a plethora of options available, discerning which machines meet your specific needs can be overwhelming. This comprehensive guide aims to simplify that process by exploring the diverse types of CNC laser machines, including cutters, engravers, and welders, while also delving into their applications across different industries.

Our guide will equip you with essential knowledge on supplier vetting, key specifications to consider, and cost implications, ensuring you make informed purchasing decisions. Whether you’re a small business owner in Nigeria seeking entry-level equipment or a manufacturer in Germany looking for high-power fiber lasers, this resource is tailored to address your unique requirements. By understanding the nuances of the global market for stylecnc lasers, you can confidently navigate your purchasing journey, ultimately enhancing your operational efficiency and product quality. Empower yourself with insights that not only streamline your sourcing process but also position your business for success in an increasingly digital and automated world.

Understanding stylecnc laser Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CO2 Laser Engraving Machines | Utilizes CO2 gas for engraving and cutting; ideal for non-metals | Woodworking, textiles, signage, arts & crafts | Pros: Cost-effective, versatile for various materials. Cons: Limited metal cutting capabilities. |

| Fiber Laser Cutting Machines | Employs fiber optics to cut metals; high precision and speed | Metal fabrication, automotive, aerospace | Pros: Efficient for thick metals, low maintenance. Cons: Higher initial investment. |

| Laser Marking Machines | Focused on marking and engraving; can handle metals and plastics | Branding, part identification, jewelry | Pros: High-quality markings, fast processing. Cons: May require additional software for complex designs. |

| Handheld Laser Markers | Portable and versatile; suitable for various engraving tasks | Fieldwork, small-scale production, customization | Pros: Easy to use, flexible for different locations. Cons: Limited power compared to stationary models. |

| Mini Laser Cutters | Compact design for small spaces; suitable for hobbyists and startups | Crafting, small-scale production, prototyping | Pros: Affordable, user-friendly. Cons: Limited cutting size and material thickness. |

What Are the Characteristics of CO2 Laser Engraving Machines?

CO2 laser engraving machines are designed primarily for non-metal materials such as wood, leather, acrylic, and textiles. They are known for their affordability and versatility, making them an excellent choice for small businesses and hobbyists. When considering a CO2 laser, buyers should evaluate the power options available (ranging from 40W to 180W) and the machine’s compatibility with various materials. This type is particularly suitable for applications in signage, arts, and crafts, allowing businesses to create customized products with ease.

How Do Fiber Laser Cutting Machines Stand Out?

Fiber laser cutting machines are distinguished by their ability to cut through metals with high precision and speed. They utilize a 1064nm laser beam, making them ideal for heavy-duty applications in industries such as automotive and aerospace. These machines can handle a wide range of metals, including stainless steel and aluminum, and are capable of cutting materials up to 200 mm thick. Buyers should consider the power range (typically from 1,500W to 60,000W) and the machine’s efficiency, as fiber lasers require less maintenance than their CO2 counterparts, albeit at a higher initial cost.

What Are the Key Features of Laser Marking Machines?

Laser marking machines are primarily used for engraving and marking on both metal and non-metal surfaces. They offer high-quality, precise markings that are essential for branding and part identification. These machines can be integrated into production lines, providing fast processing times. Businesses should assess the machine’s marking speed and the software compatibility for complex designs. While they are generally efficient and reliable, additional software may be necessary for intricate tasks, making it crucial for buyers to consider their specific marking needs.

Why Consider Handheld Laser Markers?

Handheld laser markers provide a portable solution for engraving tasks and are particularly useful for fieldwork and small-scale production. Their flexibility allows operators to work in various environments, making them ideal for customization and quick jobs. Buyers should look for models that offer a balance between power and portability, as these machines typically have lower wattage than stationary options. While they are user-friendly and cost-effective, their cutting power is limited compared to more robust machines, which may restrict their use for larger projects.

What Benefits Do Mini Laser Cutters Offer to Small Businesses?

Mini laser cutters are compact and designed for hobbyists or small startups, making them an attractive option for businesses with limited space. They are generally affordable and easy to operate, enabling users to produce crafts, prototypes, and small-scale production items. When purchasing a mini laser cutter, businesses should consider the maximum cutting size and material thickness, as these machines often have limitations compared to larger models. Despite these constraints, they offer a great entry point for new businesses looking to explore laser technology without a significant investment.

Key Industrial Applications of stylecnc laser

| Industry/Sector | Specific Application of stylecnc laser | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Precision Metal Fabrication | Enhanced accuracy and reduced waste in production | Evaluate machine power and compatibility with materials used |

| Signage and Advertising | Custom Sign Making | Ability to create intricate designs and personalized signage | Look for high-speed cutting and engraving capabilities |

| Textile and Fashion | Fabric Cutting and Engraving | Streamlined production processes and unique designs | Ensure compatibility with various fabric types and thicknesses |

| Electronics and Aerospace | Component Marking and Etching | Improved traceability and branding on components | Consider laser precision and material compatibility |

| Jewelry Design | Metal Jewelry Cutting and Engraving | High-quality finishes and intricate detailing | Assess machine size and power for different metal types |

How is stylecnc laser Used in Manufacturing for Precision Metal Fabrication?

In the manufacturing sector, stylecnc lasers are essential for precision metal fabrication. They allow businesses to cut and shape metals with exceptional accuracy, which significantly reduces material waste and production costs. This technology is particularly beneficial for manufacturers in regions like Africa and South America, where optimizing resources is crucial. Buyers should focus on the machine’s power and ensure it can handle the specific metals they work with, such as stainless steel or aluminum.

What Are the Benefits of stylecnc Laser in Signage and Advertising?

In the signage and advertising industry, stylecnc lasers are used to create custom signs that feature intricate designs and personalized branding. The ability to engrave and cut various materials, including acrylic and wood, allows businesses to stand out in competitive markets. For international buyers, especially in Europe, sourcing machines with high-speed capabilities is essential to meet fast turnaround times and design flexibility.

How Does stylecnc Laser Enhance Production in Textile and Fashion?

The textile and fashion industry leverages stylecnc lasers for fabric cutting and engraving, enabling designers to produce unique patterns and designs efficiently. This technology streamlines production processes, allowing for rapid prototyping and customization. Buyers from regions like the Middle East should consider the machine’s ability to handle different fabric types and thicknesses to ensure versatility in production.

Why is stylecnc Laser Important for Electronics and Aerospace Component Marking?

In the electronics and aerospace sectors, stylecnc lasers are crucial for marking and etching components, providing improved traceability and branding. This application is vital for maintaining quality control and compliance with industry standards. International buyers must evaluate the precision of the laser and its compatibility with various materials, ensuring it meets the stringent requirements of these highly regulated industries.

How is stylecnc Laser Transforming Jewelry Design?

Jewelry designers utilize stylecnc lasers for cutting and engraving metal pieces, resulting in high-quality finishes and intricate detailing that enhance the aesthetic appeal of their products. This technology allows for the creation of unique, customized jewelry pieces that cater to consumer preferences. Buyers should assess the machine’s size and power capabilities to work with various metal types, ensuring they can produce a diverse range of designs.

3 Common User Pain Points for ‘stylecnc laser’ & Their Solutions

Scenario 1: Navigating the Complex Selection Process of CNC Lasers

The Problem: B2B buyers often feel overwhelmed by the extensive variety of CNC laser machines available in the market. With numerous options ranging from entry-level to advanced industrial machines, buyers struggle to determine which machine best suits their specific operational needs and budget. This confusion can lead to indecision, delaying potential projects and resulting in lost revenue opportunities.

The Solution: To effectively navigate the selection process, buyers should begin by conducting a thorough needs assessment. Identify the types of materials you will be working with, such as wood, metal, or acrylic, and the specific applications, whether it’s cutting, engraving, or marking. Utilize STYLECNC’s online resources, such as machine comparison charts and customer reviews, to evaluate performance metrics and user satisfaction. Additionally, consider reaching out to STYLECNC’s customer support team for personalized guidance based on your operational requirements. By clearly defining your needs and leveraging available resources, you can confidently select a CNC laser machine that aligns with your business goals.

Scenario 2: Addressing Maintenance and Downtime Concerns

The Problem: Frequent downtime due to maintenance issues is a significant pain point for B2B buyers using CNC laser machines. Buyers often lack the expertise to maintain their equipment properly, leading to unexpected breakdowns that disrupt production schedules and increase operational costs.

The Solution: Establishing a proactive maintenance schedule is essential for minimizing downtime. Buyers should refer to the user manual provided by STYLECNC for specific maintenance recommendations tailored to their laser machine model. Regularly scheduled inspections and preventive measures, such as cleaning lenses, checking alignment, and lubricating moving parts, can significantly extend the lifespan of the equipment. Additionally, consider investing in training for your staff on basic maintenance procedures or enrolling them in workshops offered by STYLECNC. This not only empowers your team with the necessary skills but also fosters a culture of care and responsibility towards the equipment, ultimately enhancing productivity and reducing the risk of unexpected failures.

Scenario 3: Overcoming Technical Skill Gaps in Laser Operation

The Problem: Many businesses, particularly small and medium enterprises, face a skills gap when it comes to operating advanced CNC laser machines. Employees may lack the technical know-how required to utilize the machines efficiently, leading to suboptimal performance and increased error rates in production.

The Solution: To bridge the technical skills gap, B2B buyers should prioritize comprehensive training programs for their operators. STYLECNC often provides training resources, including user manuals, video tutorials, and online courses focused on machine operation and software utilization. Additionally, consider organizing on-site training sessions with STYLECNC’s technical experts to offer hands-on experience tailored to your specific machine and applications. By investing in your team’s education, you not only enhance their confidence and competence but also ensure that your operations run smoothly and efficiently, ultimately leading to higher quality outputs and reduced waste.

Strategic Material Selection Guide for stylecnc laser

What Are the Key Properties of Common Materials for StyleCNC Laser Applications?

When selecting materials for use with StyleCNC laser machines, understanding the properties of each material is crucial for optimizing performance and achieving desired outcomes. Below are analyses of four common materials used in laser applications, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Do Metals Perform in Laser Cutting and Engraving Applications?

Key Properties: Metals, such as stainless steel and aluminum, exhibit high durability and strength. They can withstand high temperatures and pressures, making them suitable for various industrial applications. Corrosion resistance varies, with stainless steel offering superior protection against oxidation and rust.

Pros & Cons: The durability of metals allows for long-lasting end products, making them ideal for heavy-duty applications. However, the cost of high-quality metal can be significant, and the complexity of manufacturing processes may require specialized equipment and expertise. Additionally, while metals are excellent for structural applications, they may not be suitable for intricate designs without advanced laser technology.

Impact on Application: Metals are compatible with a range of laser cutting and engraving techniques, enabling precise cuts and engravings. They are widely used in industries such as automotive, aerospace, and manufacturing.

Considerations for International Buyers: Compliance with international standards, such as ASTM for metals, is essential. Buyers from regions like Africa and South America should consider the availability of specific metal grades and their implications for local manufacturing practices.

What Are the Benefits of Using Wood in Laser Applications?

Key Properties: Wood is a versatile material with natural aesthetics and varying densities. It is generally easy to cut and engrave, with a lower melting point compared to metals, allowing for more intricate designs.

Pros & Cons: Wood offers a cost-effective solution for a wide range of applications, from crafts to furniture manufacturing. However, its susceptibility to moisture and pests can limit its durability. Additionally, the quality of wood can vary significantly, impacting the final product.

Impact on Application: Wood is particularly well-suited for decorative items, signage, and furniture. The ability to create detailed engravings makes it a popular choice for custom products.

Considerations for International Buyers: Buyers should be aware of regulations regarding sustainable sourcing and certifications, especially in regions like Europe, where environmental standards are stringent.

How Do Plastics Compare in Laser Cutting and Engraving?

Key Properties: Plastics, such as acrylic and polycarbonate, are lightweight and available in various colors and finishes. They typically have lower melting points, making them easy to cut and engrave with lasers.

Pros & Cons: The affordability and versatility of plastics make them suitable for a wide range of applications, including signage and packaging. However, they may not offer the same level of durability as metals or wood, and certain types can emit harmful fumes when cut, necessitating proper ventilation.

Impact on Application: Plastics are widely used in consumer products, promotional items, and architectural applications due to their aesthetic appeal and ease of customization.

Considerations for International Buyers: Compliance with safety standards, such as those set by JIS or DIN, is critical for buyers in regions like Japan and Germany. Additionally, understanding the local market’s preferences for specific plastic types can guide purchasing decisions.

What Are the Advantages of Using Glass in Laser Applications?

Key Properties: Glass is a non-metallic material that offers excellent optical clarity and can be engraved to create intricate designs. It is resistant to corrosion and can withstand high temperatures.

Pros & Cons: Glass provides a high-end finish for products like awards and decorative items. However, it is brittle and can break easily during processing, which may lead to increased waste and costs. The complexity of working with glass may also require specialized laser settings.

Impact on Application: Glass is ideal for applications that require high precision and aesthetic appeal, such as trophies, awards, and decorative pieces.

Considerations for International Buyers: Buyers should consider the fragility of glass and the need for careful handling during shipping and processing. Compliance with safety regulations for glass products is also essential, particularly in regions with strict consumer protection laws.

Summary Table of Material Selection for StyleCNC Laser

| Material | Typical Use Case for stylecnc laser | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Metals | Automotive parts, industrial components | High durability and strength | Higher cost and manufacturing complexity | High |

| Wood | Furniture, crafts, signage | Cost-effective and aesthetically pleasing | Susceptible to moisture and pests | Medium |

| Plastics | Signage, packaging, consumer products | Lightweight and versatile | Lower durability and potential harmful fumes | Low |

| Glass | Awards, decorative items | High precision and aesthetic appeal | Brittle and requires careful handling | Medium |

This guide provides actionable insights for international B2B buyers looking to select the right materials for their StyleCNC laser applications, ensuring they make informed decisions that align with their operational needs and market standards.

In-depth Look: Manufacturing Processes and Quality Assurance for stylecnc laser

What Are the Key Manufacturing Processes for Stylecnc Laser Machines?

Understanding the manufacturing processes for Stylecnc laser machines is crucial for B2B buyers looking to invest in reliable and high-quality equipment. The typical manufacturing stages include material preparation, forming, assembly, and finishing, each employing specific techniques to ensure product reliability and performance.

How Is Material Prepared for Stylecnc Laser Machines?

Material preparation is the first step in the manufacturing process. It involves sourcing high-quality raw materials, including metals and polymers, which are essential for the durability of laser machines. Stylecnc emphasizes using materials that meet international standards to ensure compatibility with various applications, such as cutting, engraving, and welding.

Once materials are sourced, they undergo a rigorous selection process that includes inspections for defects and inconsistencies. This initial quality check ensures that only the best materials are used in production, contributing to the overall performance and longevity of the laser machines.

What Forming Techniques Are Used in the Production of Stylecnc Laser Machines?

The forming stage involves various techniques to shape and prepare the materials for assembly. Common methods include:

-

Laser Cutting: This method is often used to create intricate parts and components from sheet metal. Utilizing the same technology as the finished product, this process guarantees precision and accuracy.

-

CNC Machining: Computer Numerical Control (CNC) machines are employed to achieve high precision in forming components that require tight tolerances.

-

Bending and Welding: After cutting, parts may be bent into specific shapes or welded together. Skilled technicians ensure that these processes are executed flawlessly to maintain structural integrity.

These forming techniques are essential for creating components that meet the specific design and performance requirements of the final laser machines.

How Is Assembly Conducted for Stylecnc Laser Machines?

The assembly stage is critical, as it brings together all the components manufactured in the previous steps. This process is often carried out in a clean and controlled environment to minimize contamination and ensure precision. Key aspects of assembly include:

-

Component Integration: Each part, from the laser source to the control system, is meticulously integrated. Technicians follow strict guidelines to ensure that all components function harmoniously.

-

Calibration and Alignment: After assembly, machines undergo calibration to ensure that they operate within specified tolerances. This step is vital for achieving optimal performance during actual use.

-

Initial Testing: Before moving to the finishing stage, initial tests are conducted to identify any potential issues. This proactive approach helps in addressing problems early in the manufacturing process.

What Quality Assurance Measures Are Implemented for Stylecnc Laser Machines?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that each Stylecnc laser machine meets international standards and customer expectations. The QA process encompasses several checkpoints, standards, and testing methods.

Which International Standards Are Relevant for Quality Assurance in Stylecnc Laser Machines?

Stylecnc adheres to several international quality standards, including:

-

ISO 9001: This standard outlines a framework for a quality management system (QMS), focusing on consistently providing products that meet customer and regulatory requirements.

-

CE Certification: Essential for selling products in Europe, CE marking signifies that a product meets EU safety, health, and environmental protection standards.

-

API Standards: For machines used in specific industries such as oil and gas, adhering to API standards ensures that the equipment is suitable for demanding environments.

These certifications not only enhance product credibility but also assure international buyers of the quality they can expect.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is embedded at various stages of the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): Before materials are used in production, they undergo inspections to verify that they meet specified criteria.

-

In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to monitor the quality of components and assembly processes. This ongoing assessment helps in identifying deviations early.

-

Final Quality Control (FQC): After assembly, the final product undergoes comprehensive testing to ensure it meets all operational and safety standards. This includes functionality tests and performance evaluations.

By implementing these QC checkpoints, Stylecnc ensures that any potential issues are addressed before the products reach the market.

How Can B2B Buyers Verify Quality Control Practices of Stylecnc Laser Suppliers?

For international B2B buyers, verifying a supplier’s quality control practices is essential in ensuring a reliable partnership. Here are effective strategies to assess QC measures:

What Auditing Practices Can B2B Buyers Utilize?

-

Supplier Audits: Conducting on-site audits can provide valuable insights into the manufacturing processes and quality control measures employed by Stylecnc. Auditors can assess the facility, equipment, and protocols in place.

-

Reviewing Quality Reports: Requesting detailed quality reports can help buyers understand the frequency of QC checks and the results of any past inspections or tests.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality assurance processes. These organizations often have established protocols for assessing compliance with international standards.

What Specific Quality Control Nuances Should International Buyers Consider?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. These include:

-

Regulatory Compliance: Understanding the regulatory environment in their respective countries is crucial. Buyers should ensure that the products meet local regulations, which can differ significantly from international standards.

-

Cultural Differences in Quality Expectations: Different regions may have varying expectations regarding product quality and support. Open communication with suppliers about these expectations can help avoid misunderstandings.

-

Logistics and Supply Chain Considerations: Quality control does not end with manufacturing; it extends to logistics. Buyers should assess how suppliers manage their supply chains to maintain quality during shipping and delivery.

By being diligent in verifying quality control practices, B2B buyers can make informed decisions and foster successful partnerships with Stylecnc laser suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stylecnc laser’

Introduction

Navigating the procurement of CNC laser machines, particularly from StyleCNC, can be complex yet rewarding. This guide aims to equip international B2B buyers with a practical checklist to streamline the sourcing process, ensuring they select the right machine that aligns with their business needs and budget.

Step 1: Define Your Technical Specifications

Before beginning your search, it’s essential to outline your specific requirements. Consider the materials you will work with—metals, plastics, wood, or textiles—and the types of operations you need, such as cutting, engraving, or marking.

– Power and Size: Determine the wattage and size that fit your operational capacity.

– Precision Needs: Assess the level of precision required for your projects.

Step 2: Research Available Models

Explore the range of CNC laser machines offered by StyleCNC. Familiarize yourself with the specifications of various models, such as the STJ1390 and ST-FC3015FM.

– Compare Features: Look for unique features that suit your needs, such as cutting speed, maximum thickness, and user-friendliness.

– User Reviews: Check for customer feedback to gauge reliability and performance.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Accreditations and Certifications: Ensure the supplier has relevant certifications that comply with international standards.

– After-Sales Support: Investigate the level of support offered, including training, maintenance, and warranty options.

Step 4: Request Quotations and Compare Pricing

Once you’ve narrowed down potential suppliers, request detailed quotations.

– Breakdown of Costs: Ensure the quotation includes all costs—machine price, shipping, installation, and any additional fees.

– Value for Money: Compare not just on price but also on features and after-sales support to assess overall value.

Step 5: Assess Delivery and Installation Options

Understanding the logistics of delivery and installation is vital for smooth operation.

– Shipping Times: Confirm estimated delivery times and shipping methods.

– Installation Services: Check if the supplier provides installation services and what the process entails.

Step 6: Negotiate Terms and Conditions

Before finalizing the purchase, negotiate terms that protect your interests.

– Payment Terms: Discuss payment schedules that fit your cash flow.

– Return Policy: Ensure there is a clear return policy in case the machine does not meet your expectations.

Step 7: Finalize Purchase and Prepare for Operation

Once all terms are agreed upon, finalize your purchase.

– Documentation: Ensure you receive all necessary documentation, including user manuals and warranty details.

– Training: Schedule any training sessions to ensure your team is well-prepared to operate the machine effectively.

By following these steps, B2B buyers can make informed decisions that enhance their operational capabilities with StyleCNC laser machines.

Comprehensive Cost and Pricing Analysis for stylecnc laser Sourcing

What Are the Key Cost Components in Sourcing Stylecnc Lasers?

When sourcing Stylecnc lasers, understanding the cost structure is critical for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly influences the price. For example, CO2 and fiber laser machines utilize different types of lasers and components, impacting the overall cost. High-quality components may raise the initial price but can lead to better performance and longevity.

-

Labor: Labor costs vary based on the complexity of the machine and the skill level required for assembly and quality assurance. Automated systems may reduce labor costs over time but require initial investment in skilled technicians.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing practices can help lower these costs, which can be passed on to buyers.

-

Tooling: Custom tooling can be a significant expense, particularly for machines designed for specific applications or industries. Standardized tooling may reduce costs but limit customization options.

-

Quality Control: Ensuring that lasers meet international standards requires rigorous QC processes. Investing in quality assurance can prevent costly defects and returns, ultimately impacting pricing.

-

Logistics: Shipping and handling costs, especially for international buyers, can add considerable expense. Factors such as shipping distance, weight, and chosen logistics partners play crucial roles.

-

Margin: Suppliers typically apply a profit margin to cover their costs and ensure sustainability. This margin can vary widely based on market conditions and competition.

How Do Price Influencers Affect Stylecnc Laser Costs?

Several factors influence the final pricing of Stylecnc lasers:

-

Volume/MOQ: Ordering in larger quantities often leads to lower per-unit costs. Understanding minimum order quantities (MOQs) can help buyers negotiate better deals.

-

Specifications and Customization: Custom features can increase costs significantly. Buyers should weigh the benefits of customization against budget constraints.

-

Materials: The choice between standard and premium materials will impact the price. Opting for more durable materials may result in higher upfront costs but lower maintenance expenses over time.

-

Quality and Certifications: Products that meet international quality standards or have certifications may come at a premium. However, these certifications can be crucial for compliance and marketability in certain regions.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more but offer better support and warranties.

-

Incoterms: Understanding the terms of sale is essential for international buyers. Incoterms dictate who bears responsibility for shipping costs, insurance, and tariffs, which can significantly influence the total cost.

What Buyer Tips Can Help in Sourcing Stylecnc Lasers Efficiently?

To maximize value when sourcing Stylecnc lasers, consider the following strategies:

-

Negotiate Wisely: Leverage volume purchases and long-term relationships to negotiate better pricing. Suppliers may be more flexible if they see potential for repeat business.

-

Focus on Cost Efficiency: Look beyond the initial purchase price. Consider the Total Cost of Ownership (TCO), which includes maintenance, energy consumption, and potential downtime.

-

Understand Pricing Nuances for International Buyers: Be aware of additional costs such as customs duties, taxes, and shipping fees when importing lasers. These can significantly affect your total expenditure.

-

Research and Compare: Don’t settle for the first offer. Conduct thorough market research and compare multiple suppliers to ensure competitive pricing and terms.

-

Leverage Local Knowledge: Engage with local representatives or trade organizations in your region. They can provide insights into the best practices and help navigate potential hurdles in sourcing.

Disclaimer on Pricing

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and up-to-date pricing information tailored to your needs.

Alternatives Analysis: Comparing stylecnc laser With Other Solutions

Exploring Alternatives to Stylecnc Laser Solutions

When selecting a laser cutting or engraving solution, it’s crucial for B2B buyers to consider various options that meet their specific operational needs and budget constraints. While Stylecnc laser machines offer a robust range of features, exploring alternatives can provide additional insights into the best fit for your business. This analysis compares Stylecnc laser solutions with other viable technologies in the market.

| Comparison Aspect | Stylecnc Laser | CO2 Laser Cutting Machine | Fiber Laser Cutting Machine |

|---|---|---|---|

| Performance | High precision, diverse materials | Effective for non-metals | Superior speed and efficiency on metals |

| Cost | $2,400 – $56,800 | $1,500 – $30,000 | $12,000 – $60,000 |

| Ease of Implementation | User-friendly setup | Moderate complexity | Requires skilled operation |

| Maintenance | Low maintenance needs | Moderate upkeep | Generally higher maintenance |

| Best Use Case | Versatile for crafts and production | Ideal for woodworking and fabric | Best for heavy-duty metal fabrication |

What Are the Advantages and Disadvantages of CO2 Laser Cutting Machines?

CO2 laser cutting machines are widely used for their effectiveness in cutting non-metal materials like wood, acrylic, and fabric. They are generally more affordable than fiber lasers, making them attractive for small businesses and hobbyists. However, their performance can lag when it comes to cutting metals, particularly thicker gauges. Additionally, CO2 lasers require more frequent maintenance and the cost of consumables can add up over time.

How Do Fiber Laser Cutting Machines Compare to Stylecnc Lasers?

Fiber laser cutting machines excel in cutting metals with exceptional speed and accuracy. They are known for their ability to handle a wide variety of metals, including stainless steel and aluminum, with minimal thermal distortion. However, fiber lasers tend to be more expensive and may require specialized training to operate effectively. This makes them less accessible for smaller operations or those new to laser technology, despite their advanced capabilities.

Conclusion: How Should B2B Buyers Choose the Right Laser Solution?

Choosing the right laser solution involves assessing your specific business needs, budget, and operational capabilities. Stylecnc lasers offer a balanced approach for both hobbyists and industrial users, making them versatile for various applications. However, depending on the primary materials you work with and your production scale, exploring CO2 and fiber laser options may provide additional benefits. Ultimately, the right choice will align with your production goals, skill level, and financial considerations, ensuring you invest in a solution that drives efficiency and growth for your business.

Essential Technical Properties and Trade Terminology for stylecnc laser

What Are the Key Technical Properties of Stylecnc Laser Machines?

When considering a CNC laser machine, understanding its technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to evaluate:

1. Laser Type: CO2 vs. Fiber

The choice between CO2 and fiber lasers significantly impacts the machine’s capabilities. CO2 lasers are typically used for non-metal materials like wood, acrylic, and leather, while fiber lasers excel in cutting metals such as stainless steel and aluminum. B2B buyers should assess their primary materials to select the appropriate laser type, ensuring optimal performance and cost-efficiency.

2. Power Rating

Power ratings, expressed in watts (W), determine the cutting and engraving capabilities of the laser. For instance, a 60W CO2 laser can handle thin materials, while a 2000W fiber laser is necessary for thicker metals. Understanding power requirements helps businesses choose machines that meet their production needs without incurring unnecessary energy costs.

3. Working Area

The working area defines the maximum size of the material that can be processed. Larger working areas allow for more extensive projects and increased productivity, which is vital for businesses with diverse applications. Buyers must consider their typical project sizes to avoid limitations in production.

4. Cutting Speed

Measured in meters per minute (m/min), cutting speed indicates how quickly a machine can complete a job. High-speed cutting is essential for meeting tight deadlines and improving throughput. Businesses should balance speed with precision, as faster cutting may compromise the quality of intricate designs.

5. Material Compatibility

Different laser machines are designed to work with specific materials. It’s crucial for B2B buyers to verify that the machine can handle the materials they intend to use, whether it’s wood, metal, or plastic. This compatibility ensures that businesses can diversify their offerings and cater to various markets.

6. Software Compatibility

CNC laser machines often require specific software for design and operation. Compatibility with popular CAD/CAM software can streamline the workflow and reduce training time. Buyers should evaluate the software ecosystem around a machine to ensure it integrates well with their existing processes.

What Are Common Trade Terms Related to Stylecnc Lasers?

Navigating the purchasing process for CNC laser machines involves familiarizing oneself with industry-specific terminology. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of CNC lasers, knowing the OEM can help buyers assess the quality and reliability of the machines they are considering.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units a supplier is willing to sell. Understanding MOQ is critical for businesses planning their budgets and inventory levels, especially when scaling production or entering new markets.

3. RFQ (Request for Quotation)

An RFQ is a formal document that buyers send to suppliers to request pricing for specific products or services. When considering a CNC laser, submitting an RFQ can facilitate better pricing and terms, making it an essential step in the procurement process.

4. Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps businesses understand shipping costs, risk management, and delivery obligations when importing machinery.

5. Lead Time

Lead time refers to the period from placing an order until its delivery. For B2B buyers, understanding lead times is essential for planning production schedules and managing customer expectations.

6. Warranty and Support

Warranties cover repairs and replacements for a specified period, while support includes customer service and technical assistance. Knowing the warranty terms and support options is crucial for businesses to ensure they have reliable recourse should issues arise with their CNC laser machines.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the stylecnc laser Sector

What Are the Key Trends Shaping the Global stylecnc Laser Market?

The global stylecnc laser market is witnessing significant growth driven by advancements in technology, increasing automation, and a rising demand for precision manufacturing. Key trends include the proliferation of fiber laser technology, which offers improved efficiency and cost-effectiveness compared to traditional CO2 lasers. This shift is particularly relevant for international B2B buyers, as fiber lasers can handle a wide range of materials, including metals and plastics, making them suitable for diverse applications across various industries, such as automotive, aerospace, and consumer goods.

Furthermore, the adoption of cloud-based solutions and Industry 4.0 principles is enhancing operational efficiency. These technologies enable real-time monitoring and predictive maintenance, allowing businesses to optimize their laser cutting processes. For buyers in regions like Africa, South America, the Middle East, and Europe, these innovations present opportunities for cost reduction and increased productivity.

Emerging markets are also experiencing a surge in demand for affordable, entry-level CNC laser machines, catering to small businesses and startups. This trend reflects a broader shift towards democratizing access to advanced manufacturing technologies. Buyers from developing regions are particularly interested in cost-effective solutions that do not compromise on quality, paving the way for brands like stylecnc to establish a robust presence.

How Can Sustainability and Ethical Sourcing Influence Your B2B Decisions in the stylecnc Laser Sector?

Sustainability is becoming a crucial consideration for B2B buyers in the stylecnc laser sector. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under scrutiny. Companies are increasingly looking for suppliers that prioritize sustainable practices, such as using energy-efficient machinery and minimizing harmful emissions.

Ethical sourcing plays a significant role in this context. Buyers are encouraged to partner with manufacturers who adhere to strict ethical standards, ensuring fair labor practices and responsible sourcing of materials. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are valuable indicators of a supplier’s commitment to sustainability.

Moreover, the integration of ‘green’ materials into the production process is gaining traction. Buyers can enhance their brand reputation and meet consumer demand by sourcing products made from recycled or eco-friendly materials. This trend not only supports environmental goals but also aligns with the growing consumer preference for sustainable products, thus influencing purchasing decisions across markets.

How Has the stylecnc Laser Sector Evolved Over Time?

The evolution of the stylecnc laser sector has been marked by rapid technological advancements and a shift in market demand. Initially, laser cutting technology was predominantly utilized in industrial settings for large-scale manufacturing. However, over the years, the accessibility of CNC laser machines has expanded to include small businesses, educational institutions, and hobbyists, facilitating a broader range of applications.

The introduction of affordable laser cutting machines has democratized the technology, allowing diverse sectors to leverage its capabilities. This evolution has been driven by an increasing emphasis on customization and precision, enabling businesses to produce intricate designs and components that meet specific customer needs. As a result, the stylecnc laser sector continues to grow, adapting to the dynamic requirements of global markets while maintaining a focus on innovation and efficiency.

Frequently Asked Questions (FAQs) for B2B Buyers of stylecnc laser

-

How do I choose the right CNC laser machine for my business?

Choosing the right CNC laser machine requires a careful assessment of your specific needs and budget. Start by identifying the materials you will be working with (e.g., wood, metal, acrylic) and the types of applications (cutting, engraving, marking) you require. Evaluate the power options available, as this will influence the thickness and speed of cutting. Additionally, consider the machine’s size and whether it fits your workspace. Finally, reviewing customer testimonials and seeking advice from suppliers can provide insights into the machine’s reliability and performance. -

What is the best laser engraver for small businesses?

For small businesses, the best laser engraver is often one that balances affordability and functionality. Models like the STJ6040 or STJ9060 are popular choices due to their compact design and versatility, allowing for a range of materials like wood, acrylic, and leather. These machines typically offer power options between 40W to 150W, making them suitable for various engraving and cutting tasks. Assess your specific needs, including volume and material types, to determine the best fit for your operations. -

How can I ensure the quality of the laser machines I purchase?

To ensure the quality of laser machines, it is essential to vet suppliers thoroughly. Look for manufacturers with a solid reputation and positive customer feedback. Request detailed specifications and certifications for the machines, and inquire about warranties and after-sales support. Additionally, consider visiting the manufacturer’s facility if possible, or ask for a demonstration to see the machine in action. Engaging with existing customers can also provide insights into the machine’s performance and reliability. -

What are the payment terms when purchasing CNC laser machines internationally?

Payment terms for international purchases of CNC laser machines typically vary by supplier but generally include options like wire transfers, letters of credit, or payment through escrow services. It’s essential to clarify these terms upfront and ensure they align with your financial policies. Many suppliers may require a deposit (usually 30-50%) before production, with the balance due upon completion or prior to shipment. Always seek clear documentation of payment terms to avoid misunderstandings. -

What is the minimum order quantity (MOQ) for CNC laser machines?

Minimum order quantities (MOQ) for CNC laser machines can vary significantly between suppliers. Some manufacturers may allow single-unit purchases, especially for entry-level machines, while others may have an MOQ of several units to ensure cost-effectiveness in production. When negotiating, consider your business’s needs and future growth; bulk orders may lead to discounts. Always confirm the MOQ with the supplier before finalizing your order. -

How can I customize my CNC laser machine to suit my needs?

Customization options for CNC laser machines often include adjustments in power settings, bed size, and additional features like rotary attachments for cylindrical objects. Many suppliers, including STYLECNC, offer customization services tailored to specific applications and materials. When discussing customization, be clear about your requirements and any specific functionalities you need. It’s also beneficial to ask about the implications of customization on lead times and costs. -

What logistics should I consider when importing CNC laser machines?

When importing CNC laser machines, logistics involve multiple factors such as shipping methods, customs clearance, and delivery timelines. Choose a reliable shipping partner experienced in handling industrial equipment to ensure safe transport. Understand the import regulations in your country, including any tariffs or taxes that may apply. Additionally, consider insurance coverage for the shipment to mitigate risks during transit. Coordinate with the supplier for accurate documentation to facilitate smooth customs clearance. -

How do I handle maintenance and support for my CNC laser machine?

Proper maintenance is crucial for the longevity and performance of CNC laser machines. Establish a routine maintenance schedule based on the manufacturer’s recommendations, which may include cleaning, software updates, and inspection of laser components. Ensure you have access to technical support from the supplier, whether through online resources, phone support, or on-site visits. Training for your staff on machine operation and troubleshooting can also enhance efficiency and minimize downtime.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Stylecnc Laser Manufacturers & Suppliers List

1. STYLECNC – CO2 Laser Engraver

Domain: stylecnc.com

Registered: 2015 (10 years)

Introduction: Affordable CNC Laser Cutter Engraving Machines for Sale – STYLECNC offers a variety of CNC laser machines including CO2 Laser Cutters, Fiber Laser Cutting Machines, Laser Marking Machines, and more. Key products include: 1. STJ1390: CO2 Laser Engraver (60W-180W) for wood, fabric, leather, glass, acrylic, paper, plastic, stone ($3,500 – $5,500). 2. STJ9060: Entry-level small laser engraver for begi…

2. Style CNC Laser – Key Products

Domain: stylecnclaser.com

Registered: 2023 (2 years)

Introduction: Key Products: 1. CO2 Laser Cutters – Affordable options for wood cutting (e.g., STJ1390, STJ1630A). 2. Fiber Laser Cutters – High precision for metal cutting (e.g., ST-FC3015E, ST-FC3015GAR). 3. Laser Welders – Handheld and automatic options for eco-friendly welding (e.g., LW1500A, LW1800R). 4. Laser Cleaners – Portable and industrial options for surface treatment (e.g., LC200, LC100B). 5. Laser E…

3. StyleCNC – Laser Cutter Comparison

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: StyleCNC laser cutter, potential purchase consideration, comparison with Bogong CNC machines, advice from community members, similar pricing and components, emphasis on trustable brands.

4. STYLECNC – Fiber Laser Cutter with Tube Cutter Attachment

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, STYLECNC – Fiber Laser Cutter with Tube Cutter Attachment, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. STYLECNC – CNC Laser Machines

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: This company, STYLECNC – CNC Laser Machines, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. STYLECNC – CNC Laser Machines

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: STYLECNC Laser is a professional industrial smart CNC laser machine manufacturer. They offer a range of products including laser cutters, engravers, welding machines, and cleaning systems.

7. STYLECNC – Acrylic Laser Cutting Machine

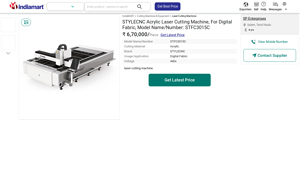

Domain: indiamart.com

Registered: 1996 (29 years)

Introduction: {‘product_name’: ‘STYLECNC Acrylic Laser Cutting Machine’, ‘model_name_number’: ‘STFC3015C’, ‘price’: ‘₹ 670000/piece’, ‘location’: ‘Salem, Tamil Nadu, India’, ‘cutting_material’: ‘Acrylic’, ‘brand’: ‘STYLECNC’, ‘usage_application’: ‘Digital Fabric’, ‘voltage’: ‘440v’, ‘seller_name’: ‘SP Enterprises’, ‘seller_contact_details’: ‘Sabari 14 Kannankuruci Main Road Chinnathirupathy Salem, Salem – 63600…

Strategic Sourcing Conclusion and Outlook for stylecnc laser

In the evolving landscape of laser technology, strategic sourcing plays a pivotal role for international B2B buyers looking to invest in stylecnc laser solutions. With a diverse range of options—from entry-level machines to high-powered industrial models—buyers can tailor their purchases to meet specific operational needs and budget constraints. Understanding the unique capabilities of each machine, such as CO2 and fiber laser technology, empowers businesses to make informed decisions that enhance productivity and innovation.

Investing in stylecnc lasers not only opens doors to precision manufacturing but also offers a competitive edge in various industries, including automotive, fashion, and metal fabrication. As markets in Africa, South America, the Middle East, and Europe continue to grow, the demand for high-quality laser cutting and engraving solutions will undoubtedly increase.

To capitalize on this opportunity, buyers are encouraged to conduct thorough market research and leverage the resources available from stylecnc. By aligning their sourcing strategies with the latest technological advancements and market trends, businesses can position themselves for success. Embrace the future of manufacturing with stylecnc lasers and unlock the potential for growth and innovation in your operations.