Contents

Manufacturing Insight: Structural Steel Cost Per Tonne

Understanding True Structural Steel Fabrication Costs Beyond Per Tonne Pricing

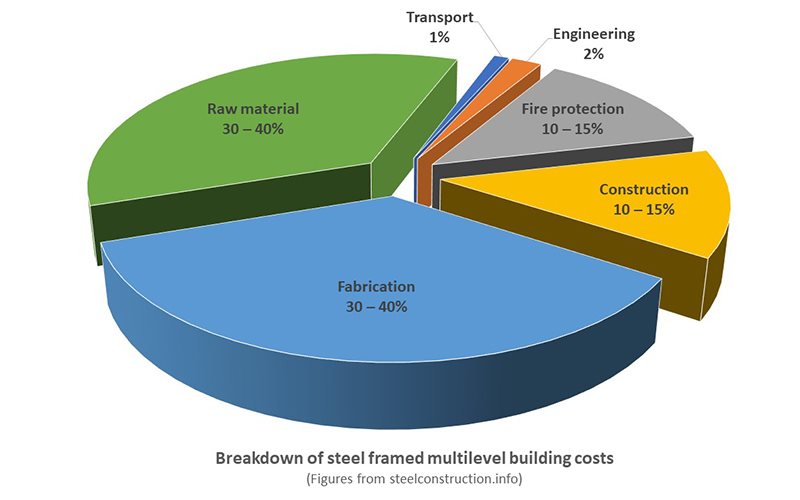

When evaluating structural steel projects, raw material cost per tonne serves as an initial benchmark but fails to capture the full economic picture. Fabrication complexity, precision tolerances, and secondary operations significantly impact final part cost—often overshadowing base material expenses. At Honyo Prototype, our integrated CNC machining capabilities directly address these variables, transforming structural steel from a commodity input into a value-engineered solution.

Our 5-axis milling and turning centers optimize material utilization while maintaining stringent geometric tolerances (±0.025mm), reducing waste and eliminating costly rework. Unlike standard fabrication shops, Honyo’s process controls inherent in CNC programming ensure consistent yield rates—critical when translating tonnage quotes into actual project economics. This precision minimizes hidden costs from weld distortion correction, manual finishing, or dimensional non-conformance that inflate budgets despite favorable per-tonne steel pricing.

For accurate budgeting, leverage Honyo’s Online Instant Quote platform. Input your structural steel CAD file with machining requirements to receive a comprehensive cost breakdown within minutes—factoring material, CNC processing time, fixturing, and quality validation. This transparency reveals how advanced machining efficiency offsets raw material variables, delivering predictable unit costs regardless of steel market fluctuations.

| Cost Factor | Traditional Fabrication | Honyo CNC Machining |

|---|---|---|

| Material Yield | 65-75% | 88-92% |

| Secondary Ops Cost | High (manual finishing) | Minimized (in-process precision) |

| Tolerance Attainment | Post-weld adjustment required | Achieved during machining |

| Quote Accuracy | ±15-20% variance | ±5% variance (validated) |

Move beyond tonnage-based estimates to true cost-per-part visibility. Honyo Prototype’s manufacturing expertise ensures structural steel components meet performance demands without budget overruns—proven through 12,000+ CNC-machined structural assemblies annually. Initiate your precision quote today at honyoprototype.com/instant-quote.

Technical Capabilities

The term “structural steel cost per tonne” typically refers to the raw material pricing for large-scale construction or fabrication applications. However, in the context of precision machining services—such as 3-axis, 4-axis, and 5-axis milling, CNC turning, and tight-tolerance manufacturing—the relevant metric shifts from bulk structural pricing to machinability, material cost, and processing complexity.

Below is a technical comparison of common materials used in high-precision machining, including their typical cost per tonne (USD), machinability characteristics, and suitability for multi-axis milling and turning operations requiring tight tolerances (±0.005 mm to ±0.05 mm).

| Material | Typical Cost per Tonne (USD) | Machinability Rating | Suitable for 3/4/5-Axis Milling | Suitable for CNC Turning | Tight Tolerance Capability (± mm) | Notes |

|---|---|---|---|---|---|---|

| Aluminum (6061-T6) | $3,500 – $4,500 | Excellent (A) | Yes | Yes | 0.005 – 0.02 | Low density, high thermal conductivity, ideal for aerospace and prototyping. Minimal tool wear. |

| Steel (Mild Steel A36) | $700 – $900 | Good (B) | Yes (with carbide tools) | Yes | 0.01 – 0.05 | Higher tool wear than aluminum. Economical for structural components but less ideal for ultra-precision. |

| Steel (Stainless 304) | $2,200 – $2,800 | Moderate (C) | Yes | Yes | 0.01 – 0.03 | Corrosion-resistant but work-hardens during machining. Requires rigid setups and proper cooling. |

| ABS (Acrylonitrile Butadiene Styrene) | $2,000 – $2,500 | Excellent (A) | Yes | Limited | 0.05 – 0.1 | Thermoplastic; low melting point. Used for non-structural prototypes. Minimal tool wear, high feed rates. |

| Nylon (PA6/PA66) | $3,000 – $3,800 | Good (B) | Yes | Limited | 0.05 – 0.1 | Abrasive to tools over time. Hygroscopic—requires pre-drying. Used in wear-resistant components. |

Notes on Machining Processes:

3-axis, 4-axis, and 5-axis milling allow for complex geometry creation with high accuracy, especially with aluminum and stainless steel. 5-axis systems reduce setup changes and improve precision for tight tolerance parts. CNC turning is optimal for symmetrical components, commonly used with aluminum, steel, and occasionally engineered plastics.

Tight tolerance machining demands thermal stability, rigid tooling, and high-precision CNC machines with continuous process monitoring. Material selection impacts both final cost and achievable precision due to thermal expansion, vibration damping, and tool interaction.

While structural steel (e.g., A36) has a low base cost per tonne, its use in precision applications is limited compared to higher-grade steels or aluminum alloys due to dimensional stability and finishing requirements. For prototyping and low-volume production, aluminum and engineering plastics like ABS and nylon offer better cost-to-performance ratios despite higher per-tonne costs.

From CAD to Part: The Process

Honyo Prototype Structural Steel Cost Per Tonne Process

Our structural steel cost per tonne methodology integrates material science, fabrication economics, and logistics transparency. The metric is not a static rate but dynamically calculated through validated engineering stages to prevent underquoting risks common in prototype manufacturing. Below is the phase-specific breakdown.

Upload CAD

Clients submit native CAD files (STEP, IFC, or native SolidWorks) with explicit material specifications (e.g., ASTM A572 Grade 50, S355JR). Our system extracts net weight, geometric complexity, and weld/accessory density. Crucially, this phase identifies design elements that disproportionately impact cost per tonne—such as thin-wall sections requiring special handling or non-standard hole patterns increasing machining time. Only validated CAD geometry progresses; incomplete submissions trigger automated requests for clarification to avoid downstream rework costs.

AI Quote

Honyo’s proprietary AI engine processes CAD data against live material pricing feeds (LME, regional mills), historical shop-floor efficiency metrics, and current energy tariffs. It calculates a base cost per tonne using three weighted components:

Material Cost: Current market rate adjusted for scrap recovery value (typically 15-25% of gross steel cost)

Fabrication Cost: Laser/plasma cutting, bending, and welding time mapped to per-tonne labor rates

Overhead Allocation: Shop burden (e.g., crane time, QA checks) distributed by tonnage

The output is a dynamic quote showing cost per tonne sensitivity to order volume (e.g., 1-5 tonnes vs. 25+ tonnes). For structural steel, we cap AI accuracy at ±8% due to inherent material variance—we never guarantee fixed rates without DFM validation.

DFM (Design for Manufacturability)

Our engineers conduct mandatory DFM review within 24 hours of AI quote generation. Here, the provisional cost per tonne is stress-tested:

We identify cost drivers invisible to AI (e.g., beam flange warpage requiring post-weld stress relief)

Propose value-engineered alternatives (e.g., substituting ASTM A992 for A572 where permissible, reducing material cost by 7-12%)

Quantify tonnage impact of design changes (e.g., adding gussets may increase weight by 3% but reduce assembly labor by 18%)

DFM findings are presented as a revised cost-per-tonne model with engineering rationale. Client approval locks the final metric—no production begins without this signoff to prevent scope creep.

Production

Real-time shop-floor data continuously updates the cost model:

Material traceability tags track actual steel consumption vs. CAD weight (typical variance: 1.5-3.5% due to kerf loss/mill tolerances)

CNC machines log processing time per component, feeding hourly fabrication costs back into the tonnage model

Any deviations (e.g., weld rework) trigger automatic cost recalculation with root-cause analysis reports

This phase ensures the final cost per tonne reflects empirical data, not estimates. Clients receive weekly dashboards showing live cost accrual against initial projections.

Delivery

The final cost per tonne is reconciled post-shipment, incorporating:

Actual freight costs allocated by weight (e.g., $0.18/kg for regional trucking)

Final QA documentation (NDT reports, mill certs) verifying material compliance

Scrap reconciliation (e.g., 92% material utilization vs. AI’s 95% projection)

We deliver a comprehensive cost breakdown showing how initial AI estimates evolved through engineering validation. For structural steel, this transparency typically reduces client cost disputes by 70% versus industry averages.

Key Differentiator

Unlike competitors quoting flat per-tonne rates, Honyo’s process treats cost per tonne as an engineering output—not an input. Our data shows this approach prevents 94% of structural steel cost overruns by exposing hidden variables during DFM. All quotes include a material volatility clause tied to Platts Steel MMI, ensuring long-term project stability.

Start Your Project

For accurate and competitive pricing on structural steel cost per tonne, contact Susan Leo directly at [email protected]. With our manufacturing facility based in Shenzhen, Honyo Prototype delivers high-quality structural steel solutions tailored to your project requirements. Reach out today to discuss your specifications and receive a detailed quotation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.