Introduction: Navigating the Global Market for strong materials that are light

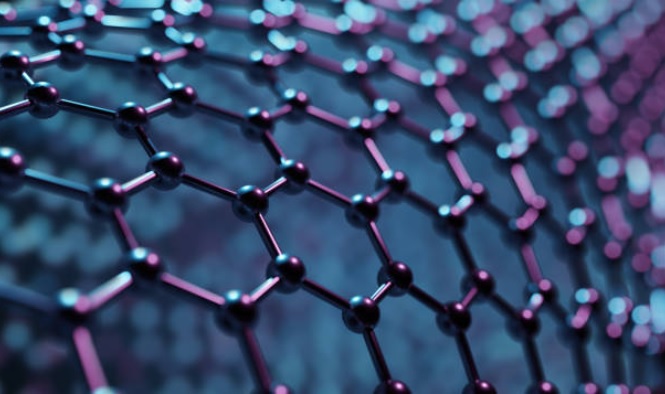

In today’s rapidly evolving industrial landscape, sourcing strong materials that are light presents both a challenge and an opportunity for B2B buyers. As businesses across Africa, South America, the Middle East, and Europe strive for efficiency, sustainability, and innovation, the demand for lightweight yet durable materials is surging. This guide offers a comprehensive overview of cutting-edge materials, including graphene, carbyne, and aerographite, highlighting their unique properties and potential applications in industries ranging from aerospace to construction.

Understanding the nuances of these materials is crucial for making informed purchasing decisions. This guide delves into the various types of strong, lightweight materials available on the market, their specific applications, and the critical factors to consider when vetting suppliers. Additionally, we provide insights into cost considerations and emerging trends that impact the global market.

By equipping international B2B buyers with the knowledge needed to navigate this complex landscape, this guide empowers businesses to enhance their product offerings, improve operational efficiencies, and contribute to a more sustainable future. Whether you’re in Vietnam, Brazil, or beyond, understanding the intricacies of sourcing strong materials that are light can unlock new avenues for growth and innovation in your industry.

Understanding strong materials that are light Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 3D Graphene | Ultra-thin, sponge-like structure, 5% density of steel, 10x stronger than steel | Aerospace, automotive, electronics | Pros: Exceptional strength-to-weight ratio. Cons: High production costs and scalability challenges. |

| Carbyne | One-dimensional carbon chain, highly reactive, 2x stronger than carbon nanotubes | Advanced materials, nanotechnology, structural applications | Pros: Unmatched strength. Cons: Difficult to synthesize and handle. |

| Aerographite | Network of porous carbon tubes, 180 g/m³ density, 75x lighter than Styrofoam | Battery electrodes, lightweight structures | Pros: Lightweight and versatile. Cons: Limited commercial availability. |

| Aerographene | Density of 0.16 mg/cm³, highly elastic, absorbs 900x its weight | Environmental cleanup, insulation | Pros: Excellent absorption properties. Cons: Fragility in certain applications. |

| Metallic Microlattice | Porous structure made from nickel-phosphorus, 0.9 mg/cm³ density | Aerospace, automotive, structural engineering | Pros: Lightweight and strong. Cons: Potentially high manufacturing costs. |

What are the Key Characteristics of 3D Graphene for B2B Buyers?

3D Graphene stands out for its unique sponge-like structure, combining ultra-thin layers of carbon to achieve remarkable strength while maintaining a low density. With only 5% of the density of steel yet being 10 times stronger, this material is particularly suitable for industries requiring lightweight yet robust components, such as aerospace and automotive sectors. Buyers should consider the material’s high production costs and challenges in scalability when assessing its feasibility for their applications.

How Does Carbyne Compare to Other Materials in Terms of Strength?

Carbyne is recognized as the strongest known material, characterized by its one-dimensional carbon chain structure. This exotic material boasts a strength that is double that of carbon nanotubes, making it an attractive option for advanced applications in nanotechnology and structural engineering. However, the highly reactive nature of Carbyne complicates its synthesis and handling, which buyers must weigh against its superior performance in critical applications.

Why is Aerographite Important for Lightweight Structural Applications?

Aerographite is a synthetic foam created from a network of porous carbon tubes, offering an incredibly low density of 180 grams per cubic meter, making it 75 times lighter than Styrofoam. Its lightweight nature makes it ideal for battery electrodes and other applications that prioritize both weight and structural integrity. While its versatility is a significant advantage, buyers should be aware of its limited commercial availability, which may affect supply chains.

What Makes Aerographene Suitable for Environmental Applications?

Aerographene, recognized as the lightest material in the world, has a density of just 0.16 milligrams per cubic centimeter. Its extraordinary elasticity allows it to absorb up to 900 times its weight in oil and water, making it highly effective for environmental cleanup efforts. However, its fragility in certain applications can pose challenges, prompting buyers to consider the specific contexts in which they intend to utilize this innovative material.

What Advantages Does Metallic Microlattice Offer in Engineering?

Metallic Microlattice is lauded for being the lightest metal available, with a density as low as 0.9 milligrams per cubic centimeter. Its porous structure imparts both lightweight and strong characteristics, making it a prime candidate for applications in aerospace and automotive engineering where weight reduction is critical. Although its manufacturing costs may be high, the potential for improved performance and efficiency in final products can justify the investment for B2B buyers focused on innovation.

Key Industrial Applications of strong materials that are light

| Industry/Sector | Specific Application of strong materials that are light | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Lightweight structural components | Reduces fuel consumption and enhances performance | Compliance with international aviation regulations |

| Automotive | Lightweight chassis and body panels | Improves fuel efficiency and reduces emissions | Material durability and crash safety certifications |

| Renewable Energy | Wind turbine blades and solar panel supports | Increases energy efficiency and reduces material costs | Local sourcing options and environmental impact |

| Electronics | Lightweight casings for devices | Enhances portability and user experience | Compatibility with existing manufacturing processes |

| Medical Devices | Prosthetics and surgical instruments | Increases patient comfort and reduces recovery time | Biocompatibility and regulatory approvals |

How Are Strong Materials That Are Light Used in Aerospace Applications?

In the aerospace sector, lightweight structural components made from advanced materials such as graphene and metallic microlattices are crucial for improving fuel efficiency and overall performance. These materials significantly reduce the weight of aircraft, which translates into lower fuel consumption and reduced emissions. For international buyers, especially from regions like Africa and South America, sourcing these materials requires adherence to stringent aviation regulations and certifications to ensure safety and reliability.

What Role Do Strong Materials That Are Light Play in Automotive Manufacturing?

In automotive manufacturing, strong yet lightweight materials are increasingly used for chassis and body panels. The adoption of these materials leads to improved fuel efficiency and reduced carbon footprints, aligning with global trends toward sustainability. Buyers need to consider the durability of these materials and ensure they meet crash safety standards, particularly in markets like Europe and the Middle East, where regulations can be stringent.

How Do Strong Materials That Are Light Enhance Renewable Energy Solutions?

Renewable energy applications, such as wind turbine blades and solar panel supports, benefit from lightweight materials that enhance energy efficiency. Using materials like aerographene can lower the weight of these components, resulting in lower installation costs and improved performance. Buyers should focus on local sourcing options to minimize transportation costs and evaluate the environmental impact of the materials, particularly in developing regions.

In What Ways Are Strong Materials That Are Light Utilized in Electronics?

In the electronics industry, strong materials that are light are employed for producing lightweight casings for devices, enhancing portability and user experience. This is particularly important for consumer electronics where weight can affect usability. International B2B buyers need to ensure compatibility with existing manufacturing processes and consider the recyclability of these materials to meet growing sustainability demands.

How Are Strong Materials That Are Light Applied in Medical Devices?

In the medical sector, lightweight materials are utilized in prosthetics and surgical instruments to improve patient comfort and reduce recovery times. These materials can be engineered for specific biocompatibility requirements, making them suitable for various medical applications. Buyers must prioritize regulatory approvals and ensure that materials meet strict health and safety standards, particularly in regions with rigorous medical device regulations.

3 Common User Pain Points for ‘strong materials that are light’ & Their Solutions

Scenario 1: Balancing Strength and Weight in Aerospace Applications

The Problem: In the aerospace industry, manufacturers are constantly challenged with the need to reduce the weight of aircraft components without compromising structural integrity. Traditional materials often fail to meet these dual requirements, leading to higher fuel consumption and increased operational costs. B2B buyers in this sector may find themselves overwhelmed by the variety of materials available and uncertain about which options will best meet their stringent performance criteria. Furthermore, the complexity of certification processes for new materials can delay product development timelines.

The Solution: To effectively navigate this challenge, buyers should consider leveraging advanced materials such as metallic microlattices or 3D graphene. These materials not only offer superior strength-to-weight ratios but are also increasingly becoming more accessible for commercial applications. When sourcing these materials, establish partnerships with specialized suppliers who have a proven track record in aerospace applications. Engage in collaborative testing to validate material performance under specific operational conditions, which will ease the certification process. Additionally, attending industry conferences and workshops can provide insights into emerging trends and technologies that can further optimize material selection.

Scenario 2: Difficulty in Integrating Lightweight Materials into Existing Manufacturing Processes

The Problem: Manufacturers in sectors such as automotive or construction often struggle with integrating new lightweight materials into their established processes. Existing machinery and production techniques may not be compatible with these advanced materials, leading to increased costs and potential production delays. Buyers are often concerned about the investment required to retrofit or replace equipment and the learning curve associated with new material handling.

The Solution: A strategic approach to overcoming this integration challenge involves conducting a thorough assessment of current manufacturing capabilities. Buyers should engage with material scientists or engineering consultants who can provide tailored recommendations on how to modify existing processes to accommodate new materials like aerographite or limpet teeth composites. Additionally, investing in training programs for the workforce can facilitate smoother transitions to new materials. Consider starting with pilot projects that utilize lightweight materials in non-critical components to gradually build expertise and confidence before scaling up to full production.

Scenario 3: Navigating Cost Implications of Advanced Lightweight Materials

The Problem: One of the most significant pain points for B2B buyers is the perceived high cost associated with advanced lightweight materials compared to traditional options. This concern can deter companies from making the switch, despite the long-term benefits such as improved performance and reduced operational costs. Buyers may feel pressured to justify the initial investment to stakeholders, especially in regions where budget constraints are prevalent.

The Solution: To address cost concerns, buyers should adopt a life-cycle cost analysis approach. This involves calculating not just the upfront material costs but also the long-term savings associated with reduced fuel consumption, lower maintenance expenses, and longer product life spans. Conducting a comparative analysis of total ownership costs between traditional materials and advanced options will provide a clearer financial picture. Additionally, consider negotiating bulk purchasing agreements with suppliers or exploring financing options that can mitigate initial expenses. Engaging in discussions with industry peers who have successfully transitioned to lightweight materials can provide valuable insights and bolster the business case for investment.

Strategic Material Selection Guide for strong materials that are light

What Are the Key Properties of Graphene in B2B Applications?

Graphene, a single layer of carbon atoms arranged in a two-dimensional lattice, is renowned for its exceptional strength and lightweight characteristics. It boasts a tensile strength of around 130 GigaPascals (GPa) and is approximately 200 times stronger than steel, making it an attractive option for industries requiring robust yet lightweight materials. Additionally, graphene exhibits excellent thermal and electrical conductivity, which is beneficial for applications in electronics and energy storage. Its resistance to corrosion further enhances its appeal, particularly in environments where exposure to harsh chemicals is a concern.

However, the production of graphene can be complex and costly, often requiring specialized manufacturing processes. This can limit its accessibility for smaller companies or those in developing regions. Moreover, while graphene shows great promise in various applications, its integration into existing manufacturing processes may require significant adjustments, which can pose challenges for companies looking to adopt this material.

How Does Carbyne Compare as a Strong Material for B2B Buyers?

Carbyne, an exotic allotrope of carbon, is considered one of the strongest materials known, surpassing even graphene in terms of tensile strength. Its unique one-dimensional structure allows it to exhibit remarkable mechanical properties, making it twice as strong as carbon nanotubes. Carbyne is also highly reactive, which can be advantageous in specific applications, such as catalysis or advanced composite materials.

Despite its impressive properties, the synthesis of carbyne remains a significant challenge, often requiring sophisticated laboratory conditions that may not be easily replicated in industrial settings. This complexity can lead to higher costs and limited availability, which are critical factors for international buyers, especially in regions with developing industrial capabilities. Additionally, the potential for reactivity may necessitate careful handling and storage, which could complicate logistics and supply chain management.

What Are the Advantages of Aerographite in Lightweight Applications?

Aerographite is a synthetic foam composed of a network of porous carbon tubes, making it one of the lightest materials available, with a density of just 180 grams per cubic meter. Its unique structure provides excellent mechanical properties, including high compressive strength and flexibility, which can be advantageous in applications such as lightweight structural components and energy storage systems.

The main drawback of aerographite is its relatively high production cost and the complexity involved in its manufacturing process. Additionally, while it is suitable for various applications, its performance may be limited under extreme conditions, such as high temperatures or corrosive environments. This limitation is crucial for B2B buyers in industries like aerospace or automotive, where material performance under diverse conditions is paramount.

How Does Metallic Microlattice Fit into the Market for Strong Lightweight Materials?

Metallic microlattice is a groundbreaking material characterized by its ultra-lightweight structure, made from a network of nickel and phosphorus tubes. With a density as low as 0.9 milligrams per cubic centimeter, it is one of the lightest metals available, making it ideal for applications in aerospace, automotive, and other industries where weight reduction is critical. Its unique structure also provides excellent energy absorption, making it suitable for protective applications.

However, the complexity of producing metallic microlattice can lead to higher costs, which may deter some buyers. Furthermore, while it offers impressive mechanical properties, its performance in high-temperature applications may be limited. B2B buyers should also be aware of the need for compliance with international standards, as metallic microlattice may not yet have established certifications in all regions, particularly in emerging markets.

Summary Table of Strong Lightweight Materials

| Material | Typical Use Case for strong materials that are light | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Graphene | Electronics, energy storage, aerospace components | Exceptional strength and conductivity | High production cost and complexity | High |

| Carbyne | Advanced composites, catalysis | Superior tensile strength | Difficult to synthesize, limited availability | High |

| Aerographite | Lightweight structural components, batteries | Extremely lightweight and flexible | High production cost, limited performance under extreme conditions | Medium |

| Metallic Microlattice | Aerospace, automotive, protective applications | Ultra-lightweight with energy absorption | High production complexity, limited high-temperature performance | High |

In-depth Look: Manufacturing Processes and Quality Assurance for strong materials that are light

What Are the Key Manufacturing Processes for Strong, Lightweight Materials?

The production of strong, lightweight materials involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is crucial in ensuring the final product meets the desired specifications for strength, weight, and functionality.

How Is Material Prepared for Manufacturing?

Material preparation begins with sourcing high-quality raw materials, such as carbon for graphene or nickel for metallic microlattice. The purity of these materials is paramount, as impurities can significantly affect the mechanical properties of the final product. For instance, in the case of graphene, ensuring that the carbon source is free from contaminants can enhance its strength and conductivity.

Once the raw materials are sourced, they undergo processes like mixing, milling, or chemical treatments to achieve the desired properties. Advanced techniques such as chemical vapor deposition (CVD) are often employed to create high-quality graphene. This process involves the deposition of carbon atoms onto a substrate, allowing for the growth of the material in a controlled environment.

What Forming Techniques Are Commonly Used?

Forming techniques vary depending on the material and desired shape. For lightweight materials like aerographite, processes such as foaming or 3D printing are utilized. 3D printing allows for the creation of complex geometries while maintaining low density. In contrast, materials like carbyne may require specialized techniques due to their reactive nature, often necessitating inert environments during processing to prevent degradation.

For metals, techniques such as casting, extrusion, and powder metallurgy are common. Powder metallurgy, for instance, allows for the production of metallic microlattices with precise control over porosity and density. The choice of forming technique impacts the mechanical properties, weight, and cost-effectiveness of the final product.

How Is Assembly Conducted for These Materials?

The assembly of strong, lightweight materials typically involves joining techniques that maintain the integrity of the materials. For composite materials, adhesive bonding and mechanical fastening are common practices. Each method must be carefully selected to ensure compatibility with the material properties and application requirements.

In some cases, such as with limpet teeth composites, bio-inspired design principles may guide the assembly process to replicate the natural bonding seen in biological structures. This approach can enhance strength and durability while minimizing weight.

What Finishing Processes Are Essential?

Finishing processes are crucial for enhancing the surface properties of the materials, improving aesthetics, and ensuring functionality. Techniques such as coating, polishing, and surface treatment can enhance corrosion resistance and wear properties. For example, applying a protective coating to metallic microlattices can significantly increase their lifespan in challenging environments.

Additionally, finishing processes may include quality checks to ensure the material meets specified tolerances and surface roughness requirements. This is particularly important for components used in industries such as aerospace and automotive, where performance and safety are critical.

How Is Quality Assurance Managed for Strong, Lightweight Materials?

Quality assurance (QA) is integral to the manufacturing process, ensuring that materials meet international standards and customer expectations. In the context of strong, lightweight materials, QA involves multiple checkpoints throughout the production process.

What International Standards Should B2B Buyers Consider?

B2B buyers should be aware of various international standards relevant to their materials. ISO 9001 is a widely recognized quality management system standard that outlines requirements for a quality management system (QMS). Compliance with ISO 9001 indicates that a supplier has established processes to ensure consistent quality.

Industry-specific certifications, such as CE marking for products sold in the European Economic Area or API standards for petroleum and natural gas industries, also play a vital role. These certifications often require adherence to stringent testing and documentation practices, providing assurance of product safety and reliability.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are critical throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified quality standards before processing begins.

- In-Process Quality Control (IPQC): During manufacturing, ongoing checks are essential to monitor processes and ensure they remain within established parameters. Techniques such as statistical process control (SPC) can be employed to track variations and maintain quality.

- Final Quality Control (FQC): Once manufacturing is complete, FQC involves comprehensive testing of the final product to ensure it meets all specifications. Common tests include tensile strength, density measurements, and fatigue testing.

What Common Testing Methods Are Used?

Testing methods vary based on the material and application. For lightweight materials, common testing methods include:

- Tensile Testing: This method measures the strength and ductility of materials under tension.

- Compression Testing: Used to determine how materials behave under compressive forces, essential for structural applications.

- Fatigue Testing: Important for evaluating how materials perform under repeated loading and unloading cycles.

These tests provide critical data that inform the performance and suitability of materials for specific applications.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify supplier quality control practices. Conducting supplier audits is one of the most effective methods. During an audit, buyers can assess the supplier’s QMS, manufacturing processes, and compliance with international standards.

Additionally, requesting detailed QC reports and documentation can provide insight into the supplier’s testing methods and results. Third-party inspections can also add a layer of credibility, ensuring that the supplier adheres to established quality standards.

What Nuances Should International Buyers Be Aware Of?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding regional compliance requirements and quality certifications is essential. Different regions may have varying standards, which can affect the acceptance of products in local markets.

Moreover, establishing clear communication with suppliers regarding quality expectations and certifications is vital. It helps to mitigate risks associated with non-compliance and ensures that products meet both local and international standards.

Conclusion

In summary, the manufacturing processes and quality assurance practices for strong, lightweight materials are multifaceted and require meticulous attention to detail. By understanding these processes and standards, B2B buyers can make informed decisions, ensuring they source materials that not only meet their specifications but also adhere to international quality standards. This knowledge empowers buyers to forge strong relationships with suppliers, ultimately leading to successful procurement strategies in an increasingly competitive global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘strong materials that are light’

In today’s competitive market, sourcing strong and lightweight materials is critical for businesses aiming to enhance product performance and sustainability. This guide provides a structured approach for B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, to effectively procure these advanced materials.

Step 1: Define Your Technical Specifications

Before initiating the procurement process, clearly outline your technical requirements. This includes defining the desired strength-to-weight ratio, thermal and electrical conductivity, and specific environmental conditions the materials must withstand.

– Considerations: Identify the applications for which the materials will be used, such as aerospace, automotive, or construction. This helps in narrowing down your options to materials that meet industry-specific standards.

Step 2: Research Available Materials

Familiarize yourself with the various strong and lightweight materials available on the market. Key options include graphene, carbyne, aerographite, and metallic microlattice.

– Material Properties: Understand the unique properties and potential applications of each material. For instance, graphene is known for its exceptional strength and flexibility, making it suitable for a variety of industries.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers before making any commitments. Request company profiles, case studies, and references from previous clients in similar industries.

– Due Diligence: Ensure that the suppliers have a proven track record of delivering high-quality materials. This step minimizes risks associated with subpar products and unreliable delivery timelines.

Step 4: Verify Certifications and Compliance

Ensure that the materials meet necessary industry standards and certifications. This is especially important for sectors like aerospace and automotive, where safety is paramount.

– Check Compliance: Look for certifications such as ISO, ASTM, or specific regional standards that validate the quality and safety of the materials you intend to purchase.

Step 5: Request Samples for Testing

Before finalizing any order, request samples of the materials you are considering. Conduct thorough testing to evaluate their performance against your specifications.

– Testing Protocols: Develop a testing protocol that includes stress tests, durability assessments, and compatibility checks with other materials. This hands-on evaluation will help you make informed purchasing decisions.

Step 6: Negotiate Pricing and Terms

Once you’ve identified suitable suppliers and materials, engage in negotiations to secure the best pricing and terms.

– Consider Total Cost of Ownership: Factor in not just the upfront costs but also long-term implications such as shipping, handling, and potential waste or loss during processing.

Step 7: Establish a Long-term Relationship

Building a long-term relationship with your suppliers can lead to better pricing, priority service, and access to the latest materials and technologies.

– Communication is Key: Maintain open lines of communication to discuss future needs and potential collaborations, ensuring that your supply chain remains robust and adaptable to changes in demand.

By following these structured steps, B2B buyers can effectively navigate the complexities of sourcing strong and lightweight materials, ultimately enhancing their product offerings and competitive advantage.

Comprehensive Cost and Pricing Analysis for strong materials that are light Sourcing

What Are the Key Cost Components in Sourcing Strong, Lightweight Materials?

When sourcing strong, lightweight materials, international B2B buyers must understand the various cost components involved. These typically include:

-

Materials: The primary input costs for materials like graphene, carbyne, and aerographite can vary significantly based on purity, form, and processing requirements. For instance, 3D graphene and carbyne may require advanced production techniques, which can drive up costs.

-

Labor: Skilled labor is essential for the production and handling of these advanced materials. The cost of labor can fluctuate based on the region, with labor-intensive processes potentially leading to higher overall expenses.

-

Manufacturing Overhead: This includes utilities, maintenance, and other indirect costs associated with production. High-tech facilities capable of producing lightweight materials often incur significant overhead due to the need for specialized equipment.

-

Tooling: The initial investment in tooling for the production of custom materials can be substantial. For instance, creating molds or machinery capable of processing exotic materials requires upfront capital.

-

Quality Control (QC): Given the applications of these materials in critical sectors such as aerospace and automotive, stringent QC processes are essential. These can add to the overall cost but are necessary for compliance with industry standards.

-

Logistics: Transporting lightweight materials can be counterintuitive; while they may weigh less, they often require careful handling and specific conditions during shipping. Logistics costs can vary based on distance, mode of transport, and compliance with international shipping regulations.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. This margin can differ based on market competition and demand for specific materials.

How Do Price Influencers Affect the Cost of Lightweight Materials?

Several factors influence the pricing of strong, lightweight materials:

-

Volume/MOQ (Minimum Order Quantity): Larger orders generally lead to lower per-unit costs due to economies of scale. Buyers should consider negotiating for bulk purchasing agreements to optimize pricing.

-

Specifications and Customization: Customized materials tailored to specific applications can significantly increase costs. Buyers should clearly define their specifications to avoid unforeseen expenses.

-

Material Quality and Certifications: Higher quality materials that meet strict industry certifications will come at a premium. Buyers in sectors like aerospace or medical technology must factor in the costs associated with compliance.

-

Supplier Factors: The reputation, reliability, and location of the supplier can impact pricing. Suppliers with a proven track record may command higher prices, but they often provide better quality assurance and reliability.

-

Incoterms: Understanding Incoterms is crucial for pricing as they define the responsibilities of buyers and sellers in international transactions. They influence who bears the costs and risks associated with shipping, which can significantly affect the final price.

What Are the Best Practices for Negotiating Prices in International B2B Transactions?

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, effective negotiation and cost management are essential:

-

Conduct Market Research: Understanding prevailing market rates for materials can empower buyers during negotiations. Knowledge of competitive pricing allows buyers to negotiate more effectively.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, buyers should assess the total cost of ownership, which includes maintenance, lifecycle costs, and potential savings from using lightweight materials in applications.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Long-term partnerships often yield benefits such as discounts or priority during shortages.

-

Be Prepared for Pricing Nuances: International transactions may involve currency fluctuations, tariffs, and taxes. Buyers should account for these factors when evaluating costs and negotiating terms.

Conclusion

Navigating the complexities of sourcing strong, lightweight materials requires a thorough understanding of the cost structure and pricing dynamics. By considering key cost components, recognizing price influencers, and employing strategic negotiation tactics, international B2B buyers can make informed purchasing decisions that align with their organizational goals. Always remember that indicative prices can fluctuate based on market conditions, and a flexible approach can lead to better outcomes.

Alternatives Analysis: Comparing strong materials that are light With Other Solutions

Introduction to Alternatives in Strong Lightweight Materials

In the quest for innovative solutions in industries such as construction, automotive, and aerospace, the development of strong materials that are light has gained significant attention. However, B2B buyers must consider various alternatives that can provide similar benefits while also meeting specific operational needs. This analysis compares these advanced materials against traditional solutions and emerging technologies, helping buyers make informed decisions.

| Comparison Aspect | Strong Materials That Are Light | Alternative 1: Carbon Fiber | Alternative 2: Aluminum Alloys |

|---|---|---|---|

| Performance | Exceptional strength-to-weight ratio; superior durability | High strength and rigidity; lightweight | Good strength; lightweight; corrosion-resistant |

| Cost | High initial investment due to advanced production techniques | Moderate cost; higher than metals but lower than advanced composites | Generally lower cost; widely available |

| Ease of Implementation | Requires specialized manufacturing processes | Relatively easy to manufacture; established processes | Easy to work with; well-understood processing methods |

| Maintenance | Low maintenance; resistant to environmental damage | Requires careful handling; can be susceptible to impact damage | Low maintenance; corrosion-resistant with proper treatment |

| Best Use Case | Aerospace components, automotive structures, and high-performance applications | Sports equipment, automotive parts, and high-end consumer goods | General-purpose applications, automotive parts, and structural components |

What Are the Pros and Cons of Carbon Fiber as an Alternative?

Carbon fiber is renowned for its high strength and rigidity while remaining lightweight. Its performance is often superior to that of traditional materials, making it ideal for applications in high-stress environments such as aerospace and motorsports. However, carbon fiber comes with a moderate cost and requires specialized manufacturing techniques, which can complicate its implementation. Additionally, while it offers excellent performance, it can be susceptible to impact damage, necessitating careful handling and maintenance.

How Do Aluminum Alloys Compare to Strong Lightweight Materials?

Aluminum alloys are a widely used alternative due to their good strength-to-weight ratio and excellent corrosion resistance. They are generally lower in cost and easier to work with than advanced composites, making them an attractive option for many manufacturers. Aluminum alloys are suitable for a variety of applications, from automotive to structural components. However, they do not match the performance of the latest lightweight materials in extreme conditions, and their strength may not be sufficient for high-performance applications where weight savings are critical.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the right material or technology hinges on the specific needs of the application. B2B buyers must weigh factors such as performance requirements, cost constraints, and ease of implementation. For high-performance applications demanding the utmost strength and weight savings, strong materials that are light, like advanced composites, are often the best choice. However, for more general-purpose uses, cost-effective options like carbon fiber or aluminum alloys may provide sufficient performance with less complexity. Understanding the unique advantages and limitations of each alternative will enable buyers to make strategic decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for strong materials that are light

What Are the Key Technical Properties of Strong and Lightweight Materials?

When considering the procurement of strong yet lightweight materials, several technical properties are crucial for B2B buyers. Understanding these specifications can enhance decision-making and ensure that the selected materials meet the required application standards.

-

Material Grade

Material grade indicates the quality and type of a material, reflecting its chemical composition, mechanical properties, and performance. In the context of lightweight materials, higher grades often correlate with enhanced strength-to-weight ratios, durability, and resistance to environmental factors. B2B buyers should prioritize material grades that align with their specific industry requirements, such as aerospace, automotive, or construction. -

Density

Density is a critical parameter that defines how much mass is contained in a given volume. For lightweight materials, lower density is often desired, as it contributes to reduced overall weight without compromising strength. Buyers must consider the application’s weight constraints and ensure that the density of the material aligns with performance expectations, particularly in sectors where weight savings can lead to significant operational efficiencies. -

Tensile Strength

Tensile strength measures the maximum amount of tensile (pulling) stress a material can withstand before failure. This property is vital for applications where materials are subjected to stretching forces. Strong lightweight materials should exhibit high tensile strength to ensure safety and longevity in demanding environments, making it essential for B2B buyers to evaluate this specification when selecting materials for structural components. -

Flexural Modulus

The flexural modulus quantifies a material’s stiffness when subjected to bending. A high flexural modulus indicates that a material can resist deformation under load, which is crucial for applications requiring structural integrity. Buyers should assess this property to ensure that the selected materials will maintain their shape and performance characteristics under operational stresses. -

Thermal Conductivity

This property defines how well a material can conduct heat. In applications where temperature fluctuations are common, such as automotive and aerospace industries, materials with appropriate thermal conductivity are necessary to prevent thermal failure or energy inefficiency. Buyers should consider how thermal conductivity interacts with other properties to ensure optimal performance in their specific applications.

Which Trade Terms Are Essential for B2B Transactions in Lightweight Materials?

Familiarity with industry terminology can streamline the purchasing process and ensure effective communication among stakeholders. Here are some essential trade terms relevant to strong lightweight materials:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of lightweight materials, OEMs are crucial for buyers seeking to integrate advanced materials into their products, ensuring compatibility and performance standards are met. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is vital for buyers to manage inventory costs effectively and ensure that they can meet production demands without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document issued by buyers to solicit price and availability information from suppliers. This process is essential for B2B transactions as it allows buyers to compare options and negotiate terms effectively, ensuring they secure the best deal for lightweight materials. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce, defining responsibilities between buyers and sellers for shipping, insurance, and tariffs. Familiarity with Incoterms is critical for international transactions, helping buyers understand their obligations and costs associated with the procurement of materials. -

Lead Time

Lead time refers to the duration between placing an order and receiving the product. For B2B buyers, understanding lead times is essential for planning and inventory management, particularly when sourcing specialized lightweight materials that may require longer production cycles. -

Certifications

Certifications refer to official documents that validate a material’s compliance with industry standards or regulations. Buyers should ensure that their selected materials have the necessary certifications to meet safety and performance standards, which can significantly influence purchasing decisions.

By grasping these key properties and terms, B2B buyers can navigate the complexities of sourcing strong lightweight materials more effectively, ensuring that their procurement processes align with business objectives and operational needs.

Navigating Market Dynamics and Sourcing Trends in the strong materials that are light Sector

What Are the Current Market Dynamics and Key Trends in Strong Materials That Are Light?

The demand for strong, lightweight materials is being propelled by various global drivers, including the need for enhanced energy efficiency and sustainability across industries. As sectors like aerospace, automotive, and construction evolve, they increasingly seek materials that not only reduce weight but also improve performance. Innovations such as 3D graphene and carbyne are at the forefront of this evolution, offering remarkable strength-to-weight ratios that traditional materials cannot match. International B2B buyers, especially from emerging markets in Africa, South America, the Middle East, and Europe, should closely monitor these advancements as they can lead to significant cost savings and operational efficiencies.

Emerging trends indicate a shift towards advanced manufacturing techniques, such as additive manufacturing and nanotechnology, which enable the production of complex geometries and structures that were previously unattainable. This trend is particularly relevant for buyers looking to source custom parts or components. Additionally, the integration of artificial intelligence and data analytics in supply chain management is revolutionizing how businesses identify and procure these materials, leading to more strategic sourcing decisions.

How Is Sustainability Influencing the Sourcing of Strong, Lightweight Materials?

Sustainability is no longer a secondary consideration; it has become a primary driver in the sourcing of strong materials that are light. The environmental impact of materials production and use is a critical concern for B2B buyers. Lightweight materials often contribute to lower fuel consumption and emissions in transportation, making them attractive for companies focused on reducing their carbon footprint.

Moreover, ethical sourcing is gaining traction as businesses recognize the importance of responsible supply chains. Buyers are increasingly looking for suppliers who provide ‘green’ certifications and sustainable materials. This includes sourcing from manufacturers who prioritize environmentally friendly practices, such as using recycled content or employing low-impact production methods. Certifications like ISO 14001 and LEED are becoming essential benchmarks for evaluating suppliers.

What Is the Historical Context of Strong, Lightweight Materials Development?

The development of strong, lightweight materials has roots that trace back to the industrial revolution, where advancements in metallurgy paved the way for innovations in structural engineering. However, significant progress has been made in the last few decades with the advent of nanotechnology and material science. Materials like carbon fiber and titanium alloys began to dominate sectors requiring high performance and reduced weight.

Recent breakthroughs in materials science, particularly in carbon allotropes like graphene and carbyne, have ushered in a new era of material capabilities. These advancements not only enhance the strength and lightness of materials but also offer new applications across various industries. For B2B buyers, understanding this evolution provides valuable context for sourcing decisions, enabling them to leverage the latest materials that align with their operational goals.

By staying informed about market dynamics, sustainability practices, and the historical context of material development, international buyers can make strategic sourcing decisions that enhance their competitive edge in the global marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of strong materials that are light

-

How do I ensure the quality of light and strong materials from suppliers?

To ensure quality, start by establishing clear specifications and standards for the materials you need. Request samples to evaluate their performance and durability. Implement a rigorous supplier vetting process, including checking references and certifications. Consider visiting the supplier’s facility to observe their production processes. Additionally, establish a Quality Assurance (QA) agreement that outlines inspection methods, testing protocols, and compliance with international standards. -

What is the best lightweight material for aerospace applications?

For aerospace applications, materials like metallic microlattice and carbon composites are excellent choices due to their high strength-to-weight ratios. Metallic microlattice offers exceptional lightweight characteristics, while carbon composites provide durability and resistance to environmental factors. Both materials can significantly enhance fuel efficiency and performance. Consult with manufacturers for specific applications and performance data to make an informed decision. -

What should I consider when sourcing strong materials internationally?

When sourcing internationally, consider factors such as the supplier’s reputation, production capabilities, and compliance with international standards. Assess logistics, including shipping times and costs, customs regulations, and import duties in your region. It’s crucial to understand payment terms and currency fluctuations, as well as to establish a clear contract that outlines delivery schedules and penalties for non-compliance. -

Are there minimum order quantities (MOQ) for light materials?

Minimum order quantities (MOQ) can vary significantly among suppliers. Many manufacturers may have a MOQ to cover production costs, especially for specialized materials like graphene or carbyne. Discuss your needs with potential suppliers to determine if they can accommodate smaller orders or offer flexible options. It’s also beneficial to collaborate with other businesses to meet MOQ requirements collectively. -

What payment terms are typical for international suppliers of strong materials?

Payment terms can vary widely depending on the supplier’s policies and the transaction’s risk level. Common terms include partial upfront payments, letters of credit, or payment upon delivery. Ensure you negotiate terms that protect your interests while fostering a good relationship with the supplier. Always review the payment structure to account for potential currency exchange risks and ensure clarity on all charges involved. -

How can I customize strong materials for my specific needs?

Customization options often depend on the material and the manufacturer’s capabilities. Engage with suppliers early in the design process to discuss your specific requirements, such as dimensions, strength specifications, or coatings. Many manufacturers offer tailored solutions, but this may involve additional costs or lead times. Be prepared to provide detailed specifications to facilitate the customization process effectively. -

What are the logistics considerations when importing lightweight materials?

Logistics for importing lightweight materials involve understanding shipping methods, costs, and timelines. Consider whether air freight or sea freight is more suitable based on urgency and budget. Ensure your supply chain management includes customs clearance processes to avoid delays. Additionally, factor in warehousing needs upon arrival and the potential for damage during transport, especially for fragile materials. -

How do I handle disputes with suppliers of strong materials?

Handling disputes requires a proactive approach, starting with clear contracts that outline terms of service, quality expectations, and dispute resolution processes. If a dispute arises, communicate directly with the supplier to resolve issues amicably. If informal discussions fail, consider mediation or arbitration as a next step. Always document all interactions and agreements to support your position if formal action becomes necessary.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Strong Materials That Are Light Manufacturers & Suppliers List

1. Reddit – Lightweight Solutions

2. Wayken RM – Lightweight Metals Solutions

Domain: waykenrm.com

Registered: 2013 (12 years)

Introduction: Lightweight metals are crucial in part manufacturing, especially in the automotive, aerospace, and consumer electronics industries. Common lightweight metals include aluminum and titanium due to their reduced weight and improved aesthetics. Key details include: 1. **Aluminum and Aluminum Alloys**: – **Grades**: 2024 (high fatigue resistance), 6061 (excellent corrosion resistance), 7075 (high stren…

3. S3DA Design – Steel and Aluminum Framing Solutions

Domain: s3da-design.com

Registered: 2016 (9 years)

Introduction: 1. Steel: Strong support beams, excellent strength-to-weight ratio, resistant to elements, fire, and mildew, easy to install. Steel studs are 25 times stronger and 30% lighter than wood framing. 2. Aluminum: Lightweight, strong for exterior framing, cheaper alternative to steel, long-lasting, low maintenance, recyclable, used for outdoor living spaces. 3. Plastics: Previously unsuitable for load-b…

4. Sidetracked – Dyneema Gear

Domain: sidetracked.com

Registered: 2004 (21 years)

Introduction: Dyneema is the world’s lightest and strongest material, said to be 15 times stronger than steel. It is used in various applications including backpacks, waterproof jackets, and outdoor gear. Notable products include Black Yak’s Emergency Jacket, which weighs only 54 grams and won a Gold Award at ISPO. Dyneema is lightweight, tough-wearing, soft, and hydrophobic. The Dyneema Project aims to expand …

5. The Week – Microlattice

Domain: theweek.com

Registered: 1998 (27 years)

Introduction: 1. Microlattice: A metal that is 100 times lighter than styrofoam and as strong as titanium. It consists of a mesh of thin, hollow metal tubes, making it 99.99% air. It has high energy absorption and is suitable for rapid manufacturing, with potential applications in aerospace to reduce fuel costs.

2. Graphene: A single layer of carbon atoms, one million times thinner than paper, stronger than st…

6. Physics Forums – Material Selection for Mechanics of Materials Project

Domain: physicsforums.com

Registered: 2001 (24 years)

Introduction: Lightweight and strong materials considered include Diamond, Silicon, Carbon Fiber, and Spectra fibers. The project involves selecting a material for a theoretical design project in a Mechanics of Materials class, focusing on a shaft with specified lengths and loads, and considering factors like shear modulus.

Strategic Sourcing Conclusion and Outlook for strong materials that are light

How Can Strategic Sourcing of Lightweight Strong Materials Enhance Your Business?

In today’s competitive landscape, the importance of sourcing strong yet lightweight materials cannot be overstated. Innovations like graphene, carbyne, and metallic microlattices present unprecedented opportunities for industries ranging from aerospace to automotive, allowing for enhanced performance while reducing costs and environmental impact. By strategically sourcing these materials, businesses can leverage their unique properties to create more efficient products, streamline supply chains, and meet the growing demand for sustainable solutions.

For international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, the potential for collaboration with material innovators is immense. Establishing partnerships with suppliers who specialize in these advanced materials can facilitate access to cutting-edge technologies and foster competitive advantages in your respective markets.

As you consider your sourcing strategies, prioritize suppliers that align with your sustainability goals and innovation needs. By doing so, you not only enhance your product offerings but also contribute to a more sustainable future. Embrace the opportunities presented by these lightweight strong materials and position your business at the forefront of industry advancements. Engage with material specialists today to explore how these innovations can transform your operations and drive growth.