Introduction: Navigating the Global Market for stl files for cnc router

In the rapidly evolving landscape of CNC machining, sourcing high-quality STL files for CNC routers can be a formidable challenge for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. With numerous suppliers offering a myriad of designs, the task of identifying reliable sources while ensuring compatibility and precision can be daunting. This guide serves as a comprehensive resource, addressing the complexities of sourcing STL files by exploring various types of files, their applications in different industries, and essential criteria for supplier vetting.

Our detailed analysis covers the diverse range of STL files available, from intricate decorative pieces to functional components tailored for specific machining tasks. Additionally, we delve into the critical aspects of cost considerations and the benefits of leveraging digital downloads, enabling buyers to make informed decisions that align with their operational needs and budget constraints.

By empowering international B2B buyers with actionable insights, this guide aims to streamline the procurement process, enhance operational efficiency, and ultimately drive business success. Whether you are a small workshop in Nigeria or a large manufacturing firm in Brazil, understanding the global market for STL files is essential for staying competitive in today’s dynamic landscape.

Understanding stl files for cnc router Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Decorative STL Files | Focused on aesthetic designs, often intricate patterns | Signage, art installations, furniture | Pros: High visual appeal; Cons: May require post-processing |

| Functional STL Files | Designed for practical use, often with mechanical parts | Machinery components, prototypes | Pros: High utility; Cons: Can be complex to manufacture |

| Scaled STL Files | Optimized for specific dimensions and scaling | Architectural models, product design | Pros: Precision in size; Cons: Limited versatility |

| Free STL Files | Available at no cost, often community-created | Prototyping, hobby projects | Pros: Cost-effective; Cons: Quality may vary |

| Custom STL Files | Tailored to specific client requirements | Specialized machinery, custom projects | Pros: Meets exact needs; Cons: Higher cost and lead time |

What Are Decorative STL Files and Their B2B Applications?

Decorative STL files are primarily designed for aesthetics, featuring intricate designs that enhance visual appeal. These files are widely used in industries such as signage, art installations, and furniture design. For B2B buyers, investing in decorative STL files can elevate product offerings and attract clients seeking unique designs. However, these files may require additional post-processing to achieve the desired finish, which could increase production time and costs.

How Do Functional STL Files Enhance Production Efficiency?

Functional STL files are engineered for practical applications, often incorporating mechanical components. They are commonly utilized in manufacturing machinery parts and prototypes, making them invaluable in industries like automotive and aerospace. B2B buyers should consider the complexity of these designs, as they may require advanced CNC capabilities and expertise. While functional STL files offer high utility, their intricate nature can pose challenges during the machining process.

Why Are Scaled STL Files Important for Precision Projects?

Scaled STL files are meticulously optimized for specific dimensions, making them essential for projects requiring high precision, such as architectural models and product designs. These files ensure that the final output matches the intended scale, which is crucial for industries that demand accuracy. B2B buyers should prioritize these files when precision is non-negotiable. However, the limited versatility of scaled files may restrict their use in broader applications.

What Are the Benefits of Using Free STL Files in Prototyping?

Free STL files are often community-created and available at no cost, making them an attractive option for prototyping and hobby projects. They allow businesses to experiment without significant financial investment, fostering innovation. However, B2B buyers should be cautious about the quality, as free files may not always meet professional standards. The variability in quality could affect the outcome of projects, making it essential to vet these files thoroughly.

How Do Custom STL Files Cater to Unique Business Needs?

Custom STL files are tailored to meet specific client requirements, providing a unique solution for specialized machinery and custom projects. These files are beneficial for businesses looking to differentiate themselves in competitive markets. While they ensure that products meet exact specifications, buyers should be prepared for potentially higher costs and longer lead times associated with custom designs. This investment can yield significant returns when aligned with strategic business goals.

Key Industrial Applications of stl files for cnc router

| Industry/Sector | Specific Application of STL Files for CNC Router | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Custom furniture design and prototyping | Enables rapid prototyping and customization for client needs | Look for STL files that are optimized for CNC machining and compatible with various materials. |

| Aerospace | Production of lightweight components | Reduces material waste and enhances design flexibility | Ensure STL files meet stringent industry standards and are tested for structural integrity. |

| Automotive | Creation of precision tooling and fixtures | Increases production efficiency and reduces lead times | Source STL files that are designed for high precision and can withstand rigorous testing. |

| Jewelry Design | Intricate jewelry patterns and molds | Facilitates unique designs and personalized products | Seek STL files that offer high detail and precision for intricate designs. |

| Architectural Modeling | Scale models and architectural features | Provides visual representation and aids in client presentations | Ensure STL files are scalable and accurately represent architectural details. |

How are STL Files for CNC Routers Used in Furniture Manufacturing?

In the furniture manufacturing sector, STL files are utilized to create custom designs and prototypes for various furniture pieces. This application allows manufacturers to quickly iterate designs based on client feedback, significantly reducing the time from concept to production. For businesses operating in diverse markets, such as Africa and South America, sourcing STL files that are optimized for CNC machining is crucial to ensure compatibility with local materials and machinery.

What Role Do STL Files Play in Aerospace Component Production?

Aerospace industries leverage STL files for the production of lightweight components that require high precision. These files enable the design of complex geometries that traditional manufacturing methods might not achieve. International buyers, particularly from regions like the Middle East and Europe, must consider sourcing STL files that meet rigorous industry standards, ensuring that components are safe and reliable for flight applications.

How Do Automotive Manufacturers Benefit from STL Files?

In the automotive industry, STL files are essential for creating precision tooling and fixtures that enhance production efficiency. By using these files, manufacturers can reduce lead times and improve the accuracy of parts. Buyers should prioritize sourcing STL files that are specifically designed for high precision to withstand the demanding conditions of automotive production.

Why Are STL Files Important for Jewelry Design?

STL files in jewelry design allow for the creation of intricate patterns and molds, enabling designers to offer unique and personalized products. This capability is particularly beneficial in markets where customization is a key differentiator. Buyers should seek STL files that provide high detail and precision to ensure the quality of the final product, especially in regions with growing luxury markets.

How Are STL Files Used in Architectural Modeling?

In architectural modeling, STL files are employed to create scale models and detailed architectural features. These models serve as valuable tools for visual representation during client presentations and project approvals. For international buyers, it is vital to source STL files that can be easily scaled and accurately reflect architectural details, ensuring effective communication of design intent across diverse markets.

3 Common User Pain Points for ‘stl files for cnc router’ & Their Solutions

Scenario 1: Difficulty in Finding High-Quality STL Files for CNC Machining

The Problem: One of the main challenges B2B buyers face is sourcing high-quality STL files that are optimized for CNC machining. Many available files may not meet the precision or detail required for professional applications. This can lead to wasted materials and time, as poorly designed files may not machine correctly, resulting in defects or the need for rework. Moreover, buyers often struggle to differentiate between free and paid resources, leading to uncertainty about the quality and usability of the files.

The Solution: To overcome this challenge, buyers should prioritize sourcing STL files from reputable platforms that specialize in CNC applications. Websites like 3DWave and Cults3D provide a variety of professionally crafted STL files optimized for CNC machining. When selecting files, look for those that explicitly state they are designed for CNC use, as these will typically include necessary details like proper scaling and structural integrity. Additionally, consider investing in premium models that come with guarantees of quality and support. Always check user reviews and ratings to validate the reliability of the files before making a purchase.

Scenario 2: Compatibility Issues with CNC Software and Machines

The Problem: Many buyers encounter compatibility issues when attempting to use STL files with their CNC software or machines. This can stem from differences in software versions, file format discrepancies, or the specific capabilities of the CNC equipment. Such problems can lead to frustration and delays in production, as files may fail to load or process correctly, requiring significant troubleshooting or even the need to reconfigure software settings.

The Solution: To mitigate compatibility issues, buyers should conduct thorough research on their CNC machine’s specifications and the software they are using. Before purchasing STL files, verify that the files are compatible with the specific software and machine model. Most reputable STL file providers will list compatibility details. Additionally, buyers should consider using conversion tools or software that can transform STL files into formats better suited for their CNC operations, such as DXF or G-code. Engaging with online forums or communities can also provide insights into best practices for file compatibility and troubleshooting common issues.

Scenario 3: Lack of Customization Options for STL Files

The Problem: Another significant pain point for B2B buyers is the lack of customization in available STL files. Often, the pre-designed models do not fit specific project needs or dimensions, which can lead to additional costs and time spent on modifications. This is particularly problematic for businesses that require tailored solutions to meet unique client demands or project specifications.

The Solution: To address the need for customization, buyers should consider partnering with designers or using platforms that allow for file modification. Websites like Cults3D not only offer STL files but also connect users with designers who can create custom models based on specific requirements. Alternatively, buyers with CAD expertise can use software such as Fusion 360 or SolidWorks to modify existing STL files to fit their needs. Investing in training for in-house designers to develop or tweak STL files can also enhance a company’s agility in meeting client demands. Implementing a collaborative approach with designers can lead to innovative solutions tailored precisely for projects, ultimately saving time and resources.

Strategic Material Selection Guide for stl files for cnc router

What Are the Key Properties of Common Materials for STL Files in CNC Routing?

When selecting materials for STL files intended for CNC routing, it is essential to consider properties that directly impact performance. Here, we analyze four common materials: wood, acrylic, aluminum, and polycarbonate.

How Does Wood Perform as a Material for STL Files?

Wood is a traditional material often used in CNC routing due to its natural aesthetic and ease of machining. Key properties include a moderate strength-to-weight ratio and good machinability. It is generally not resistant to moisture, which can lead to warping or swelling.

Pros: Wood is relatively inexpensive and widely available, making it a cost-effective choice for prototypes or decorative items. It also provides a warm, appealing finish suitable for furniture and crafts.

Cons: Wood’s susceptibility to environmental factors can limit its use in outdoor applications. Additionally, variations in grain and density can affect the consistency of the final product.

For international buyers, especially in regions like Africa and South America, sourcing sustainably harvested wood is crucial. Compliance with local regulations regarding forestry practices and certifications (e.g., FSC) should be considered.

What Are the Advantages of Using Acrylic in CNC Routing?

Acrylic, or PMMA, is a versatile thermoplastic known for its clarity and durability. It offers excellent weather resistance and can be easily colored, making it suitable for signage and display applications.

Pros: Acrylic is lightweight and has a high impact resistance compared to glass, which makes it a popular choice for protective covers and light fixtures.

Cons: While acrylic is easier to machine than glass, it can be prone to scratching and may require additional finishing processes to achieve a polished look.

For B2B buyers in Europe and the Middle East, compliance with safety standards (like EN 71 for toys) is essential when using acrylic in consumer products. Additionally, understanding local market preferences for color and finish can enhance product appeal.

Why Choose Aluminum for STL Files in CNC Routing?

Aluminum is a lightweight metal that offers excellent strength and corrosion resistance. It is suitable for a variety of applications, including automotive and aerospace components.

Pros: Aluminum’s durability and ability to withstand high temperatures make it ideal for functional parts. It can also be anodized for added protection and aesthetic appeal.

Cons: The cost of aluminum is generally higher than plastics or wood, and machining can be more complex, requiring specialized tools and techniques.

For international buyers, especially in regions like the Middle East, understanding local material standards (such as ASTM or DIN) is crucial for compliance. Additionally, sourcing aluminum from reputable suppliers can ensure quality and consistency.

What Are the Benefits of Polycarbonate in CNC Routing Applications?

Polycarbonate is a robust thermoplastic known for its high impact resistance and optical clarity. It is often used in applications requiring safety and durability, such as eyewear lenses and safety shields.

Pros: Polycarbonate is lightweight and has excellent dimensional stability, making it suitable for precision parts. It also offers good UV resistance.

Cons: The material can be more expensive than other plastics, and it may require specific machining techniques to avoid cracking during processing.

For B2B buyers in Africa and South America, understanding the import regulations and standards for polycarbonate products is vital. Compliance with local safety standards can enhance marketability and acceptance.

Summary Table of Material Selection for STL Files in CNC Routing

| Material | Typical Use Case for STL Files for CNC Router | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Furniture, decorative items | Cost-effective and widely available | Susceptible to moisture and warping | Low |

| Acrylic | Signage, display cases | Lightweight with high impact resistance | Prone to scratching | Medium |

| Aluminum | Automotive parts, aerospace components | Excellent strength and corrosion resistance | Higher cost and complex machining | High |

| Polycarbonate | Safety shields, eyewear lenses | High impact resistance and clarity | More expensive and requires careful machining | Medium |

This guide serves as a strategic resource for B2B buyers looking to optimize their material selection for STL files in CNC routing, ensuring compliance and suitability for diverse applications across various international markets.

In-depth Look: Manufacturing Processes and Quality Assurance for stl files for cnc router

What Are the Main Stages in the Manufacturing Process of STL Files for CNC Routers?

The manufacturing process for STL files tailored for CNC routers involves several critical stages that ensure the final product meets the high standards of precision and quality expected by B2B buyers. Understanding these stages is essential for making informed purchasing decisions.

Material Preparation: What Comes First?

Material preparation is the initial phase where designers and engineers select the appropriate materials based on the intended application of the STL files. This may involve using various types of CAD software to design models that can be efficiently machined. Key considerations include:

- Material Selection: The choice of material (wood, metal, plastic, etc.) greatly influences the design of the STL files. Each material has unique properties that affect how it can be machined.

- Design Optimization: Models are optimized for CNC machining, ensuring that they are not only aesthetically pleasing but also practical in terms of manufacturability.

- File Format Compatibility: The STL files must be compatible with the CNC machine’s software, which may include formats like OBJ, STEP, or 3MF for broader usability.

How Are STL Files Formed for CNC Machining?

Once the designs are finalized, the next step involves forming the STL files into usable formats. This step can include several techniques:

- 3D Modeling: Advanced 3D modeling techniques are employed to create intricate designs. Software like SolidWorks or AutoCAD is typically used to generate the 3D models, which are then converted to STL format.

- Conversion and Slicing: The STL files are converted into machine-readable code (G-code) that guides the CNC router during the machining process. This conversion must ensure that the dimensional accuracy and details of the design are preserved.

What Finishing Techniques Are Commonly Used?

After the STL files have been machined, finishing techniques are applied to enhance the aesthetics and functionality of the final products. Common finishing methods include:

- Sanding and Polishing: These techniques improve surface finish and remove any machining marks, providing a smoother texture.

- Coating and Treatment: Depending on the material, various coatings (e.g., varnishes, paints) may be applied to protect against wear and environmental factors, thereby extending the life of the product.

- Quality Checks: Finishing is often accompanied by quality checks to ensure that the final product adheres to the specified tolerances and design requirements.

What Quality Assurance Measures Are Essential for STL Files?

Quality assurance is a critical component in the manufacturing of STL files for CNC routers. It ensures that the final products meet international standards and customer specifications.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should familiarize themselves with various international quality standards that govern manufacturing processes. Key standards include:

- ISO 9001: This standard outlines the criteria for a quality management system, emphasizing customer satisfaction and continuous improvement. Suppliers with ISO 9001 certification are generally more reliable.

- CE Marking: For products intended for the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For industries such as oil and gas, adherence to API standards is crucial, particularly for components that may be subject to high pressure or extreme conditions.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control checkpoints are essential for maintaining the integrity of the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This phase involves inspecting raw materials upon receipt to ensure they meet specified criteria before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify issues in real-time, minimizing defects.

- Final Quality Control (FQC): A thorough inspection of the finished product ensures that it meets all specifications and standards before shipment.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is critical for B2B buyers, especially when sourcing from international markets. Here are effective strategies:

- Supplier Audits: Conducting on-site audits can provide firsthand insights into a supplier’s manufacturing processes and quality control measures.

- Quality Reports: Requesting detailed quality reports can help assess the supplier’s performance over time, including defect rates and corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices.

What Are the Unique Quality Control Considerations for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face specific challenges related to quality control:

- Regulatory Compliance: Different regions may have varying regulations that impact product standards. Understanding these nuances is essential for compliance.

- Logistical Challenges: Shipping and handling can affect product quality. Buyers should ensure that suppliers have robust packaging and transportation measures in place to protect products during transit.

- Cultural Differences: Variations in manufacturing practices and business ethics across regions may affect quality. Building strong relationships with suppliers and understanding local practices can help mitigate risks.

Conclusion: Ensuring Quality in STL File Manufacturing for CNC Routers

By comprehensively understanding the manufacturing processes and quality assurance measures associated with STL files for CNC routers, B2B buyers can make informed decisions that align with their specific requirements. From material preparation to final quality control, each stage plays a crucial role in delivering high-quality products that meet international standards. Adopting a proactive approach to verifying supplier quality control can further enhance the likelihood of successful partnerships and high-quality outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stl files for cnc router’

Introduction

This guide aims to provide a comprehensive checklist for B2B buyers seeking to procure STL files specifically designed for CNC routers. By following this step-by-step approach, businesses can ensure they select high-quality digital models that meet their operational needs and enhance their production capabilities.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for the STL files you need. This includes understanding the dimensions, complexity, and intended materials of the parts you will be machining.

– Considerations: Specify whether you need models for decorative or functional parts, and any particular design features that are essential for your project.

Step 2: Research Reputable Suppliers

Conduct thorough research to identify suppliers with a strong reputation in the market. Look for companies that specialize in STL files for CNC applications and have positive reviews from previous clients.

– Check Online Platforms: Utilize platforms like Cults3D or 3DWave, which offer a variety of STL files, to gauge supplier credibility through user feedback and ratings.

Step 3: Evaluate File Quality and Compatibility

Before purchasing, assess the quality of the STL files offered by potential suppliers. High-quality files should be optimized for CNC machining, ensuring smooth operation and accurate results.

– Key Features to Look For: Ensure the models are designed with precision, are free of errors, and are compatible with your specific CNC software. Some suppliers provide sample files for evaluation, which can be beneficial.

Step 4: Verify Licensing and Usage Rights

Understanding the licensing agreements associated with STL files is crucial. Ensure that the files you intend to purchase come with appropriate usage rights that align with your business objectives.

– Commercial Use: Confirm whether the files can be used for commercial purposes, as some licenses may restrict selling products made from the files.

Step 5: Assess Customer Support and Service

Evaluate the level of customer support offered by the supplier. Reliable customer service is essential, especially if you encounter technical issues or need assistance with file compatibility.

– Support Channels: Look for suppliers that provide multiple support channels, such as email, chat, or phone, and check their responsiveness to inquiries.

Step 6: Consider Pricing and Payment Terms

Analyze the pricing structure for the STL files, taking into account the balance between quality and cost. While budget constraints are important, opting for the cheapest option may not yield the best results.

– Bulk Discounts: Inquire about discounts for bulk purchases if you require multiple files, as this can lead to significant savings.

Step 7: Read Reviews and Case Studies

Before finalizing your supplier choice, read reviews and case studies from other businesses in your industry. This will provide insight into the supplier’s reliability and the performance of their STL files in real-world applications.

– Industry Relevance: Focus on reviews from companies similar to yours in terms of size and project scope to gauge the supplier’s fit for your specific needs.

By following these steps, B2B buyers can make informed decisions when sourcing STL files for CNC routers, ensuring they select high-quality, reliable digital assets that enhance their manufacturing processes.

Comprehensive Cost and Pricing Analysis for stl files for cnc router Sourcing

What Are the Key Cost Components for STL Files for CNC Routers?

When sourcing STL files for CNC routers, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: Although STL files are digital products, the design process relies on software tools and the expertise of designers. This indirectly contributes to material costs, such as licensing fees for CAD software and cloud storage for digital files.

-

Labor: The time and skill required to create high-quality STL files can significantly impact pricing. Experienced designers typically command higher fees due to their expertise in producing optimized models that minimize machining time and enhance the final product’s quality.

-

Manufacturing Overhead: This includes costs associated with the operation of design facilities, including utilities, maintenance of software, and administrative expenses. Companies that invest in high-quality design processes may pass these costs onto buyers.

-

Tooling: While STL files do not require physical tooling, the design process may involve specialized software tools that incur costs. These tools ensure that files are compatible with various CNC machines and meet industry standards.

-

Quality Control (QC): To ensure that STL files perform well during machining, quality control measures must be implemented. This may involve testing files on CNC machines, which can add to the overall cost.

-

Logistics: Although STL files are digital, logistics can refer to the platforms used for distribution and any associated fees. Companies may also incur costs related to customer support and file updates.

-

Margin: Suppliers typically mark up prices to cover their costs and ensure profitability. This margin can vary based on competition and the perceived value of the STL files.

How Do Price Influencers Affect the Cost of STL Files for CNC Routers?

Several factors can influence the pricing of STL files, particularly in the B2B landscape:

-

Volume/MOQ: Suppliers often offer discounts for bulk purchases, making it essential for buyers to consider their expected usage. Higher volume orders can lead to significant cost savings.

-

Specifications/Customization: Customized STL files that cater to specific project requirements generally cost more than standard models. Buyers should weigh the benefits of custom designs against their budget constraints.

-

Materials: The type of materials used in the original designs can affect costs. Files that represent complex geometries or require advanced design techniques may command higher prices.

-

Quality/Certifications: Files that come with quality assurances or certifications (e.g., compatibility with specific CNC machines) often have a premium price. Buyers should assess whether such certifications are necessary for their projects.

-

Supplier Factors: The reputation and reliability of the supplier can significantly influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants may offer competitive pricing to attract customers.

-

Incoterms: For international buyers, understanding Incoterms is crucial. These terms dictate the responsibilities of buyers and sellers in shipping arrangements and can affect overall costs.

What Are the Best Buyer Tips for Sourcing STL Files for CNC Routers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, navigating the STL file sourcing landscape can be complex. Here are some actionable tips:

-

Negotiation: Don’t hesitate to negotiate prices, especially for bulk orders or long-term partnerships. Suppliers are often willing to provide discounts to secure a deal.

-

Cost-Efficiency: Evaluate the total cost of ownership, including the potential costs of errors or inefficiencies that may arise from poorly designed STL files. Opting for higher-quality files may save money in the long run.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and import duties that may impact the final cost. Building relationships with local suppliers can mitigate some of these challenges.

-

Research and Compare: Take the time to compare multiple suppliers and their offerings. Consider factors like file quality, customer service, and delivery times alongside pricing.

-

Stay Updated: The market for STL files is dynamic, with new designs and technologies emerging regularly. Subscribe to updates from suppliers or join industry forums to stay informed about trends and pricing changes.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier policies, and specific buyer requirements. Always verify current pricing and terms with suppliers before making purchasing decisions.

Alternatives Analysis: Comparing stl files for cnc router With Other Solutions

Exploring Alternatives to STL Files for CNC Routing

When considering solutions for CNC routing, it’s essential to evaluate various file formats and methods that can achieve similar results to STL files. While STL files are widely recognized for their compatibility and ease of use in CNC machining, other alternatives may offer unique advantages depending on specific project requirements. Below, we compare STL files with two viable alternatives: OBJ Files and DXF Files.

| Comparison Aspect | STL Files For CNC Router | OBJ Files | DXF Files |

|---|---|---|---|

| Performance | High precision; suitable for complex geometries | Good for 3D models but may require conversion for CNC | Excellent for 2D vector designs; widely used in CAD |

| Cost | Generally low; files often available for purchase or free | Often free; some may be paid; no additional costs for conversion | Typically free; CAD software often supports DXF |

| Ease of Implementation | Easy to use with most CNC software | Requires conversion for some CNC machines | Directly compatible with CAD software, often requiring less setup |

| Maintenance | Minimal; files can be reused across projects | May require updates or adjustments for accuracy | Regular updates may be needed to maintain compatibility with CAD systems |

| Best Use Case | Ideal for intricate 3D designs and sculptures | Suitable for 3D models needing texture and color | Best for technical drawings, schematics, and 2D profiles |

What Are the Advantages and Disadvantages of Using OBJ Files?

OBJ files are a popular alternative, especially in applications requiring high-quality visuals. They can represent complex geometries and are capable of storing additional information such as texture and color. However, when it comes to CNC routing, OBJ files may need conversion to a compatible format, which can introduce additional steps in the workflow. The conversion process may also result in slight inaccuracies, impacting the final output. Therefore, while OBJ files are excellent for design purposes, their use in CNC machining may be limited by the need for conversion and potential loss of precision.

Why Consider DXF Files for CNC Routing?

DXF (Drawing Exchange Format) files are primarily used for 2D designs and are exceptionally well-suited for technical drawings, schematics, and vector-based designs. They offer seamless compatibility with CAD software and are often the preferred choice for projects that involve straightforward cutting or engraving processes. However, DXF files lack the capability to represent 3D geometries, making them less suitable for projects that require detailed 3D modeling. While their ease of use in 2D applications is a significant advantage, any project requiring 3D intricacies will necessitate a different format, such as STL.

How Should B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right file format or method for CNC routing hinges on the specific requirements of a project. Buyers should assess factors such as the complexity of the design, the precision needed, and the software compatibility. For intricate 3D projects that demand high precision, STL files are often the best choice. Conversely, if the project is primarily 2D or requires compatibility with CAD systems, DXF files may be more appropriate. Understanding these distinctions will empower B2B buyers to make informed decisions tailored to their operational needs, ensuring optimal results in their CNC routing endeavors.

Essential Technical Properties and Trade Terminology for stl files for cnc router

What Are the Key Technical Properties of STL Files for CNC Routers?

When working with STL files for CNC routers, understanding the essential technical properties is crucial for ensuring high-quality outputs and efficient production processes. Here are some critical specifications:

-

File Format Compatibility

– Definition: STL (Stereolithography) files are the standard format for 3D models, widely used in CNC machining and 3D printing.

– Importance: Ensuring compatibility with various CAD software and CNC machines is vital. This reduces the risk of errors during file import, leading to smoother operations and less downtime. -

Triangle Count

– Definition: STL files represent 3D models as a collection of triangles. The triangle count indicates the model’s complexity and detail level.

– Importance: A higher triangle count can enhance the detail of the machined part but may also increase processing time and machine load. B2B buyers must balance detail and efficiency based on their specific applications. -

Tolerance

– Definition: Tolerance refers to the allowable deviation from a specified dimension in the design. It is critical in defining how closely the manufactured part must match the intended design.

– Importance: Precise tolerances are essential for parts that need to fit together or operate under specific conditions. Understanding tolerance requirements helps buyers ensure their CNC machined parts meet performance and quality standards. -

Resolution

– Definition: Resolution in the context of STL files refers to the precision of the model’s surface representation. Higher resolution means finer details but larger file sizes.

– Importance: In B2B applications, selecting the appropriate resolution affects machining speed and quality. Buyers must consider the trade-offs between detail and processing efficiency. -

Material Properties

– Definition: While STL files do not contain material specifications, understanding the materials used for CNC machining (e.g., wood, metal, plastics) is crucial.

– Importance: Different materials have unique machining characteristics. Buyers need to align STL file specifications with the material properties to avoid issues during production.

What Are Common Trade Terms Related to STL Files for CNC Routers?

Familiarity with industry jargon can streamline communications and negotiations in the B2B space. Here are key terms to know:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Understanding OEM relationships can help buyers identify reliable sources for STL files or CNC parts that meet their specific needs. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is crucial for budgeting and inventory management. Buyers should negotiate MOQs that align with their production schedules and demands. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for specific products or services.

– Importance: Sending RFQs allows buyers to compare prices and services from multiple suppliers, facilitating informed decision-making in sourcing STL files and CNC machining services. -

Incoterms (International Commercial Terms)

– Definition: A set of rules that define the responsibilities of buyers and sellers in international transactions.

– Importance: Understanding Incoterms helps buyers clarify shipping, risk, and cost responsibilities when importing STL files or CNC machined parts, ensuring smoother transactions across borders. -

BOM (Bill of Materials)

– Definition: A comprehensive list of materials and components required to manufacture a product.

– Importance: A clear BOM helps in planning and cost estimation for projects involving CNC machining, ensuring all necessary STL files and materials are accounted for.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions, optimize production processes, and enhance product quality in their CNC routing projects.

Navigating Market Dynamics and Sourcing Trends in the stl files for cnc router Sector

What Are the Key Trends Shaping the STL Files Market for CNC Routers?

The global market for STL files tailored for CNC routers is experiencing significant transformation, driven by advancements in technology and shifting consumer demands. One of the primary drivers is the increasing adoption of CNC machinery across various industries, including woodworking, automotive, and aerospace. As manufacturers seek to enhance precision and efficiency in production, the demand for high-quality STL files is surging. Additionally, the rise of digital fabrication and the maker movement has led to a broader base of hobbyists and small businesses seeking easy access to ready-to-use designs.

Emerging B2B tech trends highlight the growing integration of AI and machine learning in design software, facilitating the creation of more complex and optimized STL files. Furthermore, platforms that allow for the sharing and customization of designs are gaining traction, empowering users to modify existing models to better suit their specific needs. For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for sourcing high-quality STL files that meet local market demands while ensuring compatibility with a variety of CNC machines.

How Does Sustainability Influence B2B Sourcing of STL Files for CNC Routers?

Sustainability is becoming a pivotal factor in the sourcing of STL files for CNC routers, reflecting a broader shift towards environmentally responsible manufacturing practices. The environmental impact of traditional manufacturing methods is prompting buyers to seek digital alternatives that reduce material waste and energy consumption. STL files enable precise machining, which can minimize excess material usage during production.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials or obtaining ‘green’ certifications. This trend is particularly relevant for B2B buyers in developing markets, where the demand for sustainable solutions is growing alongside economic development. By choosing to source STL files from suppliers that prioritize sustainability, businesses can enhance their brand reputation and align with global sustainability goals.

What Is the Historical Context of STL Files for CNC Routers?

The evolution of STL files for CNC routers is rooted in the advancements of 3D modeling and CAD technology. Initially developed for 3D printing, the STL file format gained popularity due to its versatility and ease of use. As CNC machining technology progressed, the need for high-quality 3D models became evident, leading to the adaptation of STL files for CNC applications.

Over the years, the accessibility of digital design tools has democratized the production of STL files, allowing a diverse range of creators—from hobbyists to professional designers—to contribute to the market. This evolution has resulted in a vast library of STL files available for various applications, catering to the specific needs of different industries. Today, international B2B buyers can leverage this rich resource to find tailored solutions that enhance their CNC machining processes.

Frequently Asked Questions (FAQs) for B2B Buyers of stl files for cnc router

-

How do I select the right STL files for CNC routing projects?

When selecting STL files for CNC routing, consider the complexity of the design and the capabilities of your CNC machine. Ensure the files are optimized for CNC use, meaning they should be well-structured and free of errors. Look for models with detailed descriptions and reviews from other users. It’s also beneficial to check if the STL files are compatible with your CAD software to streamline the design process. -

What are the key benefits of using STL files for CNC routing?

STL files are widely used for CNC routing due to their versatility and ease of use. They represent 3D models as a mesh of triangles, making them suitable for various CNC machines. The format is compatible with most CAD software, allowing for quick modifications. Moreover, STL files facilitate precise machining, enabling the production of intricate designs with high accuracy, essential for professional applications. -

What should I consider regarding payment terms when sourcing STL files internationally?

When sourcing STL files internationally, it’s crucial to discuss payment terms upfront. Common methods include credit card payments, wire transfers, or escrow services, which provide security for both parties. Be clear about currency exchange rates, potential taxes, and any additional fees that may apply. Establishing clear terms in a contract can help mitigate risks and ensure a smooth transaction process. -

How can I ensure the quality of STL files from suppliers?

To ensure quality, vet suppliers by checking their reputation through reviews and testimonials from previous customers. Request sample files to evaluate their precision and detail. Ask about the design process they follow and whether they perform quality assurance checks before selling the files. Establishing a good communication channel can also help clarify any concerns before making a purchase. -

Are there customization options available for STL files?

Many suppliers offer customization services for STL files, allowing you to tailor designs to your specific needs. This can include altering dimensions, modifying features, or creating entirely new designs based on your specifications. Discuss your requirements with the supplier before purchase, and inquire about any additional costs or lead times associated with customization. -

What are the minimum order quantities (MOQ) for STL files?

STL files are typically sold on a per-file basis, so there may not be a minimum order quantity. However, some suppliers may offer discounts for bulk purchases or subscriptions that provide access to a wider range of files. Always clarify MOQ policies with your supplier to ensure you’re making the most cost-effective decision for your business. -

How can I verify the compatibility of STL files with my CNC machine?

To verify compatibility, consult your CNC machine’s specifications and the software you plan to use. Most modern CNC machines support STL files, but it’s important to ensure the file’s geometry aligns with your machine’s capabilities. You can also reach out to the supplier for confirmation or guidance on using their files with specific CNC setups. -

What logistics considerations should I keep in mind when sourcing STL files internationally?

Sourcing STL files is largely digital, which simplifies logistics. However, consider factors such as file transfer security and internet bandwidth, especially in regions with limited connectivity. Ensure that the supplier offers secure download methods, and clarify how file updates or revisions will be handled. Additionally, consider time zone differences when planning communication and project timelines.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Stl Files For Cnc Router Manufacturers & Suppliers List

1. Cults3D – Premium 3D Printing Models

Domain: cults3d.com

Registered: 2013 (12 years)

Introduction: Router CNC best 3D printing models, 0 free models to download, 2.4M free and premium models available, compatible with FDM, SLA, or SLS 3D printers, supports various file formats including STL, OBJ, STEP, 3MF, SCAD for 3D printing and DXF, SVG, PDF, AI for CNC machining & laser cutting. Community of 199k designers, option to upload and share 3D prints.

2. Inventables – Easel Pro

Domain: inventables.com

Registered: 2001 (24 years)

Introduction: Easel Pro allows import of 3D STL files for carving 3D reliefs, with a file size up to 100 MB. STL is a 3D file format native to CAD software, suitable for CNC machines like X-Carve and X-Carve Pro. Best STL files for 3D carving have flat faces or bottoms. Recommended sites for STL files include: 1. STLFinder (Paid and Free) – Search engine for STL files. 2. Free3D (Paid and Free) – Marketplace wi…

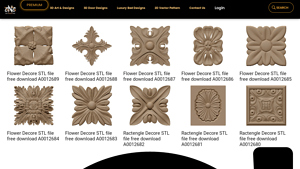

3. CNC Design Hub – STL Files for Wood Carving Projects

Domain: cncdesignhub.com

Registered: 2020 (5 years)

Introduction: STL files for CNC wood carving projects, including: 3D Wall Panel Designs, 3D Art Pattern Designs, Table Legs, Mirror Frame, Wall Clock, Ceiling Rose, Religious 3D Art, Animals 3D Art, Painting, Jewelry Design, 3D Door Designs, Luxury Bed Designs, 2D Vector Patterns. Free downloads available for various designs such as Flower Decore and Rectangle Decore.

4. All3DP – Best Sites for Free STL Files

Domain: all3dp.com

Registered: 2013 (12 years)

Introduction: The article discusses the best sites for free STL files specifically for CNC routers. It highlights that while STL is not the most common CNC file format, it is still a viable option for users. The content is authored by Gabriel Slump and Guilherme Schendel, and was updated on May 31, 2024. The article is free to access and is financed through advertising and shopping links, with a note that the s…

5. CNC Woodworking – Free 3D Models Resources

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Free 3D models for CNC woodworking can be found on various sites. A reliable source mentioned is https://free-stl.ru/. Other suggested sites include GrabCAD, Thingiverse, and Shapeoko’s wiki for online resources. Users also recommend avoiding STL files due to their triangulated surfaces, which can complicate routing; instead, STP and STEP files are preferred for maintaining design structure. Some …

Strategic Sourcing Conclusion and Outlook for stl files for cnc router

In today’s competitive landscape, sourcing high-quality STL files for CNC routers is essential for businesses aiming to enhance their production capabilities. By strategically selecting reliable suppliers, B2B buyers can ensure access to meticulously crafted models that are optimized for smooth machining and precision. The ability to download files instantly not only streamlines project initiation but also allows companies to remain agile in responding to market demands.

For international buyers from regions such as Africa, South America, the Middle East, and Europe, leveraging a diverse range of STL file sources can significantly improve operational efficiency and innovation. Engaging with platforms that offer both free and premium models enables businesses to experiment with new designs without incurring substantial costs.

As we look ahead, the demand for customizable and intricate designs will only grow. B2B buyers are encouraged to explore the vast array of STL files available, fostering collaboration with designers and suppliers to create unique offerings. Embrace this opportunity to elevate your CNC machining projects—invest in strategic sourcing today and position your business for success in an evolving market landscape.