Introduction: Navigating the Global Market for stl file software free

Navigating the complexities of sourcing free STL file software can be a daunting task for international B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. With the increasing demand for 3D printing applications across various industries, finding the right tools to edit and repair STL files is essential for ensuring quality and efficiency in production. This guide delves into a comprehensive overview of free STL file software, examining the types available, their applications in diverse sectors, and practical insights into vetting suppliers.

By equipping B2B buyers with actionable intelligence on software capabilities, cost considerations, and user-friendliness, this resource aims to empower informed purchasing decisions. Whether your organization is focused on prototyping, manufacturing, or design, understanding the nuances of STL editing tools can significantly enhance operational workflows and reduce time-to-market. From identifying the best free editors for specific needs to evaluating their effectiveness in a professional setting, this guide serves as a vital resource for businesses aiming to optimize their 3D printing processes. Embrace the potential of free STL file software and elevate your production capabilities to meet the demands of a global market.

Understanding stl file software free Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CAD Software | Parametric modeling, precise measurements, engineering focus | Mechanical design, prototyping | Pros: High precision, professional-grade tools. Cons: Steeper learning curve for beginners. |

| Mesh Editing Tools | Focus on surface manipulation, mesh repair, and sculpting | Artistic modeling, detailed edits | Pros: User-friendly for creative tasks. Cons: Limited in creating complex geometries from scratch. |

| Online STL Editors | Browser-based, no installation required | Quick edits, remote collaboration | Pros: Accessibility, ease of use. Cons: May lack advanced features of desktop applications. |

| Slicing Software | Converts 3D models into printer-ready files | 3D printing preparation | Pros: Essential for 3D printing workflows. Cons: Specific to printing, not for design. |

| Specialized Tools | Tailored for specific industries (e.g., medical, aerospace) | Niche applications, compliance checks | Pros: Optimized for industry needs. Cons: May have limited general functionality. |

What Are the Key Characteristics of CAD Software for STL File Editing?

CAD (Computer-Aided Design) software is characterized by its precise modeling capabilities and parametric features. This type of software is particularly useful in fields like engineering and architecture, where accuracy is paramount. For B2B buyers, the ability to create intricate designs or modify existing STL files with exact measurements is invaluable, especially in prototyping and mechanical design. However, the complexity of these tools may require training, making them less accessible for non-technical users.

How Do Mesh Editing Tools Enhance STL File Customization?

Mesh editing tools focus primarily on the surface of 3D models, allowing users to manipulate and repair meshes easily. These tools are well-suited for artistic applications, enabling users to sculpt and refine models for detailed outputs. For B2B buyers, the intuitive interfaces of these programs can reduce the time spent on edits, although they may not support the creation of complex geometries from scratch. This makes them ideal for businesses needing quick fixes or enhancements to existing designs.

What Advantages Do Online STL Editors Offer for B2B Collaboration?

Online STL editors provide a convenient, browser-based platform for users to edit and share STL files without the need for installation. This flexibility is beneficial for teams that require remote collaboration on projects. B2B buyers will appreciate the ease of access and the ability to make quick edits, though these tools may lack the advanced features found in dedicated desktop applications. For businesses looking for straightforward solutions without the overhead of software management, online editors can be a practical choice.

Why Is Slicing Software Essential for 3D Printing?

Slicing software plays a critical role in the 3D printing process by converting STL files into printer-compatible formats. This software is essential for businesses engaged in additive manufacturing, ensuring that designs are accurately translated into physical objects. While slicing software is indispensable for printing, its functionality is limited to preparing models rather than creating them. B2B buyers must consider this software as part of their overall 3D printing workflow, particularly if they aim to streamline production processes.

What Are the Benefits of Specialized Tools for Industry-Specific Applications?

Specialized tools are designed to meet the unique demands of various industries, such as medical or aerospace. These applications often include features that ensure compliance with specific regulations and standards, making them crucial for businesses operating in niche markets. B2B buyers can benefit from these tools as they offer optimized functionalities tailored to their sector’s needs. However, the trade-off may be a limitation in general-purpose features, which could restrict their use in broader applications.

Key Industrial Applications of stl file software free

| Industry/Sector | Specific Application of stl file software free | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Rapid Prototyping of Components | Accelerates product development cycles, reducing time-to-market | Compatibility with existing CAD systems and file formats |

| Architecture & Construction | Design Visualization and Modelling | Enhances client presentations and project approvals | Software capability to handle large files and detailed models |

| Healthcare | Custom Medical Devices and Prosthetics | Tailors solutions to specific patient needs, improving outcomes | Regulatory compliance and material suitability |

| Education & Training | 3D Model Creation for Learning Tools | Provides interactive learning experiences, enhancing engagement | User-friendliness and availability of tutorials |

| Automotive | Tooling and Fixture Design | Improves precision in manufacturing processes, reducing waste | Ability to integrate with CNC machining and 3D printing tech |

How is STL File Software Used in Manufacturing for Rapid Prototyping?

In the manufacturing sector, free STL file software is crucial for rapid prototyping of components. Companies can quickly create and iterate designs, allowing for faster adjustments based on testing and feedback. This capability minimizes production costs and time, ultimately leading to a more agile manufacturing process. For international buyers, especially from regions like Africa and South America, it’s essential to consider software that integrates seamlessly with existing CAD systems to ensure compatibility and efficiency in the prototyping stage.

What Role Does STL File Software Play in Architecture and Construction?

In architecture and construction, STL file software is employed for design visualization and modelling. Architects can create detailed 3D models of their designs, which can be presented to clients for approvals. This not only enhances the visual representation of projects but also aids in identifying potential design flaws early in the process. Buyers in Europe and the Middle East should prioritize software that can handle large files and complex designs, ensuring that it meets the demands of intricate architectural projects.

How is STL File Software Beneficial in Healthcare for Custom Medical Devices?

The healthcare industry utilizes STL file software for the development of custom medical devices and prosthetics. By creating tailored solutions that meet specific patient needs, healthcare providers can significantly improve patient outcomes. Free software options enable smaller healthcare facilities in regions like Africa to innovate without the burden of high costs. Buyers must ensure that the software complies with local regulatory standards and can work with biocompatible materials.

How Can STL File Software Enhance Education and Training?

In educational settings, STL file software facilitates the creation of 3D models for learning tools. This technology enables students to engage with complex concepts through interactive models, enhancing the learning experience. For institutions in developing regions, such as Nigeria and Vietnam, user-friendly software with accessible tutorials is vital for effective implementation in classrooms. Buyers should look for solutions that offer robust support and community resources to aid in adoption.

What Advantages Does STL File Software Provide in Automotive Tooling and Fixture Design?

In the automotive industry, STL file software is essential for designing tooling and fixtures. This application enhances precision in manufacturing processes, leading to reduced material waste and improved product quality. For international buyers, especially in Europe and the Middle East, it is crucial to select software that can integrate with CNC machining and 3D printing technologies, ensuring a smooth transition from design to production.

3 Common User Pain Points for ‘stl file software free’ & Their Solutions

Scenario 1: Difficulty in Repairing Corrupted STL Files

The Problem:

B2B buyers often encounter corrupted STL files, particularly when downloading models from various online repositories. These files may be incomplete, contain non-manifold edges, or have other defects that prevent successful 3D printing. This can lead to wasted time and resources, especially for businesses relying on timely production cycles. For instance, a manufacturing company in Nigeria may find that a crucial model for a new product launch is unusable, creating delays and potential revenue loss.

The Solution:

To address this issue, businesses should utilize free STL editing software such as MeshLab or Blender, which are powerful tools for repairing STL files. Begin by importing the problematic STL file into MeshLab, which offers comprehensive mesh processing tools, including options for cleaning up errors and remeshing. Users should focus on using the “Cleaning” and “Repair” functions, which can automatically identify and fix common issues like holes or non-manifold edges. For more complex repairs, Blender offers a sculpting feature that allows users to manually adjust problematic areas. It’s crucial to familiarize the team with these tools through online tutorials and documentation, ensuring they can efficiently troubleshoot and repair STL files, ultimately streamlining the production process.

Scenario 2: Incompatibility Issues with 3D Printers

The Problem:

Another common pain point is the incompatibility of STL files with different 3D printers. Businesses often find that models designed for one type of printer do not work well with another, leading to frustration and costly delays. For example, a 3D printing service in South America may receive an STL file that is too large or has a resolution unsuitable for their equipment, requiring additional modifications that could have been avoided with proper preparation.

The Solution:

To mitigate compatibility issues, businesses should implement a standard procedure for preparing STL files before sending them to the printer. This involves using free software such as FreeCAD or Tinkercad, which allow users to scale models, adjust dimensions, and even convert file formats as necessary. Companies should establish clear guidelines on the preferred specifications for STL files, including maximum dimensions and resolution settings suitable for their specific printers. Additionally, it’s beneficial to create a checklist for team members to follow when preparing STL files, which can include verifying model integrity and confirming compatibility with the intended printing technology. By taking these proactive steps, businesses can significantly reduce the risk of incompatibility and ensure smoother production workflows.

Scenario 3: Lack of Design Customization Options

The Problem:

Many B2B buyers find that pre-made STL models do not fully meet their design needs, lacking specific features or adaptations required for their projects. For instance, a company in the Middle East may need to adjust an existing model to fit a particular application or integrate new components, but they struggle with the limited capabilities of basic STL editing tools. This lack of customization can hinder innovation and product development timelines.

The Solution:

To enhance design flexibility, businesses should leverage advanced free STL editing software like Blender or FreeCAD, which provide robust modeling capabilities. Users should explore the parametric modeling features in FreeCAD, which allow for precise adjustments and iterative design changes. Furthermore, Blender’s sculpting tools enable intricate modifications, making it easier to adapt existing models to specific requirements. Companies can benefit from investing time in training their teams on these platforms, encouraging experimentation with various design techniques. Hosting workshops or providing access to online courses can empower employees to become proficient in these tools, fostering a culture of creativity and innovation. By embracing these solutions, businesses can fully customize their STL files to better align with their unique project goals, enhancing product offerings and competitive advantage.

Strategic Material Selection Guide for stl file software free

What Are the Key Properties of Common Materials for STL File Software?

When selecting materials for STL file software, especially in the context of 3D printing, it is essential to understand the properties and implications of different materials. Here, we analyze four common materials utilized in conjunction with STL file software, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

How Do PLA and ABS Compare in Terms of Performance?

PLA (Polylactic Acid) is a biodegradable thermoplastic derived from renewable resources like corn starch. It is known for its ease of use, making it a popular choice among beginners and professionals alike.

- Key Properties: PLA has a low melting temperature (around 180-220°C) and is not as heat-resistant as other materials. It is biodegradable and offers good rigidity.

- Pros & Cons: The advantages of PLA include its low cost and ease of printing, while its limitations include lower durability and heat resistance compared to ABS. It is prone to warping under high temperatures.

- Impact on Application: PLA is suitable for prototypes, decorative items, and educational models but is not ideal for functional parts exposed to high stress or heat.

- Considerations for International Buyers: Compliance with environmental regulations is crucial, especially in regions like Europe where sustainability is prioritized. Buyers should also consider local preferences for biodegradable materials.

ABS (Acrylonitrile Butadiene Styrene) is another widely used thermoplastic, known for its strength and impact resistance.

- Key Properties: ABS has a higher melting temperature (around 210-250°C) and provides excellent durability and toughness.

- Pros & Cons: Its advantages include higher strength and heat resistance, making it suitable for functional parts. However, it can be more challenging to print due to warping and requires a heated bed.

- Impact on Application: ABS is ideal for automotive parts, electronic housings, and toys. Its robustness makes it suitable for applications requiring durability.

- Considerations for International Buyers: Buyers should be aware of the need for proper ventilation during printing due to the fumes emitted. Compliance with safety standards like ASTM and ISO is also critical.

What Are the Advantages of Using PETG and Nylon?

PETG (Polyethylene Terephthalate Glycol-Modified) is gaining popularity due to its excellent balance of strength, flexibility, and ease of printing.

- Key Properties: PETG has a melting temperature of around 230-250°C and offers good chemical resistance.

- Pros & Cons: Its advantages include excellent layer adhesion and durability, while its limitations include a tendency to string during printing.

- Impact on Application: PETG is suitable for functional prototypes, containers, and mechanical parts due to its strength and flexibility.

- Considerations for International Buyers: Compliance with food safety standards is crucial for applications involving food contact. Buyers should also consider the availability of PETG in their region.

Nylon is known for its exceptional strength and flexibility, making it a favorite for industrial applications.

- Key Properties: Nylon has a high melting temperature (around 240-260°C) and is resistant to wear and chemicals.

- Pros & Cons: Its advantages include high durability and flexibility, while its disadvantages include moisture absorption and difficulty in printing.

- Impact on Application: Nylon is ideal for functional parts that require high strength and flexibility, such as gears and mechanical components.

- Considerations for International Buyers: Buyers should be aware of the need for moisture control during storage and printing. Compliance with industry-specific standards is essential.

Summary Table of Material Selection for STL File Software

| Material | Typical Use Case for stl file software free | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PLA | Prototyping, decorative items | Biodegradable, easy to print | Low durability, heat sensitivity | Low |

| ABS | Functional parts, automotive components | High strength, heat resistance | Warping, requires heated bed | Medium |

| PETG | Functional prototypes, containers | Strong, good chemical resistance | Tendency to string during printing | Medium |

| Nylon | Industrial applications, gears | High strength, flexibility | Moisture absorption, printing complexity | High |

This guide provides a comprehensive overview of material selection for STL file software, emphasizing the importance of understanding material properties and their implications for various applications. International B2B buyers should carefully consider these factors to ensure compliance and suitability for their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for stl file software free

What Are the Key Manufacturing Processes for STL File Software?

The manufacturing processes for STL file software primarily focus on the stages of material preparation, forming, assembly, and finishing. Understanding these stages helps B2B buyers identify the software’s capabilities, ensuring it meets their specific needs in 3D printing and manufacturing.

How Is Material Prepared for STL File Software?

Material preparation is crucial for developing high-quality STL files. This stage involves selecting appropriate 3D modeling materials, which can vary based on the intended application. For instance, materials may include PLA, ABS, or resin, each offering different properties such as strength, flexibility, and temperature resistance. The choice of material directly impacts the design process, as certain materials may require specific design considerations.

Furthermore, the software must facilitate the importation of various file formats and allow users to manipulate 3D models efficiently. This includes cleaning up mesh data, repairing errors, and optimizing models for 3D printing. Effective material preparation ensures that the STL files generated are accurate representations of the intended designs.

What Techniques Are Used in Forming STL Files?

Forming STL files involves creating the actual 3D model through various techniques. The most common methods include parametric modeling and mesh editing. Parametric modeling, often found in CAD software, allows users to create precise geometries that can be easily modified. This is particularly beneficial for industries requiring exact specifications, such as aerospace and automotive.

On the other hand, mesh editing tools are designed to manipulate existing 3D models. These tools enable users to sculpt, refine, and repair models, making them suitable for complex designs. The ability to seamlessly transition between different modeling techniques is vital for producing high-quality STL files that meet diverse manufacturing requirements.

How Is Assembly Managed in STL File Software Development?

While assembly is less relevant in the context of STL file software than in physical manufacturing, it still plays a role in how software integrates with other systems. For instance, STL files often need to be assembled with slicing software to prepare for 3D printing. This integration is critical, as it ensures that the model is sliced correctly, taking into account factors like layer height, print speed, and support structures.

Moreover, B2B buyers should consider software that allows for easy collaboration between teams, enabling multiple users to work on the same STL file simultaneously. This collaborative approach can streamline the design process, reduce errors, and enhance overall productivity.

What Finishing Techniques Are Relevant for STL File Software?

Finishing techniques in the context of STL file software involve the final adjustments made to the 3D model before printing. This includes smoothing surfaces, adding textures, and ensuring that the model is optimized for printing. The software should provide tools for visual inspection and error correction, allowing users to detect and rectify issues before the manufacturing stage.

Additionally, buyers should look for software that supports post-processing features, such as exporting files in multiple formats or integrating with other manufacturing technologies. This capability is essential for ensuring that the final product meets industry standards and customer expectations.

How Does Quality Assurance Work for STL File Software?

Quality assurance (QA) is a critical aspect of STL file software development and usage. It ensures that the software produces reliable and accurate STL files that can be used in 3D printing and other manufacturing processes.

What International Standards Are Relevant for STL File Software Quality?

B2B buyers should be aware of various international standards that govern quality assurance in software development. ISO 9001, for example, is a widely recognized standard that outlines the requirements for a quality management system. Adherence to ISO 9001 ensures that the software development processes are consistent and that the final products meet customer requirements.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also apply, depending on the sector. These certifications indicate compliance with safety and performance standards, which is particularly important for buyers in regulated industries.

What Are the Key Quality Control Checkpoints in STL File Software Development?

Quality control (QC) checkpoints are essential for maintaining high standards throughout the software development process. Key checkpoints include:

-

Incoming Quality Control (IQC): This phase involves verifying the quality of input materials, such as 3D models or design specifications, before they enter the production process.

-

In-Process Quality Control (IPQC): During this stage, the software’s functionality and performance are monitored to ensure that it meets predefined quality standards. This may involve testing the software’s ability to import and export various file formats accurately.

-

Final Quality Control (FQC): At this stage, the final output—STL files—undergo thorough testing to ensure they are free from errors and meet the required specifications. This may involve visual inspections and automated testing tools.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying supplier quality control is crucial to ensuring that the STL file software meets their needs. Buyers can employ several strategies:

-

Conduct Audits: Periodic audits of the supplier’s development processes can help assess compliance with quality standards. This can include reviewing documentation related to ISO certifications or other relevant industry standards.

-

Request Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes, testing methods, and results. These reports should be transparent and readily available for review.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the software’s quality. These inspectors can evaluate the software based on established standards and provide recommendations for improvement.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider several nuances when evaluating quality control:

-

Cultural Differences: Different regions may have varying expectations regarding quality and compliance. Buyers should communicate clearly with suppliers to ensure mutual understanding.

-

Regulatory Compliance: Understanding local regulations and compliance requirements is vital. Buyers must ensure that the software adheres to the relevant laws and standards in their regions.

-

Supply Chain Transparency: A transparent supply chain can enhance trust between buyers and suppliers. Buyers should seek suppliers who provide visibility into their QC processes and practices.

In conclusion, understanding the manufacturing processes and quality assurance for STL file software is essential for B2B buyers. By focusing on material preparation, forming techniques, assembly considerations, finishing processes, and robust quality assurance practices, buyers can make informed decisions that enhance their 3D printing and manufacturing capabilities.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stl file software free’

To effectively procure free STL file software, it’s essential to follow a structured approach that ensures the software meets your specific needs for 3D modeling and printing. This guide provides a practical checklist for international B2B buyers looking to enhance their 3D printing capabilities.

Step 1: Define Your Technical Requirements

Understanding your specific needs is the first step in sourcing STL file software. Determine the types of STL files you plan to work with, such as complex models requiring advanced editing or simpler designs. This clarity will guide you in selecting software that aligns with your technical specifications.

- Key Considerations:

- Do you need advanced features for mesh repair and editing?

- Are your projects more focused on basic resizing and modifications?

Step 2: Research Available Free Software Options

Explore various free STL file software options available on the market. Popular tools like FreeCAD, Blender, and MeshMixer each have unique features catering to different skill levels and project requirements.

- Recommendations:

- FreeCAD for parametric modeling and mechanical designs.

- Blender for detailed sculpting and advanced editing.

Step 3: Evaluate User Community and Support Resources

A strong user community can be invaluable, especially for free software. Look for forums, tutorials, and user-generated content that can assist you in overcoming technical challenges.

- Considerations:

- Are there active forums where users discuss common issues?

- Is there comprehensive documentation available for the software?

Step 4: Assess Compatibility with Existing Systems

Ensure the software you choose integrates well with your current 3D printing hardware and other design tools. Compatibility issues can lead to inefficiencies and additional costs.

- Check for:

- Supported file formats beyond STL, such as OBJ or AMF.

- System requirements that match your existing hardware capabilities.

Step 5: Test Software Usability

Before fully committing to a specific software, utilize trial versions or free downloads to assess usability. A user-friendly interface can significantly enhance productivity and reduce training time for your team.

- Look for:

- Intuitive navigation and ease of use for team members.

- Availability of tutorials or guided walkthroughs for new users.

Step 6: Verify Licensing and Usage Rights

Even though the software is free, it’s crucial to understand the licensing agreements and usage rights. Some free software may have restrictions on commercial use or redistribution.

- Important Points:

- Review the terms of service for any limitations on commercial projects.

- Ensure that you can legally use the software in your business context.

Step 7: Gather Feedback from Team Members

Involve your design and engineering teams in the evaluation process. Their insights can provide a practical perspective on how well the software meets operational needs and improves workflow.

- Action Items:

- Conduct a survey or feedback session after testing the software.

- Compile a list of pros and cons from team members to facilitate decision-making.

By following this checklist, B2B buyers can effectively navigate the landscape of free STL file software, ensuring a well-informed choice that enhances their 3D printing processes.

Comprehensive Cost and Pricing Analysis for stl file software free Sourcing

What Are the Key Cost Components for Free STL File Software?

When evaluating the cost structure of free STL file software, it’s essential to understand the various components that contribute to the overall pricing model, even for free solutions. The primary cost components include:

-

Materials: While STL file software itself doesn’t involve physical materials, the final product—3D printed objects—will incur material costs. Understanding the types of materials compatible with different STL editors is crucial. For instance, certain software may optimize designs for specific filament types, which can influence material costs in the production phase.

-

Labor: Even though software is free, the time and expertise required to effectively use these tools represent a significant cost factor. Companies should consider the labor costs associated with training employees to utilize the software effectively. Investing in skilled personnel can enhance productivity and ensure efficient file editing.

-

Manufacturing Overhead: This includes costs related to the infrastructure required to support 3D printing operations, such as electricity and maintenance of printing equipment. Although these are indirect costs, they become relevant when evaluating the total cost of ownership.

-

Tooling: While STL file software does not require physical tooling, understanding the software’s capabilities to manage complex designs can impact operational efficiency. Businesses may need to invest in additional tools or software plugins to maximize the software’s utility.

-

Quality Control (QC): Ensuring that STL files are error-free before printing is critical. The QC process may involve additional software or labor costs to verify that files meet specific standards, especially for industries that require high precision.

-

Logistics: This includes the costs associated with the distribution of the final printed products. For international buyers, understanding shipping and handling costs is essential, as they can significantly affect the overall price.

-

Margin: Although the software itself is free, companies may still factor in a margin when pricing their final products to cover operational costs and ensure profitability.

How Do Price Influencers Impact the Sourcing of Free STL File Software?

Several factors can influence the pricing and sourcing strategies for STL file software, even if the software itself is free:

-

Volume/MOQ: For businesses that require bulk editing or processing of STL files, negotiating for volume-based pricing on complementary services (like 3D printing) can yield significant savings.

-

Specifications/Customization: Customization options within STL file software can impact usability and effectiveness. Buyers should consider whether they require specific features that may necessitate investment in paid software solutions.

-

Materials: The choice of materials for 3D printing can affect the final product’s cost. Buyers should ensure that the STL software they choose can handle the materials they plan to use.

-

Quality/Certifications: Some industries demand high-quality standards and certifications for 3D printed products. Buyers may need to invest in software that meets these standards, impacting overall costs.

-

Supplier Factors: When sourcing STL file software, consider the reliability and reputation of the supplier. Established suppliers may provide better support and updates, which can save costs in the long run.

-

Incoterms: Understanding international trade terms is vital for B2B buyers. Incoterms define the responsibilities of buyers and sellers in shipping, which can affect logistics costs and timelines.

What Are Effective Buyer Tips for Cost-Efficient Sourcing?

B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should adopt the following strategies to ensure cost-efficient sourcing of STL file software:

-

Negotiation: Leverage your purchasing power by negotiating terms with suppliers. Many providers are willing to offer discounts or additional features for bulk purchases or long-term agreements.

-

Cost-Efficiency: Look for software that offers comprehensive features without hidden costs. Evaluate whether free options can meet your needs before considering premium solutions.

-

Total Cost of Ownership: Assess not just the upfront costs but also the long-term costs associated with using the software, including maintenance, support, and potential upgrades.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and import duties that may affect the total cost of acquiring software or related services. Additionally, consider local support availability when choosing a supplier.

Disclaimer

The pricing and cost components discussed are indicative and may vary based on specific circumstances, market conditions, and individual supplier agreements. Always conduct thorough research and consult with suppliers to obtain accurate pricing information tailored to your business needs.

Alternatives Analysis: Comparing stl file software free With Other Solutions

Exploring Alternatives to Free STL File Software

In the dynamic landscape of 3D printing and design, businesses often seek various tools to edit and repair STL files. While free STL file software provides essential functionalities for many users, there are alternative solutions that may better align with specific business needs. This analysis will compare free STL file software against two viable alternatives: professional CAD software and online 3D modeling platforms.

Comparison Table

| Comparison Aspect | Stl File Software Free | Professional CAD Software | Online 3D Modeling Platforms |

|---|---|---|---|

| Performance | Basic editing features; suitable for simple tasks | High precision and extensive features for complex designs | Good for quick edits; dependent on internet speed |

| Cost | Free | Subscription or one-time purchase; typically expensive | Usually free or freemium, depending on features |

| Ease of Implementation | User-friendly; quick setup | Steeper learning curve; requires training | Easy to use; no installation required |

| Maintenance | Low; community support available | Higher; requires regular updates and technical support | Low; platform-managed updates |

| Best Use Case | Basic repairs and modifications | Professional design and engineering tasks | Collaborative projects and rapid prototyping |

Detailed Breakdown of Alternatives

1. Professional CAD Software

Professional CAD software, such as AutoCAD or SolidWorks, offers advanced capabilities that far exceed those of free STL editors. These tools provide high precision, extensive libraries, and the ability to create complex models from scratch. However, they come with significant costs, often requiring a subscription or a hefty one-time purchase. The learning curve is steep, necessitating training for effective use, which can be a barrier for smaller businesses or those with limited resources. Still, for companies that prioritize high-quality designs and complex engineering tasks, investing in professional CAD software can yield substantial returns.

2. Online 3D Modeling Platforms

Online 3D modeling platforms like Tinkercad or SketchUp offer a user-friendly interface for users to create and edit STL files without the need for software installation. These platforms are particularly useful for collaborative projects, allowing multiple users to work on a model in real-time. They often come with free or freemium pricing structures, making them accessible to startups and smaller firms. However, their performance can be hindered by internet speed, and they may lack the advanced features necessary for more intricate designs. Nevertheless, they serve as excellent solutions for rapid prototyping and educational purposes.

Conclusion: How to Choose the Right Solution for Your Business

When evaluating the right solution for STL file management, B2B buyers should consider their specific needs, budget constraints, and the complexity of their projects. Free STL software is ideal for basic editing and is suitable for startups or businesses with limited resources. In contrast, professional CAD software is better suited for those requiring precision and advanced features, while online 3D modeling platforms offer flexibility and collaboration for dynamic teams. By assessing these factors, businesses can select the most appropriate tool to enhance their 3D printing capabilities and streamline their workflows.

Essential Technical Properties and Trade Terminology for stl file software free

What Are the Critical Technical Properties of Free STL File Software?

When selecting free STL file software, understanding the technical specifications is essential for B2B buyers. Here are some of the critical properties to consider:

1. File Compatibility

Free STL editors must support a range of file formats beyond just STL, including OBJ, AMF, and PLY. Compatibility ensures seamless integration with various CAD systems and 3D printing technologies. This is particularly important for businesses that utilize multiple software tools or collaborate with partners using different platforms.

2. Mesh Repair Capabilities

Many STL files downloaded from online repositories may contain errors or imperfections. Effective mesh repair functionality, such as automatic hole filling and error detection, is crucial. This capability reduces the time and cost associated with preparing files for 3D printing, allowing companies to streamline their production processes and avoid costly reprints.

3. Slicing Features

Some free STL software includes integrated slicing tools that convert 3D models into G-code for 3D printers. This feature is vital for users who want to bypass separate slicing software, saving time and simplifying workflows. Businesses that prioritize efficiency will benefit from software that minimizes the need for multiple applications.

4. User Interface and Usability

An intuitive user interface enhances productivity, especially for users with varying levels of technical expertise. Software that is easy to navigate can reduce training time and improve user adoption rates. For B2B buyers, selecting software with a user-friendly design can lead to quicker implementation and less downtime.

5. Performance and Speed

The software’s performance in handling large files or complex models is crucial. Fast processing speeds can significantly impact project timelines, especially in industries where time-to-market is critical. B2B buyers should assess software performance through user reviews or trial versions to ensure it meets their operational needs.

6. Support and Community Resources

Access to customer support and community forums is an important consideration. Robust support can help businesses troubleshoot issues and optimize their use of the software. Additionally, an active community can provide valuable resources, tutorials, and shared experiences that can enhance the user experience.

What Are Common Trade Terms Related to Free STL File Software?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of STL software, it can refer to software developed for specific 3D printers or machines. Knowing OEM relationships can help buyers understand compatibility and support options.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the realm of STL software, this could pertain to bundled software packages or support services. Understanding MOQ is essential for budgeting and ensuring that procurement aligns with production needs.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products or services. B2B buyers should utilize RFQs when seeking quotes for software licenses or services related to STL editing and repair, ensuring they receive competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including delivery and risk management. Familiarity with Incoterms is critical for B2B buyers when negotiating contracts for software licenses that may involve cross-border transactions.

5. API (Application Programming Interface)

An API allows different software applications to communicate with each other. For STL software, an API can enable integration with other tools, enhancing functionality. Understanding API capabilities can help businesses select software that fits into their existing tech ecosystem.

6. Version Control

Version control refers to the management of changes to documents, software, or other collections of information. In the context of STL files, effective version control systems help teams track edits and ensure that the correct file versions are used in production, reducing errors and improving collaboration.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting free STL file software, ultimately enhancing their operational efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the stl file software free Sector

What Are the Current Market Dynamics and Key Trends Influencing STL File Software?

The STL file software market is currently experiencing significant growth, driven by the increasing adoption of 3D printing technology across various industries. This trend is particularly prominent among international B2B buyers in regions such as Africa, South America, the Middle East, and Europe. The proliferation of affordable 3D printers and the rising demand for rapid prototyping are compelling businesses to seek efficient STL editing solutions. Emerging trends include the integration of cloud-based platforms that allow for collaborative editing and sharing of STL files, streamlining the design-to-production process.

Furthermore, the demand for user-friendly, open-source software is growing, as it reduces entry barriers for new players in the 3D printing space. Buyers are increasingly looking for software that not only meets their immediate needs but also offers scalability and versatility for future projects. As the market becomes more competitive, suppliers are enhancing their offerings with features such as advanced mesh repair tools and compatibility with various CAD systems. This focus on interoperability is critical for international buyers who require seamless integration with existing workflows.

How Are Sustainability and Ethical Sourcing Addressing Environmental Concerns in STL File Software?

Sustainability is becoming a crucial factor in the B2B purchasing decisions of STL file software. As companies strive to minimize their environmental footprint, there is a growing emphasis on ethical sourcing and the use of sustainable materials. For instance, software providers are increasingly promoting ‘green’ certifications and eco-friendly practices, which resonate with buyers committed to corporate social responsibility.

Moreover, the emphasis on digital solutions, such as STL file editing software, contributes to sustainability by reducing material waste associated with traditional manufacturing processes. Businesses are encouraged to adopt software that facilitates recycling and reusability of designs, ultimately leading to a more circular economy. B2B buyers can leverage this trend by selecting software solutions that align with their sustainability goals, ensuring that their sourcing decisions reflect their commitment to environmental stewardship.

What Is the Evolution and Historical Context of STL File Software in the B2B Space?

The STL file format, introduced in the 1980s by 3D Systems, was initially designed for stereolithography applications. Over the decades, it has evolved to become the de facto standard for 3D printing, transcending its original purpose to accommodate a wide array of industries, including manufacturing, healthcare, and architecture.

As 3D printing technology advanced, so too did the tools for creating and editing STL files. Early software was primarily focused on basic modeling tasks, but today’s offerings include sophisticated features such as error detection, mesh repair, and even AI-driven enhancements. This evolution reflects the growing complexity of 3D printing applications and the need for more robust solutions to support international B2B buyers in diverse markets. The historical context of STL software highlights the ongoing innovation and adaptability required to meet the demands of a rapidly changing industry.

Frequently Asked Questions (FAQs) for B2B Buyers of stl file software free

-

1. How do I solve issues with my STL files before 3D printing?

To solve issues with your STL files, you can utilize free STL editing software such as Blender, FreeCAD, or MeshLab. These tools allow you to repair common problems like non-manifold edges, holes, or intersecting geometries. Start by importing your STL file into the software, use the repair or analysis features to identify issues, and then make necessary adjustments. Always check the final model using a slicer to ensure it is ready for 3D printing. -

2. What is the best free STL file editor for beginners?

For beginners, MeshMixer is highly recommended due to its user-friendly interface and intuitive features. It allows users to easily resize, repair, and modify STL files without a steep learning curve. Additionally, it offers built-in tutorials and a community forum for troubleshooting. Blender is another option, but it may require more time to learn due to its extensive features. -

3. How can I evaluate the quality of free STL editing software?

When evaluating free STL editing software, consider factors such as user reviews, the software’s update frequency, and community support. Look for tools that have strong documentation and tutorials to assist you in learning. Additionally, assess the software’s compatibility with your existing systems and its ability to handle complex models. Testing the software with a sample project can also provide insights into its performance and usability. -

4. Are there any customization options available with free STL software?

Most free STL editing software allows for a degree of customization in terms of tools and features. For instance, software like Blender offers extensive scripting capabilities and user-created plugins to enhance functionality. However, the level of customization varies, so it’s essential to review the specific software documentation or community forums to explore what modifications can be made to suit your needs. -

5. What are the common payment terms for B2B software purchases?

In B2B transactions, common payment terms often include net 30, net 60, or upfront payments depending on the supplier’s policy. Always clarify terms such as payment methods (credit card, bank transfer, etc.) and any applicable discounts for early payment. Ensure that the terms are documented in a contract to avoid misunderstandings and negotiate favorable conditions if possible. -

6. How can I vet suppliers of STL file software in international markets?

To vet suppliers of STL file software, start by checking their reputation through online reviews and industry forums. Look for verified certifications or partnerships with recognized organizations. Conduct interviews to assess their customer service responsiveness and technical support capabilities. Additionally, request demos or trial periods to evaluate the software’s performance before committing to a purchase. -

7. What logistics should I consider when sourcing STL software internationally?

When sourcing STL software internationally, consider aspects like software delivery methods (download vs. physical media), support time zones, and data privacy regulations in your region. Ensure that the software complies with local laws and standards. It’s also wise to inquire about post-purchase support, such as updates and troubleshooting assistance, to ensure a smooth integration into your workflow. -

8. What are the minimum order quantities (MOQ) for STL software licenses?

Minimum order quantities for STL software licenses can vary significantly by supplier. Some offer individual licenses with no MOQ, while others may have bulk pricing models that require a minimum number of licenses for discounted rates. Always clarify these terms upfront and consider your organization’s needs to negotiate favorable terms, especially if you plan to scale up in the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Stl File Software Free Manufacturers & Suppliers List

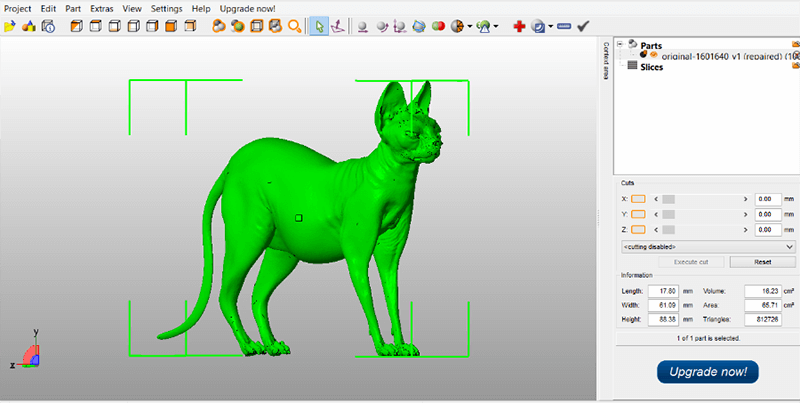

1. Reddit – Key 3D Modeling Software

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. **Blender**: Free software with a steep learning curve; best for organic models. Recommended tutorials available on BlenderGuru on YouTube.

2. **Fusion 360**: Free for non-commercial use; offers a personal license for purchase.

3. **OpenSCAD**: Good for CAD work; allows mathematical description of models.

4. **FreeCAD**: Has an OpenSCAD interface; suitable for functional prints.

5. **Onshape**:…

2. Sculpteo – Top 7 Free STL Editors

Domain: sculpteo.com

Registered: 2009 (16 years)

Introduction: The text discusses the top 7 free STL editors for editing and repairing STL files, which are essential for 3D printing. It mentions the importance of having a 3D file and the need for editing or repairing it to meet specific requirements. The editors highlighted include: 1. FreeCAD – A free and open-source CAD software suitable for beginners to professionals, primarily used for mechanical objects….

3. Phrozen3D – Top 10 Free STL Editors of 2024

Domain: phrozen3d.com

Registered: 2017 (8 years)

Introduction: Top 10 Free STL Editors of 2024: Best Tools to Edit and Repair STL Files. These tools are suitable for both beginners and professionals, offering powerful features for 3D printing projects. STL files, which stand for STereoLithography, are the standard format used in 3D printing, describing the surface geometry of 3D objects using a mesh of interconnected triangles. Free STL editors are essential …

4. MeshInspector – STL Editor

Domain: meshinspector.com

Registered: 2021 (4 years)

Introduction: MeshInspector’s STL Editor allows users to edit .stl files online, providing a comprehensive toolkit for modifying and optimizing STL files for 3D printing and modeling. Key features include: 1. Decimation: Streamlines 3D models without quality loss, reducing structured elements for quicker processing and manageable file sizes. 2. Remesh: Ensures consistency and quality by uniformly distributing p…

5. All3DP – Free STL Editors

Domain: all3dp.com

Registered: 2013 (12 years)

Introduction: This article discusses free STL editors for editing and repairing STL files, highlighting tools ranging from basic options like Tinkercad to more advanced software like Blender. It was published on March 19, 2024, by Guilherme Schendel and Frederik Bedrich.

6. Printing Atoms – Best Free STL Editors in 2024

Domain: printingatoms.com

Registered: 2018 (7 years)

Introduction: Best Free STL Editors in 2024:

1. MeshMixer: Developed by Autodesk, offers extensive mesh editing tools, overhang analysis, support generation, and sculpting features. Although development has ceased, it remains a powerful tool for editing STL files.

2. Blender: A comprehensive design program with thousands of tools for 3D modeling, image editing, and animation. It includes unique mesh editing too…

Strategic Sourcing Conclusion and Outlook for stl file software free

In the rapidly evolving landscape of 3D printing, selecting the right free STL file software is crucial for international B2B buyers looking to enhance their manufacturing capabilities. By leveraging powerful tools like FreeCAD, Blender, and MeshLab, businesses can efficiently edit, repair, and optimize STL files, ensuring that their 3D models meet specific requirements without incurring significant costs. This strategic sourcing of software not only streamlines the design process but also mitigates risks associated with faulty or incompatible files.

For companies in regions such as Africa, South America, the Middle East, and Europe, investing in robust STL editing solutions can unlock new avenues for innovation and competitiveness. With the ability to customize designs and rectify issues in real-time, organizations can significantly reduce lead times and improve product quality.

As you evaluate your sourcing strategies, consider the long-term benefits of integrating free STL file software into your workflow. Embrace this opportunity to enhance your 3D printing projects and position your business at the forefront of the industry. Start exploring these tools today and take the next step toward achieving operational excellence in your 3D printing endeavors.