Introduction: Navigating the Global Market for stl file cnc router

In today’s rapidly evolving manufacturing landscape, sourcing high-quality STL files for CNC routers is crucial for businesses aiming to enhance productivity and innovation. With the increasing demand for precision and customization in various industries, international B2B buyers face the challenge of identifying reliable suppliers who can provide optimized digital designs tailored to their specific needs. This guide serves as a comprehensive resource for navigating the global market for STL file CNC routers, addressing key considerations such as file types, applications across different sectors, and effective supplier vetting strategies.

Throughout this guide, we will delve into the diverse applications of STL files, from intricate decorative elements to functional components across woodworking, metalworking, and prototyping. We will also explore cost factors and provide insights into the best practices for evaluating potential suppliers, ensuring that buyers can make informed decisions that align with their operational goals.

Designed specifically for B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Vietnam and Nigeria—this guide empowers you to streamline your purchasing process. By equipping you with actionable insights and the latest trends, we aim to enhance your competitive edge in the global market for CNC routing solutions.

Understanding stl file cnc router Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Decorative Models | High detail, often artistic, suitable for visual projects | Signage, interior decor, awards | Pros: Enhances aesthetic appeal; Cons: May require post-processing. |

| Functional Parts | Designed for specific mechanical functions | Prototyping, custom machinery parts | Pros: Tailored for specific applications; Cons: May have higher costs. |

| Architectural Models | Scaled representations of buildings or landscapes | Real estate, urban planning | Pros: Aids in visualizing projects; Cons: Limited to specific use cases. |

| Prototyping Models | Quick to produce, focuses on design validation | Product development, testing | Pros: Speeds up development cycles; Cons: Often not suitable for final products. |

| Educational Models | Simplified designs for teaching and learning purposes | Schools, training facilities | Pros: Engaging for learners; Cons: May lack real-world application. |

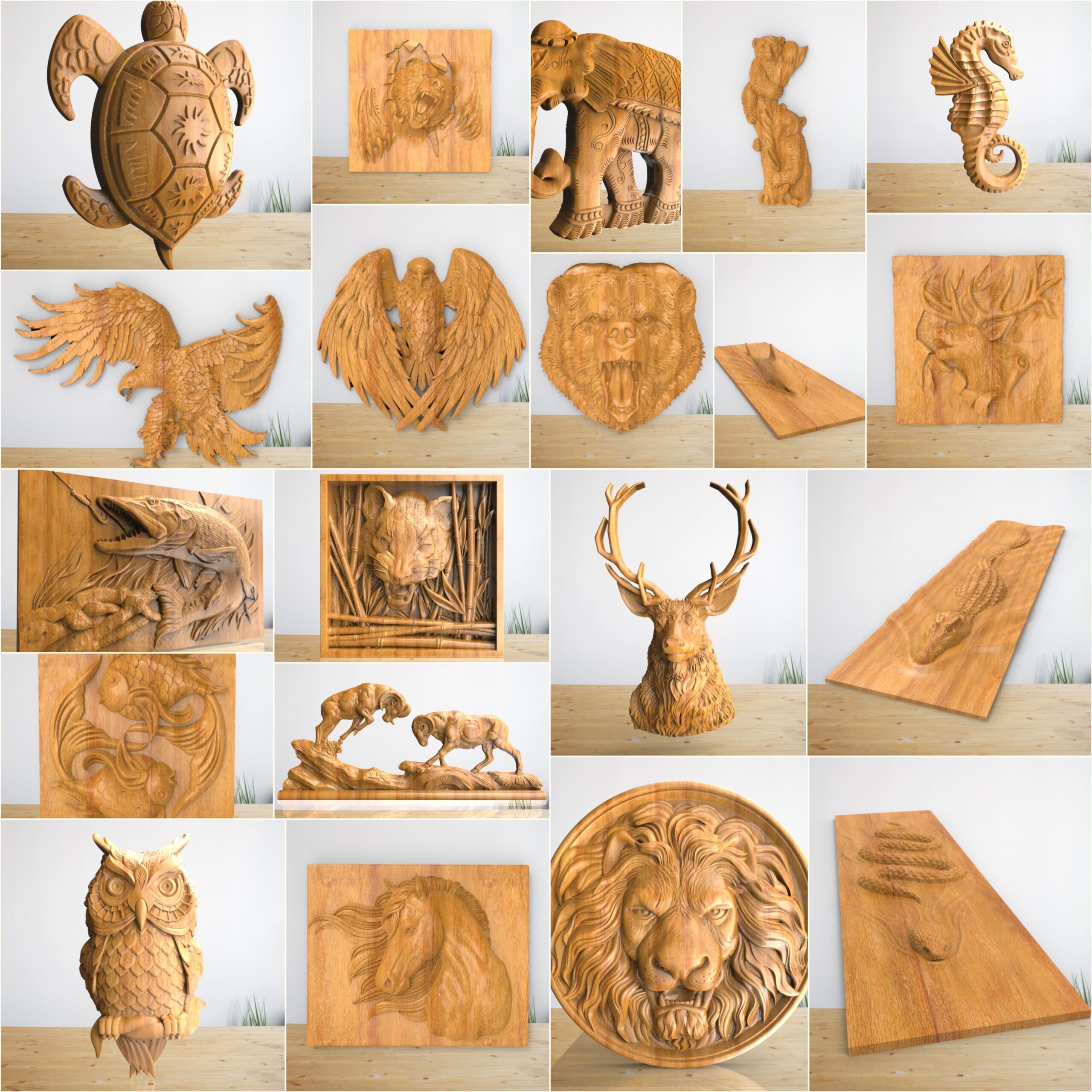

What Are Decorative Models and Their B2B Applications?

Decorative models are characterized by their intricate designs and high level of detail, making them ideal for visual projects such as signage, awards, and interior decor. B2B buyers in sectors like hospitality, retail, and corporate branding often seek these models to enhance aesthetic appeal. While they can significantly elevate a brand’s image, buyers should consider the potential need for post-processing to achieve the desired finish.

How Do Functional Parts Serve B2B Needs?

Functional parts are specifically engineered for mechanical applications, ensuring compatibility with various machinery and devices. Industries such as manufacturing and engineering frequently utilize these STL files for prototyping and custom machinery. Although tailored for specific functions can justify higher costs, the precision and performance offered make them a valuable investment for businesses looking to optimize their operations.

Why Are Architectural Models Important for B2B Buyers?

Architectural models serve as scaled representations of buildings or landscapes, providing valuable visualization tools for real estate and urban planning projects. These models help stakeholders understand spatial relationships and design concepts, making them essential for architects, developers, and city planners. However, their use may be limited to specific projects, so buyers should assess their long-term applicability before purchase.

What Role Do Prototyping Models Play in Product Development?

Prototyping models are designed for rapid production, focusing on validating designs before full-scale manufacturing. They are crucial in product development and testing, allowing businesses to refine concepts efficiently. While they significantly speed up development cycles, it’s important for buyers to note that these models may not be suitable for final products due to material limitations or durability concerns.

How Are Educational Models Utilized in B2B Settings?

Educational models are simplified designs intended for teaching and learning, making them particularly useful in schools and training facilities. These models engage learners and facilitate understanding of complex concepts, making them valuable tools in educational environments. However, businesses should consider that these models may lack practical applications in real-world scenarios, which could limit their usefulness in certain B2B contexts.

Key Industrial Applications of stl file cnc router

| Industry/Sector | Specific Application of STL File CNC Router | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Custom furniture design and prototyping | Enables rapid prototyping, reducing time to market | Look for STL files that are optimized for CNC machining. |

| Automotive Parts | Production of intricate automotive components | High precision and reduced waste in material usage | Ensure files are compatible with specific CNC machines. |

| Aerospace Engineering | Creation of lightweight structural components | Enhances fuel efficiency through weight reduction | Focus on suppliers with aerospace-grade STL file standards. |

| Art and Decor | Crafting decorative items and art installations | Unique designs can enhance brand differentiation | Seek files that allow for customization and scalability. |

| Electronics Enclosure | Production of enclosures and mounts for devices | Improves product aesthetics and functionality | Verify compatibility with electronic components and designs. |

How is the STL File CNC Router Used in Furniture Manufacturing?

In the furniture manufacturing industry, STL file CNC routers are utilized to create custom furniture pieces and prototypes. This application allows businesses to quickly produce intricate designs, thus significantly reducing the time needed for traditional manufacturing methods. By using STL files optimized for CNC machining, manufacturers can ensure high precision and a better fit for their products. International buyers should prioritize sourcing files that are easy to manipulate and adapt, ensuring they meet local market needs and preferences.

What Role Does the STL File CNC Router Play in Automotive Parts Production?

The automotive industry relies heavily on STL file CNC routers for producing complex automotive components. These routers enable manufacturers to create parts with high precision, which is crucial for vehicle safety and performance. By minimizing material waste during production, businesses can achieve significant cost savings. Buyers from regions like Africa and South America should consider sourcing STL files that comply with regional automotive standards to ensure compatibility and regulatory compliance.

How is Aerospace Engineering Enhanced by STL File CNC Routers?

In aerospace engineering, STL file CNC routers are essential for crafting lightweight structural components that are critical for aircraft performance. The precision offered by CNC routers helps in achieving the complex geometries required in aerospace applications, contributing to improved fuel efficiency. B2B buyers in this sector should focus on suppliers that provide STL files meeting stringent aerospace standards, ensuring that the final products are both safe and efficient.

How Do STL File CNC Routers Benefit the Art and Decor Industry?

The art and decor sector utilizes STL file CNC routers for crafting unique decorative items and installations. This technology allows artists and designers to bring their creative visions to life with precision and efficiency. By offering customization options, businesses can differentiate their products in a competitive market. Buyers should seek STL files that allow for artistic flexibility while ensuring they are compatible with various CNC machines used in the industry.

What Advantages Do STL File CNC Routers Provide in Electronics Enclosure Production?

STL file CNC routers are widely used for producing enclosures and mounts for electronic devices, enhancing both functionality and aesthetics. This application allows manufacturers to create tailored solutions that meet specific product requirements. Buyers, especially in emerging markets, should focus on sourcing STL files that are designed for easy integration with various electronic components, ensuring that they can effectively support their product lines.

3 Common User Pain Points for ‘stl file cnc router’ & Their Solutions

Scenario 1: Navigating Compatibility Issues with STL Files

The Problem: B2B buyers often encounter compatibility issues when sourcing STL files for CNC routers. Different CNC machines may support various file formats, and a lack of standardization can lead to frustration. For instance, a manufacturer in Nigeria may purchase STL files that are perfectly designed but not compatible with their specific CNC software. This can result in wasted time, additional costs for file conversion, and delays in production, ultimately affecting the bottom line.

The Solution: To mitigate compatibility issues, buyers should prioritize sourcing STL files from reputable platforms that explicitly state compatibility with a range of CNC software. Before purchasing, it’s crucial to verify that the files are optimized for the specific CNC router being used. Buyers can also consult the machine’s user manual or reach out to the manufacturer for guidance on supported file types. Additionally, utilizing file conversion software can be beneficial. Tools like Autodesk Fusion 360 or MeshLab can convert STL files to other formats like DXF or OBJ, ensuring that they can be easily integrated into existing workflows. Regularly updating CNC software can also enhance compatibility and streamline operations.

Scenario 2: Overcoming Quality Concerns in STL Files

The Problem: Quality control is a significant concern for businesses that rely on STL files for CNC machining. Many buyers, especially in regions like South America and Africa, face challenges in finding high-quality, professionally designed STL files. Poor-quality files can lead to subpar machining results, including inaccurate dimensions and rough finishes, which can compromise product integrity and customer satisfaction.

The Solution: To ensure high-quality STL files, buyers should source their designs from established marketplaces that offer a community of designers with proven track records. Platforms such as 3DWave and Cults3D provide user reviews and ratings, allowing buyers to gauge the quality of files before purchasing. It’s also advisable to look for files that come with detailed descriptions and specifications, including information on the design’s scalability and intended material. For critical applications, conducting a test run with a sample file can help assess quality before committing to larger production runs. Additionally, investing in a quality control process that includes checking STL files for errors using software like Netfabb can prevent downstream issues.

Scenario 3: Addressing Cost Concerns with STL Files for CNC Routers

The Problem: Cost sensitivity is a prevalent issue among B2B buyers, particularly in emerging markets. Many businesses are hesitant to invest in premium STL files, fearing that the initial outlay may not yield a corresponding return on investment. This concern can lead to purchasing lower-quality files or relying on free resources that may not meet production standards, ultimately affecting efficiency and profitability.

The Solution: To address cost concerns, buyers should conduct a thorough cost-benefit analysis before purchasing STL files. It’s essential to consider not just the purchase price but also the potential savings from reduced waste and improved machining efficiency. Buyers should explore subscription models or bulk purchase options offered by some platforms, which can significantly reduce costs per file. Additionally, collaborating with local designers to create custom STL files can be a cost-effective solution, ensuring that designs meet specific business needs without the premium price tag associated with popular designs. Establishing long-term partnerships with trusted STL file suppliers can also lead to negotiated discounts and access to exclusive designs, fostering both cost savings and quality assurance.

Strategic Material Selection Guide for stl file cnc router

When selecting materials for STL files used in CNC routers, it is essential to consider the specific properties and applications of each material. This analysis focuses on four common materials: wood, plastics (particularly acrylic and PVC), metals (aluminum), and composites. Each material has unique characteristics that can significantly impact the performance of the final product.

What Are the Key Properties of Wood for CNC Routing?

Wood is a traditional material widely used in CNC routing due to its availability and versatility. It has favorable properties such as a low density, which allows for easier machining and a natural aesthetic appeal. However, wood can be sensitive to moisture, leading to warping or swelling, which can affect the precision of CNC operations.

Pros: Wood is generally cost-effective and easy to work with, making it suitable for various applications, including furniture and decorative items. Its natural finish often requires minimal post-processing.

Cons: The main limitations of wood include its susceptibility to environmental changes and potential inconsistencies in grain and density, which can affect machining precision.

Impact on Application: Wood is compatible with a range of finishes and adhesives, making it suitable for both indoor and outdoor applications. However, its performance may be compromised in high-humidity environments.

How Do Plastics Like Acrylic and PVC Perform in CNC Routing?

Plastics such as acrylic and PVC are popular choices for CNC routing due to their lightweight nature and excellent machinability. Acrylic, for instance, offers high clarity and UV resistance, making it ideal for applications requiring transparency, such as signage and displays.

Pros: These materials are durable, resistant to chemicals, and can be easily colored or finished. They also provide a smooth surface finish, enhancing the aesthetic appeal of the final product.

Cons: Plastics can be more expensive than wood and may require specialized tooling to avoid melting during machining. Additionally, they may not be suitable for high-temperature applications.

Impact on Application: Acrylic and PVC are widely used in various industries, including advertising, construction, and automotive. However, B2B buyers should ensure compliance with local regulations regarding plastic use and recycling.

What Are the Benefits of Using Aluminum in CNC Routing?

Aluminum is a lightweight metal that offers excellent strength and corrosion resistance, making it a preferred choice for many industrial applications. Its thermal conductivity and machinability make it suitable for precision components.

Pros: Aluminum is highly durable and can withstand harsh environments. It is also recyclable, aligning with sustainability goals.

Cons: The cost of aluminum can be significantly higher than that of wood or plastics, and it may require specialized equipment for effective machining.

Impact on Application: Aluminum is often used in aerospace, automotive, and electronics sectors. International buyers should consider compliance with standards such as ASTM for material specifications.

How Do Composites Enhance CNC Routing Applications?

Composite materials, which combine two or more materials to achieve superior properties, are increasingly used in CNC routing. These materials can include fiberglass and carbon fiber composites, known for their high strength-to-weight ratios.

Pros: Composites can be tailored for specific applications, offering excellent durability and resistance to environmental factors. They are also lightweight, making them ideal for applications where weight is a concern.

Cons: The complexity of manufacturing composites can lead to higher costs and longer lead times. Additionally, they may require specialized machining techniques.

Impact on Application: Composites are commonly used in high-performance applications, such as aerospace and automotive components. Buyers should be aware of the specific standards for composite materials in their regions.

Summary Table of Material Selection for STL File CNC Routers

| Material | Typical Use Case for stl file cnc router | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Furniture, decorative items | Cost-effective, easy to work with | Sensitive to moisture, warping | Low |

| Plastics (Acrylic/PVC) | Signage, displays | Durable, smooth finish | Higher cost, requires specialized tooling | Med |

| Aluminum | Precision components | Lightweight, corrosion-resistant | Higher cost, requires specialized equipment | High |

| Composites | Aerospace, automotive parts | Tailored properties, lightweight | Higher manufacturing complexity | High |

This strategic material selection guide provides valuable insights for B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, ensuring they make informed decisions based on material properties, application suitability, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for stl file cnc router

What Are the Key Stages in the Manufacturing Process of STL Files for CNC Routers?

The manufacturing process of STL files for CNC routers involves several critical stages that ensure the final product meets both functional and aesthetic standards. Here’s a breakdown of the main stages:

1. Material Preparation

Before any design can be translated into a physical product, selecting the appropriate material is paramount. Common materials for CNC machining include wood, plastic, and metal. Each material requires specific considerations regarding its properties, such as density, hardness, and machinability. Additionally, suppliers must ensure that the materials are sourced from reputable vendors to guarantee quality.

2. Forming

Once the material is prepared, the next step involves forming the STL design into a machine-readable format. This stage often includes using CAD (Computer-Aided Design) software to create and optimize the 3D models. The STL file format is widely used because it effectively represents the surface geometry of a 3D object. The model is broken down into triangular facets, enabling precise machining.

3. Assembly

For more complex designs, multiple components may need to be assembled after machining. Assembly might involve fastening, welding, or other joining techniques, depending on the materials used. During this phase, it is essential to maintain alignment and dimensional accuracy to ensure the final product functions as intended.

4. Finishing

The finishing stage is crucial for enhancing the aesthetic and functional properties of the product. Techniques such as sanding, painting, or coating can be employed to improve surface quality and durability. This stage also includes quality checks to ensure that the product meets design specifications.

How is Quality Assurance Implemented in the Manufacturing of STL Files for CNC Routers?

Quality assurance (QA) is integral to the manufacturing process, especially when catering to international markets. Implementing robust QA measures ensures that products meet industry standards and buyer expectations.

Relevant International Standards for Quality Assurance

B2B buyers should be aware of various international standards that govern quality assurance in manufacturing:

-

ISO 9001: This standard outlines the requirements for a quality management system, focusing on customer satisfaction and continuous improvement. Adherence to ISO 9001 can significantly enhance a supplier’s credibility.

-

CE Marking: Particularly relevant for products sold within the European Economic Area (EEA), CE marking indicates that a product complies with EU safety, health, and environmental protection standards.

-

API Standards: For industries related to oil and gas, API (American Petroleum Institute) standards ensure that products meet specific performance and safety criteria.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically segmented into various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves checking the quality of raw materials upon receipt. This initial checkpoint is critical to ensuring that only high-quality materials enter the production line.

-

In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring is essential to catch any deviations from quality standards. This may involve visual inspections, dimensional checks, and functional testing.

-

Final Quality Control (FQC): At the end of the production line, final inspections ensure that the finished product meets all specifications and standards before shipping. This often includes performance testing and compliance verification.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers is vital for maintaining product integrity. Here are several methods to ensure that suppliers adhere to quality standards:

Conducting Supplier Audits

Regular audits can provide insight into a supplier’s quality management practices. These audits can be conducted by the buying company or third-party agencies to ensure objectivity. Key areas to assess during audits include manufacturing processes, quality control protocols, and adherence to international standards.

Requesting Quality Reports

Buyers should request detailed quality reports that outline the results of IQC, IPQC, and FQC processes. These reports should include statistical data, trends, and any corrective actions taken for non-conformance issues.

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can add an extra layer of assurance. These independent entities can verify that the products meet specified requirements before shipment, helping to mitigate risks associated with product quality.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating the landscape of quality control can be particularly complex for international buyers, especially in regions such as Africa, South America, the Middle East, and Europe. Here are some nuances to consider:

Understanding Regional Compliance Requirements

Different countries may have specific regulations and compliance requirements. For example, products sold in the EU must meet CE marking requirements, while those in the U.S. may need to comply with ANSI standards. Buyers should be well-informed about these regional standards to ensure compliance.

Language and Cultural Barriers

Language differences and cultural practices can impact communication regarding quality expectations. Clear documentation and effective communication strategies are essential to bridge these gaps and avoid misunderstandings.

Building Long-term Relationships

Establishing strong relationships with suppliers can facilitate better quality control. Frequent communication, feedback, and collaboration can help suppliers align their processes with the buyer’s quality expectations.

Conclusion

For B2B buyers involved in sourcing STL files for CNC routers, understanding the manufacturing processes and quality assurance protocols is crucial. By focusing on material preparation, forming, assembly, and finishing, along with robust quality control measures, buyers can ensure that they receive high-quality products that meet international standards. Engaging in thorough supplier verification processes can further enhance confidence in product quality, enabling successful partnerships across global markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stl file cnc router’

In the competitive landscape of CNC machining, sourcing high-quality STL files is essential for enhancing productivity and maintaining precision. This guide provides a structured approach for international B2B buyers interested in procuring STL files for CNC routers, ensuring you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Before beginning your search for STL files, clarify your project requirements. Identify the type of materials you will be working with, the complexity of designs needed, and the intended applications (e.g., decorative, functional). This step is crucial as it sets the foundation for evaluating the compatibility of STL files with your CNC machinery.

- Materials: Specify whether you will be machining wood, metal, or plastic.

- Complexity: Determine if you need simple shapes or intricate designs.

Step 2: Research Reputable Suppliers

Finding reliable suppliers is critical to ensure the quality of STL files. Look for platforms that specialize in CNC models, such as Cults3D or 3DWave, and assess their reputation through customer reviews and ratings. Engaging with established suppliers minimizes risks associated with quality and service delivery.

- Customer Feedback: Pay attention to ratings and testimonials.

- Industry Experience: Prefer suppliers with a proven track record in your specific industry.

Step 3: Evaluate File Quality and Compatibility

Assess the quality of STL files offered by potential suppliers. High-quality files should be optimized for CNC machining, featuring clear details and proper scaling. Also, ensure that the files are compatible with your existing CAD and CNC software to avoid workflow disruptions.

- File Formats: Confirm that the files are in STL format and compatible with your machinery.

- Detail and Precision: Request samples or review high-resolution images of the files.

Step 4: Verify Licensing and Usage Rights

Before purchasing STL files, understand the licensing agreements associated with them. Ensure that the files are available for both personal and commercial use, especially if you plan to resell or modify the designs. This step is vital to avoid legal complications in your business operations.

- Usage Restrictions: Clarify any limitations on file distribution or modification.

- Commercial Licensing: Ensure you have the rights for commercial applications.

Step 5: Request Customization Options

If your projects require specific modifications, inquire about customization options. Many suppliers offer tailored services that can adjust existing models to better fit your needs. Customization can enhance the functionality of the designs and align them more closely with your business objectives.

- Design Adaptability: Ask if the supplier can modify dimensions or features.

- Turnaround Time: Understand how long custom modifications will take.

Step 6: Evaluate Pricing and Payment Terms

Review the pricing structure of STL files and ensure it aligns with your budget. Compare prices across different suppliers while considering the quality of the files. Additionally, clarify payment terms to avoid any surprises during the transaction process.

- Bulk Discounts: Inquire about pricing for larger orders.

- Payment Flexibility: Understand accepted payment methods and conditions.

Step 7: Establish Communication Channels

Maintain open lines of communication with your chosen supplier. Clear communication can facilitate smoother transactions and allow for quick resolution of any issues that may arise. Establishing a good rapport with suppliers can also lead to better support and future collaborations.

- Contact Information: Ensure you have direct access to a representative.

- Response Times: Gauge how quickly the supplier responds to inquiries.

By following this checklist, B2B buyers can streamline the procurement process for STL files, ensuring they acquire high-quality resources that enhance their CNC machining capabilities.

Comprehensive Cost and Pricing Analysis for stl file cnc router Sourcing

What Are the Key Cost Components in STL File CNC Router Sourcing?

When sourcing STL files for CNC routers, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: While STL files themselves are digital and do not have a material cost, the final product’s material choice will significantly influence overall costs. For instance, wood, metal, or composite materials can vary widely in price.

-

Labor: Labor costs encompass both the design and production processes. If customization is required, skilled labor may be necessary, increasing overall expenses.

-

Manufacturing Overhead: This includes costs associated with operating CNC machines, software licenses, and other necessary tools for production. A higher overhead often correlates with better quality and precision.

-

Tooling: The need for specific tooling or modifications can add to costs. Advanced designs may require specialized tools, which can be costly to acquire and maintain.

-

Quality Control (QC): Implementing robust QC processes ensures that the STL files are compatible and meet the necessary specifications. This may involve testing and validation, which can contribute to overall costs.

-

Logistics: Although STL files are digital, considerations for software delivery and technical support may add logistical costs. International buyers should also factor in any potential tariffs or import duties if physical products are involved.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on their operational efficiencies and market demand.

How Do Price Influencers Impact STL File Pricing for CNC Routers?

Several factors can influence the pricing of STL files for CNC routers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often benefit from economies of scale, reducing the cost per unit. Suppliers may provide discounts for bulk purchases, making it essential to evaluate projected needs.

-

Specifications and Customization: Custom designs can significantly increase costs due to the additional labor and time required for development. Buyers should clearly define their requirements to avoid unexpected costs.

-

Materials and Quality Certifications: Higher quality materials or specialized certifications can lead to increased costs. Buyers should weigh the importance of certifications against their budget to ensure they receive value without overspending.

-

Supplier Factors: The reputation and reliability of the supplier play a crucial role in pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding shipping terms can help buyers manage costs effectively. Different Incoterms can affect who is responsible for shipping costs, insurance, and import duties, which can impact the total cost of ownership.

What Tips Can Help Buyers Optimize Costs in STL File CNC Router Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following tips can aid in negotiating better prices and enhancing cost efficiency:

-

Negotiate Terms: Don’t hesitate to negotiate pricing, especially for larger orders. Suppliers may offer better rates or additional services if they see a potential for long-term business.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial cost of STL files but also the long-term costs associated with production, maintenance, and potential waste. This holistic view can help in making informed purchasing decisions.

-

Stay Informed About Pricing Nuances: Be aware of market trends, seasonal demands, and geopolitical factors that may affect pricing. Knowledge of the local market can provide leverage during negotiations.

-

Explore Local Suppliers: When possible, sourcing from local suppliers can reduce shipping costs and lead times. This is particularly relevant for buyers in regions with developing manufacturing sectors.

-

Assess Quality vs. Cost: While it may be tempting to opt for the cheapest option, ensure that quality is not compromised. Low-quality STL files can lead to production issues, ultimately costing more in the long run.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific requirements. Buyers should conduct thorough research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing stl file cnc router With Other Solutions

Understanding Alternative Solutions to STL File CNC Routers

As industries increasingly adopt advanced manufacturing technologies, it’s essential for B2B buyers to evaluate various solutions that meet their specific needs. This analysis compares the STL file CNC router with alternative technologies, helping businesses make informed decisions based on performance, cost, implementation ease, and maintenance requirements.

Comparison Table

| Comparison Aspect | STL File CNC Router | 3D Printer (FDM/SLA) | Laser Cutter |

|---|---|---|---|

| Performance | High precision for 3D models; excellent for intricate designs | Good for prototypes; limited detail compared to CNC | High speed; excellent for flat materials |

| Cost | Moderate initial investment; file costs vary | Lower initial costs; ongoing material costs | Higher initial investment; maintenance can be costly |

| Ease of Implementation | Requires CAD proficiency; setup can be complex | User-friendly; less technical knowledge needed | Requires training; setup is straightforward |

| Maintenance | Regular calibration needed; potential software updates | Minimal; occasional nozzle cleaning | Regular lens cleaning; maintenance needed for moving parts |

| Best Use Case | Detailed carvings and 3D objects; woodworking and metalwork | Prototyping and low-volume production | Cutting and engraving materials like wood, acrylic, and metal |

Detailed Breakdown of Alternatives

3D Printer (FDM/SLA)

3D printing technologies such as Fused Deposition Modeling (FDM) and Stereolithography (SLA) have gained traction for rapid prototyping and product development. The primary advantage of 3D printing is its accessibility; users can produce complex geometries without extensive technical knowledge. However, while the initial investment is lower, the ongoing costs for materials can add up, especially for high-quality filaments or resins. Additionally, the precision of 3D prints may not match that of CNC routers, particularly for applications requiring fine detail.

Laser Cutter

Laser cutting technology is recognized for its speed and efficiency, particularly when working with flat materials. It excels in engraving and cutting intricate designs with high precision. The setup process is generally straightforward, making it easier for operators with minimal technical experience. However, the initial investment can be higher compared to CNC routers, and ongoing maintenance can be costly, particularly for the laser components. Laser cutters are best suited for applications that involve engraving or cutting rather than producing three-dimensional objects.

Conclusion: How to Choose the Right Solution for Your Business

Selecting the appropriate technology for your manufacturing needs requires a clear understanding of your specific requirements. If your focus is on producing intricate 3D designs with high precision, an STL file CNC router may be the ideal choice. Conversely, if you need to create prototypes quickly and cost-effectively, consider a 3D printer. For projects centered around cutting and engraving flat materials, a laser cutter might be the most efficient option. Carefully assess each alternative’s strengths and limitations in relation to your operational goals to ensure a strategic investment that aligns with your business objectives.

Essential Technical Properties and Trade Terminology for stl file cnc router

What Are the Key Technical Properties of STL Files for CNC Routers?

When sourcing STL files for CNC routers, understanding the technical specifications is crucial for ensuring compatibility and performance. Here are some essential properties to consider:

-

File Format Compatibility: STL (Stereolithography) is the most commonly used file format for 3D printing and CNC routing. It represents the surface geometry of a 3D object without any color or texture. For B2B buyers, ensuring that STL files are compatible with their specific CNC software and machines is essential to avoid costly errors during the production process.

-

Resolution and Detail: The resolution of an STL file determines how accurately it represents the model. Higher resolution files contain more triangles, resulting in finer details but larger file sizes. For businesses, balancing file size and detail is important to maintain machining efficiency while achieving desired product quality.

-

Scaling and Tolerance: STL files should be designed with appropriate scaling to match the specifications of the CNC machine. Tolerance refers to the permissible limit of variation in a physical dimension. In B2B contexts, precise scaling and tolerances are critical to ensure that components fit together correctly, minimizing waste and rework.

-

Polygon Count: This refers to the number of polygons used to represent the 3D model. A higher polygon count can improve detail but may slow down processing time. Buyers should consider the capabilities of their CNC routers; high-performance machines can handle complex models, while entry-level models may require simpler designs.

-

Surface Normals Orientation: Proper orientation of surface normals is vital for accurate machining. Normals define which way the surface faces and influence how the CNC router interprets the file. Incorrect normals can lead to machining errors. Understanding this aspect helps buyers ensure that the STL files will produce the intended results.

-

Material Specifications: While STL files do not specify materials, understanding the material properties required for the final product is essential. This includes factors like strength, flexibility, and compatibility with machining processes. Buyers must communicate material requirements to their suppliers to ensure that the final output meets their standards.

What Are Common Trade Terms Related to STL Files for CNC Routers?

Navigating the B2B landscape involves familiarizing oneself with industry jargon. Here are some common terms that are particularly relevant to STL files and CNC routing:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of STL files, buyers may seek OEM partners who can provide custom designs tailored to specific machine requirements.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to ensure they can meet production needs without overcommitting resources.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For buyers interested in STL files, an RFQ can help identify potential suppliers and understand pricing structures.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers to understand shipping responsibilities, costs, and risks associated with acquiring STL files and related services.

-

CAD (Computer-Aided Design): CAD refers to the use of software to create precision drawings or technical illustrations. Many STL files are derived from CAD models, and understanding CAD can help buyers communicate their design needs more effectively.

-

CNC (Computer Numerical Control): CNC refers to the automated control of machining tools via computer programming. Understanding CNC processes is vital for buyers to ensure that STL files are optimized for specific machining operations.

In summary, grasping both the technical properties and trade terminology related to STL files for CNC routers equips B2B buyers with the knowledge needed to make informed purchasing decisions. This understanding can lead to improved efficiency, cost-effectiveness, and successful project outcomes.

Navigating Market Dynamics and Sourcing Trends in the stl file cnc router Sector

What Are the Current Market Dynamics and Key Trends in the STL File CNC Router Sector?

The global market for STL file CNC routers is witnessing robust growth, driven by technological advancements and an increasing demand for customization in manufacturing. Industries such as woodworking, metalworking, and prototyping are leveraging CNC routers for their precision and efficiency. As B2B buyers from regions like Africa, South America, the Middle East, and Europe seek to enhance their production capabilities, they are increasingly adopting STL files for CNC applications. The rise of e-commerce platforms is facilitating access to a vast array of STL files, enabling buyers to source designs that fit their specific needs without significant lead times.

Emerging trends include a shift toward open-source designs and collaborative platforms where designers and manufacturers can share STL files. This trend is particularly prominent in regions like Vietnam and Nigeria, where local makerspaces are fostering innovation. Additionally, the integration of artificial intelligence and machine learning into CNC machining processes is enhancing efficiency, enabling better material utilization, and reducing waste. Buyers are also focusing on suppliers that provide high-quality, optimized STL files, which are crucial for ensuring smooth machining and high precision in final products.

How Is Sustainability and Ethical Sourcing Impacting the STL File CNC Router Market?

Sustainability is becoming a pivotal concern for international B2B buyers in the STL file CNC router sector. The environmental impact of manufacturing processes is under scrutiny, leading businesses to prioritize ethical sourcing and sustainable practices. Buyers are increasingly seeking suppliers that not only offer high-quality STL files but also adhere to eco-friendly production methods and materials. This includes the use of biodegradable materials and energy-efficient processes that minimize waste.

Moreover, certifications such as ISO 14001, which focuses on effective environmental management systems, are becoming essential for suppliers aiming to establish credibility in the market. By partnering with suppliers who have these certifications, B2B buyers can enhance their own sustainability profiles, appealing to environmentally-conscious consumers. As the demand for green products grows, sourcing STL files that comply with sustainability standards is not just a trend but a strategic necessity for competitive advantage.

What Is the Brief Evolution of the STL File CNC Router Sector?

The STL file CNC router sector has evolved significantly since the advent of computer-aided design (CAD) and computer numerical control (CNC) technologies. Initially, CNC routers were primarily used for large-scale manufacturing, with limited access to design files. However, the introduction of 3D printing and the proliferation of digital design platforms have democratized access to STL files, allowing even small businesses and individual creators to utilize CNC technology.

Over the years, the availability of online marketplaces for STL files has surged, enabling designers to share and sell their creations globally. This evolution has not only expanded the variety of designs available but has also fostered a culture of collaboration and innovation within the industry. Today, the sector is characterized by a diverse range of applications, from artistic projects to functional prototypes, reflecting the dynamic nature of modern manufacturing. As technology continues to advance, the future of the STL file CNC router sector looks promising, with opportunities for further growth and innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of stl file cnc router

-

1. How do I solve compatibility issues with STL files for my CNC router?

To resolve compatibility issues with STL files, ensure that the files are created or exported in a format recognized by your CNC software. Check if your CNC router supports various file formats, including STL, OBJ, or DXF. If issues persist, consider using file conversion software to convert the STL files into a more compatible format. Additionally, reviewing the specifications of your CNC machine and software can help identify any required adjustments or updates. -

2. What is the best STL file source for CNC routers?

The best STL file source for CNC routers depends on your specific needs and project requirements. Platforms like Cults3D, 3DWave, and 3DModelsArt offer extensive libraries of STL files tailored for CNC machining. Look for sources that provide high-quality, optimized designs that ensure smooth machining. Additionally, consider user reviews and ratings to gauge the reliability and precision of the models offered. -

3. How can I ensure the quality of STL files I purchase for CNC routing?

To ensure the quality of STL files, purchase from reputable sources that guarantee high detail and precision. Look for files that are specifically optimized for CNC machining, as they are more likely to produce accurate results. Additionally, check for user feedback and ratings on the platform, and consider requesting sample files if possible. It’s also wise to verify that the files are free from errors and are designed for your specific CNC router model. -

4. What are the typical payment terms for purchasing STL files in B2B transactions?

Payment terms for purchasing STL files can vary by supplier. Common arrangements include upfront payments, partial payments, or payment upon delivery. Some suppliers might offer discounts for bulk purchases or recurring orders. It’s essential to clarify payment methods accepted, such as credit cards, wire transfers, or digital wallets, and to ensure that terms are documented in a purchase agreement to avoid misunderstandings. -

5. What is the minimum order quantity (MOQ) for STL files when sourcing internationally?

Minimum order quantities for STL files can differ significantly among suppliers, particularly in international B2B transactions. Some platforms offer single-file purchases, while others may set a MOQ for bulk file collections. It’s crucial to communicate with potential suppliers to understand their policies regarding MOQs, especially if you are looking to secure multiple designs for a larger project. Negotiating terms may also be possible based on your business needs. -

6. How do I vet suppliers for STL files when sourcing from different countries?

When vetting suppliers for STL files internationally, start by researching their reputation through online reviews and industry references. Evaluate their website for professionalism and transparency, including details about their design processes and customer support. Additionally, check for certifications or memberships in relevant industry associations. Engaging in direct communication to discuss your needs and gauge their responsiveness can also provide insights into their reliability and professionalism. -

7. What logistics considerations should I keep in mind when purchasing STL files internationally?

Logistics for purchasing STL files internationally primarily involve digital delivery, which usually allows for instant access. However, consider the internet speed and data security when downloading large files. Additionally, confirm the supplier’s policy on file backup and support in case of technical issues. If you are collaborating with teams across different regions, ensure that the files are compatible with various software used by your partners. -

8. How can I customize STL files for specific CNC projects?

Customizing STL files typically requires CAD software that can modify 3D models. You can either edit existing STL files or commission a designer to create custom designs based on your specifications. Ensure that any modifications maintain the integrity of the design for CNC machining. When commissioning custom work, provide clear guidelines and examples of your requirements to ensure the final product meets your project goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Stl File Cnc Router Manufacturers & Suppliers List

1. Etsy – MEGA BUNDLE CNC Files

Domain: etsy.com

Registered: 2004 (21 years)

Introduction: CNC STL Files available on Etsy include various bundles and individual files for CNC routers. Key offerings include: 1. MEGA BUNDLE CNC Files – Sale Price: $9.90 (Original Price: $19.80, 50% off) – Digital Download, includes 5000 3D models with commercial license. 2. 340+ GB CNC Router STL Mega Pack – Sale Price: $55.89 (Original Price: $223.58, 75% off) – Digital Download. 3. 6700 3D models for C…

2. 3D Wave – High-Quality STL Models for CNC

Domain: 3dwave.us

Registered: 2021 (4 years)

Introduction: 3D STL Models for CNC Router and 3D Illusion Laser-Ready Files. High-quality 3D models optimized for CNC machining, available for instant download in STL format. Compatible with most CAD software. Key features include: optimized for CNC, instant access, high detail and precision, wide variety of designs, and easy to use. Models available include: TIGER 3D STL ($9.90), SKULL WITH ROSES 3D STL ($9.9…

3. Cults3D – Premium 3D Printing Models

Domain: cults3d.com

Registered: 2013 (12 years)

Introduction: Router CNC best 3D printing models; 0 free models to download; 2.4M free and premium models available; compatible with FDM, SLA, SLS 3D printers; file formats supported: STL, OBJ, STEP, 3MF, SCAD for 3D printing; DXF, SVG, PDF, AI for CNC machining & laser cutting; GBR, GBX for electronics PCB; PNG, JPG, MP4, WEBP for reference images; community of 199k designers; platform updates with fresh digit…

4. 3D Models Art – 7000+ PCS MEGA 3D STL MODELS COLLECTION SET

Domain: 3dmodelsart.com

Registered: 2018 (7 years)

Introduction: 3D STL Models for CNC Routers and 3D Printers. Instant downloads available. Categories include: Backgammon, Clock, Collections, Decor, Frames, Necklace, Panno, Personages, Religion, Ring Box, Trophies. Featured products: 7000+ PCS MEGA 3D STL MODELS COLLECTION SET – $165.00 (originally $400.00), 3000 PCS MEGA BIG 3D STL MODELS COLLECTION SET – $105.00 (originally $155.00), 500+ PCS 3D STL MODELS C…

5. Reddit – Converting STL to G-code Software

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around converting STL files to G-code for CNC routers. Users suggest various software options for this process, including MeshCAM (commercial), pyCAM (free/open-source), FreeMill (free), Estlcam (affordable paid), Kiri:Moto (promising for 2.5D work), and Fusion 360 (requires conversion to OBJ or STEP). Additionally, Vectric’s Aspire and V-Carve Pro can directly upload STL f…

6. Carbide 3D – CNC Models and Files

Domain: carbide3d.com

Registered: 2013 (12 years)

Introduction: Carbide 3D offers 3D models for CNC machines, specifically for the Shapeoko CNC Router and Nomad Desktop CNC. The primary file types for 3D models include STL, OBJ, and DXF, with STL being the most common and preferred format for CNC applications. STL files represent 3D models as a series of triangles and can be generated with high accuracy. OBJ files are less compatible with CAM software and are …

7. 3Axis – STL Files for Laser Cutting

Domain: 3axis.co

Registered: 2017 (8 years)

Introduction: STL Files available for laser cutting, including tools boxes, box generators (with and without lids), rulers, and various woodworking plans. File formats include CDR, DXF, PDF, SVG, AI, EPS, BMP, and STL. Categories include 3D puzzles (animals, vehicles), decorative items (clocks, lamps, photo frames), holiday decorations (Christmas, Easter, Halloween), kids learning tools, office supplies, jewelr…

8. Pinterest – 3D STL Models and Refurbished 3D Printers

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: 3D STL Model for CNC and 3D Printer – Bas-Relief “Stork” (1834); 3D STL Models for CNC Routers and 3D Printers – AMERICAN EAGLE; 3D STL Model for CNC and 3D Printer – Bas-Relief “Drake” (1845); Refurbished Creality Sonic Pad 7″ Touch Screen 3D Printer – Klipper Firmware – $79.99; Carved Government Seal Plaques; Graham & Brown 16-in W x 16-in H Metal Lotus Blossom Botanical Wall Sculpture.

9. Lunyee – 3D CNC Router Files

Domain: lunyeecnc.com

Registered: 2021 (4 years)

Introduction: Product Name: 3D CNC Router Files

File Type: 3D STL file

Compatible Software: Vectric Aspire, Easel, Artcam, Vcarve, Cut3D, Blender, Zbrush, Maya, Fusion360, 3dsMax

Description: Digital file for CNC machines, high resolution, designed for engraving and cutting wood, art, and wall decor.

Sale Price: $3.00 (Regular Price: $5.00, 40% off)

Shipping: Calculated at checkout

Purchase Type: Recurring or d…

Strategic Sourcing Conclusion and Outlook for stl file cnc router

In the evolving landscape of CNC routing, the strategic sourcing of STL files is paramount for businesses aiming to enhance their production capabilities and design versatility. By leveraging high-quality STL files, organizations can significantly reduce lead times, optimize material usage, and foster innovation in product development. The availability of diverse file formats, coupled with instant access to premium models, empowers manufacturers to stay ahead of market trends and meet customer demands efficiently.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the emphasis on strategic sourcing cannot be overstated. Investing in reliable sources for STL files ensures that companies can maintain competitive advantages while exploring new markets. As businesses continue to navigate the challenges of globalization, forging partnerships with reputable suppliers will be key to unlocking new opportunities.

Looking ahead, the potential for growth in the CNC routing sector is vast. Companies are encouraged to explore innovative STL file solutions that align with their strategic goals. Now is the time to embrace the future of manufacturing—connect with trusted providers and elevate your production capabilities through smart sourcing decisions.