Introduction: Navigating the Global Market for stl convert to obj

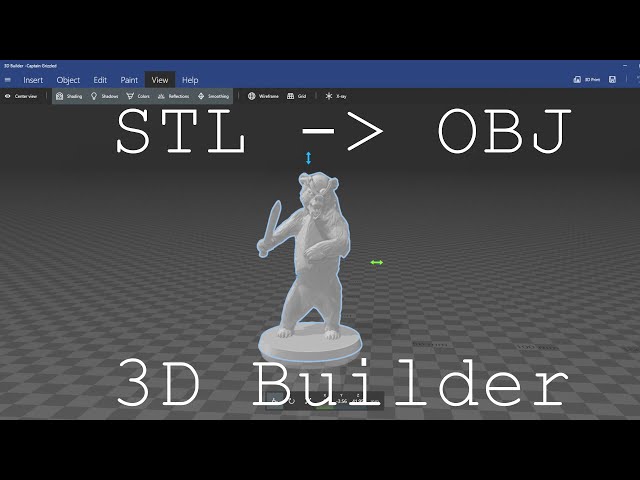

In today’s competitive global market, B2B buyers face the significant challenge of efficiently converting STL files to OBJ formats, a process crucial for enhancing 3D modeling capabilities and facilitating seamless collaboration across diverse industries. The transition from STL to OBJ not only enables the incorporation of textures and materials but also optimizes file sizes for various applications in sectors such as manufacturing, gaming, and design. This comprehensive guide delves into the intricacies of the conversion process, exploring the different types of STL and OBJ files, their applications, and the nuances of selecting the right conversion tools.

Furthermore, this guide equips international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Vietnam—with essential insights for making informed purchasing decisions. By addressing critical factors such as supplier vetting, cost considerations, and the latest technological advancements, this resource empowers businesses to navigate the complexities of file conversion with confidence. Whether you are a manufacturer seeking to improve your 3D printing capabilities or a designer aiming to streamline your workflow, understanding the STL to OBJ conversion landscape is vital for leveraging the full potential of your digital assets.

Understanding stl convert to obj Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Basic Online Converter | Simple interface, no software installation required | Quick conversions for small projects | Pros: Fast, easy to use; Cons: Limited features |

| Batch Conversion Tool | Supports multiple file conversions at once | Large-scale projects and batch processing | Pros: Time-efficient; Cons: May require more resources |

| Advanced Editing Suite | Allows for detailed editing post-conversion | High-quality design and prototyping | Pros: Comprehensive tools; Cons: Higher learning curve |

| API Integration Services | Programmatic access for automated workflows | Integration into existing pipelines | Pros: Seamless automation; Cons: Technical setup required |

| Custom Software Solutions | Tailored applications for specific business needs | Unique industry requirements | Pros: Fully customized; Cons: Higher cost and time investment |

What are the characteristics of Basic Online Converters for STL to OBJ?

Basic online converters are user-friendly tools that allow for quick and straightforward conversion of STL files to OBJ formats without the need for software installation. They typically support a limited range of features, making them suitable for small projects or one-off conversions. For B2B buyers, these tools offer a fast solution for immediate needs but may lack advanced functionalities, which could be a limitation for more complex projects.

How do Batch Conversion Tools benefit B2B buyers?

Batch conversion tools excel in processing multiple STL files simultaneously, which is invaluable for businesses dealing with large volumes of 3D data. These tools streamline workflows and save time, making them ideal for industries such as manufacturing and design where efficiency is crucial. However, buyers should consider the resource requirements, as batch processing can demand more computing power and may lead to longer processing times if not adequately managed.

What advantages do Advanced Editing Suites offer?

Advanced editing suites provide comprehensive tools for modifying 3D models after conversion. These suites cater to industries focused on high-quality design and prototyping, allowing users to make detailed adjustments, apply textures, and optimize models for various applications. While these tools offer significant advantages in terms of functionality, they may also present a steeper learning curve and require a greater investment in training and resources.

Why choose API Integration Services for STL to OBJ conversion?

API integration services facilitate the automation of STL to OBJ conversions within existing workflows. This is particularly beneficial for companies that require consistent and reliable conversions as part of their operations, such as in product development or digital asset management. While these services provide seamless integration and efficiency, buyers must consider the technical expertise required for setup and maintenance.

How do Custom Software Solutions cater to specific business needs?

Custom software solutions are designed to meet unique business requirements, offering tailored functionality for STL to OBJ conversion. These solutions are particularly advantageous for specialized industries that have specific demands not met by off-the-shelf tools. However, the development of custom solutions can involve higher costs and longer timelines, making it essential for businesses to weigh the potential return on investment against their specific needs.

Key Industrial Applications of stl convert to obj

| Industry/Sector | Specific Application of stl convert to obj | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Prototype Development for Product Design | Enables rapid prototyping and iterative design | Quality of conversion tools, file compatibility, support for batch conversion |

| Automotive | Custom Component Design and Testing | Facilitates detailed visualization and testing of components | Precision of conversion, software integration, and support for specific CAD tools |

| Architecture & Construction | 3D Visualization of Building Models | Enhances client presentations and project planning | Compatibility with visualization software, ease of use, and reliability of output |

| Medical Devices | Design and Simulation of Medical Instruments | Improves accuracy in design and reduces time-to-market | Compliance with industry standards, file integrity, and support for regulatory submissions |

| Animation & Gaming | Asset Creation for Video Games and Animation | Streamlines the creation of high-quality 3D assets | High fidelity in conversion, texture mapping capabilities, and support for various game engines |

How is ‘stl convert to obj’ Used in Manufacturing?

In the manufacturing sector, converting STL files to OBJ is crucial for prototype development. This conversion allows for rapid prototyping, enabling designers to visualize and iterate on product designs effectively. The OBJ format supports detailed textures and materials, which are essential for realistic presentations to stakeholders. International B2B buyers, especially in emerging markets, must consider the quality of conversion tools to ensure compatibility with their existing CAD systems and the ability to handle batch conversions for large-scale projects.

What Role Does ‘stl convert to obj’ Play in Automotive Design?

Automotive manufacturers use STL to OBJ conversion for custom component design and testing. The OBJ format allows for detailed visualization of parts, aiding engineers in assessing fit and functionality before physical production. This process reduces errors and accelerates the design cycle. Buyers in the automotive industry should focus on the precision of the conversion tools and their ability to integrate seamlessly with specialized automotive CAD software, ensuring that all design specifications are met without compromising quality.

How is ‘stl convert to obj’ Beneficial in Architecture & Construction?

In architecture and construction, converting STL files to OBJ enhances 3D visualization of building models. This capability is vital for client presentations and project planning, as it allows architects to showcase intricate designs with realistic textures and materials. For international buyers in this sector, ensuring compatibility with advanced visualization software is crucial, along with the ease of use of the conversion tools, to streamline the design process and improve client engagement.

How Does ‘stl convert to obj’ Impact Medical Device Development?

The medical device industry benefits from STL to OBJ conversion by improving the design and simulation of instruments. The OBJ format’s support for detailed textures and complex geometries aids in creating accurate models for testing and validation, ultimately reducing time-to-market for new devices. Buyers in this field must prioritize compliance with industry standards and the integrity of converted files, as these factors are essential for regulatory submissions and ensuring the safety of medical products.

What Advantages Does ‘stl convert to obj’ Offer in Animation & Gaming?

In the animation and gaming industries, converting STL files to OBJ is vital for asset creation. The OBJ format allows for high-quality 3D models that can be easily integrated into various game engines. This conversion process streamlines the creation of assets, ensuring that designers can produce visually appealing and functional models efficiently. B2B buyers in this sector should consider the fidelity of the conversion tools, especially regarding texture mapping capabilities, to maintain the quality of assets used in their projects.

3 Common User Pain Points for ‘stl convert to obj’ & Their Solutions

Scenario 1: Difficulty in Maintaining Model Integrity During Conversion

The Problem: B2B buyers often face the challenge of ensuring that the integrity of their 3D models is preserved when converting STL files to OBJ format. This issue is particularly pertinent for industries such as manufacturing, architecture, and animation, where precision is crucial. Users may find that after conversion, the models lose important details, such as textures or colors, which can significantly affect the visual quality and usability of the model in subsequent applications.

The Solution: To maintain model integrity, buyers should opt for high-quality conversion tools that support advanced features such as texture mapping and per-vertex normals. When selecting a conversion service, it’s essential to check if the tool supports batch processing for multiple files and can handle large file sizes without compromising quality. For instance, using platforms like Convert3D or Aspose allows for a seamless conversion process while retaining the original characteristics of the STL file. Additionally, users should familiarize themselves with the settings of the conversion tool to ensure options that preserve textures and materials are enabled before executing the conversion.

Scenario 2: Overcoming Compatibility Issues with 3D Editing Software

The Problem: Another common pain point is the compatibility of the converted OBJ files with various 3D editing software. Buyers may find that after conversion, the OBJ files do not open correctly in their preferred software, leading to frustration and delays in projects. This can be particularly problematic for teams working on collaborative projects where multiple software tools are in use, causing inefficiencies and communication breakdowns.

The Solution: To avoid compatibility issues, it’s advisable for buyers to verify the compatibility of the conversion tool with their target 3D software before starting the process. Many converters, including those mentioned, offer insights into which software supports the converted formats. Additionally, buyers should consider performing test conversions with simple models to troubleshoot potential issues before converting more complex files. Investing time in selecting the right converter and understanding the specifications of the intended software can save significant time and resources in the long run.

Scenario 3: Managing Large Files and Batch Conversions Efficiently

The Problem: In many industries, B2B buyers often work with large 3D models or need to convert multiple STL files simultaneously. This can lead to challenges in managing file sizes and ensuring efficient processing times during conversions. Slow or inefficient conversion processes can stall workflows and affect project timelines, especially when deadlines are tight.

The Solution: To effectively manage large files and batch conversions, buyers should look for conversion tools that specifically advertise their ability to handle large file sizes and batch processing capabilities. For instance, tools that allow users to upload and convert up to 25 files at once can dramatically improve efficiency. Furthermore, buyers should consider optimizing their STL files before conversion by using compression tools that reduce file sizes without sacrificing quality. This not only speeds up the conversion process but also facilitates easier sharing and collaboration across teams. Being proactive in file management and choosing the right tools can significantly enhance productivity and streamline workflows.

Strategic Material Selection Guide for stl convert to obj

What Are the Key Properties of Common Materials for STL to OBJ Conversion?

When converting STL files to OBJ format, the choice of materials used in 3D printing or modeling can significantly influence the final product’s performance. Here, we analyze four common materials: PLA, ABS, PETG, and Nylon, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does PLA Material Perform in STL to OBJ Conversion?

PLA (Polylactic Acid) is a biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane. It has a low melting temperature, typically around 180-220°C, making it easy to print. PLA is known for its excellent surface finish and vibrant colors, which can enhance the visual appeal of 3D models.

Pros: PLA is cost-effective and widely available, making it a popular choice for prototyping and educational purposes. It is also less prone to warping compared to other materials.

Cons: However, PLA has lower durability and heat resistance compared to other materials. It can become brittle over time and is not suitable for high-temperature applications.

Impact on Application: PLA is compatible with a wide range of media, but its limitations in strength and heat resistance may restrict its use in functional parts.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider local regulations regarding biodegradable materials. Compliance with ASTM standards is often necessary for product certification.

What Are the Characteristics of ABS Material for STL to OBJ Conversion?

ABS (Acrylonitrile Butadiene Styrene) is a widely used thermoplastic known for its strength and impact resistance. With a melting point of around 210-250°C, ABS is suitable for applications requiring durability and higher temperature resistance.

Pros: ABS is highly durable, making it ideal for functional prototypes and end-use parts. It also has good chemical resistance.

Cons: The main drawback of ABS is its tendency to warp during printing, requiring a heated bed for optimal results. It also emits fumes during printing, which may necessitate ventilation.

Impact on Application: ABS is commonly used in automotive and consumer products due to its strength and heat resistance, but its printing challenges can complicate its use.

Considerations for International Buyers: Compliance with safety standards such as DIN in Europe is crucial. Buyers should also consider the availability of ABS in their region, as it may vary.

How Does PETG Material Compare for STL to OBJ Conversion?

PETG (Polyethylene Terephthalate Glycol) is a popular material known for its excellent balance of strength, flexibility, and ease of printing. It has a melting temperature of around 220-250°C and is resistant to impact and moisture.

Pros: PETG is less prone to warping and offers good layer adhesion, making it easier to print than ABS. Its chemical resistance makes it suitable for a variety of applications.

Cons: However, PETG can be more expensive than PLA and may require fine-tuning of print settings to achieve optimal results.

Impact on Application: PETG is suitable for functional parts, containers, and even food-safe applications due to its non-toxic nature.

Considerations for International Buyers: Buyers should ensure that PETG complies with local food safety regulations, particularly in the food and beverage industry. Familiarity with JIS standards in Japan or ASTM in the U.S. can also be beneficial.

What Advantages Does Nylon Offer in STL to OBJ Conversion?

Nylon is a strong and flexible material known for its durability and resistance to wear and tear. With a melting point of around 220-260°C, it is suitable for applications requiring high strength and flexibility.

Pros: Nylon is highly durable and has excellent chemical resistance, making it ideal for functional parts and mechanical applications.

Cons: The main disadvantage of nylon is its tendency to absorb moisture, which can affect its mechanical properties. It also requires careful handling during printing.

Impact on Application: Nylon is widely used in engineering and industrial applications due to its strength and flexibility.

Considerations for International Buyers: Buyers should be aware of local standards regarding material safety and performance, particularly in the Middle East and Europe, where compliance with DIN standards is common.

Summary Table of Material Selection for STL to OBJ Conversion

| Material | Typical Use Case for stl convert to obj | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PLA | Prototyping, educational models | Biodegradable, easy to print | Brittle, low heat resistance | Low |

| ABS | Functional prototypes, consumer products | Durable, impact-resistant | Warping, fumes during printing | Medium |

| PETG | Functional parts, containers | Good layer adhesion, chemical resistance | More expensive, requires tuning | Medium |

| Nylon | Mechanical parts, engineering applications | High strength, flexible | Moisture absorption, handling complexity | High |

This strategic material selection guide provides B2B buyers with essential insights into the materials used for STL to OBJ conversion, enabling informed decisions based on application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for stl convert to obj

What Are the Main Stages of the Manufacturing Process for Converting STL to OBJ?

The conversion of STL (Standard Triangle Language) files to OBJ (Wavefront Object) files involves several critical stages that ensure the final product meets industry standards and customer expectations. These stages can be outlined as follows:

-

Material Preparation: In the context of digital file conversion, material preparation refers to the initial setup of the digital environment. This involves ensuring that the STL files are ready for conversion, which may include cleaning up the mesh, removing any unnecessary vertices, and checking for errors in the geometry that could affect the conversion process.

-

Forming the Model: The actual conversion process can be seen as the “forming” stage. This is where the STL file is processed by conversion software. During this stage, the software reads the STL file’s triangulated mesh data and translates it into the OBJ format. The software must handle various complexities, such as preserving vertex normals and material properties. Advanced tools may also allow batch processing, enabling the conversion of multiple STL files simultaneously.

-

Assembly of Features: After conversion, the OBJ file may need to be assembled with additional features like textures and materials. This stage is particularly relevant for B2B applications where the 3D model will be utilized in various contexts, such as animation or simulation. The OBJ format supports multiple objects and materials within a single file, allowing for a richer representation of the model.

-

Finishing Touches: The final stage involves verifying the integrity of the OBJ file. This can include checking for compatibility with various 3D modeling applications and ensuring that all textures and materials are correctly referenced and intact. The finishing process may also involve optimizing the file size for efficient use in applications, which is crucial for maintaining performance in high-demand environments.

How Is Quality Assurance Implemented During the STL to OBJ Conversion Process?

Quality assurance (QA) is vital in ensuring that the conversion process meets both international standards and specific industry requirements. The QA process typically includes the following components:

-

Adherence to International Standards: Many organizations follow ISO 9001, a global standard for quality management systems. Compliance with this standard ensures that processes are defined and documented, enabling consistent quality throughout the conversion process. For B2B buyers, this compliance can serve as a benchmark when selecting suppliers.

-

Industry-Specific Certifications: Depending on the application of the 3D models, other certifications may be relevant. For example, CE marking is crucial for products entering the European market, while API certification may be necessary for applications in the oil and gas sector. Suppliers should provide documentation demonstrating compliance with these standards.

-

Quality Control Checkpoints: Implementing quality control (QC) checkpoints throughout the conversion process is essential. Common checkpoints include:

– Incoming Quality Control (IQC): Assessing the quality of STL files before conversion to identify any issues that could affect the final product.

– In-Process Quality Control (IPQC): Monitoring the conversion process itself, ensuring that software settings are correctly applied and that the conversion is proceeding as expected.

– Final Quality Control (FQC): Conducting a thorough review of the resulting OBJ file, checking for errors, missing textures, or other discrepancies. -

Testing Methods Employed in QC: Various testing methods can be employed to verify the quality of the converted files. Common approaches include:

– Visual Inspection: Manually checking the model in a 3D viewer to identify any obvious errors.

– Automated Testing: Using software tools to validate the integrity of the OBJ file, including checking for geometry errors and ensuring that all references to materials are correctly linked.

– Performance Testing: Evaluating how the OBJ file performs in the target applications, ensuring that it meets the necessary performance benchmarks.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control Practices?

B2B buyers must conduct thorough due diligence when selecting suppliers for STL to OBJ conversion services. Here are practical steps to verify supplier quality control practices:

-

Request Documentation: Buyers should ask potential suppliers for their quality management documentation, including ISO certifications and internal QA processes. This information will provide insights into the supplier’s commitment to quality.

-

Conduct Audits: Periodic audits of suppliers can help verify adherence to quality standards. Buyers can either conduct these audits themselves or hire third-party firms to assess the supplier’s practices.

-

Review Quality Reports: Suppliers should provide quality reports detailing the results of their QC processes. These reports can include data on defect rates, corrective actions taken, and overall quality performance metrics.

-

Seek Third-Party Inspections: For critical projects, engaging a third-party inspection service can provide an unbiased assessment of the supplier’s quality control measures. These inspections can confirm that the conversion processes meet the agreed-upon specifications and standards.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe (e.g., Germany, Vietnam), buyers must navigate various quality control nuances:

-

Understanding Regional Standards: Different regions may have distinct quality standards and practices. Buyers should familiarize themselves with local regulations and certifications that may impact product quality.

-

Cultural Considerations: Cultural differences can affect how quality is perceived and implemented. Engaging in open communication and establishing clear expectations can help bridge these gaps.

-

Logistics and Supply Chain Management: International shipping can introduce risks, such as delays or damage. Buyers should ensure that suppliers have robust logistics and risk management strategies in place to mitigate these issues.

-

Building Long-Term Relationships: Establishing strong relationships with suppliers can foster better communication and collaboration on quality issues. This trust can lead to improved quality outcomes and more reliable service.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices involved in converting STL to OBJ files is crucial for B2B buyers. By carefully evaluating suppliers and their quality control measures, buyers can ensure they receive high-quality 3D models that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stl convert to obj’

In today’s competitive landscape, converting STL files to OBJ formats is essential for businesses involved in 3D modeling and printing. This guide provides a practical checklist to assist B2B buyers in sourcing the right tools and services for this conversion, ensuring quality and efficiency in their processes.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is crucial before starting the conversion process. Identify the characteristics of your STL files, such as size, complexity, and any special features like color or texture support. This information will help you determine the capabilities you need from a conversion tool or service.

Step 2: Research Available Conversion Tools

Explore various online and offline tools that can convert STL to OBJ. Look for software that supports batch conversion if you have multiple files, as this can save time and streamline your workflow. Consider both free and paid options, weighing their features against your business needs.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to conduct thorough evaluations. Request company profiles, user reviews, and case studies to understand their track record. Consider reaching out to other businesses in your region or industry for firsthand feedback on their experiences.

- Check for Compatibility: Ensure that the tools or services offered can handle the specific STL files you work with, particularly if they include unique features.

Step 4: Verify Software Capabilities

Not all conversion tools are created equal. Investigate the capabilities of the software, including whether it supports various file types and maintains the integrity of your 3D models during conversion. Look for features like texture and material retention, which are critical for high-quality outputs.

Step 5: Assess Pricing Models

Understanding the pricing structure is vital for budgeting effectively. Some tools may offer a one-time purchase, while others may operate on a subscription basis. Compare costs against the features provided and assess if the investment aligns with your business goals.

- Hidden Costs: Be cautious of any additional fees for premium features or batch processing, which can impact your overall budget.

Step 6: Test the Conversion Process

Before fully committing to a supplier, conduct a trial conversion with a sample STL file. This step will allow you to evaluate the software’s performance and the quality of the output OBJ files. Look for any loss of detail or complications in the conversion that could affect your projects.

Step 7: Ensure Customer Support Availability

Reliable customer support is essential, especially when dealing with technical issues or questions during the conversion process. Check if the supplier offers comprehensive support options, including documentation, tutorials, and direct customer service channels.

- Response Times: Prioritize suppliers known for quick and effective response times, ensuring you can address any issues without significant downtime.

By following this checklist, B2B buyers can effectively navigate the process of sourcing STL to OBJ conversion tools and services, ultimately enhancing their 3D modeling and printing capabilities.

Comprehensive Cost and Pricing Analysis for stl convert to obj Sourcing

What Are the Key Cost Components in STL to OBJ Conversion?

When considering the cost structure for converting STL to OBJ files, several components play a crucial role. The primary cost components include:

-

Materials: While the conversion process itself doesn’t involve physical materials, the quality of the original STL file impacts the output. High-quality STL files result in better OBJ files, which can affect the overall service costs.

-

Labor: Skilled labor is necessary for managing the conversion process, especially when dealing with complex files or ensuring that the conversion retains the necessary details. Labor costs can vary significantly based on the region and the expertise required.

-

Manufacturing Overhead: This includes the costs associated with maintaining and operating the conversion software and hardware. Companies offering these services need to cover their operational expenses, which can influence pricing.

-

Tooling: The software and tools used for conversion must be licensed or developed, adding to the overall cost. Subscription fees for high-quality conversion tools can impact pricing strategies.

-

Quality Control (QC): Ensuring the converted OBJ files meet certain quality standards requires additional processes. QC measures, including checks for integrity and accuracy of the files, can add to the costs.

-

Logistics: If the conversion service is part of a broader supply chain (e.g., for 3D printing), logistics costs may also need to be considered, especially if files are transferred between different geographic locations.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market demand and competition.

How Do Price Influencers Affect STL to OBJ Conversion Costs?

Several factors can influence the pricing of STL to OBJ conversions:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often come with discounts, making it essential for buyers to consider their needs when negotiating prices. Bulk conversions can lead to significant cost savings.

-

Specifications and Customization: Customized conversions that require additional features or adjustments will generally incur higher costs. Buyers should clearly define their specifications to avoid unexpected charges.

-

Materials: Although STL and OBJ files are digital, the complexity and quality of the original STL files can affect conversion costs. Higher-resolution models may require more processing power and time.

-

Quality and Certifications: Suppliers that offer certifications for their conversion processes may charge more. Quality assurance can be critical for industries like aerospace or medical, where precision is non-negotiable.

-

Supplier Factors: The reputation and location of the supplier can also affect pricing. Suppliers in regions with higher labor costs may charge more, while those with advanced technologies may offer faster turnaround times.

-

Incoterms: Understanding the terms of delivery can impact overall costs. If the buyer is responsible for logistics, this can add to the total expenditure.

What Buyer Tips Can Help in Negotiating STL to OBJ Conversion Prices?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, the following tips can enhance negotiation outcomes:

-

Negotiate Bulk Discounts: If you’re planning to convert a large number of files, don’t hesitate to negotiate for better rates based on volume.

-

Assess Total Cost of Ownership (TCO): Look beyond the initial conversion cost. Consider factors like the quality of the converted file, potential rework costs, and the reliability of the supplier when evaluating the total cost.

-

Understand Pricing Nuances: Different suppliers may have varied pricing structures. Research the market to gauge typical costs and use this information in negotiations.

-

Clarify Specifications Early: Providing clear specifications upfront can minimize back-and-forth and additional costs associated with changes.

-

Inquire About Certifications: If your project requires high-quality standards, ensure that the supplier can meet these requirements and inquire about the associated costs.

Disclaimer on Pricing

Pricing for STL to OBJ conversion services can vary widely based on the factors mentioned above. It is advisable to request quotes from multiple suppliers and consider conducting a cost analysis to determine the best option for your specific needs. Always verify the credentials and capabilities of suppliers before committing to a contract.

Alternatives Analysis: Comparing stl convert to obj With Other Solutions

In the realm of 3D modeling and printing, converting STL files to OBJ format is a common task. However, several alternative solutions exist that also facilitate this conversion or serve similar purposes. Understanding these alternatives can help businesses make informed decisions based on their specific needs.

| Comparison Aspect | Stl Convert To Obj | Online File Conversion Services | Local Software Solutions |

|---|---|---|---|

| Performance | Fast processing for single and batch conversions. | Generally fast, but may vary based on server load and internet speed. | High performance with no internet dependency; speed varies by hardware. |

| Cost | Free tools available, with premium options for advanced features. | Most services are free; some may charge for higher limits or features. | Varies widely; can be free or involve a one-time purchase or subscription. |

| Ease of Implementation | Simple user interface for quick conversions. | User-friendly; no software installation required. | Requires installation and setup, which may be complex for some users. |

| Maintenance | Minimal; updates depend on the service provider. | No maintenance required; updates managed by service provider. | Requires regular updates and potential troubleshooting. |

| Best Use Case | Ideal for quick conversions for 3D printing and modeling. | Suitable for occasional users or those needing quick, one-off conversions. | Best for businesses with frequent conversion needs and advanced modeling tasks. |

What Are the Advantages and Disadvantages of Online File Conversion Services?

Online file conversion services provide a convenient way to convert STL to OBJ without the need for software installation. They are typically user-friendly and accessible from any device with internet connectivity. However, reliance on internet speed can affect performance, and there may be limitations on file size or the number of conversions per day. Additionally, data security concerns may arise when uploading sensitive files to online platforms.

How Do Local Software Solutions Compare?

Local software solutions offer robust performance and flexibility for users who frequently engage in 3D modeling and conversion tasks. These solutions allow for greater control over the conversion process and often come equipped with advanced features like batch processing and enhanced editing capabilities. However, they require installation and regular updates, which can be a barrier for some users. The initial cost can also be a consideration, particularly for small businesses or startups.

Conclusion: Which Solution Should B2B Buyers Choose?

When selecting the right solution for converting STL to OBJ, B2B buyers should consider their specific needs, including budget, frequency of use, and the complexity of tasks. For occasional users, online conversion services may provide a quick and cost-effective solution. In contrast, businesses with regular conversion needs or those requiring advanced features may benefit from investing in local software solutions. Ultimately, the choice will depend on balancing performance, cost, and ease of use against the operational demands of the business.

Essential Technical Properties and Trade Terminology for stl convert to obj

What Are the Essential Technical Properties for Converting STL to OBJ?

When engaging in the conversion of STL (Standard Triangle Language) files to OBJ (Wavefront Object) files, understanding key technical properties is crucial for ensuring compatibility and quality in 3D modeling. Below are several critical specifications that B2B buyers should consider:

-

File Format Compatibility

The STL format is widely used in 3D printing, while OBJ files are preferred in various 3D modeling applications due to their support for complex geometries and textures. Ensuring compatibility with the software used by your team or clients can significantly affect workflow efficiency. This is particularly important for industries in design and manufacturing where seamless integration of models is essential. -

Geometry Representation

STL files represent 3D objects using a collection of triangles, which can lead to larger file sizes due to the non-reusable vertex data. In contrast, OBJ files store geometry as a shared pool of vertices, allowing for more efficient data management. For B2B operations focused on large-scale projects, understanding the implications of geometry representation can impact storage solutions and processing times. -

Material and Texture Support

OBJ files can incorporate materials and textures, which STL files lack. This capability is vital for industries like architecture and product design, where visual representation is key. The ability to maintain material properties during conversion ensures that the final model meets client expectations and project specifications. -

File Size Considerations

STL files, particularly in binary format, can be larger than their OBJ counterparts due to duplicated vertex data. Smaller file sizes facilitate faster uploads and downloads, which is beneficial for teams working with large datasets or for companies with bandwidth constraints. Understanding file size implications can aid in project planning and resource allocation. -

Editing Flexibility

OBJ files allow for more extensive editing options, including the application of different materials and textures without losing data integrity. In contrast, converting back to STL after applying such features may result in data loss. For B2B partners in creative fields, the ability to retain editing capabilities is essential for iterative design processes.

What Are Common Trade Terminology and Jargon Used in STL to OBJ Conversions?

Navigating the technical landscape of file conversions often involves specific industry jargon. Familiarity with these terms can enhance communication and streamline operations:

-

OEM (Original Equipment Manufacturer)

In the context of 3D modeling, OEM refers to companies that produce parts or equipment that are marketed by another company. Understanding OEM specifications is vital for ensuring that converted files meet the production standards required by the original manufacturers. -

MOQ (Minimum Order Quantity)

This term refers to the smallest quantity of a product that a supplier is willing to sell. In the context of 3D models, knowing the MOQ can impact how businesses plan their projects and manage inventory, particularly when sourcing components for prototyping or production runs. -

RFQ (Request for Quotation)

An RFQ is a standard business process to invite suppliers to bid on specific products or services. When converting STL to OBJ, companies may issue RFQs to find the best service provider for their conversion needs, ensuring competitive pricing and quality. -

Incoterms (International Commercial Terms)

These are international trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B transactions, particularly when shipping 3D models or physical products derived from these files. -

3D CAD (Computer-Aided Design)

This term refers to the use of computer software to create, modify, analyze, or optimize a design. Understanding the role of 3D CAD is crucial in the conversion process, as it highlights the tools and software that will be used post-conversion. -

BOM (Bill of Materials)

A BOM is a comprehensive list of materials, components, and assemblies needed to construct a product. In the context of 3D modeling, having a clear BOM can help ensure that all necessary elements are included in the conversion process, facilitating smoother project execution.

Understanding these properties and terms will empower B2B buyers to make informed decisions regarding STL to OBJ conversions, optimizing both workflow and product quality.

Navigating Market Dynamics and Sourcing Trends in the stl convert to obj Sector

What Are the Global Drivers Influencing the STL to OBJ Market?

The STL to OBJ conversion sector is witnessing significant growth driven by the increasing demand for 3D modeling and printing applications. As industries such as manufacturing, architecture, and entertainment expand their digital capabilities, the necessity for versatile file formats has become evident. The OBJ format, with its support for materials and textures, is favored for its compatibility with various 3D modeling software, making it essential for businesses looking to enhance their product designs. Furthermore, the rise of additive manufacturing in regions like Africa and South America is accelerating the need for efficient file conversions to optimize production workflows.

Emerging technologies such as artificial intelligence and machine learning are also reshaping sourcing trends. Companies are leveraging these technologies to automate the conversion process, reduce turnaround times, and minimize human error. The proliferation of online conversion tools has democratized access, allowing international B2B buyers to utilize these resources without the need for extensive technical knowledge. This trend is particularly beneficial for small and medium enterprises in developing markets, where access to advanced software may be limited.

How Are Sustainability and Ethical Sourcing Shaping the STL to OBJ Sector?

Sustainability is becoming a paramount concern in the B2B landscape, influencing sourcing decisions across industries, including the STL to OBJ conversion sector. As environmental awareness grows, companies are increasingly prioritizing eco-friendly practices in their supply chains. This includes the use of sustainable materials and technologies that reduce waste during the conversion process. For instance, software solutions that optimize file sizes and minimize data redundancy can lead to lower energy consumption during file storage and transfer.

Moreover, the importance of ethical supply chains cannot be overstated. B2B buyers are more inclined to partner with suppliers who demonstrate a commitment to ethical practices, including transparency in sourcing and production processes. Certifications for green materials and environmentally friendly practices can serve as differentiators in a competitive market, providing buyers with confidence that their partners are aligned with sustainable values.

What Is the Brief Evolution of STL and OBJ Formats in B2B Context?

The STL format, introduced in the 1980s, was primarily designed for 3D printing applications and has since become a standard in the industry. Its simplicity, characterized by a straightforward triangulated mesh representation, made it popular among manufacturers and engineers. However, as the demand for more complex 3D models grew, the limitations of STL became apparent, particularly regarding material and texture support.

In response, the OBJ format emerged as a more versatile alternative, allowing for the inclusion of detailed surface attributes and multiple objects within a single file. This evolution has driven B2B buyers to seek solutions that facilitate the conversion from STL to OBJ, ensuring compatibility with modern 3D modeling tools. As businesses continue to embrace advanced design methodologies, the ability to seamlessly convert and utilize various file formats will remain crucial for maintaining a competitive edge in the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of stl convert to obj

-

1. How do I convert STL files to OBJ format effectively?

To convert STL files to OBJ format, select a reliable online conversion tool that supports batch processing, such as Convert3D or Aspose. Start by uploading your STL file, ensuring it meets the size limitations (typically around 100MB). After the upload, initiate the conversion process. Once completed, download your OBJ file, which will be ready for use in various 3D modeling applications. This process is straightforward and does not require specialized software installation, making it accessible for B2B buyers across different regions. -

2. What are the advantages of using OBJ over STL for 3D models?

The OBJ format offers several advantages over STL, particularly in terms of versatility and detail. OBJ files support multiple 3D objects within a single file, along with the capability to include textures and materials, which STL lacks. This allows for richer visual representations in 3D modeling applications. Additionally, OBJ files typically have smaller sizes when compared to STL, especially when vertex data is considered. For B2B buyers focused on detailed 3D presentations, choosing OBJ is often the better option. -

3. What should I look for when selecting a supplier for STL to OBJ conversion services?

When sourcing suppliers for STL to OBJ conversion, consider their reputation and customer reviews to gauge reliability. Check if they offer batch conversion services, which can save time for businesses handling multiple files. It’s also essential to confirm their data security measures to protect proprietary designs. Additionally, inquire about turnaround times and customer support availability, ensuring that they can meet your project deadlines and provide assistance when needed. -

4. What are typical payment terms for international suppliers offering conversion services?

Payment terms can vary widely among international suppliers. Common practices include upfront payments, partial payments upon order confirmation, or payment upon delivery. It’s vital to clarify these terms before finalizing the agreement. Also, consider using secure payment methods that offer buyer protection, such as PayPal or escrow services, particularly when working with suppliers in different regions like Africa or South America, where risks may be higher. -

5. How can I ensure quality assurance in STL to OBJ conversion processes?

To ensure quality assurance, request samples of previous conversion work from potential suppliers. Establish clear specifications for your files, including size, detail, and format requirements. Additionally, consider implementing a review process where you test the converted files in your 3D applications before full-scale implementation. Regular communication with the supplier during the conversion process can also help address any issues early on. -

6. What are the logistics involved in sourcing STL to OBJ conversion services internationally?

Logistics can play a significant role in sourcing conversion services. Consider factors such as shipping times, customs regulations, and potential tariffs when dealing with international suppliers. Digital file transfers can mitigate some logistics concerns, but ensure that your supplier has a robust system for handling file exchanges securely. Establishing a clear timeline for delivery and communication channels can also help streamline the process. -

7. Are there any customization options available for STL to OBJ conversion?

Many conversion service providers offer customization options tailored to specific business needs. This may include adding materials and textures to the OBJ files or adjusting the geometry to meet particular design specifications. Discuss your requirements with potential suppliers to understand their capabilities and whether they can accommodate your customization needs. This dialogue is crucial for ensuring the final product aligns with your expectations. -

8. What minimum order quantities (MOQs) should I expect from STL to OBJ conversion suppliers?

Minimum order quantities can differ based on the supplier’s business model. Some may have MOQs for batch conversions, while others might accept single-file conversions. It’s advisable to clarify these terms upfront to avoid misunderstandings. If your needs are modest, look for suppliers that cater to smaller orders or offer flexible solutions, particularly if you’re a startup or operating on a limited budget.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Stl Convert To Obj Manufacturers & Suppliers List

1. ImageToSTL – Free STL to OBJ Converter

Domain: imagetostl.com

Registered: 2019 (6 years)

Introduction: Convert STL to OBJ for free. Supports batch conversion of up to 25 STL files at a time. Maximum file size for upload is 100MB. The tool allows editing in popular 3D modeling applications like Blender. STL files do not support materials or textures, while OBJ files do. The conversion process involves uploading an STL file and downloading the converted OBJ file. The tool supports both binary and tex…

2. Aspose – STL to Wavefront OBJ Converter

Domain: products.aspose.app

Introduction: STL to Wavefront OBJ converter is an online tool that allows users to convert STL files to Wavefront OBJ format for free. It is powered by Aspose.com and Aspose.cloud, and does not require any software installation. Users can upload files via drag-and-drop or by selecting them from their device. The conversion process is fast, typically taking only a few seconds. The service is accessible from any…

3. 3D PEA – STL to OBJ Converter

Domain: 3dpea.com

Registered: 2020 (5 years)

Introduction: Convert STL to OBJ Online For Free – Effortlessly convert your STL files to OBJ for 3D printing with our powerful online 3D file conversion tool. No downloads or installations required. Supported formats include STL, OBJ, 3MF, STP, FBX, and more. Conversion process: Upload your STL file, set properties, select OBJ as target format, and download the converted file. Conversion typically takes about …

4. 3D Convert – STL to OBJ Conversion

Domain: 3d-convert.com

Registered: 2019 (6 years)

Introduction: Convert STL to OBJ online for free at 3d-convert.com. The service allows conversion of STL files to OBJ and over 12 other formats, with a total of 627 different conversion possibilities including STL, OBJ, Blend, FBX, and PLY. The conversion process is quick and easy, requiring users to upload their STL model, select the output format, and start the conversion. Uploaded models are deleted immediat…

5. Meshy AI – STL to OBJ Converter

Domain: meshy.ai

Registered: 2023 (2 years)

Introduction: Convert 3D Models from STL to OBJ Online for Free – Meshy AI offers a fast and free online tool to convert 3D models from STL to OBJ format in seconds without software installation. The converter supports a maximum file size of 50MB and preserves geometry details, materials, and textures during conversion. Users can drag and drop files or click to upload, and the conversion process is done locally…

6. AnyConv – STL to OBJ Converter

Domain: anyconv.com

Registered: 2019 (6 years)

Introduction: Convert STL to OBJ Online — Free & Fast | AnyConv

Key Features:

– Quickly convert multiple STL files to OBJ format.

– Free and online service.

– Supports file uploads via drag & drop or manual selection.

– Maximum file size: 100 MB.

– Conversion process typically takes just a few seconds.

– Download link is private and works only on the user’s device.

– No registration required for conversion.

– …

7. makexyz – OBJ to STL Converter

Domain: makexyz.com

Registered: 2012 (13 years)

Introduction: Convert OBJ files to STL files using makexyz’s free tool. Upload your OBJ models for instant conversion. Services include 3D printing on demand with options for FDM, SLA, SLS, and PolyJet printing. Available materials include PLA, ABS, Nylon, TPU (Flexible Plastic), and High Detail Resin. Additional services include CAD designers, 3D scanners, and CNCs. Discounts available for universities.

8. All3DP – STL to OBJ Conversion Guide

Domain: all3dp.com

Registered: 2013 (12 years)

Introduction: This article provides a guide on how to convert STL files to OBJ format, detailing the conversion process and tools available. It is authored by Raphael Bertasius and Tian Ooi, and was updated on February 14, 2023. The content is free from outside influence and is supported by advertising and shopping links.

9. Marathon OS – Free STL to OBJ Converter

Domain: marathon-os.com

Registered: 2023 (2 years)

Introduction: Free online STL to OBJ converter by Marathon OS. Fast, secure, and cloud-based. Supports multiple formats including STEP, IGES, STL, OBJ, PLY, OFF, and BREP. No software installation required; users can drag and drop files directly in the browser. Files are encrypted during upload, processed securely, and automatically deleted after 24 hours. Optimized for professionals, capable of handling large …

Strategic Sourcing Conclusion and Outlook for stl convert to obj

The conversion from STL to OBJ format presents significant advantages for businesses engaged in 3D modeling and printing across diverse sectors. Understanding the nuances between these file formats is crucial for strategic sourcing decisions. The OBJ format not only allows for more efficient storage with smaller file sizes but also supports advanced features such as per-vertex normals and material definitions, making it a superior choice for editing and visualization.

For international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe, leveraging these insights can enhance productivity and collaboration within design and manufacturing processes. Strategic sourcing of reliable STL to OBJ conversion tools can significantly streamline workflows, reduce costs, and improve the quality of 3D models used in production.

As the global demand for 3D printing and modeling continues to grow, investing in robust conversion solutions is essential for staying competitive. Embrace this opportunity to enhance your digital capabilities and connect with suppliers who offer advanced conversion tools tailored to your specific needs. The future of 3D modeling is here—are you ready to take the next step?