Contents

Manufacturing Insight: Steel’S Melting Point

Steel’s Melting Point: A Foundation for Precision CNC Machining

Understanding steel’s inherent thermal properties is critical for high-integrity manufacturing. Common carbon and alloy steels exhibit melting points ranging from 1,370°C to 1,510°C (2,500°F to 2,750°F), depending on composition—such as 304 stainless steel at approximately 1,400–1,455°C or 4140 alloy steel near 1,427°C. This high thermal threshold provides a substantial operational buffer during CNC machining processes, where localized heat generation from cutting tools must remain well below critical temperatures to preserve dimensional stability and material integrity. At Honyo Prototype, we leverage this thermal stability to deliver micron-level precision in complex steel components, utilizing advanced CNC milling, turning, and grinding techniques that maintain strict thermal control. Our processes ensure optimal surface finishes and tolerance adherence—typically ±0.005 mm—without inducing thermal distortion or microstructural compromise, even in demanding alloys.

When your design demands steel parts with uncompromised accuracy and repeatability, Honyo Prototype’s end-to-end CNC machining services provide the technical rigor required for aerospace, medical, and industrial applications. Validate feasibility and accelerate prototyping with our Online Instant Quote platform, which delivers precise cost and lead-time estimates within hours—backed by decades of metallurgical expertise and ISO 9001-certified production. Submit your CAD file today to initiate a seamless transition from concept to certified steel component.

Technical Capabilities

The melting point of steel is not a single fixed value due to the wide range of steel alloys, each with different compositions and corresponding thermal properties. In precision manufacturing environments—particularly those involving 3-axis, 4-axis, and 5-axis milling and turning—understanding material thermal behavior is critical for tool selection, cutting parameters, and achieving tight tolerances (typically ±0.0005″ to ±0.005″, depending on application).

While the melting point itself does not directly dictate machining parameters, it correlates with thermal conductivity, hardness at elevated temperatures, and tool wear. Materials such as aluminum and steel behave very differently under machining loads, especially in high-speed or multi-axis operations where heat accumulation can affect dimensional stability.

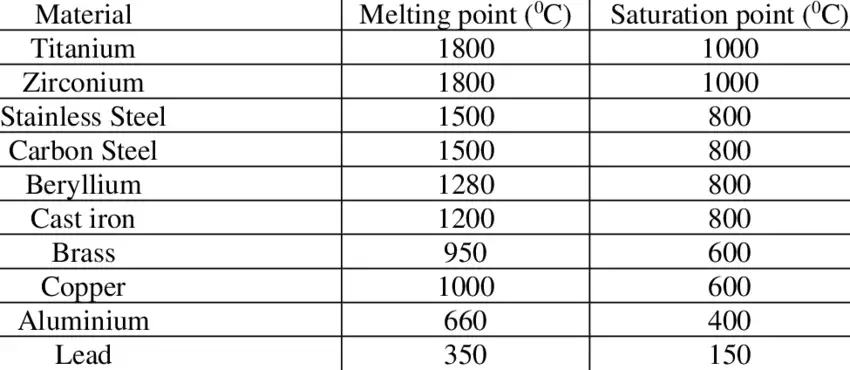

Below is a comparative table of key engineering materials used in precision CNC machining, including their melting points and relevance to multi-axis milling, turning, and tight tolerance work.

| Material | Melting Point Range (°C) | Melting Point Range (°F) | Common Machining Applications | Notes for 3/4/5-Axis Milling & Turning |

|---|---|---|---|---|

| Steel (General Carbon & Alloy Steels) | 1370–1510°C | 2500–2750°F | Precision shafts, tooling, structural components | High melting point indicates high thermal resistance; requires rigid setups and carbide or ceramic tooling. Generates significant heat during machining—critical for maintaining tight tolerances. Coolant and proper chip evacuation are essential. |

| Stainless Steel (e.g., 304, 17-4PH) | 1400–1450°C | 2550–2650°F | Aerospace, medical, and high-corrosion environments | Work-hardening tendency requires optimized feeds/speeds. Higher thermal resistance demands reduced cutting speeds and frequent tool monitoring to maintain tolerances in 5-axis contours. |

| Aluminum (e.g., 6061, 7075) | 580–650°C | 1076–1202°F | Enclosures, heat sinks, lightweight structural parts | Low melting point requires careful heat management. Excellent machinability allows high-speed 3/5-axis milling with tight tolerance control. Minimal thermal expansion vs. steel, but softness requires sharp tools to avoid burring. |

| ABS (Acrylonitrile Butadiene Styrene) | 105°C (softens) | 221°F (softens) | Prototypes, jigs, non-structural housings | Thermoplastic—does not have a true melting point like metals. Softens gradually. Low thermal resistance requires minimal cutting forces and low RPM to prevent melting or deformation during turning or milling. Not suitable for high-tolerance thermal-critical applications. |

| Nylon (Polyamide, e.g., PA6, PA66) | 215–265°C | 420–509°F | Gears, bushings, wear components | Semi-crystalline thermoplastic with higher melting range than ABS. Prone to moisture absorption—must be dried before precision machining. Dimensional stability is achievable with controlled feeds, but thermal expansion is higher than metals—tight tolerances require post-machining stabilization. |

In high-precision 3/4/5-axis CNC operations, thermal management derived from material melting behavior directly impacts tool life, surface finish, and geometric accuracy. For steel, the high melting point necessitates robust tooling strategies and thermal monitoring to sustain tolerances, especially in deep cavities or thin-wall features. In contrast, aluminum’s lower melting point allows faster material removal but demands attention to edge definition and heat dispersion.

For non-metallic materials like ABS and nylon, the focus shifts from melting point to glass transition and softening behavior, where excessive friction can lead to part deformation even below melting thresholds. Machinists must adjust parameters accordingly to maintain dimensional integrity across all materials.

From CAD to Part: The Process

Honyo Prototype does not treat “steel’s melting point” as a discrete process step within our workflow. Steel’s melting point is a fixed material property (approximately 1370–1510°C depending on alloy composition), not an actionable stage in manufacturing. Our clients sometimes misunderstand this terminology, so we clarify how material science integrates into our standardized process for producing steel components. Below is the accurate sequence for steel part production, emphasizing where melting point knowledge is applied:

Upload CAD

Clients submit detailed 3D models specifying material requirements (e.g., “AISI 4140 steel”). Our system validates file integrity and extracts critical parameters, including material grade. This step ensures we identify if the design requires high-temperature processes like casting—where melting point is directly relevant—or if it involves cold-forming methods like CNC machining, where melting point is not a factor.

AI Quote

Our proprietary AI engine analyzes the CAD file against real-time material databases. For steel parts, it cross-references the specified alloy against thermal properties:

| Steel Grade | Typical Melting Range (°C) | Primary Relevance in Quoting |

|————-|—————————-|——————————|

| 304 Stainless | 1400–1450 | Casting feasibility, weld distortion risk |

| 4140 Alloy | 1416–1510 | Heat treatment compatibility, tool wear in machining |

| A36 Carbon | 1425–1540 | Forge temperature limits, casting shrinkage |

The AI flags thermal constraints early, generating cost and lead time estimates based on whether melting point affects the process (e.g., investment casting vs. milling).

DFM (Design for Manufacturability)

Engineers conduct thermal analysis during DFM review. For steel components requiring melting (e.g., castings), we verify:

Pouring temperatures are 50–100°C above the alloy’s liquidus point to ensure fluidity

Mold design accommodates solidification shrinkage per the material’s thermal contraction rate

Heat treatment cycles avoid critical phase transition temperatures that could cause cracking

For non-melting processes like CNC machining, we focus on thermal management of cutting tools to prevent work hardening—leveraging steel’s melting point indirectly to calculate safe machining parameters.

Production

Execution aligns with the validated process:

Casting/Welding: Precise furnace control maintains temperatures within 5°C of optimal melt points. Real-time pyrometers monitor molten steel to prevent carbon burnout or slag inclusions.

Machining/Forming: No melting occurs; instead, we apply cooling strategies informed by steel’s thermal conductivity (derived from melting point data) to minimize thermal deformation.

Delivery

All steel parts undergo material certification, including mill test reports verifying composition and thermal processing history. For high-temperature applications, we provide traceability to exact melt batches and heat treatment curves.

Critical Clarification

Honyo’s process leverages steel’s melting point as an engineering input—not a workflow step. Misinterpreting this can lead to incorrect process selection; for example, quoting a CNC-machined steel bracket using casting parameters would incur unnecessary costs. Always specify your steel alloy and intended manufacturing method during CAD submission to ensure accurate thermal analysis in DFM. We recommend providing application context (e.g., “high-temp service environment”) to optimize our material science integration.

Start Your Project

For precise manufacturing applications requiring knowledge of steel’s melting point, contact Susan Leo at [email protected]. Our engineering team at Honyo Prototype provides technical support and custom fabrication services to ensure material compatibility and performance. With a fully equipped factory located in Shenzhen, we deliver rapid prototyping and low-volume production with strict quality control. Reach out to discuss your project specifications and material requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.