Contents

Manufacturing Insight: Steel Versus Iron

Material Selection Intelligence: Steel Versus Iron in Precision Manufacturing

Understanding the fundamental distinctions between steel and cast iron is critical for achieving optimal performance, durability, and cost-efficiency in engineered components. While both derive from iron-carbon alloys, steel typically contains less than 2.1% carbon, offering superior tensile strength, weldability, and versatility across applications ranging from aerospace to medical devices. Cast iron, with carbon content exceeding 2.1%, provides exceptional compressive strength, vibration damping, and castability—ideal for heavy machinery bases, engine blocks, and industrial housings. The choice between these materials directly impacts machinability, tool wear, surface finish, and final part integrity, demanding expert evaluation of design requirements, load conditions, and production volume.

At Honyo Prototype, our CNC machining expertise transforms this material selection challenge into a strategic advantage. We leverage advanced 3-, 4-, and 5-axis milling and turning centers to precisely machine both steel alloys (including stainless, tool steel, and carbon variants) and cast iron grades (gray, ductile, and white iron), mitigating inherent challenges such as iron’s abrasiveness or steel’s work-hardening tendencies. Our process-driven approach ensures tight tolerances (±0.005 mm), superior surface finishes, and adherence to ISO 9001 quality standards—turning complex geometries into high-performance reality without compromising lead times.

Your design intent dictates the optimal material and machining pathway. To accelerate your project from concept to certified prototype or low-volume production, leverage Honyo Prototype’s Online Instant Quote platform. Input your CAD file and specifications to receive a detailed manufacturability analysis and competitive pricing within hours—enabling data-driven decisions before a single chip is cut.

Technical Capabilities

When evaluating materials for precision CNC machining processes such as 3-axis, 4-axis, and 5-axis milling and turning, material selection significantly impacts tool wear, achievable tolerances, surface finish, and overall production efficiency. Steel and iron differ fundamentally in composition, mechanical properties, and machinability, especially under tight tolerance requirements (±0.001″ or tighter). Below is a comparative analysis of steel versus iron, with contextual reference to other commonly machined materials such as aluminum, ABS, and nylon.

Key Differences: Steel vs. Iron in CNC Machining

| Property | Steel (e.g., 4140, 1018) | Cast Iron (e.g., Gray Iron 60-40-18) | Aluminum (e.g., 6061-T6) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (Polyamide, PA66) |

|---|---|---|---|---|---|

| Composition | Primarily iron with controlled carbon (0.2–2.1%) and alloying elements (Cr, Mo, Ni) | Iron with 2–4% carbon, high silicon, graphite flakes | Aluminum with Mg, Si (6061: ~1% Mg, 0.6% Si) | Thermoplastic polymer: C₈H₈·C₃H₃N·C₃H₄ | Semi-crystalline thermoplastic: (C₆H₁₁NO)ₙ |

| Tensile Strength (Ultimate) | 60–250 ksi (varies by grade) | 30–60 ksi | 42–45 ksi | 7,000 psi (~48 MPa) | 10,000 psi (~70 MPa) |

| Hardness (Brinell, HB) | 150–300 HB | 170–250 HB | 95 HB | Not applicable (soft polymer) | 80–90 MPa (ball indentation) |

| Machinability Rating | 40–70% (medium to poor; 1018 better than 4140) | 80–100% (excellent due to graphite acting as chip breaker) | 90–100% (excellent) | Excellent (but gummy; requires sharp tools) | Good (but hygroscopic; prone to dimensional shift) |

| Thermal Conductivity | 25–50 W/m·K | 40–60 W/m·K | 167 W/m·K | 0.19 W/m·K | 0.25 W/m·K |

| Thermal Expansion (CTE) | ~6–7 µin/in·°F | ~5.5–6 µin/in·°F | ~13 µin/in·°F | ~40–60 µin/in·°F | ~50–70 µin/in·°F |

| Typical Tolerance Capability (CNC Milling/Turning) | ±0.0005″ to ±0.001″ (with proper fixturing and tool control) | ±0.001″ to ±0.002″ (stable but abrasive to tools) | ±0.0005″ to ±0.001″ (high precision achievable) | ±0.002″ to ±0.005″ (thermal sensitivity) | ±0.002″ to ±0.005″ (moisture absorption affects stability) |

| Tool Wear (Relative) | High (especially in hardened grades) | Moderate (graphite lubricates but is abrasive) | Low | Very low | Low to moderate (can gum up) |

| Coolant Requirement | Required (especially for continuous cuts) | Often dry machining possible | Recommended | Not required (air blow often sufficient) | Not required |

| Surface Finish (Typical Ra) | 16–32 µin (milled), can achieve <8 µin with finishing | 32–63 µin (as-machined), can reach 16 µin | 8–16 µin (excellent finishability) | 32–125 µin (depends on tool sharpness) | 32–64 µin |

| Applications in Precision Machining | High-strength components, molds, shafts, aerospace fittings | Engine blocks, fixtures, machine bases | Enclosures, aerospace parts, heat sinks | Prototypes, jigs, low-wear components | Gears, bushings, insulating parts |

Summary for High-Axis CNC Operations (3/4/5-Axis Milling & Turning):

Steel is preferred when high strength, wear resistance, and dimensional stability under load are critical. It supports tight tolerances but demands robust tooling, slower speeds, and rigid setups due to work hardening and thermal buildup.

Cast iron machines efficiently due to its self-lubricating graphite structure, making it suitable for complex 5-axis milling of fixtures or housings. However, its lower tensile strength and brittleness limit structural use compared to steel.

Aluminum excels in multi-axis machining due to high material removal rates, excellent thermal dissipation, and fine surface finishes. It is ideal for tight-tolerance aerospace and consumer electronics parts.

ABS and nylon are used where weight, insulation, or cost are prioritized over mechanical strength. Their high thermal expansion and moisture absorption limit their use in ultra-precision applications unless post-processed or stabilized.

For tight tolerance work across all materials, environmental control (temperature, humidity), tool path optimization, and in-process metrology are essential—especially when transitioning between metals and polymers.

From CAD to Part: The Process

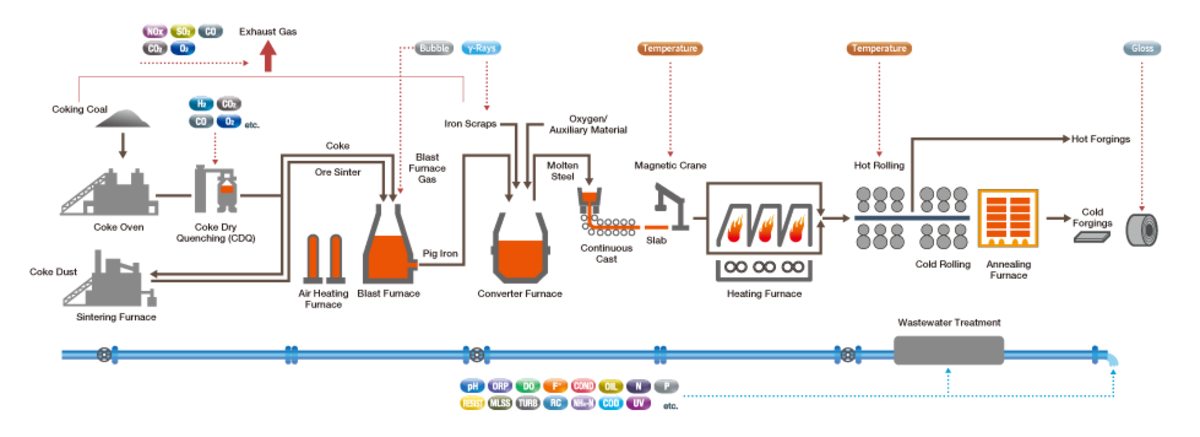

Honyo Prototype Steel Versus Iron Material Handling Process

Honyo Prototype maintains distinct technical protocols for steel and iron materials throughout our integrated workflow, ensuring material-specific optimization from design validation to delivery. This differentiation is critical due to iron’s (typically cast iron) higher carbon content, brittleness, and vibration-damping properties versus steel’s weldability, tensile strength, and machinability. Below is our structured process:

Upload CAD

Clients submit CAD files specifying material requirements (e.g., ASTM A48 Class 30 for gray iron or AISI 1045 steel). Our system immediately flags material designations, triggering iron-specific validation checks for section thickness uniformity and draft angles to prevent casting defects, while steel files undergo weld-prep and heat-treat zone verification. Non-compliant geometries for the selected material auto-generate client alerts prior to quoting.

AI Quote

Honyo’s AI engine cross-references material properties with real-time supplier data and machine capabilities. For cast iron, the system applies a 15–20% cost multiplier for extended machining times due to abrasive graphite flakes and incorporates foundry tooling fees. Steel quotes factor in lower scrap rates but include anti-rust packaging costs. Material substitution suggestions (e.g., ductile iron vs. low-carbon steel) are proposed if CAD analysis indicates performance or cost advantages, with technical rationale provided.

DFM Analysis

Our engineering team conducts material-specific Design for Manufacturability reviews:

Cast Iron: Focuses on eliminating sharp corners (minimum 3mm radii), verifying 3–5° draft for sand casting, and confirming rib thickness ≤ 70% of primary walls to avoid shrinkage.

Steel: Prioritizes weld accessibility (minimum 6mm clearance), heat-affected zone mitigation, and machinability thresholds (e.g., max 300 HB hardness for standard tooling).

DFM reports detail actionable revisions, such as converting iron bosses to steel press-fits or adjusting steel parting lines to reduce post-weld grinding.

Production

Material dictates dedicated production paths:

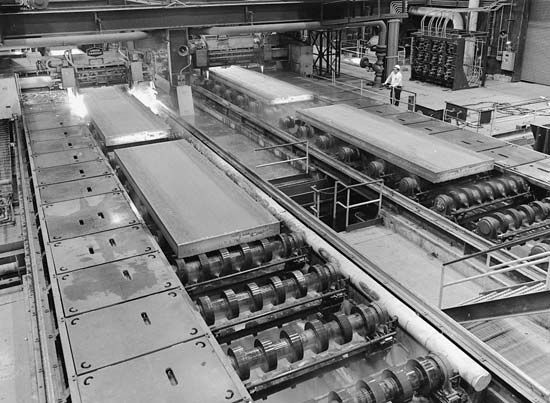

Cast Iron: Utilizes green sand molding with controlled cooling rates; CNC machining employs carbide tooling at 40% lower feeds versus steel to minimize chipping. All iron parts undergo magnaflux testing for subsurface cracks.

Steel: Leverages laser cutting or precision forging; welding follows ASME Section IX procedures with pre/post-heat treatment as specified. Steel components receive passivation or zinc plating per ISO 4042.

Real-time spindle load monitoring ensures iron machining stays below 65% torque to prevent tool fracture, while steel runs optimize for 85% load efficiency.

Delivery

Final inspection certificates explicitly validate material compliance:

| Parameter | Cast Iron Verification | Steel Verification |

|——————|——————————|—————————–|

| Hardness | 180–220 HB (ASTM E10) | 150–250 HB (ASTM E10) |

| Dimensional | ±0.5% linear tolerance | ±0.3% linear tolerance |

| Documentation | Mill test report + casting | Material certs (EN 10204 3.1)|

All iron shipments include desiccant packs and vapor corrosion inhibitors, while steel parts are sealed in VCI paper. Lead times account for iron’s 72-hour stress-relief annealing versus steel’s 24-hour tempering cycle.

This end-to-end material-aware workflow ensures steel and iron components meet application-specific mechanical requirements while minimizing cost overruns and rework. Honyo’s process guarantees traceability from CAD intent to certified physical part, with no interchangeability assumptions between these metallurgically distinct material families.

Start Your Project

When comparing steel versus iron for your next prototyping or production project, understanding material properties is critical for performance, durability, and cost-efficiency. At Honyo Prototype, we specialize in precision manufacturing using both steel and iron-based alloys, with full in-house capabilities at our Shenzhen factory.

For expert guidance tailored to your application, contact Susan Leo at [email protected]. Let us help you select the optimal material for strength, wear resistance, and manufacturability.

| Material | Typical Applications | Key Advantages |

|---|---|---|

| Steel | Automotive components, tooling, structural parts | High tensile strength, corrosion resistance (with alloys), weldability |

| Iron (Cast) | Engine blocks, piping, industrial frames | Excellent damping capacity, good machinability, cost-effective for large castings |

All projects benefit from our ISO-compliant processes and rapid turnaround times. Reach out today to discuss your material selection with a manufacturing engineer.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.