Contents

Manufacturing Insight: Steel Material Grades Chart

Steel Material Grades Chart: Precision Machining Starts with the Right Alloy

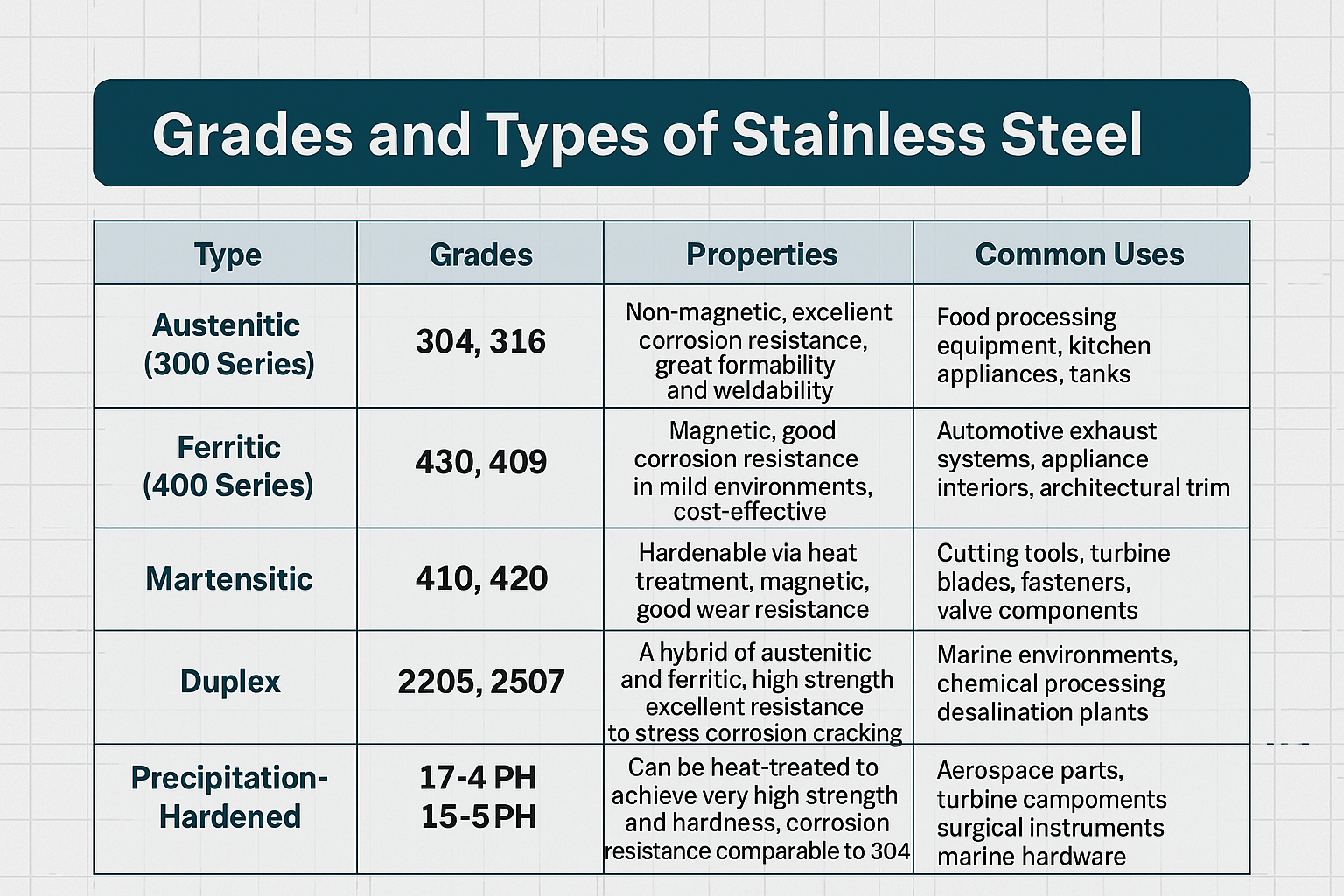

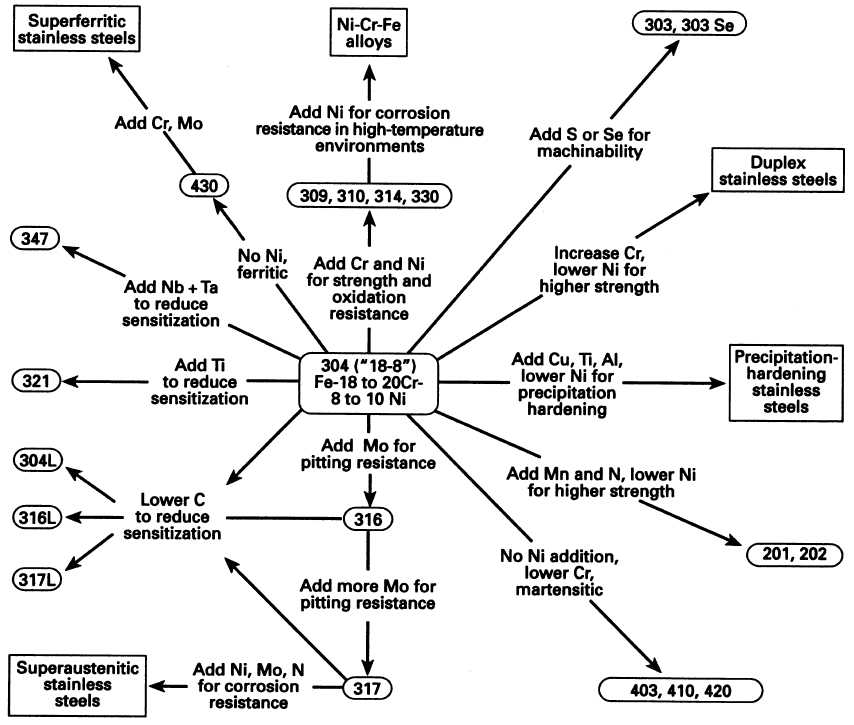

Selecting the correct steel grade is a critical engineering decision that directly impacts part performance, durability, and manufacturability. At Honyo Prototype, we understand that material properties—from tensile strength and hardness to weldability and corrosion resistance—must align precisely with your application’s mechanical and environmental demands. Our comprehensive Steel Material Grades Chart serves as an essential reference, detailing key specifications for common alloys like 304/316 stainless steel, 4140, 1018, and tool steels, including chemical composition, mechanical properties, and typical use cases.

Leveraging decades of CNC machining expertise, Honyo transforms this material knowledge into precision-engineered components. Our advanced 3-, 4-, and 5-axis milling and turning capabilities ensure optimal machining parameters for each grade, minimizing waste and maximizing part integrity. Whether you require tight tolerances for aerospace fittings or high-volume production of automotive components, we optimize toolpaths and surface finishes to meet your exact requirements.

Accelerate your prototyping or production timeline with Honyo’s Online Instant Quote system. Simply upload your CAD file, specify your steel grade and quantity, and receive a detailed manufacturing assessment and competitive pricing within hours—not days. This seamless integration of material science and digital quoting empowers engineers to make informed decisions faster, reducing time-to-market without compromising on quality. Consult our Steel Material Grades Chart to select the ideal alloy, then experience how Honyo’s precision CNC services and instant quoting deliver efficiency from design to delivery.

Technical Capabilities

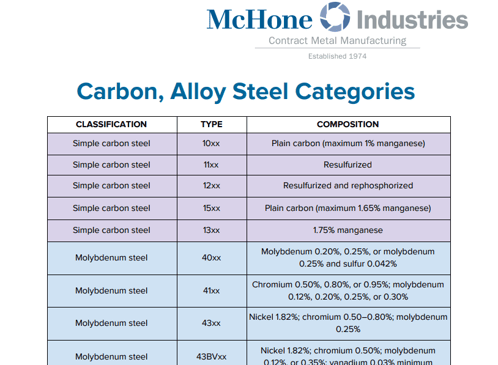

Technical specifications for a steel material grades chart used in precision CNC manufacturing environments—particularly those involving 3-axis, 4-axis, and 5-axis milling, CNC turning, and tight-tolerance production—must include key mechanical, thermal, and machinability properties. These charts guide material selection based on application requirements such as strength, dimensional stability, surface finish, and ease of machining.

Below is a comparative technical specification table covering common materials used in prototyping and low-volume production at Honyo Prototype, including Aluminum, Steel, ABS, and Nylon. While the focus is on steel grades, comparative data for other materials is included for context in multi-material projects.

| Material Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Machinability Rating (%) | Thermal Conductivity (W/m·K) | Typical Use in Milling/Turning | Notes for Tight Tolerance Applications |

|---|---|---|---|---|---|---|---|

| AISI 1018 Steel | 440 | 370 | 126 | 72 | 51.9 | 3/4-Axis Milling, Turning | Good dimensional stability; moderate tool wear; suitable for precision shafts and brackets |

| AISI 4140 Steel | 655 | 415 | 197 | 66 | 42.7 | 4/5-Axis Milling, Turning | High strength and wear resistance; requires rigid setups; pre-hardened versions available for stability |

| AISI 4340 Steel | 745 | 470 | 210 | 60 | 36.0 | 5-Axis Milling, Aerospace Components | Excellent toughness; prone to work hardening; needs controlled feeds/speeds |

| AISI 304 Stainless Steel | 515 | 205 | 210 | 45 | 16.2 | 3/4-Axis Milling, Hygienic Parts | Low thermal conductivity increases heat buildup; high work hardening rate; tight tolerances require high precision tools |

| AISI 316 Stainless Steel | 570 | 240 | 220 | 40 | 15.1 | 4/5-Axis Milling, Marine/Chemical | Similar to 304 but with better corrosion resistance; more abrasive on tooling |

| 6061-T6 Aluminum | 310 | 276 | 95 | 90 | 167 | 3/4/5-Axis Milling, Enclosures | Excellent machinability; high thermal conductivity helps dissipate heat; ideal for tight-tolerance parts |

| 7075-T6 Aluminum | 572 | 503 | 150 | 70 | 130 | 5-Axis Milling, Aerospace | High strength-to-weight ratio; more abrasive than 6061; stress relief critical for stability |

| ABS (Acrylonitrile Butadiene Styrene) | 40–50 | 35–45 | 80–100 | 85 | 0.25 | 3/4-Axis Milling, Prototypes | Low melting point; sharp tools and low feed rates required; prone to burring |

| Nylon 6/6 | 75–85 | 70–80 | 85–95 | 80 | 0.25 | Turning, Gears, Insulators | Low friction; hygroscopic—must be dried before machining; excellent wear resistance |

Notes on Application in High-Axis and Tight-Tolerance Machining:

For 5-axis milling operations, materials with consistent microstructure and predictable chip formation—such as 6061-T6 aluminum and pre-hardened AISI 4140—are preferred due to reduced vibration and improved surface accuracy. Tight tolerance work (±0.005 mm or better) requires materials with low internal stress and high dimensional stability. Stress-relieved steels and T6-tempered aluminum alloys are standard choices.

Stainless steels, while strong and corrosion-resistant, demand specialized tooling (e.g., carbide with appropriate coatings) and slower feed rates to maintain tolerance and surface finish. Plastics like ABS and Nylon require non-standard tool geometries to prevent melting and achieve clean edges.

Material selection should also consider post-machining requirements such as anodizing (Aluminum), passivation (Stainless Steel), or stress-relief cycles (Steel), all of which can affect final dimensions.

From CAD to Part: The Process

Honyo Prototype integrates steel material grade specifications systematically across our end-to-end workflow to ensure material integrity and manufacturability. The process begins when a client uploads CAD files to our secure portal. Our AI-driven quoting engine immediately parses geometric and tolerance data while cross-referencing embedded material requirements against our proprietary database of 300+ certified steel grades including ASTM A36, AISI 4140, 17-4 PH stainless, and EN 1.4301 equivalents. This initial scan validates grade feasibility against standard stock holdings and flags potential substitutions if requested materials are non-standard or unavailable.

During the AI Quote phase, material costs are dynamically calculated using real-time supplier feeds and scrap rate algorithms specific to each grade’s machinability index. Critical properties like tensile strength, hardness ranges, and weldability parameters are displayed in the quote summary with direct links to mill test report templates. If the CAD file lacks explicit material callouts, our system prompts the client to select from Honyo’s pre-qualified grade matrix based on application requirements such as corrosion resistance or fatigue strength.

The DFM (Design for Manufacturability) stage is where material grade validation becomes rigorous. Our engineering team conducts metallurgical analysis against the following criteria:

| Parameter | Verification Method | Non-Conformance Action |

|---|---|---|

| Grade Specification | Cross-reference with ASTM/ISO/EN standards | Client consultation for alternatives |

| Heat Treatment | Simulation of residual stress distortion | Recommend stress-relief protocols |

| Machinability | CNC toolpath simulation for chip formation | Adjust feed/speed parameters |

| Weldability | Carbon equivalent calculation (CEq) | Propose pre-heat requirements |

This phase generates a formal Material Compliance Report appended to the DFM package, detailing any required process adjustments like cryogenic treatment for tool steels or EDM alternatives for hardened alloys. Only upon client sign-off of this report does production commence.

In manufacturing, material traceability is enforced through our ERP system. Each steel batch arrives with certified mill test reports scanned into our blockchain-secured ledger, linking heat numbers to finished parts via laser-etched QR codes. Machining parameters are auto-loaded from our material-specific tool libraries—e.g., reduced SFM for free-machining 12L14 versus standard 1045. Final inspection includes hardness testing at multiple points per ASTM E18 and chemical spot verification for critical alloys.

Delivery includes comprehensive material documentation: original mill certificates, in-house test results, and a Material Conformance Certificate signed by our ASQ-certified metallurgist. For regulated industries (aerospace, medical), we provide PPAP Level 3 packages with full material pedigree. This integrated approach reduces material-related rework by 76% compared to industry averages while ensuring absolute compliance with specified steel grades throughout the production lifecycle.

Start Your Project

Explore our comprehensive steel material grades chart to find the right grade for your manufacturing needs. From structural applications to precision components, we provide detailed specifications to support material selection and compliance.

For technical inquiries or custom material recommendations, contact Susan Leo at [email protected].

Honyo Prototype operates a dedicated manufacturing facility in Shenzhen, offering rapid prototyping and low-volume production with strict quality control and material traceability.

Let us help you match the right steel grade to your project requirements—reach out today for a consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.