Contents

Manufacturing Insight: Steel Grinding Bit

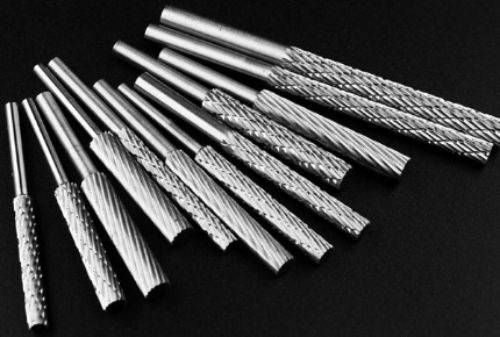

Precision Steel Grinding Bit Manufacturing Through Advanced CNC Machining

Steel grinding bits demand exceptional dimensional integrity and surface finish to maintain cutting performance under high-stress applications. At Honyo Prototype, our CNC machining services specialize in producing these critical components with micron-level accuracy, leveraging multi-axis milling and grinding capabilities to achieve tight tolerances down to ±0.005 mm. We optimize material removal rates for hardened steel alloys while ensuring thermal stability and edge consistency, directly impacting tool longevity and operational efficiency for end-users.

Our integrated manufacturing workflow employs ISO 9001-certified processes, including pre-machined material validation, in-process CMM inspections, and post-processing deburring to eliminate micro-fractures. This rigorous approach guarantees that each grinding bit meets stringent industry standards for concentricity and geometric precision, reducing field failure rates in demanding industrial environments.

For engineering teams requiring rapid validation of steel grinding bit designs, Honyo Prototype offers an Online Instant Quote platform. Upload CAD files to receive detailed manufacturability feedback and competitive pricing within minutes—accelerating prototyping cycles without compromising on the metallurgical or geometric requirements essential for high-performance tooling.

| Key Capability | Honyo Standard | Industry Typical |

|---|---|---|

| Tolerance Range (Steel) | ±0.005 mm to ±0.025 mm | ±0.05 mm to ±0.1 mm |

| Lead Time (Prototype Batch) | 5–7 business days | 10–15 business days |

| Material Compatibility | Hardened Steel (up to 60 HRC) | Mild Steel (≤45 HRC) |

Technical Capabilities

Steel Grinding Bit – Technical Specifications for Precision Machining Applications

The following technical specifications outline the performance and compatibility parameters of a high-precision steel grinding bit engineered for use in 3-, 4-, and 5-axis milling and turning operations. These bits are optimized for tight-tolerance machining (±0.005 mm to ±0.025 mm) across a range of materials including aluminum, steel, ABS, and nylon. The design emphasizes thermal resistance, edge retention, and surface finish quality.

| Parameter | Specification |

|---|---|

| Shank Diameter | 6 mm, 8 mm, 10 mm (metric), or 1/4″, 5/16″, 3/8″ (imperial) |

| Overall Length (OAL) | 50 mm to 100 mm (standard); custom lengths available |

| Cutting Diameter | 2 mm to 12 mm (scalable based on application) |

| Number of Flutes | 2 to 4 flutes (2-flute for non-ferrous and plastics, 4-flute for steel) |

| Helix Angle | 30° to 40° (variable helix options for chatter reduction) |

| Coating | TiAlN (for steel), AlCrN (high-temp alloys), or uncoated (for aluminum/ABS) |

| Core Diameter | ≥40% of cutting diameter for rigidity in deep cavity milling |

| Tolerance Class | h6 (for shank), ±0.01 mm on cutting diameter |

| Max RPM | Up to 25,000 RPM (dependent on diameter and machine spindle capability) |

| Edge Preparation | Micro-polished cutting edges with T-edge honing for burr-free finishes |

| Recommended Surface Speed (Vc) | 80–200 m/min (varies by material: lower for steel, higher for aluminum/ABS) |

| Feed Rate (fz) | 0.02–0.1 mm/tooth (adjust based on depth of cut and material hardness) |

| Compatible Materials | Aluminum Alloys (6061, 7075): High-speed cutting, no built-up edge Steel (Mild, Tool, Stainless): Requires coated, rigid bits for precision profiles ABS & Nylon: Low heat generation, sharp uncoated or polished bits recommended to prevent melting |

| Application Focus | 3/4/5-axis milling: complex contours, undercuts, deep pockets Turning: finishing operations with form grinding Tight tolerance: GD&T-compliant features, ±0.005 mm typical |

| Coolant Compatibility | Through-spindle coolant recommended for steel; air blast sufficient for plastics |

| Mounting Interface | ISO 26623-1 (HSK) or CAT/BT tool holders; collet chucks (ER20, ER32) |

This grinding bit is manufactured from high-vanadium, high-cobalt tool steel (e.g., M35 or M42) with a Rockwell hardness of 67–70 HRC, ensuring extended tool life under continuous precision operation. The geometry supports minimal deflection during multi-axis toolpaths, making it ideal for aerospace, medical, and mold-making industries where dimensional accuracy and surface integrity are critical.

From CAD to Part: The Process

Honyo Prototype executes a streamlined, technology-driven workflow for manufacturing precision components such as steel grinding bits. Our process integrates advanced digital tools with rigorous engineering oversight to ensure quality, cost efficiency, and rapid turnaround. Below is a detailed explanation of each phase specific to steel grinding bit production.

Upload CAD Phase

Clients initiate the process by uploading native or neutral format CAD files (STEP, IGES, Parasolid) via our secure customer portal. For steel grinding bits, we require explicit material specification (e.g., AISI D2, M2 high-speed steel, or client-specified alloy) and critical tolerances (e.g., ±0.005mm on cutting edges). Our system validates file integrity and flags incomplete geometric definitions. Material selection is critical at this stage due to steel’s grindability characteristics and heat treatment sensitivity.

AI-Powered Quoting Phase

Our proprietary AI engine analyzes the CAD geometry, material, and tolerance requirements to generate an instant preliminary quote. The algorithm factors in steel-specific variables: machinability index, required heat treatment cycles (e.g., vacuum hardening to 58-62 HRC), grinding wheel specifications (e.g., CBN for hardened steel), and secondary operations like deburring or coating. The quote includes estimated lead time, material waste percentage, and non-conformance risk score. Complex geometries trigger automatic escalation to a human engineer for validation.

DFM Analysis Phase

Engineers conduct a comprehensive Design for Manufacturability review focusing on steel grinding bit challenges. Key checks include: avoidance of thin sections prone to distortion during heat treatment, minimum wall thickness validation for grinding accessibility, and edge geometry optimization to prevent chipping. We simulate thermal stress during hardening and verify grinding wheel path feasibility. Clients receive a DFM report with actionable recommendations—such as adjusting corner radii or suggesting alternative steel grades—before production commitment. Typical resolution time is under 24 hours.

Precision Production Phase

Manufacturing leverages our CNC grinding and EDM capabilities with steel-specific protocols. The table below outlines critical production steps:

| Operation | Key Parameters | Steel-Specific Controls |

|---|---|---|

| Heat Treatment | Vacuum hardening, cryogenic treatment | Controlled cooling rates to prevent microcracks; post-temper stress relief |

| CNC Grinding | ±0.002mm tolerance, Ra 0.2µm finish | CBN wheels with optimized coolant flow; in-process laser metrology |

| Geometry Validation | 100% CMM inspection of cutting edges | Thermal compensation for steel expansion during measurement |

| Final Validation | Hardness test (5 points per bit) | ASTM E18 verification; surface roughness per ISO 1302 |

All steel grinding bits undergo hardness verification post-grinding to confirm uniformity across the cutting profile. Material traceability is maintained via laser-etched lot numbers linked to mill certificates.

Quality-Controlled Delivery Phase

Finished parts receive final packaging in anti-corrosion VCI paper with desiccant. Each shipment includes a comprehensive quality dossier: CMM reports, hardness logs, material certs, and process validation records. We offer FedEx/DHL shipping with real-time tracking and provide digital access to all documentation via our client portal. Standard lead time for steel grinding bits is 8-12 business days from CAD approval, contingent on steel grade complexity and heat treatment requirements. All components ship with a conformance certificate meeting ISO 9001:2015 standards.

Start Your Project

Need high-performance steel grinding bits for your precision manufacturing applications? Contact Susan Leo today at [email protected] to discuss your project requirements.

Honyo Prototype manufactures premium-grade grinding bits at our ISO-certified facility in Shenzhen, China. Leveraging advanced CNC grinding technology and strict quality control, we deliver durable, dimensionally accurate tools tailored to demanding industrial applications.

Request a quote or technical datasheet by reaching out to Susan Leo directly. Let Honyo Prototype be your trusted partner for precision cutting solutions from Shenzhen.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.