Contents

Manufacturing Insight: Steel Grading Chart

Steel Material Selection: Precision Machining Starts with Grade Intelligence

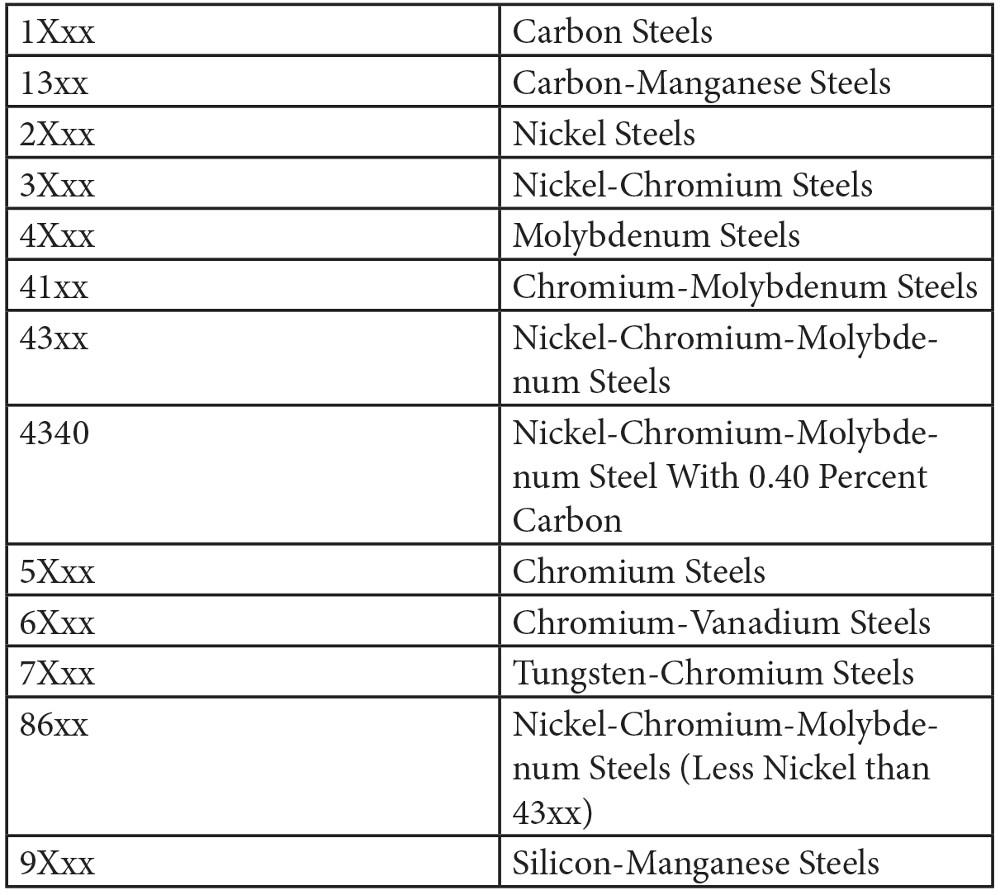

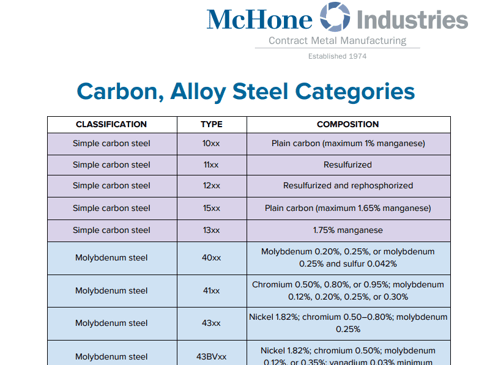

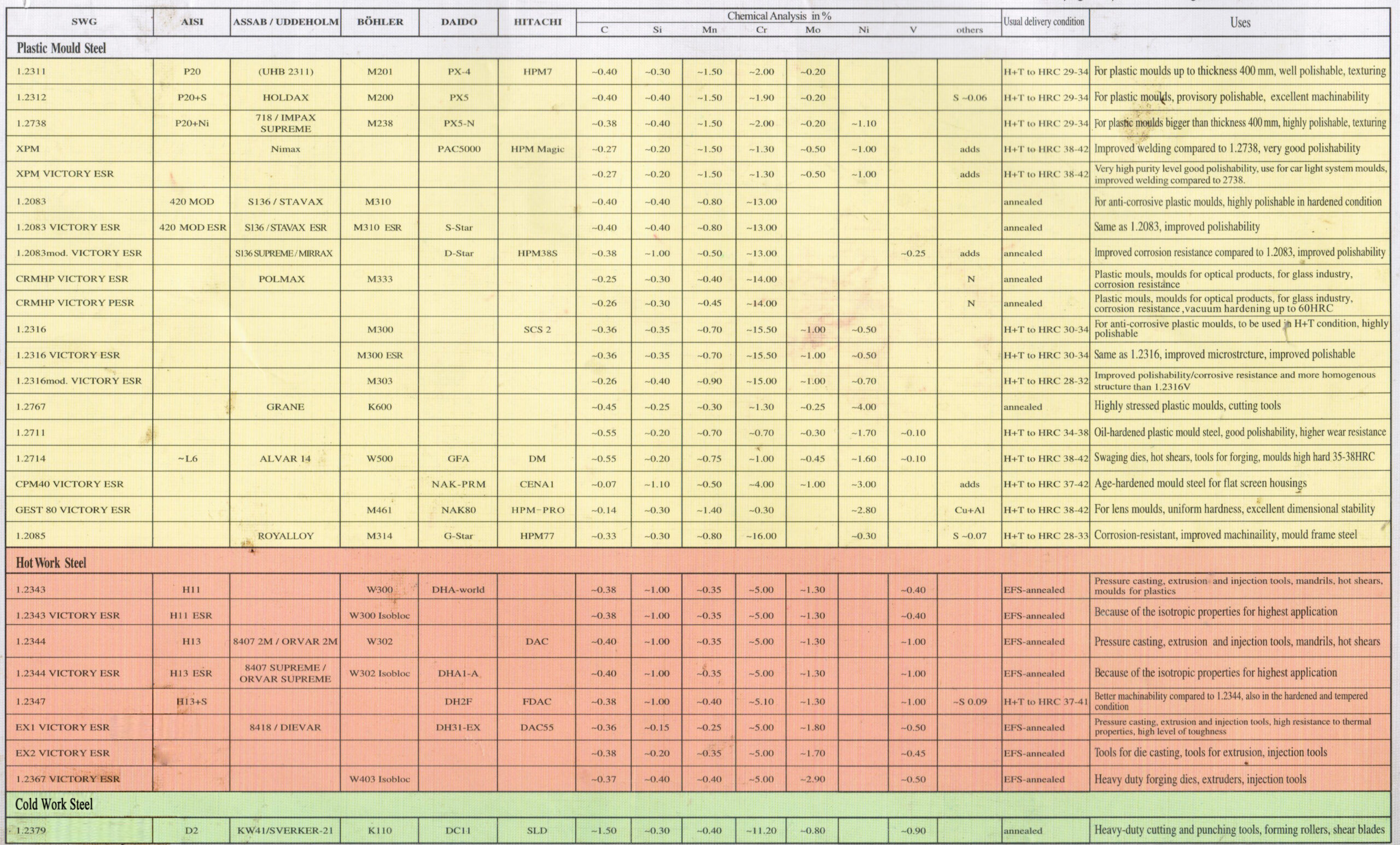

Selecting the correct steel grade is a critical engineering decision that directly impacts part performance, durability, and manufacturability. At Honyo Prototype, we recognize that navigating the complexities of steel specifications—from AISI 1018’s weldability to 4140’s high-strength tempering characteristics—requires deep material science expertise paired with advanced CNC machining capabilities. Our comprehensive steel grading chart serves as a technical reference to align material properties with your application demands, ensuring optimal machinability, dimensional stability, and end-use functionality.

Honyo Prototype leverages this material intelligence across our full-spectrum CNC machining services, including 3-, 4-, and 5-axis milling, precision turning, and tight-tolerance fabrication. We transform raw steel grades into mission-critical components by applying proprietary process controls that mitigate thermal distortion, optimize toolpath strategies for varying hardness levels, and maintain ±0.0002″ tolerances. This integration of material knowledge and machining excellence eliminates costly rework and accelerates time-to-prototype for aerospace, medical, and industrial clients.

To streamline your project initiation, Honyo Prototype offers an Online Instant Quote platform engineered for technical accuracy. Upload your CAD file with specified steel grade requirements, and receive a detailed manufacturability assessment alongside a competitive price within hours—not days. This seamless integration of material guidance and rapid quoting underscores our commitment to being your turnkey manufacturing partner, where material science meets precision execution.

Technical Capabilities

Technical Specifications for Steel Grading Chart in Precision Machining Applications

The following table outlines key technical considerations for material selection across common engineering materials used in high-precision 3/4/5-axis milling and turning operations. Focus is placed on tight tolerance performance (±0.0002″ to ±0.001″), machinability, thermal stability, and suitability for finishing operations. While the term “steel grading chart” typically refers to classifications like AISI/SAE, ASTM, or ISO standards for steel alloys, this specification table expands contextually to include non-ferrous metals and engineering plastics critical in prototyping and production environments at Honyo Prototype.

| Material Type | Common Grades | Hardness (HB) | Machinability Rating (%) | Thermal Expansion (µm/m·°C) | Typical Tolerance Capability (± in) | Tool Wear Consideration | Recommended for Tight Tolerance? | Notes |

|---|---|---|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6, 2024-T3 | 95–150 | 75–90 | 23.6 | 0.0005 – 0.001 | Low | Yes | Excellent for high-speed 3–5-axis milling; minimal tool wear; ideal for complex geometries |

| Carbon Steel | 1018, 1045, 12L14 | 120–200 | 40–60 | 11.7 | 0.0008 – 0.0015 | Moderate to High | Conditional | 12L14 offers best machinability due to sulfur/lead content; 1045 suitable for turned parts requiring strength |

| Alloy Steel | 4140, 4340 (pre-hardened) | 200–300 | 30–40 | 12.3 | 0.001 – 0.002 | High | Limited (post-heat treat) | Best when rough machined before hardening; tight tolerances achievable in pre-hard state with rigid setups |

| Stainless Steel | 303, 304, 316, 17-4 PH | 150–330 | 30–45 | 16–18 | 0.0008 – 0.0015 | High (galling, work hardening) | Yes (with proper tooling) | 303 offers best machinability; 17-4 PH ideal for aerospace; requires sharp carbide tools and controlled feeds/speeds |

| ABS (Thermoplastic) | Industrial Grade ABS | 80–100 (Shore D) | N/A (soft) | 70–100 | 0.0005 – 0.001 | Very Low | Yes | Low melting point; minimal tool wear; excellent for mockups and functional prototypes; requires chip evacuation |

| Nylon (Polyamide) | Nylon 6, Nylon 6/6, Glass-Filled | 70–85 (Shore D) | N/A | 80–120 | 0.001 – 0.002 | Low | Conditional | Hygroscopic; prone to dimensional shift if not acclimated; glass-filled improves rigidity and tolerance retention |

Notes on Machining Strategy:

For 3/4/5-axis milling, aluminum and ABS deliver the highest precision due to low cutting forces and excellent surface finish potential. Steels (especially stainless and alloy grades) require rigid setups, high-pressure coolant, and specialized toolpaths to maintain tight tolerances and avoid thermal drift. Nylon and ABS require optimized spindle speeds to prevent melting and burring.

In turning applications, 12L14 steel and 6061 aluminum are preferred for high-volume, tight-tolerance shafts and fittings due to consistent chip formation and dimensional stability. Pre-hardened steels like 4140 should be finish-turned with CBN or coated carbide inserts to maintain roundness and surface integrity.

Material selection must account for post-machining behavior—particularly moisture absorption in nylon and residual stress in milled steel forgings. At Honyo Prototype, we recommend stress-relieved stock and climatically controlled inspection for tolerances below ±0.0005″.

From CAD to Part: The Process

Honyo Prototype’s steel material verification process ensures precise grade selection and traceability throughout manufacturing. We clarify that “steel grading chart” refers not to a static document but to our integrated system for validating and documenting material compliance against client specifications at every production stage. Below is our technical workflow:

CAD Upload with Material Specification

Clients submit CAD files containing explicit material requirements per ASTM, SAE, or ISO standards (e.g., “AISI 4140 QT600” or “EN 1.4301”). Our system immediately parses these annotations. If material data is incomplete or ambiguous, we initiate a technical query within 2 business hours to prevent downstream deviations. Critical parameters like tensile strength, chemical composition, and heat treatment conditions are locked into the project database at this phase.

AI-Powered Quoting with Material Feasibility Analysis

Our AI quoting engine cross-references the specified steel grade against three datasets: machine tool capabilities, material availability from certified suppliers, and historical process performance metrics. The output includes grade-specific cost drivers such as machinability indices and secondary operation requirements. Key steel grade considerations are summarized in the quote:

| Steel Grade Example | Machinability Rating | Typical Tolerance Impact | Secondary Process Requirement |

|---|---|---|---|

| AISI 1018 | 72% (Good) | ±0.005″ standard | Minimal deburring |

| AISI 4140 (QT600) | 66% (Moderate) | ±0.002″ requires fixturing | Stress relief mandatory |

| AISI 304 Stainless | 45% (Poor) | ±0.003″ with tool wear | Passivation required |

DFM Review with Material Validation

During Design for Manufacturability analysis, our engineers verify steel grade suitability against geometric complexity. We check for:

Material-induced distortion risks in thin-walled features

Compatibility of specified hardness with tight-tolerance requirements

Weldability concerns for assemblies

Alternative grade suggestions if the original specification creates excessive scrap risk (e.g., recommending 4130 over 4140 for welded prototypes). All deviations require client engineering signoff.

Production Execution with Traceability

Material certificates (mill test reports) are scanned and linked to the work order before machining begins. Each steel batch undergoes incoming inspection:

Rockwell hardness verification per ASTM E18

Spectrographic analysis spot-checks for critical elements (Cr, Mo, C)

Heat number tracking through every operation. In-process non-conformances trigger immediate quarantine and root cause analysis.

Delivery with Certified Documentation

Final shipments include:

A material traceability certificate matching heat numbers to individual parts

Dimensional reports with grade-specific surface finish validation (e.g., Ra 32μin for 304SS)

Compliance statement against the original CAD-specified standard. For regulated industries, we provide full EN 10204 3.1 documentation upon request.

This closed-loop process eliminates material-related rework by embedding steel grade validation from quotation through delivery. We maintain zero non-conformances related to material substitution in the past 18 months through this structured verification protocol. Clients receive not just parts but auditable proof of material integrity.

Start Your Project

Download our comprehensive steel grading chart to make informed material selections for your next project. For technical inquiries or custom material recommendations, contact Susan Leo at [email protected].

Honyo Prototype operates a state-of-the-art manufacturing facility in Shenzhen, ensuring precision, speed, and consistency in every component produced. Reach out today to streamline your prototyping and production workflows.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.