Contents

Manufacturing Insight: Steel Finish Types

Steel Finish Types: Precision Engineering for Performance-Critical Applications

Selecting the appropriate steel finish is a fundamental engineering decision that directly impacts component functionality, durability, and compliance in demanding industrial environments. Beyond aesthetics, surface integrity influences fatigue resistance, corrosion behavior, wear characteristics, and mating part performance. At Honyo Prototype, our advanced CNC machining capabilities ensure precise control over surface finish parameters, transforming raw steel into mission-critical components that meet exacting functional requirements.

Our multi-axis CNC milling, turning, and grinding processes are optimized to achieve consistent, repeatable finishes—from tight-tolerance ground surfaces (Ra 0.2 µm) to controlled machined textures—while maintaining dimensional accuracy within ±0.005 mm. We leverage rigorous in-process metrology and material-specific toolpath strategies to eliminate secondary operations where feasible, reducing lead times without compromising integrity. Every finish specification is treated as an integral part of the manufacturing blueprint, not an afterthought.

Accelerate your prototyping or low-volume production with Honyo’s Online Instant Quote system. Upload CAD files to receive precise, transparent pricing for CNC-machined steel components with your required finish within hours—enabling faster design validation and time-to-market for engineered solutions.

Technical Capabilities

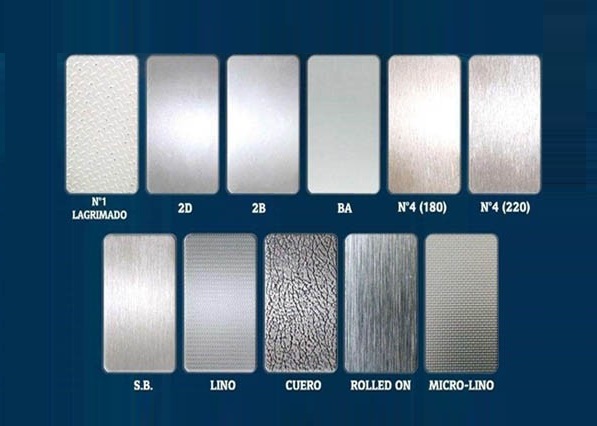

Technical finish types in precision machining—particularly in 3/4/5-axis milling and turning—are critical for achieving tight tolerances, optimal part function, and surface performance. The choice of surface finish depends on material properties (e.g., machinability of Aluminum vs. Steel or thermal behavior of ABS and Nylon), functional requirements, and post-processing needs. Below is a comparative table outlining common steel finish types applicable across materials used in Honyo Prototype’s precision manufacturing workflows.

| Finish Type | Process Description | Typical Ra (µm) | Applicable Materials | Machining Compatibility | Notes on Tight Tolerance (±0.005 mm or better) |

|---|---|---|---|---|---|

| As-Machined | Standard CNC finish with visible tool marks | 3.2 – 6.3 | Aluminum, Steel, ABS, Nylon | 3/4/5-axis Milling, Turning | Acceptable for non-critical surfaces; may require edge breaking |

| Smooth Machined | Optimized toolpaths, reduced step-over, high-speed finishing | 1.6 – 3.2 | Aluminum, Steel | 4/5-axis Milling preferred | Suitable for tight tolerance components; minimal post-work |

| Fine Surface Finish | Polished or diamond-turned surface; secondary operation | 0.4 – 0.8 | Aluminum, Steel | 5-axis Milling, Precision Turning | Used in sealing surfaces, optics, or high-fit assemblies |

| Bead Blast (Medium) | Uniform matte texture via glass bead media | 1.0 – 2.0 | Aluminum, Steel | Post-machining only | Improves aesthetics; may affect dimensional control if not masked |

| Anodized (Type II) | Electrochemical coating (Aluminum only) | 0.8 – 1.6 | Aluminum only | Post-machining; pre-clean critical | Adds corrosion resistance; dimensional gain ~±0.005 mm on surfaces |

| Powder Coating | Electrostatic paint application + cure | 5.0 – 10.0 | Steel, Aluminum | Post-machining; masking required | Not for tight tolerance surfaces; used for enclosures |

| Passivation | Chemical treatment for stainless steel | 0.8 – 1.6 | Stainless Steel only | Post-machining | Enhances corrosion resistance without altering dimensions |

| As-Turned (Precision) | High-feed turning with sharp inserts | 0.8 – 1.6 | Steel, Aluminum | CNC Turning | Capable of holding ±0.003 mm on diameters; ideal for shafts |

Notes:

Aluminum: High thermal conductivity and softness allow for fine finishes but require proper chip evacuation and tool selection to prevent built-up edge.

Steel (including stainless): Harder materials necessitate rigid setups and coated carbide tools; fine finishes often require post-process treatments.

ABS & Nylon: Thermoplastics are machined with sharp, polished tools at high speeds and low feed to avoid melting; finishes are typically as-machined due to low wear requirements.

Tight tolerance work demands stable workholding, thermal compensation, and in-process metrology—especially in 5-axis environments where angular accuracy is critical.

For mission-critical components, Honyo Prototype recommends combining fine surface finish specifications with GD&T callouts and first-article inspection reports to ensure compliance with functional and assembly requirements.

From CAD to Part: The Process

Honyo Prototype Steel Finish Integration Process

Honyo Prototype integrates steel finish specifications throughout our end-to-end workflow, ensuring surface requirements are validated and executed from initial design to final delivery. This is not a standalone process but a critical parameter embedded within each phase of our standard manufacturing sequence. Below is a technical breakdown of how steel finish types are managed across the workflow.

Upload CAD

Upon CAD file submission, our system performs initial geometry and annotation analysis. Steel finish requirements must be explicitly defined in the model or accompanying documentation per ISO 1302 or ASME Y14.36M standards. Acceptable inputs include surface roughness callouts (e.g., Ra 0.8 µm), grit specifications (e.g., 120 grit bead blast), or finish codes (e.g., ASTM A967 for passivation). Unspecified finishes default to our standard machined finish (Ra 3.2 µm), which may not meet functional requirements.

AI Quote Generation

Our AI engine cross-references finish specifications against material properties, geometric complexity, and tolerance zones. For instance, electropolishing on 304 stainless steel triggers checks for minimum wall thickness (≥0.5mm) and exclusion of sharp internal corners. The quote explicitly lists finish feasibility, cost impact, and lead time adjustments. Critical constraints are flagged here—such as the incompatibility of powder coating with tight-tolerance bores (<±0.05mm)—preventing downstream rework.

DFM Review

During Design for Manufacturability analysis, our engineers validate finish requirements against production capabilities. Key considerations include:

| Finish Type | DFM Constraints | Honyo Capability Limits |

|---|---|---|

| Bead Blasting | Minimum radius 0.2mm; no blind holes | Grit range: 80–320 |

| Electropolishing | Material must be non-ferrous or specific alloys | Max part size: 600x400x300mm |

| Passivation (ASTM) | Requires 300-series SS; no carbon steel alloys | Nitric acid concentration tolerance ±2% |

| Powder Coating | Requires thermal stability >180°C | Film thickness 60–120µm |

Unresolvable conflicts (e.g., mirror polish on porous cast steel) trigger a formal Engineering Change Request with alternative finish recommendations.

Production Execution

Finish application occurs in dedicated cleanrooms with ISO Class 8 compliance for critical processes like passivation. Steel substrates undergo:

1. Pre-treatment: Degreasing and abrasive blasting per finish type

2. Process-specific execution: e.g., electrochemical baths for electropolishing with real-time conductivity monitoring

3. In-process verification: Surface roughness measured via profilometer (calibrated to ISO 4287) at 3+ locations per part

All parameters are logged in our MES for full traceability, including bath chemistry records for plating processes.

Delivery Assurance

Finished parts undergo final inspection against the original finish specification. Reports include:

Surface roughness certification (with measurement points mapped to CAD)

Passivation validation via copper sulfate testing per ASTM A967

Visual inspection under 1000-lux lighting for defects

Parts are packaged in VCI paper for corrosion-sensitive finishes (e.g., bare carbon steel) with humidity indicators. Documentation includes material certs, process logs, and finish verification data for audit compliance.

This integrated approach ensures steel finishes meet functional requirements while minimizing iteration. Critical to success is early specification clarity during CAD upload—ambiguities here increase DFM resolution time by 35% based on our Q2 2024 operational data. We recommend clients reference our Finish Specification Guide (HNY-PRC-007) during design to optimize manufacturability.

Start Your Project

Explore our range of precision steel finish types engineered for superior performance and durability. From matte to mirror finishes, we deliver surface treatments tailored to your functional and aesthetic requirements.

All manufacturing is conducted at our ISO-certified factory in Shenzhen, ensuring strict quality control and consistency across production runs.

For technical specifications or project consultation, contact Susan Leo at [email protected]. Let’s refine your next component together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.