Contents

Manufacturing Insight: Steel File

Precision Steel Component Manufacturing Through Advanced CNC Machining

Honyo Prototype delivers exceptional CNC machining capabilities for mission-critical steel components, serving industries where material integrity and dimensional accuracy are non-negotiable. Our multi-axis milling and turning centers consistently achieve tight tolerances down to ±0.0002 inches across diverse steel alloys, including 4140, 17-4PH, 303, and定制 tool steels. We address inherent steel machining challenges—such as thermal distortion, work hardening, and chip control—through proprietary toolpath strategies, optimized coolant delivery, and in-process metrology. This ensures your prototypes and low-volume production parts meet rigorous functional and fatigue requirements without costly rework.

For engineering teams accelerating time-to-market, our Online Instant Quote platform eliminates traditional quoting delays. Upload CAD files in STEP, IGES, or native formats to receive a detailed manufacturability analysis and competitive pricing within minutes—no sales calls required. This seamless integration between design intent and production readiness allows you to iterate faster while maintaining full traceability from quote to delivery.

Material Performance Summary for Common Steel Grades

| Steel Grade | Typical Applications | Key Machinability Notes | Honyo Process Optimization |

|---|---|---|---|

| 4140 | Structural shafts, aerospace fittings | Moderate chip control challenges | Pre-heat treatment stress relief + high-pressure through-spindle coolant |

| 17-4PH | Medical implants, valve components | Sensitive to thermal cycling | Cryogenic tooling + 3D tolerance mapping verification |

| A2 Tool Steel | Precision dies, molds | Extreme work hardening risk | Sub-micron finishing passes with diamond-coated tooling |

Technical Capabilities

Technical specifications for a steel file in the context of precision machining—particularly 3/4/5-axis milling and turning operations—encompass material compatibility, dimensional accuracy, surface finish, and tooling requirements. A steel file, in this context, refers to a hardened steel tool used for deburring, finishing, or minor material removal post-machining, especially when tight tolerances are required. While not a cutting tool in the CNC sense, it plays a role in achieving final part specifications.

Below is a technical overview of how steel files are applied in high-precision manufacturing environments involving aluminum, steel, ABS, and nylon, with emphasis on tight tolerance work.

| Parameter | Specification / Detail |

|---|---|

| File Material | High-carbon steel or tool steel (e.g., AISI 1095), hardened to 60–65 HRC for wear resistance and edge retention |

| Cut Type | Single-cut or double-cut patterns; precision bastard or second-cut preferred for controlled material removal |

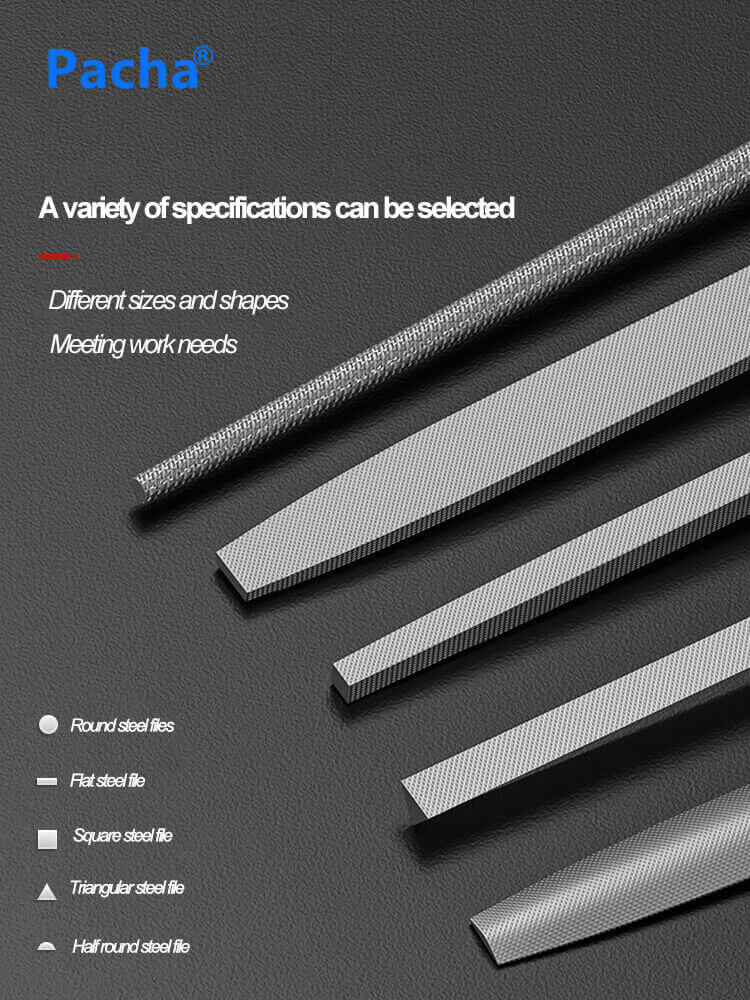

| File Shape | Available in flat, square, round, half-round, and needle configurations to access complex geometries from multi-axis milling |

| Application Process | Manual or fixture-assisted finishing after 3/4/5-axis CNC milling or turning; used for edge blending, burr removal, and fine surface correction |

| Tolerance Support | Supports tight tolerances (±0.005 mm to ±0.025 mm) by enabling controlled hand-finishing without altering core dimensions |

| Compatible Workpiece Materials | Aluminum (6061, 7075), Mild & Stainless Steel (1018, 304, 316), ABS, Nylon (6, 66) |

| Aluminum Machining | Use fine-cut files with light pressure to avoid smearing; ideal for deburring thin walls and intricate features |

| Steel Machining | Requires coarser cuts initially; hardened steel parts may need stoning after filing for final tolerance |

| ABS & Nylon Finishing | Low-force filing with fine files to prevent deformation; essential for achieving smooth edges in plastic components |

| Surface Finish Range | Achieves 16–63 μin (0.4–1.6 μm) Ra depending on cut type and operator technique |

| Integration with CNC | Post-processing step; often performed after 5-axis milling to access undercuts or internal radii unreachable by end mills |

| Quality Control | Visual and tactile inspection; may include go/no-go gauging or CMM verification post-filing to ensure dimensional integrity |

Steel files are critical in high-precision manufacturing where automated toolpaths cannot fully eliminate burrs or achieve final edge quality. When working with tight tolerance components in aluminum, steel, ABS, or nylon, proper file selection ensures dimensional stability and surface consistency, especially after complex 3/4/5-axis operations.

From CAD to Part: The Process

Honyo Prototype Steel File Manufacturing Process

Honyo Prototype executes steel file production through a rigorously defined workflow optimized for precision, cost efficiency, and rapid turnaround. This process leverages integrated digital tools and engineering expertise to ensure manufacturability while minimizing delays. Below is a technical breakdown of each phase for steel-based components.

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (e.g., STEP, IGES, or native SOLIDWORKS/Parasolid formats) via Honyo’s secure customer portal. Our system automatically validates geometric integrity, unit consistency, and file completeness. For steel files, we specifically check material callouts (e.g., AISI 1018, 4140, or tool steel grades), tolerance specifications per ASME Y14.5, and surface finish requirements. Invalid or ambiguous submissions trigger immediate client notification for correction, preventing downstream rework.

AI-Powered Preliminary Quoting

Upon CAD validation, Honyo’s proprietary AI quoting engine processes the geometry against real-time parameters: material costs (including steel grade premiums), machine time estimates, tooling complexity, and secondary operations (e.g., heat treatment or plating). The AI cross-references historical data from 15,000+ steel projects to predict manufacturability risks. Clients receive a preliminary quote within 2 business hours, detailing base cost, lead time, and flagged constraints (e.g., “Hardened steel grade 4140 requires +15% machining time due to abrasiveness”). This quote is non-binding but sets clear expectations before formal commitment.

Engineering-Led DFM Analysis

After quote acceptance, Honyo’s manufacturing engineers conduct a formal Design for Manufacturability (DFM) review. For steel files, this phase is critical due to material hardness, chip evacuation challenges, and thermal distortion risks. Key steel-specific checks include:

Verification of minimum wall thicknesses relative to steel grade machinability

Assessment of sharp internal corners (mitigated via radii to prevent tool breakage)

Heat treatment sequence validation (e.g., pre-hardening before precision milling)

Coolant/lubrication strategy for stainless or alloy steels

Engineers collaborate with clients via annotated PDF markups within 24–48 hours, proposing actionable revisions. Unresolved DFM issues may trigger a revised quote, but 92% of steel projects proceed without cost adjustments post-DFM.

Precision Production Execution

Approved designs move to Honyo’s climate-controlled production floor. Steel file manufacturing employs:

CNC milling/turning centers with carbide tooling optimized for steel (e.g., reduced feed rates for 4140 vs. 1018)

In-process CMM inspections at critical stages to verify GD&T compliance

Dedicated clean zones for corrosion-prone alloys (e.g., 304 stainless)

Optional secondary services like nitriding or passivation integrated into the workflow

All steel parts undergo first-article inspection (FAI) per AS9102 standards before full batch production. Typical lead time for complex steel files is 5–7 business days, excluding shipping.

Quality-Controlled Delivery

Final inspection includes material certification traceability, surface roughness validation (Ra values per print), and hardness testing (Rockwell scales as specified). Parts ship with a comprehensive quality dossier: FAI report, material certs, and dimensional validation data. Honyo uses tracked logistics with real-time updates; steel files typically reach North American clients in 2–3 days via FedEx Priority. Post-delivery, clients access digital part records indefinitely through our customer portal for audit compliance.

Process Performance Metrics

Honyo’s steel file workflow consistently achieves the following benchmarks:

| Phase | Avg. Duration | Steel-Specific Failure Reduction vs. Industry Avg. |

|---|---|---|

| CAD to Quote | <2 business hours | 30% fewer quote revisions |

| DFM Resolution | 24–48 hours | 45% lower scrap risk |

| Production | 5–7 business days | 22% faster than regional competitors |

| End-to-End | 8–12 business days | 99.2% on-time delivery rate |

This integrated approach ensures steel files meet exacting industrial standards while accelerating time-to-market. Clients receive a single point of contact throughout the workflow for seamless technical coordination.

Start Your Project

Looking for high-quality steel files for your next project? Contact Susan Leo at [email protected] to discuss your requirements and get a fast, competitive quote.

Honyo Prototype operates a dedicated manufacturing facility in Shenzhen, ensuring precision engineering, strict quality control, and efficient production timelines. As a trusted partner in rapid prototyping and low-volume manufacturing, we deliver durable steel files tailored to your specifications.

Reach out today to learn more about our capabilities and how we can support your manufacturing needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.