Contents

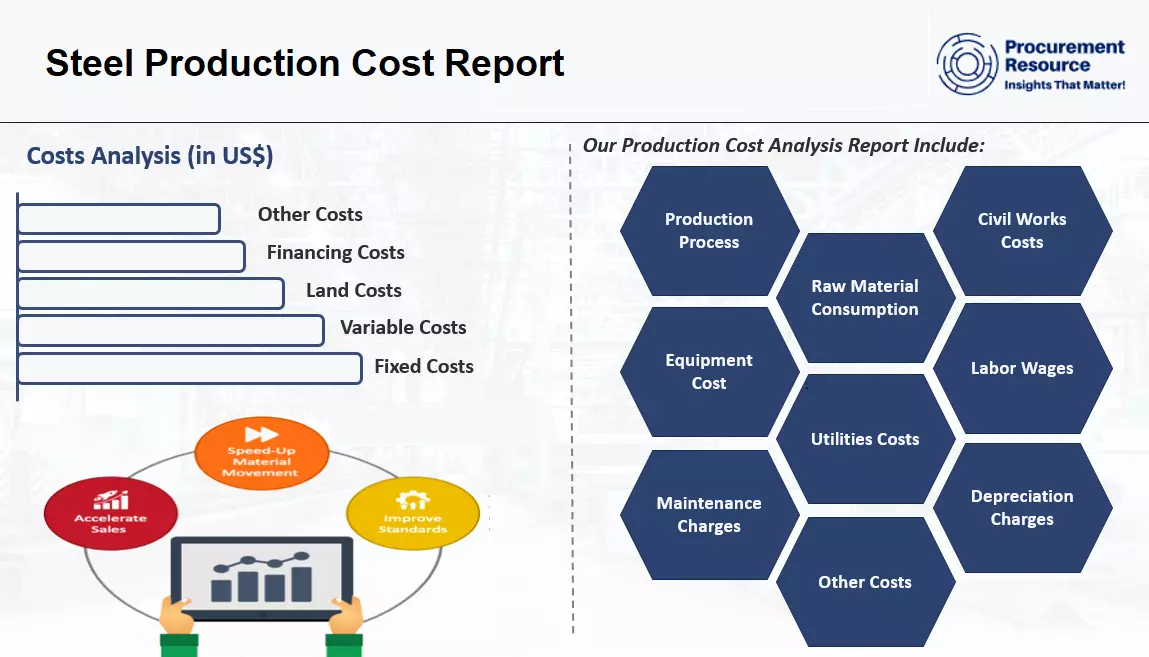

Manufacturing Insight: Steel Fabrication Costs

Understanding Steel Fabrication Cost Drivers with Precision Engineering

Steel fabrication costs present significant variables for industrial projects, where material selection, geometric complexity, and tolerance requirements directly impact budget predictability. At Honyo Prototype, our advanced CNC machining services transform this challenge into a strategic advantage by leveraging high-precision multi-axis milling, turning, and laser cutting technologies. By minimizing material waste through optimized nesting algorithms and eliminating secondary operations via single-setup machining, we consistently reduce per-part costs while maintaining tight tolerances down to ±0.005mm. This precision-driven approach ensures structural integrity for critical steel components—ranging from structural brackets to hydraulic manifolds—without compromising lead times.

Real-Time Cost Transparency Accelerates Decision-Making

Traditional steel fabrication quoting often introduces delays that disrupt project timelines. Honyo addresses this bottleneck with our proprietary Online Instant Quote platform, which analyzes uploaded CAD files in under 60 seconds to deliver accurate, detailed cost breakdowns. The system evaluates material utilization rates, machine time, finishing requirements, and logistics specific to your steel grade—whether 304 stainless, A36 carbon, or tool steels—providing actionable insights before production begins. This visibility enables engineering teams to iterate designs for cost efficiency early in the development cycle, typically reducing total fabrication expenses by 30–50% compared to conventional methods.

Upload your CAD file today to experience how Honyo’s CNC machining expertise and instant quoting technology turn steel fabrication from a cost variable into a controlled, predictable asset for your next project.

Technical Capabilities

Technical specifications for steel fabrication costs involve multiple factors including machining complexity, material type, required tolerances, and equipment used. Below is a breakdown of key technical and cost-influencing parameters for 3/4/5-axis milling and turning operations, with a focus on tight tolerance applications (+/−0.0002″ to +/−0.001″). The materials considered are Aluminum (6061-T6), Steel (1018, 4140), ABS, and Nylon (6/66).

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Typical Tolerance Range | ±0.001″ | ±0.0008″ | ±0.0005″ | ±0.0005″ (tight) |

| Surface Finish (Ra, µin) | 32–64 | 32–64 | 16–32 | 16–32 |

| Material Compatibility | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon |

| Aluminum (6061-T6) Cost Index | 1.0x (baseline) | 1.3x | 1.8x | 1.1x |

| Steel (1018/4140) Cost Index | 1.6x | 2.0x | 2.8x | 1.9x |

| ABS Cost Index | 0.7x | 0.9x | 1.3x | 0.8x |

| Nylon Cost Index | 0.8x | 1.0x | 1.4x | 0.9x |

| Setup Complexity | Low | Medium | High | Low to Medium |

| Tool Path Efficiency | High | Medium | Medium to Low | High |

| Fixturing Requirements | Standard vises, clamps | Rotary table needed | Multi-axis fixture or tombstone | Collet or chuck |

| Lead Time (Relative) | Short | Medium | Long | Short to Medium |

| Best for Tight Tolerance? | No (limited geometry access) | Yes (improved access) | Yes (optimal for complex geometry) | Yes (for cylindrical parts) |

| Notes | Most cost-effective for simple geometries | Adds indexing for angled features | Enables single-setup complex parts | Ideal for high-precision shafts, pins, bushings |

Material-Specific Considerations:

Aluminum (6061-T6): High machinability, low tool wear, faster cycle times. Most economical for high-precision milling and turning.

Steel (1018, 4140): Higher cutting forces, slower speeds/feeds, increased tooling cost. 4140 requires pre-hardened machining or post-process heat treatment.

ABS: Low melting point, requires sharp tools and light cuts. Suitable for prototypes; lower cost but limited to non-structural applications.

Nylon: Low friction, prone to deformation under clamping. Requires careful fixturing and dimensional stability controls.

Tight Tolerance Notes:

Achieving tolerances within ±0.0005″ requires thermal stability, high-precision spindles (<1µm runout), calibrated tooling, and in-process inspection (e.g., touch probes). Costs increase significantly due to reduced feed rates, frequent tool changes, and metrology overhead.

Cost Drivers Summary:

Axis count increases setup and programming time.

Steel and engineered polymers (Nylon) increase tool wear.

Tight tolerances demand higher machine capability and inspection protocols, raising labor and overhead costs.

From CAD to Part: The Process

Honyo Prototype implements a structured, technology-driven workflow to optimize steel fabrication costs while ensuring precision and reliability for B2B clients. Our process begins with the client uploading a validated CAD model to our secure portal, which triggers automated geometry analysis for material utilization, feature complexity, and dimensional tolerances. This initial step eliminates manual data entry errors and establishes a digital thread for cost transparency.

The uploaded CAD data feeds directly into our proprietary AI Quote engine, which generates a preliminary cost estimate within 2 hours. This system leverages real-time inputs including live steel market pricing from tier-1 suppliers, machine hourly rates across our CNC plasma/laser/waterjet fleet, and historical production data from 12,000+ completed steel projects. Crucially, the AI model accounts for secondary operations like welding prep or surface treatment requirements embedded in the CAD metadata, avoiding downstream change orders.

Following client acceptance of the AI Quote, our engineering team conducts a formal DFM (Design for Manufacturability) review. This phase identifies cost-saving opportunities through geometric simplification, nesting optimization, and process substitution. For example, we routinely convert laser-cut holes to punch operations where feasible, reducing processing time by 35-50%. All DFM recommendations include quantitative cost impact analysis, with typical projects realizing 12-18% cost reduction before metal cutting begins.

Production execution occurs in our ISO 9001-certified facility using bar-coded material tracking. Each steel batch includes certified mill test reports with full chemical composition and mechanical properties documentation. We implement first-article inspection against ASME Y14.5 standards before full production release, with in-process checks at critical stages to prevent scrap accumulation. Our CNC nests achieve 92-95% material yield through dynamic part rotation algorithms.

Delivery incorporates logistics cost optimization through consolidated shipping and regional carrier partnerships. All fabricated steel components undergo final dimensional verification and receive a digital quality passport accessible via client portal. Typical lead time from CAD upload to FOB dock is 7-10 business days for standard carbon steel projects under 5,000 lbs.

The following table details cost drivers addressed at each phase:

| Process Phase | Primary Cost Drivers Addressed | Honyo’s Value-Add Mechanism |

|---|---|---|

| CAD Upload | Geometry complexity, Tolerance stringency | Automated feature recognition flags high-cost elements (e.g., tight tolerances on non-critical features) |

| AI Quote | Raw material volatility, Machine time estimation | Live API integration with steel commodity markets and machine telemetry data |

| DFM Analysis | Material waste, Secondary operations | Nesting optimization algorithms and process substitution recommendations with cost validation |

| Production | Scrap rates, Rework costs | Real-time CNC monitoring with automatic parameter adjustment to maintain yield targets |

| Delivery | Logistics overhead, Inventory holding | Route optimization and JIT scheduling aligned with client assembly timelines |

This integrated approach ensures steel fabrication costs remain predictable and competitive, with 98.7% of projects delivered within 3% of the final quoted price. We maintain continuous cost improvement through quarterly reviews of material utilization metrics and machine performance data, directly benefiting client programs through sustained cost reductions.

Start Your Project

Looking to optimize your steel fabrication costs? Contact Susan Leo at [email protected] to discuss your project requirements and receive a detailed, competitive quote. With our precision manufacturing capabilities and efficient production processes at our Shenzhen factory, Honyo Prototype delivers high-quality steel fabrication solutions on time and within budget. Partner with us for cost-effective, scalable results backed by engineering expertise.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.