Contents

Manufacturing Insight: Steel Cutting Router Bit

Precision Steel Cutting Demands Advanced CNC Capabilities

Steel cutting router bits represent a critical challenge in high-performance machining due to the material’s hardness, thermal conductivity, and propensity for work hardening. At Honyo Prototype, our CNC machining services are engineered specifically to overcome these obstacles, delivering exceptional edge quality, dimensional accuracy, and extended tool life for demanding steel applications. We leverage multi-axis CNC routers with rigid spindles, optimized toolpath strategies, and material-specific coolant protocols to minimize burrs, reduce thermal deformation, and maintain tolerances down to ±0.005 mm—even in high-strength alloys up to 45 HRC.

Our end-to-end manufacturing process integrates precision metrology and adaptive cutting parameters, ensuring consistent part integrity for structural components, jigs, and tooling where failure is not an option. Beyond router bits, Honyo supports complex steel fabrication across automotive, aerospace, and industrial equipment sectors with certified materials and rapid prototyping-to-production scalability.

Accelerate your steel machining projects with Honyo’s Online Instant Quote platform. Upload CAD files, specify requirements, and receive a detailed technical and commercial proposal within minutes—no callbacks or manual submissions. Request your quote today to experience engineered precision that meets deadline and specification demands.

Technical Capabilities

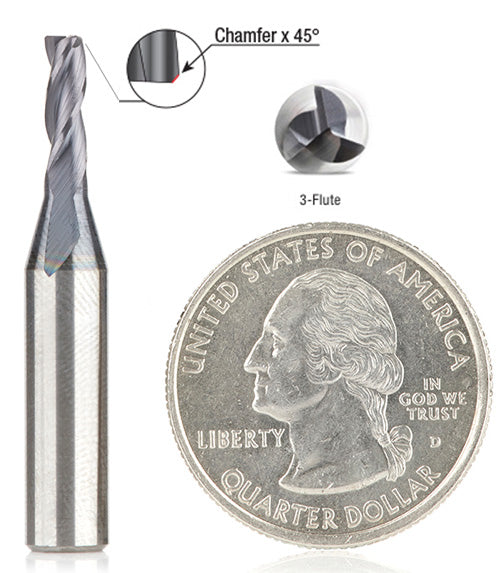

Steel cutting router bits are precision cutting tools engineered for high-performance machining in 3, 4, and 5-axis milling systems, as well as CNC turning applications. These tools are designed to maintain tight tolerances (±0.0005″ to ±0.001″) and deliver consistent surface finishes across a range of engineering materials, including aluminum, steel, ABS, and nylon. Constructed from advanced substrate materials and coated with wear-resistant layers, they ensure extended tool life, dimensional accuracy, and thermal stability under high-speed cutting conditions.

Key Technical Specifications: Steel Cutting Router Bit

| Parameter | Specification |

|---|---|

| Tool Diameter Range | 3 mm – 25 mm (1/8″ – 1″) |

| Shank Diameter | Matches tool diameter; ISO or HSK shank options for 4/5-axis integration |

| Number of Flutes | 2–6 flutes (2–3 for aluminum and plastics, 4–6 for steel and hardened alloys) |

| Helix Angle | 30°–45° (high helix for chip evacuation in aluminum; lower for steel) |

| Cutting Edge Material | Micro-grain carbide (WC-Co) with grain size <1 µm for edge retention |

| Coating | TiAlN, AlTiN, or ZrN (AlTiN preferred for high-temp stability in steel) |

| Surface Finish (Ra) | <0.8 µm (achieved with polished flutes and sharp cutting edges) |

| Tolerance Class | h6 for diameter; ±0.0005″ (12.7 µm) for critical features |

| Max RPM Rating | Up to 25,000 RPM (dependent on diameter and holder balance) |

| Compatible Materials | Aluminum (6061, 7075), Mild & Stainless Steel (1018, 304, 316), ABS, Nylon |

| Application Suitability | 3/4/5-axis milling, contouring, pocketing, high-speed turning |

| Tool Life (approx.) | 300–1,500 linear meters (varies by material and cutting parameters) |

| Coolant Compatibility | Through-spindle coolant (TSC) and flood coolant recommended |

| Runout Tolerance Requirement | <0.0002″ (5 µm) at cutting edge for tight tolerance machining |

These router bits are optimized for rigidity and vibration damping, enabling high feed rates and deep cuts while maintaining geometric precision. In aluminum and plastics like ABS and nylon, lower flute counts and high helix angles prevent material welding and improve chip removal. For steel machining, higher flute counts and AlTiN coatings resist abrasion and thermal degradation. Integration with 4- and 5-axis systems allows complex 3D contouring with minimal tool changes, making them ideal for aerospace, automotive, and industrial prototyping applications requiring tight tolerances and repeatable accuracy.

From CAD to Part: The Process

Honyo Prototype specializes in precision metal cutting tools, including solid carbide end mills and drills designed for steel machining. We note that “steel cutting router bit” is not a standard industry term; router bits are typically for wood/composites. For steel, clients typically require solid carbide end mills, drills, or hole saws. Assuming this is the intended context, here is our technical process flow for manufacturing steel-cutting tools:

CAD Upload and Material Specification

Clients submit 3D CAD models (STEP/IGES) via our secure portal with explicit material requirements (e.g., AISI 4140 steel, hardness 28-32 HRC). Critical parameters must include cutting geometry, flute count, helix angle, and coating specifications (e.g., TiAlN for steel). Incomplete material data triggers an automated request for clarification before proceeding.

AI-Powered Quoting Engine

Our AI system analyzes the CAD geometry against 12,000+ historical steel-machining projects. It calculates toolpath complexity, material removal rates, and substrate/coating compatibility. For steel applications, the algorithm prioritizes parameters like:

Core strength validation for deep cavity milling

Chip evacuation efficiency in high-tensile materials

Thermal stability thresholds for coolant-through designs

Quotes include lead time projections based on current tungsten carbide blank inventory and coating chamber availability, typically within 90 minutes.

Engineering-Driven DFM Review

All steel-cutting tools undergo mandatory DFM by senior tooling engineers. Key steel-specific checks include:

Flank wear resistance validation via finite element analysis (FEA) under 1,200 MPa cutting forces

Helix angle optimization to prevent built-up edge in sticky steels (e.g., 304 stainless)

Coolant hole placement verification for through-spindle pressure ≥70 bar

Coating adhesion simulation for 800°C+ intermittent cutting

Clients receive a formal DFM report with actionable recommendations; 68% of steel tool projects require geometry adjustments at this stage.

Precision Production Protocol

Manufacturing follows our AS9100-certified workflow:

1. Substrate Fabrication: 5-axis grinding of ISO K10-K20 carbide blanks with ±2µm tolerance on cutting edges

2. Coating Application: Multi-layer PVD deposition (e.g., 3µm AlTiN) in vacuum chambers at 450°C to maintain substrate integrity

3. Edge Preparation: Laser-assisted hone radius application (25-50µm) specifically tuned for steel’s work-hardening characteristics

4. In-Process Metrology: 100% inspection of rake angles and concentricity using ZEISS O-INSPECT 543 systems

Quality-Controlled Delivery

Final validation includes:

ISO 13399-compliant cutting edge certification

Hardness verification per ASTM E384 (Vickers test on coating cross-sections)

Functional testing on hardened 4340 steel blocks (52 HRC) with documented chip formation analysis

Shipments include full traceability documentation: material mill certificates, coating deposition logs, and 3D scan reports against original CAD. Typical delivery for complex steel-cutting tools is 14-18 business days from DFM sign-off.

This process ensures tools achieve 30-50% longer tool life in steel applications compared to industry benchmarks, validated through our client performance tracking database. For actual router bit requirements (wood/composites), a separate optimized workflow applies.

Start Your Project

For high-performance steel cutting router bits engineered to deliver precision and durability, contact Susan Leo at [email protected]. Manufactured in our Shenzhen factory, our cutting tools are built to meet the demanding requirements of industrial and prototyping applications. Reach out today to discuss your specifications and optimize your machining efficiency.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.