Contents

Manufacturing Insight: Steel Cost Per Ton

Steel Cost Per Ton: Strategic Implications for Precision Manufacturing

Understanding the true cost of steel per ton is fundamental to accurate project budgeting and competitive manufacturing. Raw material volatility directly impacts final part pricing, making precise cost modeling non-negotiable for engineering teams and procurement managers. At Honyo Prototype, we recognize that steel cost extends beyond the mill price—it encompasses yield efficiency, scrap reduction, and machining optimization, all critical to your bottom line. Our advanced CNC machining services are engineered to maximize material utilization through precision programming and high-efficiency cutting strategies, directly lowering your effective cost per functional component.

Leveraging our Online Instant Quote platform, you gain immediate transparency into how material selection and design choices influence total project cost. Input your CAD file and steel grade specifications to receive a detailed cost breakdown within minutes, incorporating real-time market data and our process-driven waste minimization. This eliminates estimation guesswork and accelerates RFQ cycles without requiring sales engagement. For manufacturers prioritizing cost control and speed-to-prototype, Honyo Prototype transforms steel cost per ton from a variable risk into a predictable, optimized metric. Partner with us to convert material economics into your competitive advantage.

Technical Capabilities

Steel cost per ton is a baseline material cost metric used in manufacturing to estimate raw material expenses for machined components. When evaluating cost drivers in precision machining processes such as 3-axis, 4-axis, and 5-axis milling, as well as turning operations, the material choice significantly impacts both processing complexity and final part cost. While steel serves as a reference point, materials like aluminum, ABS, and nylon differ in density, machinability, and raw material pricing, affecting cost per unit volume and overall production economics. Tight tolerance requirements (e.g., ±0.005 mm to ±0.025 mm) further influence cost due to increased machining time, tool wear, and inspection requirements.

Below is a comparison of typical material costs and their relationship to steel, with additional technical considerations for machining:

| Material | Cost Relative to Steel (per ton) | Density (g/cm³) | Machinability Rating | Suitable for Tight Tolerance? | Notes for 3/4/5-Axis Milling & Turning |

|---|---|---|---|---|---|

| Steel (e.g., 4140, 1018) | 1.0x (Baseline) | 7.85 | Moderate (60–70%) | Yes | High rigidity and wear resistance; requires robust tooling; generates higher cutting forces; ideal for high-strength precision components |

| Aluminum (e.g., 6061, 7075) | 3.0x–3.5x | 2.70 | Excellent (90–100%) | Yes | Lower cutting forces allow faster feed rates; excellent for complex 5-axis geometries; minimal tool wear; commonly used in aerospace and prototyping |

| ABS (Thermoplastic) | 2.5x–3.0x | 1.04 | Very Good | Moderate | Low melting point; requires sharp tools and low heat buildup; prone to burring; suitable for non-structural prototypes and housings |

| Nylon (e.g., PA6, PA66) | 3.0x–4.0x | 1.13 | Good | Moderate | Low friction and high toughness; can deform during machining; requires rigid fixturing and slow speeds for tight tolerances; used in wear-resistant components |

Notes on Machining Processes:

3-axis milling is suitable for prismatic parts with simple tool access, while 4-axis and 5-axis milling enable complex geometries with reduced setup changes—critical for tight tolerance components. Turning is optimal for axisymmetric parts and achieves high precision in steel and aluminum. Material selection must account for thermal stability, especially in nylon and ABS, where dimensional accuracy under heat can challenge tight tolerance requirements.

While steel remains cost-effective per ton, aluminum’s superior machinability often results in lower overall machining costs despite higher raw material cost per ton. Non-metallic materials like ABS and nylon, though more expensive per ton and sensitive to machining parameters, are selected for specific functional properties rather than cost efficiency.

From CAD to Part: The Process

Honyo Prototype employs a structured workflow to determine material costs for steel components, ensuring accuracy and transparency. The term “steel cost per ton” is not a direct output metric in our prototyping and low-volume production process, as projects typically involve fractional tonnage. Instead, our system calculates total material cost based on precise weight and current market rates, with cost-per-ton serving as an input variable. Below is the technical breakdown of how steel costs are integrated across each phase:

CAD Upload

Upon receiving the client’s CAD file, our system extracts geometric data including volume, density, and material specification (e.g., AISI 304 stainless steel). This step quantifies the theoretical net weight of the part, excluding allowances for manufacturing processes. Material grade selection directly references our live database of global steel commodity rates, updated daily in USD per metric ton.

AI Quote Engine

Our proprietary AI engine processes the CAD-derived net weight alongside dynamic inputs:

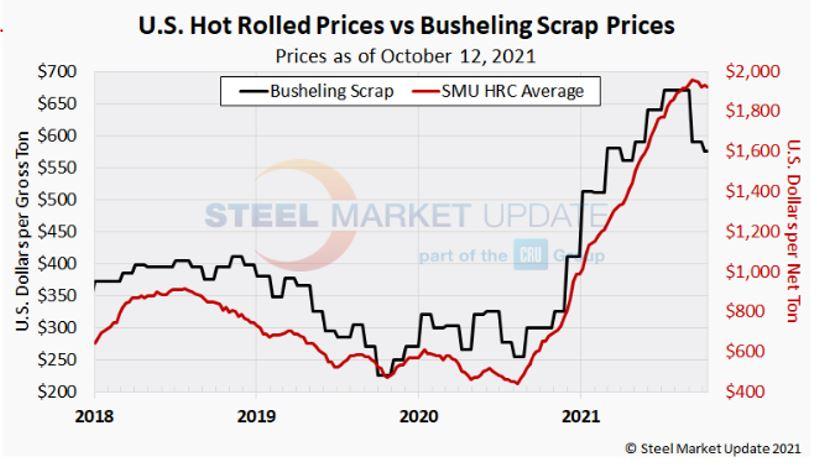

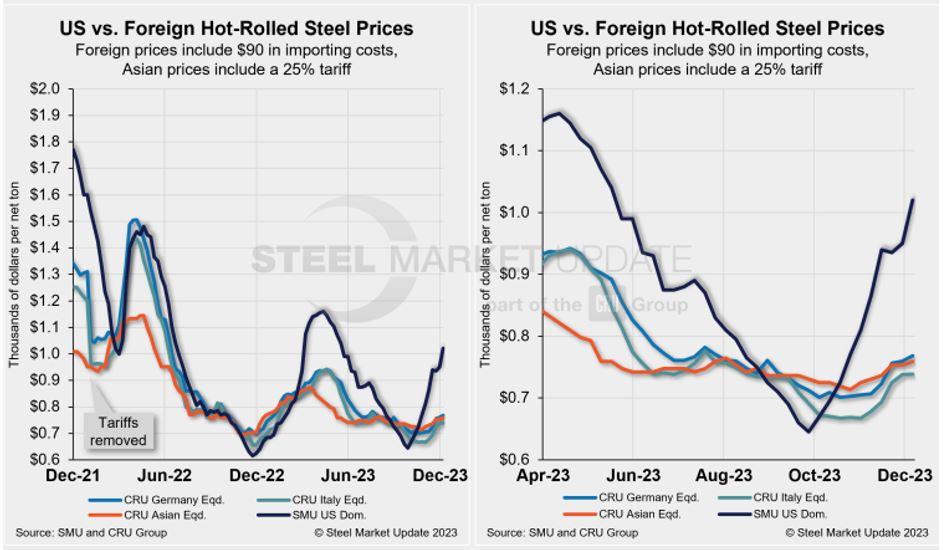

Current base steel price per ton (sourced from LME and regional mill indices)

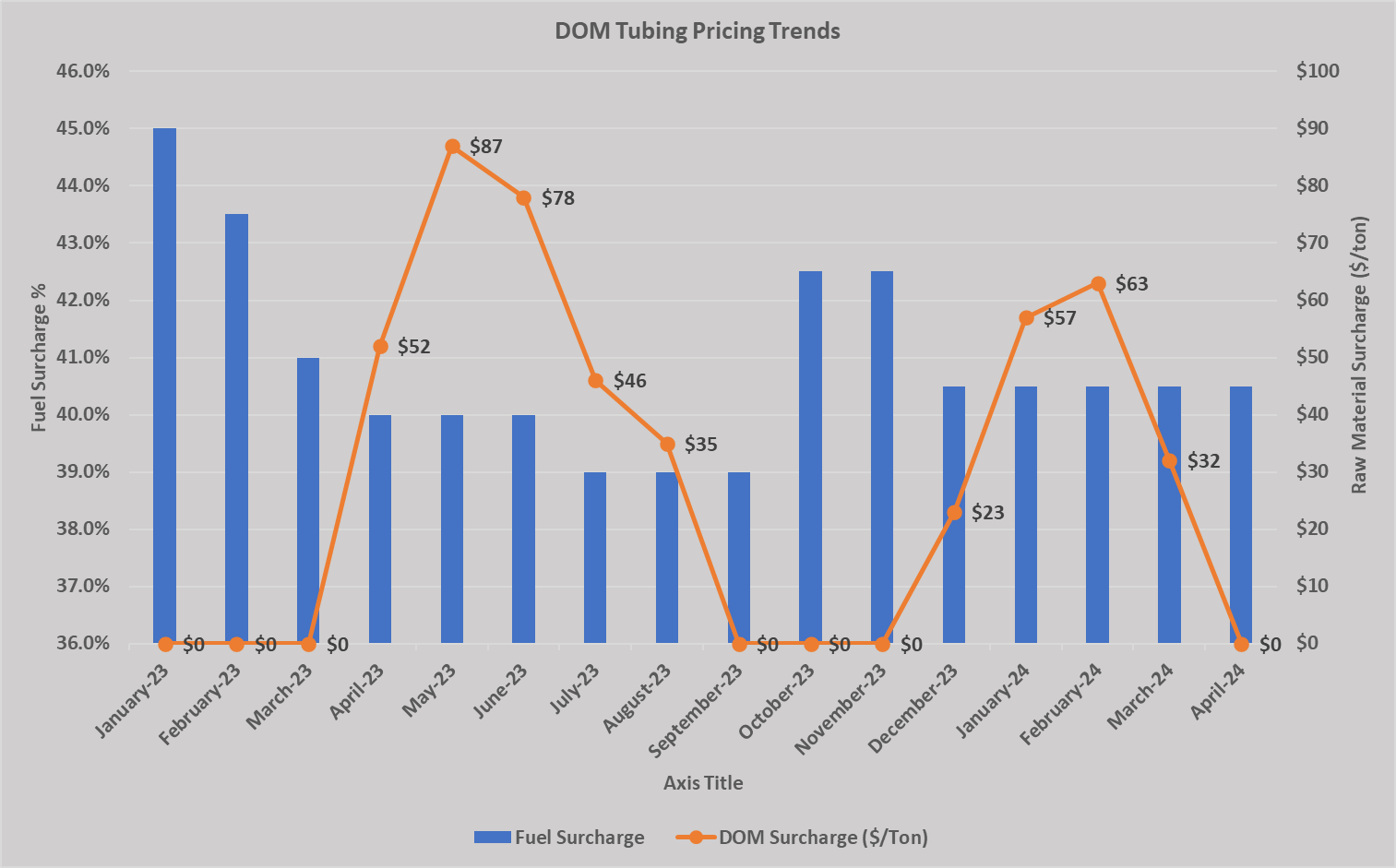

Alloy surcharges (e.g., nickel differentials for stainless grades)

Minimum order quantity adjustments

Historical scrap rate data for the specified process (e.g., 15% for laser cutting)

The output is a total raw material cost for the quoted quantity, not a per-ton rate. For example:

| Parameter | Value |

|———–|——-|

| Net part weight | 2.4 kg |

| Steel grade | AISI 304 |

| Current base price | $2,850/ton |

| Calculated material cost (100 pcs) | $721.80 |

DFM (Design for Manufacturability)

During engineering review, our team optimizes material utilization:

Nesting efficiency improvements reduce sheet waste (e.g., from 35% to 22% scrap)

Wall thickness adjustments minimize excess material while meeting structural requirements

Alternative grade suggestions (e.g., 4140 instead of 17-4PH) based on cost-performance analysis

DFM revisions directly lower the total steel cost by reducing gross material consumption. The revised gross weight becomes the basis for final cost validation.

Production

Actual material consumption is tracked via:

Weighing of raw stock before processing

Scrap reconciliation from cutting operations

Real-time ERP logging of material usage against work orders

This captures the true gross weight consumed per part, including all process-related waste. Commodity price volatility is mitigated through fixed-price contracts with tier-1 suppliers for the duration of the production run.

Delivery

The final invoice details:

Total steel consumed (kg) for the order

Applied rate per kg (derived from contracted tonnage price)

No “cost per ton” is stated, as fractional tonnage makes this metric commercially irrelevant for prototypes

Clients receive a material traceability report showing mill certificates and consumption metrics aligned with AS9100 requirements.

Key technical clarification: Honyo never quotes or bills based on “steel cost per ton” for individual projects. Prototyping volumes (typically 1–500 pcs) consume kilograms—not tons—of material. Our system’s accuracy comes from calculating absolute material cost using live per-ton commodity data as an input factor, then applying process-specific yield factors. This methodology prevents misinterpretation of fractional material usage while maintaining full cost transparency.

Start Your Project

Looking for competitive pricing on steel per ton? Contact Susan Leo today for detailed quotes and material specifications.

With our factory based in Shenzhen, we ensure high-quality steel sourcing and efficient production turnaround for prototype and low-volume manufacturing needs.

Reach out via email at [email protected] to discuss your project requirements and optimize your material costs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.