Contents

Manufacturing Insight: Steel Cost Per Kg

Understanding Steel Cost Per Kilogram in Precision CNC Machining

Steel cost per kilogram represents more than a simple material metric—it directly impacts project scalability, budget predictability, and resource allocation for engineered prototypes and production components. At Honyo Prototype, we recognize that volatile raw material pricing, grade specifications, and machining efficiency can significantly alter total part costs. Our advanced CNC machining services mitigate these variables through optimized material utilization, high-precision toolpaths, and strategic steel sourcing across carbon, alloy, and stainless grades. By integrating lean manufacturing principles with real-time market data, we ensure your steel investment translates to minimal waste and maximal component integrity.

Transparency Through Technology: The Honyo Advantage

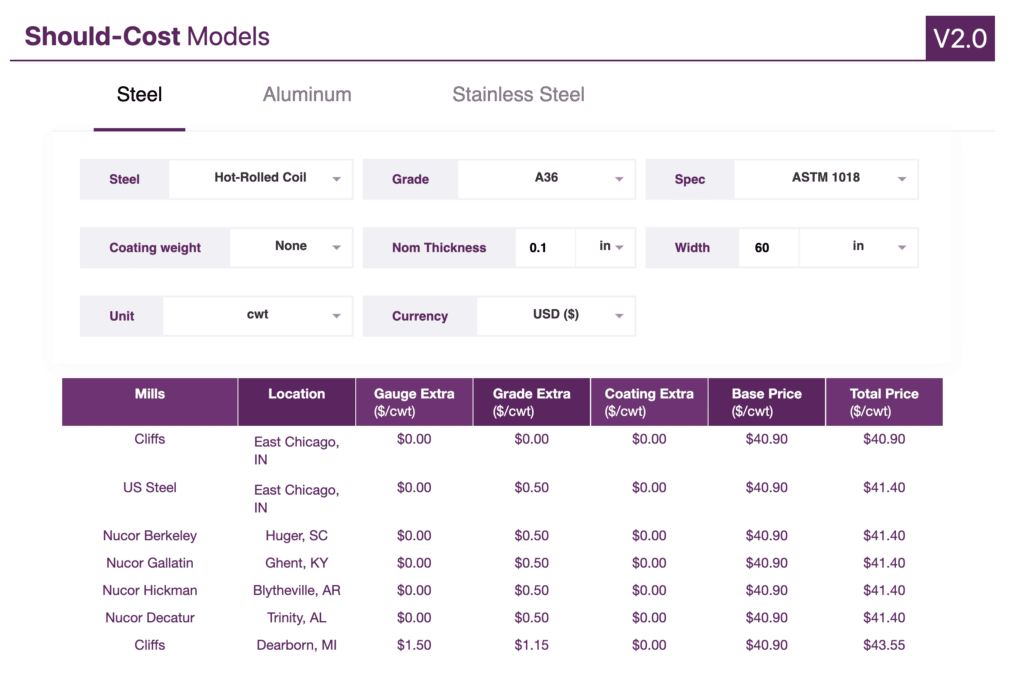

Unlike traditional suppliers where steel cost estimation remains opaque, Honyo delivers immediate clarity via our Online Instant Quote platform. Input your CAD file, material grade (e.g., AISI 1045, 304SS), and quantity to receive a granular cost breakdown—including steel kg pricing, machining time, and finishing—within seconds. This eliminates guesswork, accelerates RFQ cycles, and empowers data-driven decisions. For instance, our system dynamically adjusts for factors like raw material surcharges or bulk-order efficiencies, ensuring quotes reflect current market conditions without hidden premiums.

Key Variables Influencing Steel Cost Per Kilogram

| Factor | Impact on Cost/kg | Honyo’s Mitigation Strategy |

|---|---|---|

| Steel Grade & Purity | Higher alloys (e.g., 17-4PH) cost 2–3× carbon steel | Grade substitution guidance & certified mill sourcing |

| Order Volume | Bulk orders reduce kg cost by 15–25% | Agile micro-factory scaling for low-to-mid volumes |

| Machining Complexity | Complex geometries increase material waste | AI-driven nesting & near-net-shape programming |

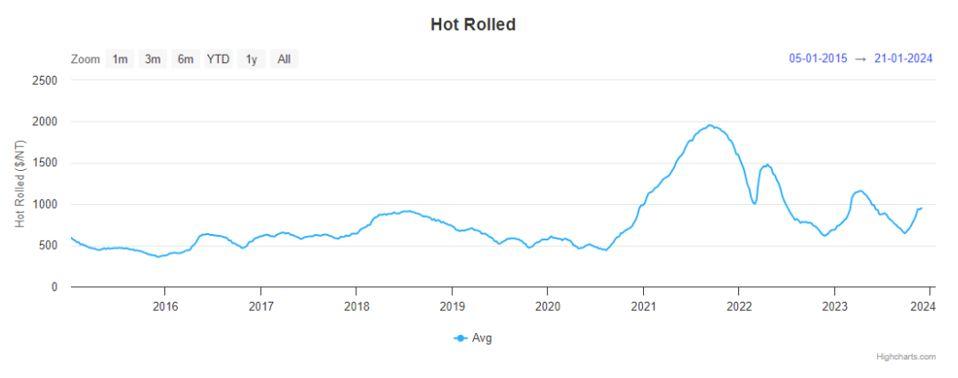

| Market Volatility | Scrap rates fluctuate daily | Fixed-price quotes locked for 30 days |

Accelerate Your Project with Actionable Insights

Stop treating steel cost as an uncontrollable variable. Honyo Prototype’s CNC machining ecosystem—backed by ISO 9001-certified processes and 200+ HAAS/DMA machines—turns material economics into a strategic advantage. Leverage our Online Instant Quote tool to model scenarios, compare steel alternatives, and secure certified pricing in under 60 seconds. For urgent RFQs or technical collaboration on material optimization, our engineering team remains accessible to refine your cost-per-kg strategy. Begin quoting now at honyoprototype.com/quote.

Technical Capabilities

The term “steel cost per kg” refers to the raw material cost of steel used in precision manufacturing processes such as 3-axis, 4-axis, and 5-axis milling, as well as CNC turning. However, when evaluating cost in high-precision machining involving tight tolerances (e.g., ±0.005 mm to ±0.025 mm), the effective cost per kg must also account for material machinability, waste (k-factor), tool wear, cycle time, and setup complexity. While steel is a primary reference material, comparative analysis often includes Aluminum, ABS, and Nylon due to their frequent use in prototyping and production at Honyo Prototype.

Below is a technical comparison of material properties and effective cost factors relevant to multi-axis milling and turning with tight tolerance requirements:

| Material | Density (g/cm³) | Typical Raw Cost (USD/kg) | Machinability Rating | Thermal Stability | Notes on Tight Tolerance Machining | Relative Processing Cost Factor |

|---|---|---|---|---|---|---|

| Steel (e.g., 1045, 4140) | 7.85 | 3.00 – 5.00 | Moderate (60–70% relative to free-machining steel) | High | High rigidity and thermal stability support tight tolerances; slower removal rates increase machining cost | 1.00 (baseline) |

| Aluminum (e.g., 6061, 7075) | 2.70 | 3.50 – 6.00 | Excellent (85–95%) | Moderate | High thermal expansion requires compensation in ultra-precision work; fast cutting speeds reduce labor cost | 0.85 |

| ABS (Acrylonitrile Butadiene Styrene) | 1.04 | 2.50 – 4.00 | Good (for plastic) | Low | Prone to creep and thermal deformation; suitable for non-load-bearing prototypes; low tool wear | 0.65 |

| Nylon (Polyamide, e.g., PA6, PA66) | 1.13 | 4.00 – 7.00 | Moderate | Low to Moderate | Absorbs moisture, dimensional changes post-machining; requires post-stabilization for tight tolerance | 0.75 |

Key Observations:

Steel remains the benchmark for structural and high-precision applications due to its dimensional stability and strength. While raw cost per kg is competitive, the total cost of machining steel under tight tolerances is higher due to slower cutting speeds, increased tooling wear, and longer cycle times—especially in 4-axis and 5-axis configurations where tool reach and orientation add complexity.

Aluminum, despite a similar or higher raw material cost per kg, often results in lower total machining cost due to superior machinability and faster cycle times. This makes it ideal for complex geometries in 5-axis milling where efficiency is critical.

Engineering plastics like ABS and Nylon have lower raw material density and cost but present challenges in maintaining tight tolerances due to thermal sensitivity and moisture absorption. Their lower processing temperatures limit tool speed and require careful fixturing.

At Honyo Prototype, material selection for milling and turning operations is optimized based on functional requirements, tolerance demands, and total cost of ownership—not just raw material price per kg.

From CAD to Part: The Process

Honyo Prototype’s steel cost per kilogram calculation is not a static material rate but a dynamic, process-driven metric derived from our integrated engineering-to-manufacturing workflow. This approach ensures accuracy by accounting for real-world production variables beyond raw material pricing. Below is the technical breakdown of how each stage directly influences the final cost per kilogram:

Upload CAD initiates the precision costing process. Our system extracts geometric data including part volume, surface area, and feature complexity. Crucially, it calculates the theoretical minimum material volume required versus the actual stock size needed for manufacturability. For steel parts, this identifies inherent material inefficiencies such as excessive stock removal or non-optimal nesting potential. The initial material weight estimate is generated here but remains provisional until validated against production constraints.

AI Quote transforms geometric data into a preliminary cost model using our proprietary algorithm. This engine integrates real-time steel market rates from tier-1 mills, regional scrap value fluctuations, and historical process efficiency data. However, it applies conservative yield factors based on part geometry—for instance, a complex bracket may start with a 35% material utilization assumption. The output provides a baseline cost per kilogram that explicitly separates raw material cost from estimated processing burden, but this quote is contingent on design feasibility.

DFM (Design for Manufacturability) is where steel cost per kilogram is actively optimized. Our engineering team reviews the CAD model to identify opportunities for material reduction without compromising function. Common steel-specific interventions include modifying radii to reduce machining time, adjusting wall thicknesses to minimize raw stock size, or reorienting features to improve nesting yield. Each change is quantified: a 10% reduction in raw stock volume directly lowers the material cost component. Critically, DFM also addresses steel-specific factors like grain direction for structural parts or thermal distortion risks that could lead to scrap. Post-DFM, the cost per kilogram is recalculated using validated process parameters and actual expected yield rates.

Production executes the optimized design with traceable material accountability. We use certified steel stock with documented mill test reports, tracking exact weight from bar stock or plate to final part. In-process weighing at machining stages captures actual scrap generation. For example, a part designed for 2.0 kg may consume 2.8 kg of raw steel due to necessary machining allowances—this true consumption rate defines the final cost basis. Our MES system logs real-time machine time and tool wear specific to steel alloys, allocating overhead accurately.

Delivery provides full cost transparency through our digital package. The final steel cost per kilogram is presented as a verified calculation: (Certified Raw Material Cost + Process-Specific Overhead) / Net Part Weight. This includes documentation of actual material consumed versus theoretical minimum, scrap reconciliation, and alloy certification. The metric reflects true landed cost, not just commodity pricing.

The table below illustrates how DFM adjustments impact steel cost per kilogram for a representative hydraulic manifold block (AISI 4140 steel):

| Stage | Raw Stock Volume (cm³) | Net Part Volume (cm³) | Material Utilization | Steel Cost/kg (USD) | Primary Cost Drivers Addressed |

|---|---|---|---|---|---|

| Initial AI Quote | 1,850 | 920 | 49.7% | $6.85 | Base material rate, conservative yield factor |

| Post-DFM Validation | 1,420 | 920 | 64.8% | $5.20 | Optimized stock size, reduced machining allowances, improved nesting |

| Actual Production | 1,455 | 920 | 63.2% | $5.35 | Verified scrap rate, machine time allocation, alloy certification |

This methodology ensures our quoted steel cost per kilogram is engineering-validated and production-realistic. By embedding cost accountability into each phase—from geometric analysis through physical manufacturing—we eliminate estimation gaps common in traditional quoting. The result is a transparent, defensible metric that aligns material science with operational execution for strategic procurement decisions.

Start Your Project

Looking for competitive pricing on steel per kilogram? Contact Susan Leo today for detailed quotes and material options. With our factory based in Shenzhen, we ensure fast turnaround and high-quality manufacturing standards for all your prototyping and production needs.

Email Susan Leo at [email protected] to discuss your project and get accurate, real-time steel cost information tailored to your requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.