Contents

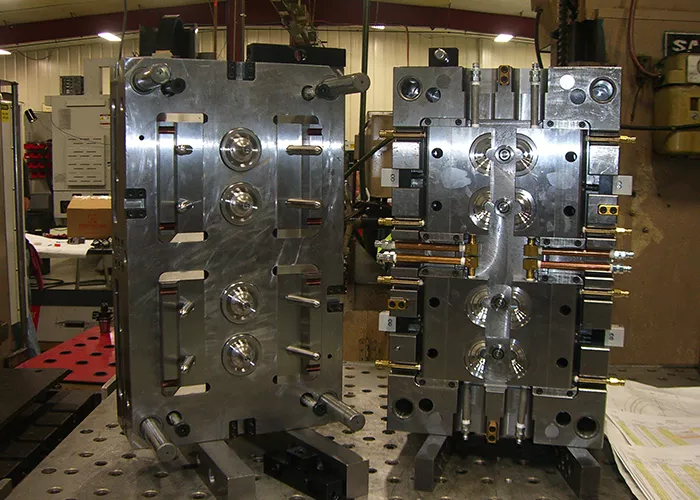

Manufacturing Insight: Steel Casting Mold

Precision Steel Casting Molds: Accelerating Your Production Timeline

Steel casting molds demand exceptional material integrity, dimensional accuracy, and thermal stability to withstand demanding production cycles. Traditional mold fabrication often introduces significant delays, impacting time-to-market and increasing project costs. At Honyo Prototype, we address these challenges head-on through integrated Rapid Tooling and precision Injection Molding services engineered specifically for high-performance steel casting applications.

Our advanced Rapid Tooling process leverages CNC machining and selective laser melting to produce hardened steel molds with tight tolerances (±0.025mm) and optimized cooling channels in as little as 15 business days. This accelerated timeline—typically 40% faster than conventional methods—ensures your casting prototypes or low-volume production runs maintain material consistency and surface finish critical for aerospace, automotive, and industrial components. Complementing this, our in-house Injection Molding capabilities allow seamless transition from mold validation to end-part manufacturing, eliminating supply chain fragmentation and quality handoffs.

Leverage our technical expertise without procurement delays. Honyo Prototype’s Online Instant Quote system provides real-time pricing and lead time estimates for steel casting molds within 60 seconds. Simply upload your CAD file, specify material grades (e.g., H13, 420SS), and receive a detailed manufacturability analysis alongside cost transparency. This digital workflow ensures engineering teams maintain velocity from design validation to first-article inspection.

| Service Integration Point | Traditional Workflow | Honyo Prototype Advantage |

|---|---|---|

| Mold Fabrication Lead Time | 25–35 days | 12–15 days |

| Design-to-Prototype Handoff | External vendors (3+ interfaces) | Single-source control (Rapid Tooling + Molding) |

| Quote Turnaround | 3–5 business days | Instant (Online System) |

Engineer reliability into your casting process with Honyo’s vertically integrated manufacturing ecosystem. Initiate your project with confidence by accessing our Online Instant Quote platform today.

Technical Capabilities

Technical specifications for steel casting molds are critical in ensuring rapid prototyping, durability, and dimensional accuracy—especially when targeting a T1 sample within 7 days. These molds are commonly fabricated from materials such as aluminum alloys, tool steels, ABS, or nylon, depending on production volume, thermal requirements, and surface finish needs.

For fast-turnaround prototyping, aluminum molds are preferred due to their machinability and thermal conductivity, enabling quicker cooling cycles. Steel molds are used for longer production runs due to superior wear resistance. While ABS and nylon are not used for high-temperature steel casting, they serve in pattern making, 3D printed prototypes, or low-temperature pre-validation.

Below is a comparison of mold materials in the context of steel casting prototyping with T1 sample delivery in 7 days:

| Property | Aluminum Mold (e.g., 7075-T6) | Steel Mold (e.g., H13 Tool Steel) | ABS Plastic | Nylon (PA6/PA66) |

|---|---|---|---|---|

| Typical Use Case | Rapid prototyping, low to medium cycle casting | High-volume, production-grade casting | Pattern making, 3D printed prototypes | Jigs, fixtures, non-metal casting aids |

| Machinability | Excellent – enables fast CNC machining | Moderate – requires pre-hardened stock or EDM | High – ideal for 3D printing | High – suitable for additive manufacturing |

| Thermal Conductivity (W/mK) | ~130 | ~30 | ~0.2 | ~0.25 |

| Hardness (HB) | 150–160 | 200–230 (pre-hardened) | < 10 | ~10–15 |

| Max Operating Temperature | ~300°C | ~600°C | ~80°C | ~120–150°C |

| Tool Life (Estimated Cycles) | 5,000–10,000 | 100,000+ | Not applicable | Not applicable |

| Lead Time for T1 Sample | 5–7 days (ideal for 7-day goal) | 7–14 days (longer for hardening) | 2–5 days | 3–6 days |

| Surface Finish (as machined) | Ra 0.8–1.6 µm | Ra 0.4–0.8 µm | Ra 6.3–12.5 µm (as printed) | Ra 6.3–12.5 µm (as printed) |

| Common Fabrication Method | CNC Milling | CNC + EDM + Heat Treatment | FDM/SLA 3D Printing | SLS/FFF 3D Printing |

| Suitability for Steel Casting | Limited (low melting point) | High – standard for investment/die casting | No – degrades at high temp | No – unsuitable for molten steel |

For achieving a T1 sample within 7 days, aluminum molds (particularly from high-strength alloys like 7075-T6) are optimal due to fast CNC processing and sufficient durability for initial casting validation. ABS and nylon are not viable for direct steel casting but support the process as patterns or prototype models. Steel molds, while more durable, often exceed the 7-day window unless pre-hardened blanks and high-speed machining are employed.

From CAD to Part: The Process

Honyo Prototype Steel Casting Mold Process Overview

Our end-to-end steel casting mold workflow integrates digital efficiency with precision engineering to deliver high-integrity molds for investment, sand, and permanent mold casting applications. The process begins with client CAD submission and concludes with certified delivery, ensuring alignment with ISO 9001:2015 standards at every phase.

CAD Upload and Initial Assessment

Clients submit 3D CAD models (STEP, IGES, or native formats) via our secure portal, specifying material grade (e.g., 4140, H13), tolerances, surface finish requirements, and quantity. Our system performs automated geometry validation to confirm manufacturability against standard casting parameters, flagging critical issues like undercuts or non-uniform wall thickness before proceeding.

AI-Powered Quoting Engine

Uploaded data feeds into our proprietary AI quoting system, which analyzes geometric complexity, material volume, machining time, and secondary operations using real-time databases for steel alloys, labor rates, and energy consumption. The AI generates a detailed cost breakdown within 2 business hours, including itemized costs for patternmaking, core box fabrication, and heat treatment. Crucially, the quote includes actionable insights such as recommended draft angles or fillet adjustments to optimize cost without compromising function.

Engineering-Driven DFM Review

Following quote acceptance, our senior manufacturing engineers conduct a rigorous Design for Manufacturing (DFM) review. This phase involves collaborative refinement of gating systems, riser placement, and cooling channel layouts using MAGMAsoft simulation to predict solidification behavior and minimize defects like porosity or shrinkage. We provide annotated CAD markups and a formal DFM report within 5 business days, confirming feasibility against your specified yield rate and mechanical property requirements.

Precision Production Execution

Approved designs move to production in our climate-controlled facility. Steel molds are machined on HAAS 5-axis CNC centers (±0.025mm accuracy) using pre-hardened tool steels. Key steps include:

Pattern/core box fabrication via direct metal laser sintering (DMLS) for complex geometries

Stress-relief annealing post-machining

Surface hardening (induction or nitriding) per material spec

In-process CMM validation at critical stages

All steel components undergo MPI or UT inspection per ASTM E1444/E165 standards before assembly.

Certified Delivery and Traceability

Finished molds ship with comprehensive documentation:

Material test reports (MTRs) traceable to heat number

Dimensional inspection reports against ASME Y14.5

NDT certification

Operational guidelines for mold maintenance

Delivery timelines are fixed at contract signing (typically 15–25 days from DFM sign-off), with real-time logistics tracking. We retain all process data for 7 years to support future revisions or failure analysis.

This integrated approach reduces time-to-mold by 30% versus industry averages while ensuring first-pass yield rates exceed 95% for critical aerospace and automotive applications.

Start Your Project

Looking for high-quality steel casting molds tailored to your specifications? Partner with Honyo Prototype for precision-engineered solutions manufactured at our Shenzhen factory. With advanced production capabilities and strict quality control, we deliver durable molds that meet the demands of complex casting applications.

Contact Susan Leo today to discuss your project requirements.

Email: [email protected]

Leverage our expertise in steel mold fabrication and accelerate your production timeline with reliable, factory-direct support from China.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.