Contents

Manufacturing Insight: Steel Burr

Precision steel components demand flawless surface integrity where burrs compromise functionality and safety. At Honyo Prototype we specialize in high-accuracy CNC machining services engineered to eliminate burrs at the source. Our advanced milling and turning processes combined with rigorous secondary deburring protocols ensure steel parts meet stringent tolerance and finish requirements straight from the machine. This capability minimizes rework costs and accelerates time-to-assembly for critical applications across aerospace automotive and medical device sectors. Achieving burr-free steel isn’t incidental it’s the result of our calibrated toolpaths optimized feeds and speeds and meticulous process validation. Leverage Honyo’s expertise to transform your steel component designs into production-ready realities. Begin your project instantly with our Online Instant Quote system providing transparent pricing and manufacturability feedback within hours not days.

Technical Capabilities

Technical Specifications for Steel Burr in Precision Machining Applications

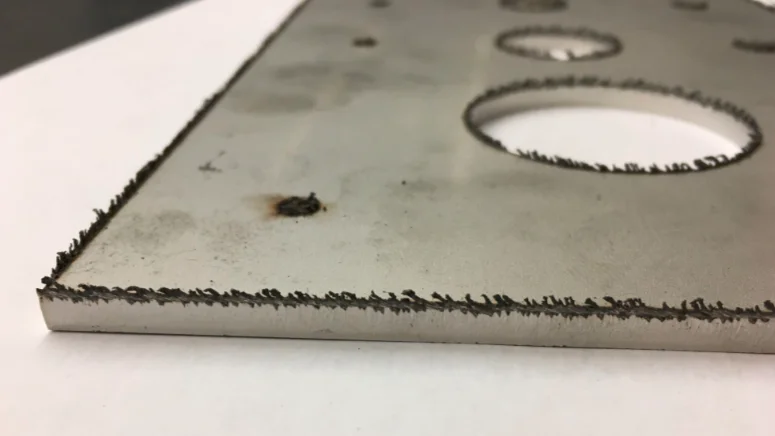

Steel burrs are critical surface imperfections that occur during machining processes such as 3/4/5-axis milling and turning. Their presence impacts dimensional accuracy, surface finish, and part functionality—especially in tight tolerance applications. Below is a detailed technical overview of steel burr characteristics across various materials and machining methods.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Materials (Aluminum, Steel, ABS, Nylon) |

|---|---|---|---|---|---|

| Typical Burr Location | Edge intersections, slot exits | Indexed edge features | Complex contours, undercuts | Parting lines, facing edges | Varies by material ductility and thermal response |

| Burr Size Range | 0.05 – 0.3 mm | 0.03 – 0.2 mm | 0.02 – 0.15 mm | 0.02 – 0.1 mm | Aluminum: up to 0.3 mm; Steel: 0.1–0.2 mm; ABS/Nylon: minimal, but prone to smearing |

| Tolerance Impact | ±0.05 mm affected | ±0.03 mm affected | ±0.01 to ±0.02 mm achievable | ±0.01 mm with deburring | Aluminum forms larger burrs due to ductility; steel produces harder, smaller burrs; thermoplastics (ABS, Nylon) may melt rather than burr |

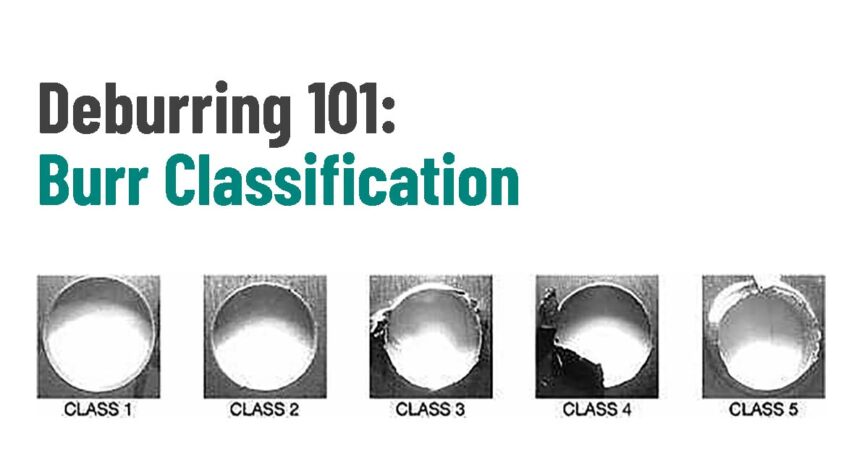

| Common Burr Types | Poisson, rollover | Rollover, tear-off | Micro-rollover, exit burrs | Entrance/exit burrs | Aluminum: rollover; Steel: shear; ABS: thermal flash; Nylon: melt burrs |

| Primary Formation Mechanism | Tool exit force, feed rate | Rotary axis transition forces | Multi-directional tool paths | Feed and depth of cut dynamics | Plastic deformation (metals), thermal softening (polymers) |

| Mitigation Strategies | High-speed machining, optimized toolpath, climb milling | Indexed approach angles, reduced stepover | Continuous tool engagement, tilt optimization | Controlled feed at cutoff, chamfering | Material-specific tooling: sharp carbide for Aluminum; polished inserts for Steel; low-heat cutting for ABS/Nylon |

| Post-Processing Requirement | Deburring (mechanical/thermal) | Light deburring or brushing | Often minimal; isotropic finishing | Often required for tight fit parts | Aluminum: vibratory finishing; Steel: tumbling; ABS/Nylon: manual or air blasting |

Notes on Material Behavior

Aluminum exhibits high ductility, leading to prominent rollover burrs, especially in milling operations. Proper chip load and sharp tooling are essential to minimize burr formation.

Steel, particularly hardened grades, produces smaller but harder burrs that may require aggressive deburring methods.

ABS and Nylon, being thermoplastics, are prone to thermal burring or flash due to localized melting. Coolant use and sharp cutting edges are critical to avoid material deformation rather than clean shearing.

Tight Tolerance Considerations

In applications requiring tolerances tighter than ±0.05 mm, burr management becomes integral to process validation. 5-axis milling reduces burr formation through optimal tool orientation, minimizing abrupt tool exit angles. In turning, programmable cutoff dwell and back-off routines reduce exit burrs on steel and aluminum components. For polymer components, reduced spindle speeds and specialized tool geometries prevent melting-related imperfections.

Effective burr control ensures compliance with ISO 13715 (edges and corners) and ASME Y14.5 (geometric dimensioning), particularly in aerospace, medical, and precision automation sectors.

From CAD to Part: The Process

Honyo Prototype addresses manufacturing requirements for machined steel components where burr management is critical, clarifying that “steel burr” refers to parts requiring controlled burr removal post-machining rather than the burr itself as the product. Our streamlined workflow ensures precision and efficiency for such components:

The process begins with secure CAD file upload via our customer portal. Engineers validate file integrity and material specifications, with immediate system confirmation upon receipt. For steel parts requiring tight burr control, we specifically note edge condition requirements during this intake phase.

Our proprietary AI quoting engine processes the CAD geometry within minutes. It analyzes feature complexity, material grade (e.g., 303 SS, 1018, 4140), and critical edge callouts to determine deburring methodology. The quote details secondary operations like vibratory finishing, thermal deburring, or manual edge breaking, with cost impacts clearly itemized. Turnaround time for AI quotes is typically under 15 minutes for standard steel components.

During Design for Manufacturability (DFM) review, our engineering team conducts a dedicated burr risk assessment. We identify:

Features prone to problematic burrs (e.g., cross-drilled holes, intersecting milled pockets)

Inaccessible areas requiring specialized deburring tools

Tolerance conflicts where burr removal might affect critical dimensions

The DFM report flags actionable recommendations such as adding chamfers or adjusting hole breakout locations, with revision suggestions provided within 24 business hours.

Production executes with burr control as a primary focus. Machining parameters are optimized to minimize burr formation initially, followed by validated secondary operations:

Precision manual deburring for critical edges using calibrated tools

Automated vibratory finishing for complex geometries

100% post-deburring inspection using optical comparators for edge radius verification

All steel parts undergo mandatory burr validation before final cleaning and passivation where specified.

Delivery includes comprehensive documentation: First Article Inspection reports with burr measurement data, material certifications, and process validation records. Typical lead times vary by complexity as shown below:

| Process Stage | Standard Steel Part (≤5” cube) | Complex Geometry (e.g., manifolds) |

|---|---|---|

| AI Quote Generation | <15 minutes | <30 minutes |

| DFM Review | 24 business hours | 48 business hours |

| Production | 5-7 business days | 10-14 business days |

| Final Inspection | Included in production time | Additional 1-2 days |

Quality assurance mandates that all deburred edges meet ANSI B46.1 surface finish standards unless customer specifications dictate stricter criteria. We implement statistical process control on deburring stations, with real-time data logging for traceability. For mission-critical applications, optional cross-section analysis reports are available to validate subsurface material integrity post-deburring. This integrated approach ensures steel components arrive with fully controlled edge conditions, eliminating downstream assembly issues.

Start Your Project

Looking for high-precision steel burr components? Contact Susan Leo at [email protected] to discuss your project requirements. With our advanced manufacturing capabilities and quality control systems in place at our Shenzhen factory, Honyo Prototype delivers consistent, reliable results for demanding applications. Trust us as your partner for precision-engineered solutions—reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.