Guide Contents

Project Insight: Steel Bending And Fabrication

Manufacturing Insight: Steel Bending and Fabrication

Why Speed & Precision Matter in Modern Product Development

In today’s competitive hardware landscape, delays or inaccuracies can derail timelines, inflate costs, and erode customer trust. Here’s why your project demands both:

Time-to-market pressure: Startups need to iterate fast—every day saved in prototyping accelerates market validation and investor confidence.

Functional reliability: Precision tolerances (±0.1mm) ensure enclosures, brackets, and chassis align perfectly with assembly requirements, eliminating costly rework.

Cost predictability: Optimized designs reduce material waste and labor-intensive adjustments, keeping projects on budget.

“In sheet metal fabrication, speed without precision is a liability. Precision without speed is a bottleneck. The best partners deliver both.” — Susan Leo, Founder of Honyo Prototype

Honyo Prototype: Your Digital Manufacturing Partner

We merge cutting-edge technology with deep manufacturing expertise to transform your designs into reality—faster, smarter, and more cost-effectively.

🚀 Online Instant Quote Platform

Get real-time pricing in seconds—no email chains or manual estimates.

AI analyzes your design’s bend count (cost: $1–$5/bend), material thickness, weld length ($1+/inch), and finish requirements to deliver transparent, itemized quotes.

Example: A 5-bend enclosure with 2mm steel, powder coating—quoted in <60 seconds with clear cost drivers.

💡 AI-Powered Design for Manufacturability (DFM)

Our platform flags issues before production: suboptimal bend locations, unnecessary complexity, or material mismatches.

Optimizes part geometry to reduce bends, minimize waste, and enhance structural integrity—cutting costs by up to 30% while meeting aerospace-grade tolerances.

Use case: A chassis design revised for fewer weld points and streamlined bending paths, slashing lead time by 40%.

⚡ 24–72 Hour Turnaround for Prototypes & Production

Fully automated workflows: Laser cutting → precision bending → robotic welding → in-house powder coating—no handoffs, no delays.

Shenzhen-based production hub leverages local supply chains for rapid material sourcing and quality control.

Scale seamlessly from 1 prototype to 1,000+ units without compromising speed or precision.

“At Honyo, we don’t just fabricate parts—we accelerate innovation. Your vision becomes reality faster, smarter, and with confidence.”

Ready to build with confidence?

Get Your Instant Quote in seconds—no commitment, no delays.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

Precision Manufacturing Technologies

Laser Cutting: Achieve micron-level precision on complex geometries with state-of-the-art fiber laser cutters, minimizing material waste and maximizing edge quality for flawless assembly.

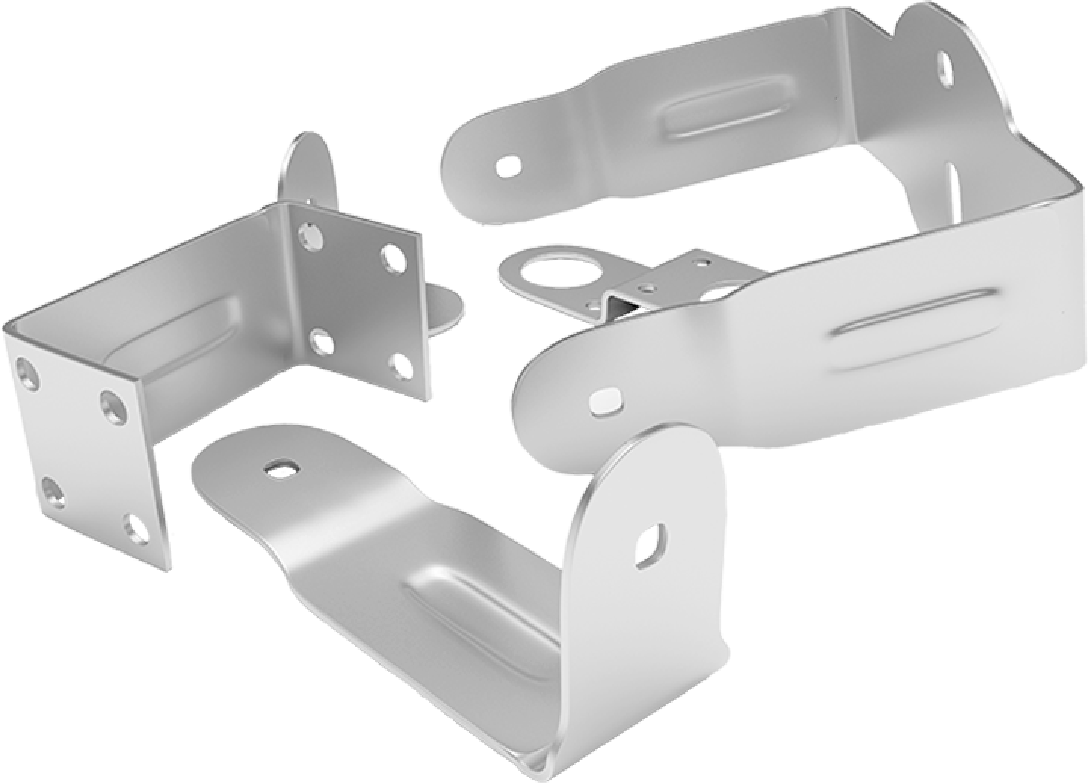

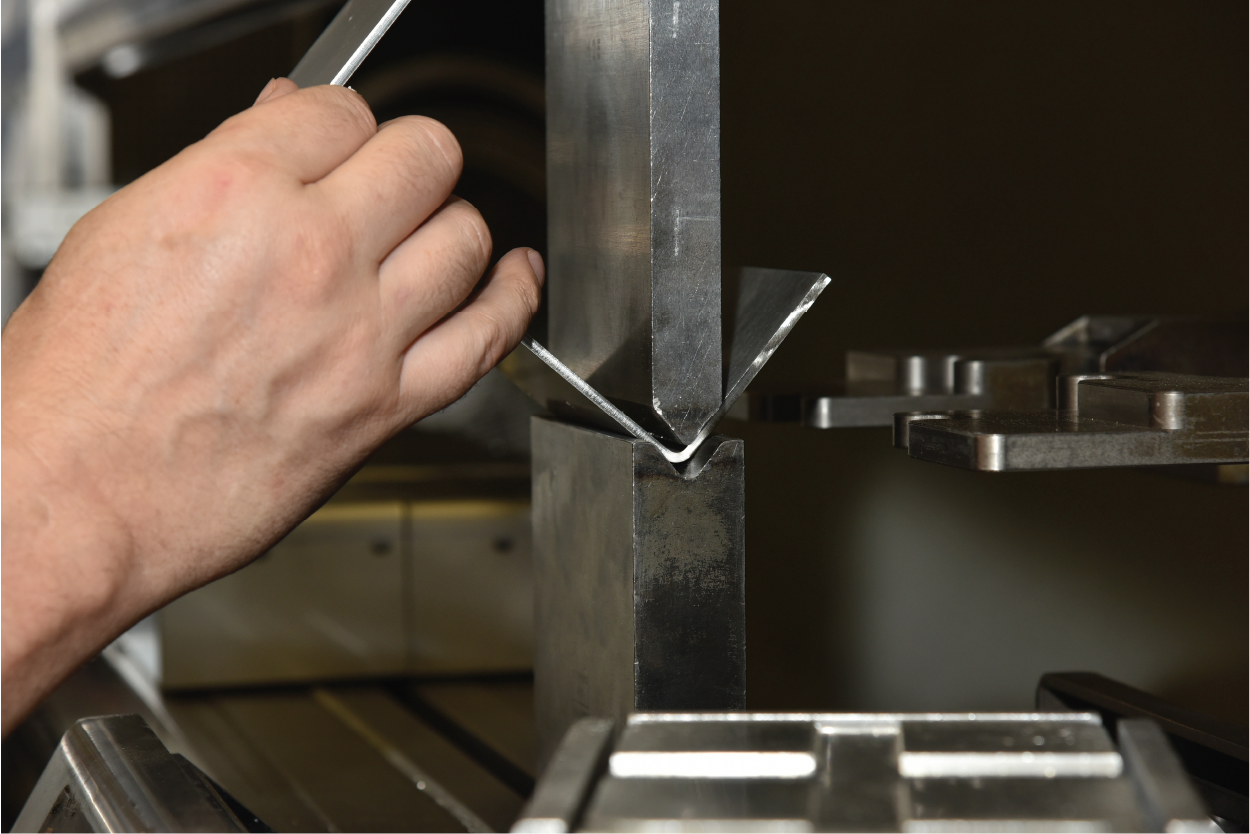

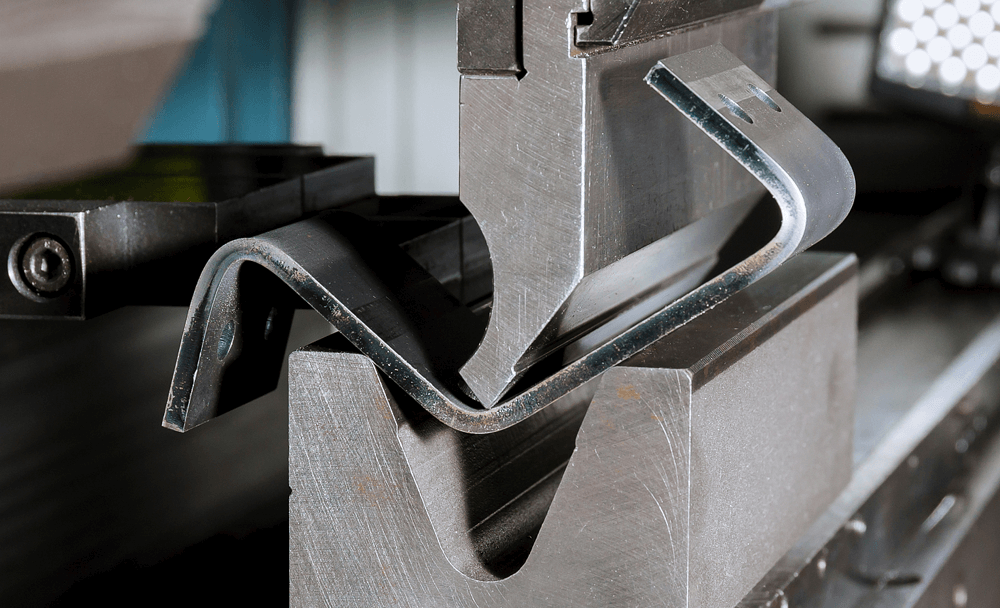

Advanced Bending: Cost-efficient CNC bending at $1–$5 per bend, with ±0.1° accuracy across material thicknesses (0.5mm–6mm), optimized for enclosures, brackets, and chassis.

Robotic Welding: Automated MIG/TIG processes deliver consistent, high-strength joints—cutting labor costs by 25% while ensuring structural reliability for mission-critical assemblies.

Powder Coating: Eco-friendly, durable finishes with uniform coverage and 15+ color options, meeting automotive-grade standards for both function and aesthetics.

Scalable Production Capacity

Seamlessly transition from 1 prototype to 10,000+ parts with zero setup adjustments—perfect for hardware startups scaling from proof-of-concept to mass production.

ISO-Certified Quality Assurance

Rigorous multi-stage inspections with real-time metrology, ensuring every part meets ISO 9001 standards for dimensional accuracy, material integrity, and surface finish.

AI-Driven Digital Workflow

Instant Online Quoting: Upload CAD files and receive transparent, itemized cost breakdowns in under 60 seconds—no hidden fees, no delays.

Smart DFM Optimization: Our AI analyzes designs for manufacturability, suggesting cost-saving tweaks to bends, weld points, and material choices—reducing total project costs by up to 20%.

30% Faster Turnaround: Prototypes delivered in 3–5 business days, production batches shipped in 1–2 weeks—keeping your innovation pipeline moving at speed.

“At Honyo, we don’t just manufacture—we engineer efficiency. From your first sketch to final delivery, our AI-powered platform turns complexity into simplicity.”

— Susan Leo, Founder

Materials & Surface Finishes

Material Options & Finishes for Precision Sheet Metal Fabrication

Strategic Material Selection for Cost-Effective Production

Choose materials that balance performance, cost, and application needs. Our platform dynamically calculates real-time costs based on thickness, geometry, and volume to maximize savings:

Aluminum (6061-T6, 5052): Lightweight, corrosion-resistant, and ideal for enclosures where weight matters. 20% lower machining costs than steel for prototypes due to faster processing.

Steel (Mild & Stainless 304/316): High-strength solutions for brackets and chassis. Mild steel delivers 30% cost savings for structural parts; stainless excels in medical or marine environments with superior corrosion resistance.

Copper: Exceptional electrical conductivity for heat sinks or specialized components. Higher material cost offset by 15% faster fabrication for conductive applications.

Surface Finishes That Elevate Performance & Aesthetics

Enhance durability, corrosion resistance, and visual appeal with finishes optimized for your material and use case:

Powder Coating: Eco-friendly, scratch-resistant finish with 200+ color options. Perfect for steel enclosures; 24-hour turnaround on our automated line.

Anodizing (Aluminum Only): Wear-resistant, electrically insulating protection. Type II for standard use; Type III for heavy-duty industrial applications.

Polishing & Brushing: Premium aesthetic finishes for visible components. Minimal cost impact (<5% premium) with precision robotic techniques.

Optimize Costs with Our AI-Powered Platform

Innovate faster, spend smarter—our smart tools eliminate guesswork and accelerate your path to production:

Instant Online Quote: Upload CAD files for real-time pricing on materials, bends, and finishes. Save up to 30% on prototyping with automated cost analysis.

AI-Driven Design Feedback: Our platform flags potential cost drivers (e.g., excessive bends, tight tolerances) and suggests optimizations in seconds—no engineer consultation needed.

48-Hour Turnaround Guarantee: From quote to delivery for standard orders. Transparent pricing with no hidden fees—just fast, reliable service for hardware startups and engineers.

💡 Pro Tip: Use our AI Cost Simulator to test material/finish combinations before finalizing designs. See how switching from stainless to mild steel with powder coating cuts costs by 25% while maintaining structural integrity—perfect for enclosures and chassis.

Powered by Susan Leo’s vision for agile, data-driven manufacturing. Let’s build what’s next—faster, smarter, and cost-effectively.

From Quote to Part: Our Process

How It Works: From CAD to Part

Streamline your sheet metal fabrication journey with Honyo Prototype’s AI-driven platform—where precision meets speed.

Step 1: Upload Your CAD File

Drag-and-drop simplicity: Support for STEP, IGES, DWG, STL, and other standard formats.

Instant file validation: Automated checks for geometry errors, missing dimensions, or manufacturability red flags.

Secure & private: Cloud-based storage with zero data retention post-project—your designs stay yours.

Step 2: Get Instant AI-Powered Quote

Real-time cost analysis: AI scans your design for material type, thickness, bend count, weld length, and finishing needs.

Transparent breakdown: See itemized costs for raw materials ($X/kg), bending ($1–$5/bend), welding ($1/inch), powder coating, and more—no hidden fees.

Quotes in seconds: Skip days-long manual estimates. Get a firm price before you commit.

Step 3: DFM Optimization & Feedback

Proactive design fixes: AI flags issues like tight bend radii, inadequate hole spacing, or material waste risks.

Cost-saving recommendations: Optimize for enclosures, brackets, or chassis with suggestions like:

Adjusting tolerances to reduce machining complexity

Minimizing high-cost welding via alternative fastening methods

Selecting cost-efficient materials without compromising strength

Engineer collaboration: Refine designs in real-time with Honyo’s experts—no back-and-forth delays.

Step 4: Fast-Track Production & Delivery

Automated workflow: Laser cutting → precision bending → welding → powder coating—all in one seamless process.

Real-time tracking: Monitor progress via your customer portal from production start to final inspection.

Guaranteed lead times: Standard orders delivered in 3–5 days; urgent requests prioritized with expedited options.

Global-ready: Reliable shipping to 100+ countries with customs support and real-time tracking.

Why Honyo Prototype?

We don’t just manufacture—we engineer efficiency. From hardware startups scaling rapidly to enterprise engineers demanding precision, our AI platform turns complex fabrication into a transparent, cost-effective process. Your vision, accelerated.

Start Your Project with Honyo

Start Your Project with Honyo

💡 Instant AI-Powered Quoting

Upload your CAD file and receive a detailed cost breakdown in under 60 seconds

AI optimizes material selection, bend complexity, and finishing for maximum cost efficiency

Transparent pricing with zero hidden fees—see exactly how design choices impact your total cost

⚡ Rapid Prototyping to Production

3-day lead times for prototypes, 1–2 weeks for production runs

Precision bending (±0.1mm), laser cutting, and welding for enclosures, brackets, and chassis

Integrated powder coating for durable, professional finishes—no third-party handoffs

🌍 Trusted by Hardware Innovators Worldwide

Led by founder Susan Leo, our Shenzhen/Dongguan engineering team combines industry expertise with cutting-edge automation

Scalable solutions from single prototypes to high-volume runs—flexible MOQs and tailored pricing

End-to-end support from design validation to final delivery—we handle complexity so you don’t have to

📞 +86 139 2843 8620

📧 [email protected]

📍 Visit our Shenzhen & Dongguan facilities for a hands-on consultation

Ready to turn your design into reality? Let’s build something remarkable—together.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.