Contents

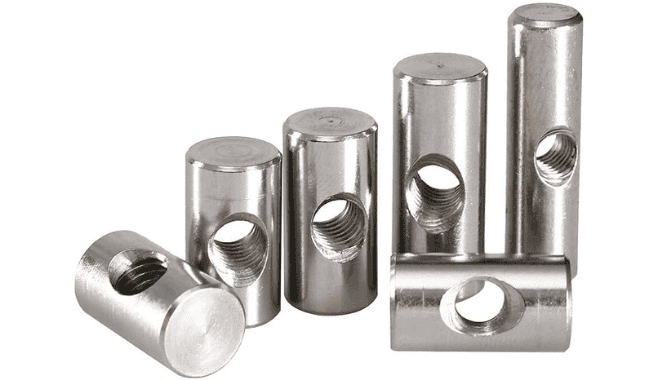

Manufacturing Insight: Steel Barrel Nut

Steel Barrel Nut Precision Manufacturing

Honyo Prototype delivers mission-critical steel barrel nuts engineered for structural integrity and exacting assembly requirements. These components demand exceptional concentricity, thread precision, and material consistency—attributes we achieve through advanced CNC machining processes. Our Swiss-type and multi-axis milling centers consistently hold tolerances to ±0.005mm on complex geometries, utilizing premium steel alloys including 4140, 1018, and 303 stainless steel with controlled heat treatment for optimal hardness and fatigue resistance. Every barrel nut undergoes rigorous in-process inspection using coordinate measuring machines (CMM) and optical comparators to verify critical dimensions such as thread pitch diameter, barrel runout, and bearing surface flatness.

We specialize in low-to-mid volume production runs where design iteration and rapid turnaround are paramount, supporting aerospace, medical device, and industrial equipment manufacturers. Our integrated workflow—from material certification to final deburring and surface finishing—ensures compliance with ISO 9001:2015 standards while minimizing lead times. Accelerate your prototyping or production schedule with Honyo’s Online Instant Quote system, providing detailed pricing and manufacturability feedback within hours, not days. Submit your STEP or DWG files directly through our portal to receive a precision-engineered solution backed by decades of CNC machining expertise.

Technical Capabilities

Technical Specifications for Steel Barrel Nut – Precision Machined Components

The steel barrel nut is a threaded fastening component commonly used in aerospace, automotive, and industrial applications requiring high strength and precise alignment. When manufactured using advanced 3-axis, 4-axis, and 5-axis CNC milling and turning processes, these components achieve tight tolerances and superior surface finishes. Below are the technical specifications and material considerations critical to high-precision manufacturing.

| Parameter | Specification Details |

|---|---|

| Manufacturing Process | 3/4/5-Axis CNC Milling and CNC Turning |

| Typical Tolerance Range | ±0.0002″ to ±0.001″ (5 to 25 µm), depending on feature and inspection requirements |

| Surface Finish (Ra) | 32–125 µin (0.8–3.2 µm); achievable down to 16 µin (0.4 µm) with fine finishing passes |

| Thread Type | Custom or standard (e.g., UNC, UNF, Metric M6–M20) with GO/NO-GO gauge compliance |

| Feature Accuracy | Positional tolerance ±0.0005″ (12.7 µm); concentricity < 0.001″ (25.4 µm) |

| Secondary Operations | Deburring, thread rolling, heat treatment, passivation, or plating as required |

| Inspection Method | CMM (Coordinate Measuring Machine), optical comparators, thread gauges |

| Lead Time (Prototype) | 7–15 business days, depending on complexity and finishing |

Material Compatibility and Machinability

While the barrel nut is typically made from steel for strength and durability, prototyping and functional testing may involve alternative materials. Below is an overview of common materials used during development and production:

| Material | Typical Use Case | Machinability | Tolerance Suitability | Notes |

|---|---|---|---|---|

| Steel | Production-grade components | Moderate | Excellent | High strength, wear resistance; requires rigid tooling and cooling |

| Aluminum (6061, 7075) | Prototypes, lightweight assemblies | High | Excellent | Easy to machine, excellent for tight tolerances; lower wear resistance |

| ABS | Non-structural prototypes, fit checks | High | Good | Suitable for rapid iteration; not for load-bearing or high-temp use |

| Nylon (PA6, PA66) | Low-friction, non-metallic assemblies | Moderate | Fair | Prone to creep; requires slow speeds and sharp tools to avoid deformation |

Notes on Machining Strategy

For tight-tolerance barrel nuts, 5-axis milling enables complete machining in a single setup, reducing cumulative error and improving feature alignment. Turning operations are ideal for cylindrical symmetry and thread generation. Multi-axis coordination ensures precise thread runout and concentricity, especially in hardened steel variants. Material selection directly impacts tool life and cycle time—steel demands carbide tooling and controlled feeds/speeds, while plastics like ABS and nylon require optimized chip evacuation to prevent melting.

All components are verified per AS9100 or ISO 9001 standards when produced for regulated industries.

From CAD to Part: The Process

Honyo Prototype Steel Barrel Nut Manufacturing Process

Our end-to-end process for steel barrel nut production begins with client CAD file submission via our secure customer portal. We accept native formats including STEP, IGES, and Parasolid, with mandatory inclusion of geometric dimensioning and tolerancing (GD&T) per ISO 1101 standards. Incomplete files trigger immediate automated feedback specifying missing critical features such as thread class (e.g., 6H internal threads), hex key dimensions, barrel radius tolerances (typically ±0.05mm), and surface finish requirements (Ra 1.6μm standard).

The AI Quote engine processes validated CAD data using parametric algorithms trained on 15+ years of fastener production data. It cross-references material costs, machine time (CNC Swiss turning vs. multi-spindle), and secondary operations against current commodity steel pricing indices. For steel barrel nuts, the system defaults to AISI 4140 alloy but flags alternatives if client specifications permit cost optimization. Quotes include granular breakout of material waste factors (typically 22-28% for hex bar stock), thread rolling vs. cutting implications on cycle time, and plating/special coating surcharges. Human engineers review all AI outputs before client release to validate technical feasibility.

During Design for Manufacturability (DFM) analysis, our engineering team conducts steel-specific validations. Critical checks include: thread root diameter verification against minor stress area calculations per ISO 898-1; barrel curvature analysis to prevent swarf accumulation during machining; and hex head concentricity assessment to ensure wrench engagement compliance with ASME B18.2.1. We identify risks such as inadequate thread engagement length causing shear failure, or insufficient case depth for carburized variants. Material substitution recommendations occur here if client specs allow equivalent alternatives like SCM435 for improved machinability.

Production executes on dedicated CNC Swiss-type lathes with live tooling for complex barrel geometries. Steel barrel nuts undergo: precision cold forming of the barrel profile to maintain grain flow integrity; thread rolling (not cutting) to achieve 20% higher fatigue strength; and optional induction hardening to 45-50 HRC surface hardness. All lots include in-process verification via coordinate measuring machines (CMM) checking positional tolerances of ±0.02mm on critical datums. Secondary operations like zinc-nickel plating (per ASTM B633 SC4) occur in-house with adhesion testing.

Final delivery includes full traceability documentation: material test reports (MTRs) showing actual tensile yield (min. 655 MPa for 4140), hardness certification, and first-article inspection reports with CMM scan data. Barrel nuts ship in anti-tarnish VCI packaging with lot-controlled labeling meeting AS9100 requirements. Typical lead time from CAD approval to shipment is 12-18 business days for lots under 5,000 pieces, with expedited options for prototyping.

Common Steel Material Options for Barrel Nuts

| Material Grade | Tensile Strength (MPa) | Hardness (HRC) | Typical Applications |

|---|---|---|---|

| AISI 4140 | 655-1000 | 28-32 | Automotive suspension, industrial machinery |

| SCM435 | 785-930 | 25-28 | High-cycle assembly tools, robotics |

| 303 Stainless | 520-758 | 20-25 | Marine hardware, chemical environments |

| 1035 Carbon | 500-700 | 18-22 | General purpose, non-critical assemblies |

Start Your Project

For inquiries about our steel barrel nuts, contact Susan Leo at [email protected]. Our manufacturing facility is located in Shenzhen, ensuring high-quality production and efficient lead times for global clients.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.