Contents

Manufacturing Insight: Steel Alloy Metals

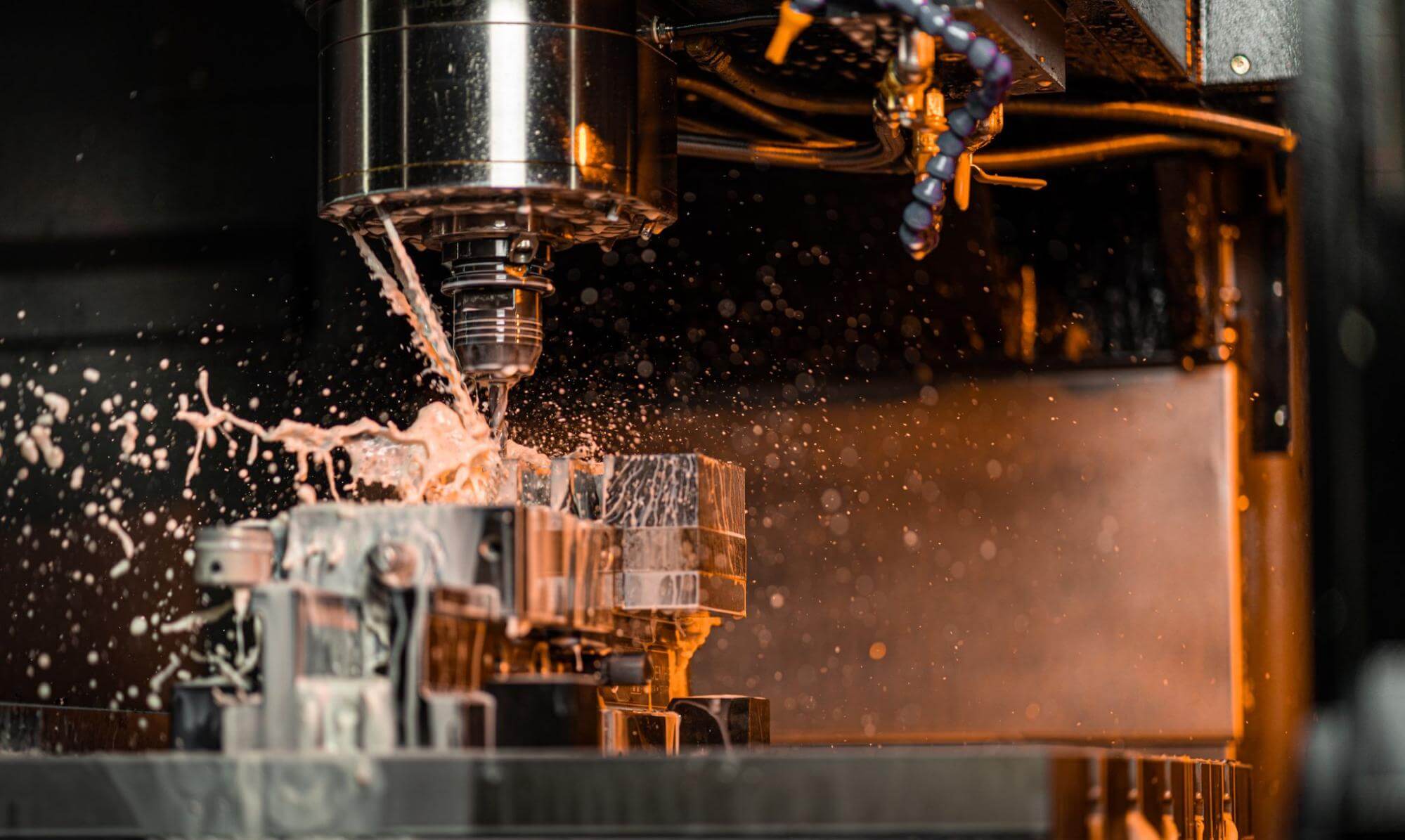

Precision Steel Alloy Fabrication for Demanding Industrial Applications

Steel alloys remain the backbone of robust industrial manufacturing, offering an unmatched balance of strength, durability, and versatility across aerospace, medical, and heavy machinery sectors. At Honyo Prototype, our sheet metal fabrication expertise centers on optimizing these critical materials—from 304/316 stainless steel to advanced carbon and tool steel alloys—to meet exacting tolerances and performance specifications. We understand that material integrity directly impacts product lifecycle and safety, which is why our processes prioritize metallurgical consistency and structural reliability at every stage.

Our end-to-end fabrication capabilities integrate state-of-the-art laser cutting, CNC precision bending, robotic welding, and comprehensive finishing services, all executed within a tightly controlled ISO 9001-certified environment. This ensures your steel alloy components achieve dimensional accuracy down to ±0.05mm while maintaining material properties critical for high-stress applications. Whether prototyping complex geometries or scaling to low-volume production, Honyo delivers engineered solutions that eliminate costly rework and accelerate time-to-market.

Access Real-Time Quoting for Your Steel Alloy Project

Streamline your procurement process with Honyo’s Online Instant Quote system. Upload your DXF, DWG, or STEP files to receive a detailed, transparent cost estimate within hours—not days—including material selection guidance, lead time projections, and DFM feedback. This digital workflow empowers engineering teams to iterate faster and make data-driven sourcing decisions without compromising on quality or technical rigor. Begin your project with confidence at honyoprototype.com/quote.

Technical Capabilities

The term “steel alloy metals” refers to a broad category of iron-based alloys with added elements such as carbon, chromium, nickel, or molybdenum to enhance mechanical properties, weldability, and formability. For manufacturing processes like laser cutting, bending, and welding, material selection is critical to ensure precision, structural integrity, and cost-efficiency. Below is a comparison of key materials used in prototype and production environments, including aluminum, steel (carbon and stainless), ABS, and nylon, focusing on their performance in laser cutting, bending, and welding applications.

| Material | Laser Cutting Suitability | Bending Suitability | Welding Suitability | Notes |

|---|---|---|---|---|

| Carbon Steel (e.g., A36, 1018) | Excellent – high absorption of laser energy; clean cuts with nitrogen or oxygen assist | Excellent – good ductility for sharp bends; springback ~2–4° | Excellent – easily welded using MIG, TIG, or spot welding; minimal pre-treatment required | Most common for structural components; prone to rust without coating |

| Stainless Steel (e.g., 304, 316) | Excellent – clean cuts with nitrogen assist; higher power required than carbon steel | Good – moderate ductility; requires higher tonnage; springback ~3–6° | Excellent – weldable with TIG or MIG; risk of intergranular corrosion if improperly treated | Corrosion-resistant; ideal for medical, food service, and outdoor applications |

| Aluminum Alloys (e.g., 5052, 6061) | Good – reflective nature requires specialized lasers (e.g., fiber with high brightness); nitrogen assist recommended | Excellent – high ductility; low springback (~2–3°); prone to galling | Good – weldable with TIG or MIG; requires cleaning and pre-weld prep to remove oxide layer | Lightweight; excellent strength-to-weight ratio; oxide layer affects weld quality |

| ABS (Acrylonitrile Butadiene Styrene) | Fair – cuts cleanly with CO₂ laser; may produce soot or melted edges | Poor – not typically bent; limited cold-forming capability | Poor – not weldable using standard metal methods; can be bonded or ultrasonically welded | Thermoplastic polymer; used for enclosures or non-structural parts; flammable |

| Nylon (Polyamide) | Poor – high laser absorption causes melting and charring; not recommended for laser cutting | Poor – limited bending; high creep under load | Poor – not weldable via arc methods; can be joined with adhesives or mechanical fasteners | High wear resistance; used in gears and bushings; hygroscopic and thermally sensitive |

Notes on Process Compatibility:

Laser Cutting: Metals like steel and aluminum respond well to fiber laser systems (1–4 kW typical). ABS and nylon are generally not recommended for laser cutting due to thermal degradation.

Bending: Steel and aluminum alloys are routinely bent on press brakes with appropriate tooling. Plastics like ABS and nylon lack the structural rigidity for precision air bending.

Welding: Only metallic materials (steel, aluminum) are compatible with arc welding processes. ABS and nylon require alternative joining methods such as solvent bonding, adhesives, or mechanical fasteners.

For prototyping and low-volume production at Honyo Prototype, carbon steel and aluminum alloys are most commonly processed due to their balance of machinability, strength, and compatibility with standard fabrication equipment.

From CAD to Part: The Process

Honyo Prototype Steel Alloy Manufacturing Process Overview

Honyo Prototype executes a streamlined, technology-driven workflow for steel alloy components, ensuring precision, cost efficiency, and rapid turnaround. This process is rigorously validated for steel-specific properties including machinability, thermal stability, and post-processing requirements. Below is the end-to-end sequence for steel alloy projects.

Upload CAD

Clients initiate the process by uploading native or neutral-format CAD files (STEP, IGES, Parasolid) via Honyo’s secure customer portal. For steel alloys, the system immediately validates geometric feasibility against material constraints such as minimum wall thickness for cast steel (≥3mm) or feature complexity for hardened alloys (e.g., AISI 4140). Critical steel-specific metadata—material grade (e.g., 304SS, 4340), required heat treatment (annealed, Q&T), and surface finish—is captured to inform downstream stages. Non-compliant geometries (e.g., undercuts in high-carbon steel) trigger automated alerts prior to quoting.

AI-Powered Quote Generation

Honyo’s proprietary AI engine analyzes the CAD geometry alongside steel alloy parameters to generate instant, data-backed quotes. The algorithm factors in material-specific variables: scrap rate differentials (e.g., 15–25% for 17-4PH vs. 10–15% for 1018), machining time multipliers for hardened alloys (e.g., 1.8x slower for 4340 vs. mild steel), and secondary operation costs (e.g., stress relieving, passivation). Real-time feedstock pricing from certified mills and historical machining performance data for steel alloys ensure accuracy within ±5% of final cost. Clients receive a detailed breakdown including material surcharges, tolerance-driven cost impacts, and lead time projections.

DFM Analysis and Optimization

Engineers conduct a steel-specialized Design for Manufacturability review, focusing on alloy-specific risk mitigation. Key interventions include: eliminating thin sections prone to warpage during heat treatment, modifying sharp corners to prevent cracking in high-strength alloys (e.g., 4340), and optimizing hole depths to reduce tool deflection in deep-hole drilling for stainless steels. The DFM report provides actionable alternatives—such as substituting welded assemblies with near-net forged blanks for 4130 chromoly—while maintaining structural integrity. All recommendations align with ASTM/AMS standards for the specified steel grade, with typical resolution time under 24 hours.

Production Execution

Steel alloy production leverages Honyo’s integrated capabilities: CNC machining (3–5-axis mills/lathes with carbide tooling for hardened steels), in-house stress relieving up to 650°C, and certified secondary services (e.g., MIL-STD-1312 for magnetic particle inspection). For stainless alloys, dedicated clean-room environments prevent carbide contamination. Each lot undergoes real-time process monitoring: thermal sensors track cooling rates during quenching, and CMM validation verifies critical dimensions post-heat treat to account for distortion (e.g., holding ±0.05mm on 17-4PH after H900). Traceability is maintained via laser-etched part IDs linked to material certs and process logs.

Delivery and Logistics

Completed steel alloy components undergo final QA per AS9100 protocols, including hardness testing (Rockwell C-scale for tool steels) and surface roughness verification. Parts are packaged with VCI paper for corrosion-prone alloys (e.g., carbon steels) and shipped via freight partners with climate-controlled options for precision assemblies. Delivery includes full documentation: material test reports (MTRs), heat treat records, and First Article Inspection (FAI) data. Honyo guarantees on-time delivery through dynamic scheduling, with typical lead times of 10–15 days for machined steel prototypes and 20–25 days for complex assemblies requiring heat treatment.

This closed-loop process ensures steel alloy components meet stringent industry requirements while minimizing time-to-part through predictive analytics and material-centric engineering rigor.

Start Your Project

Looking for high-quality steel alloy metals for your next project? Partner with Honyo Prototype for precision-engineered metal solutions backed by advanced manufacturing capabilities.

Our Shenzhen-based factory delivers consistent quality, fast turnaround times, and expert technical support for demanding industrial applications.

Contact Susan Leo today at [email protected] to discuss your steel alloy requirements and receive a tailored quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.