Contents

Manufacturing Insight: Steel 3D Print

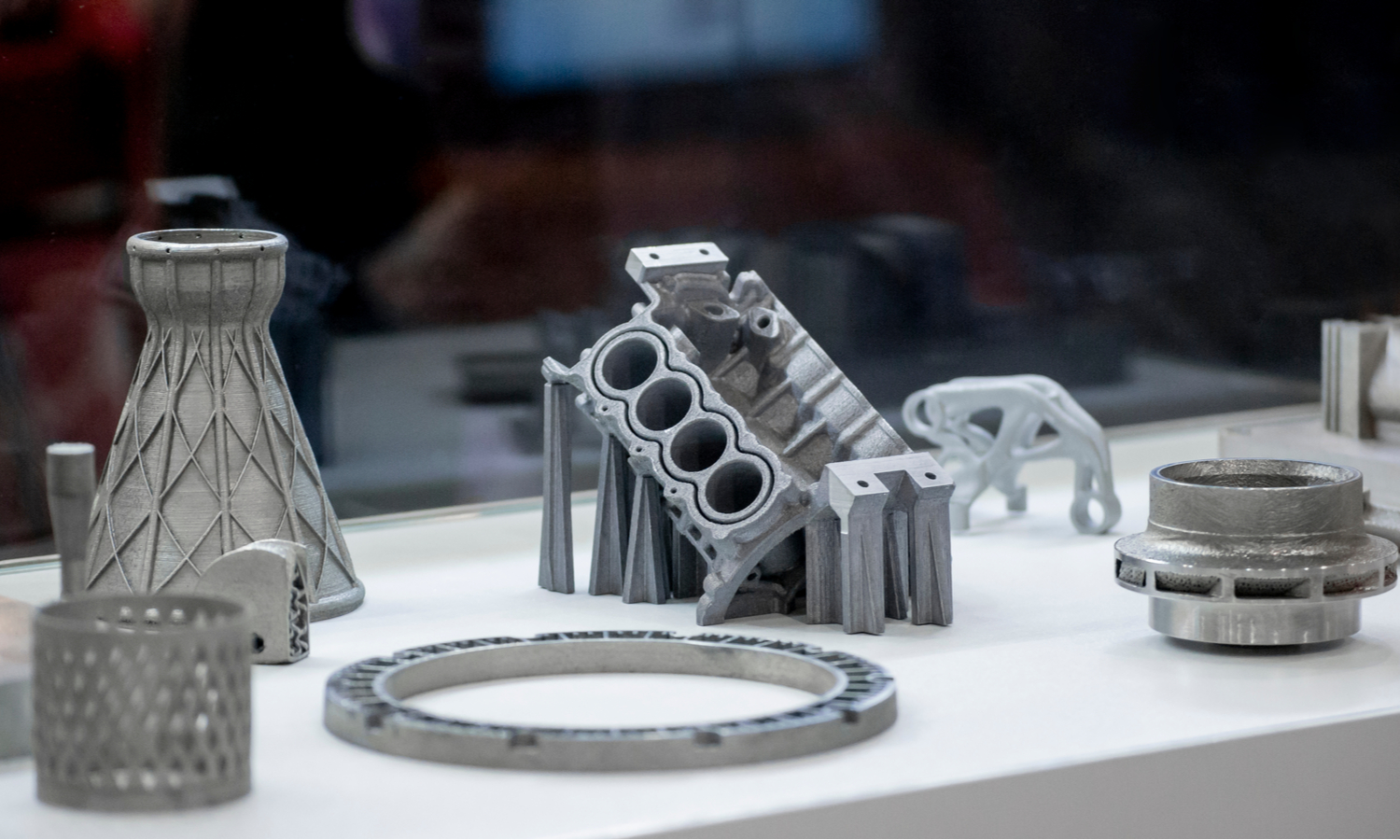

Honyo Industrial Steel 3D Printing: Precision Manufacturing for Demanding Applications

Traditional steel component production often encounters significant lead time bottlenecks and geometric limitations, hindering innovation in aerospace, medical, and energy sectors. Honyo Prototype addresses these challenges through advanced industrial-grade steel 3D printing, specifically leveraging Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM) technologies. We specialize in producing complex, high-integrity steel parts from materials including 17-4 PH stainless steel, 316L stainless steel, and tool steels, achieving near-full density and mechanical properties suitable for functional prototyping and qualified end-use production.

Our integrated service encompasses comprehensive design for additive manufacturing (DfAM) support, rigorous material certification, precise build execution on calibrated industrial systems, and extensive post-processing capabilities such as heat treatment, HIP, CNC machining, and surface finishing. Every build adheres to stringent quality management protocols, ensuring dimensional accuracy and material integrity critical for mission-critical applications. Honyo’s manufacturing expertise translates complex geometries into robust steel components that meet exacting industry standards.

Material capabilities are engineered for performance:

| Steel Grade | Key Properties | Common Applications |

|---|---|---|

| 17-4 PH SS | High strength, corrosion resistance | Aerospace fittings, medical implants |

| 316L SS | Excellent biocompatibility, weldability | Fluid systems, surgical instruments |

| Tool Steels (e.g., H13) | High hardness, thermal stability | Molds, tooling, wear parts |

Accelerate your development cycle with Honyo’s Online Instant Quote system. Upload your CAD file directly to our secure portal and receive a detailed, geometry-based manufacturing assessment and competitive pricing within hours—no manual RFQ delays. This seamless integration of industrial steel 3D printing capability with real-time quoting provides the speed and transparency modern engineering teams require to move from concept to validated steel component efficiently. Initiate your project with confidence in our technical precision and responsive service.

Technical Capabilities

The term “steel 3D print” typically refers to additive manufacturing processes capable of producing parts using steel or steel-like materials. However, the processes listed—SLA, SLS, MJF, and DMLS—vary significantly in their compatibility with metals versus polymers. Below is a technical comparison focused on these four processes, with attention to their applicability to steel and other materials such as Aluminum, ABS, and Nylon.

| Process | Full Name | Compatible Materials | Primary Material Type | Steel Capability | Aluminum Capability | ABS | Nylon | Layer Resolution Range | Typical Build Speed | Post-Processing Requirements |

|---|---|---|---|---|---|---|---|---|---|---|

| SLA | Stereolithography | Photopolymer resins (standard, engineering, castable, biocompatible) | Polymer (liquid resin) | No | No | No | No | 25–100 microns | Moderate | Support removal, cleaning, UV curing |

| SLS | Selective Laser Sintering | Nylon (PA11, PA12), Glass-filled Nylon, TPU | Polymer (powder) | No | No | No | Yes | 80–120 microns | Fast | Powder removal, bead blasting, optional dyeing |

| MJF | Multi Jet Fusion | Nylon (PA12), Glass-filled PA12, TPU | Polymer (powder) | No | No | No | Yes | 80–100 microns | Very fast | Powder removal, bead blasting, optional coloring |

| DMLS | Direct Metal Laser Sintering | Stainless steel (17-4 PH, 316L), Tool steel (Maraging), Titanium, Aluminum (AlSi10Mg), Cobalt-Chrome | Metal (powder) | Yes | Yes (AlSi10Mg, AlSi7Mg) | No | No | 20–50 microns | Slow | Support removal, heat treatment, HIP, machining, surface finishing |

Notes:

SLA is a resin-based photopolymerization process and is not suitable for metal printing. It does not support steel, aluminum, ABS, or nylon in functional material forms. It is often used for high-detail prototypes and molds.

SLS and MJF are polymer powder-bed fusion technologies primarily used with nylon-based materials. They offer strong, functional parts suitable for end-use applications but cannot process metals like steel or aluminum.

DMLS is a metal additive manufacturing process that fully melts metal powder using a high-powered laser. It supports a range of engineering metals including various stainless steels and aluminum alloys, making it the only process in this list capable of true steel 3D printing.

ABS as a material is commonly associated with FDM/FFF 3D printing and is not used in SLA, SLS, MJF, or DMLS processes. While some SLS powders may mimic ABS-like properties, true ABS filament is not processed in these systems.

For steel 3D printing applications requiring high strength, corrosion resistance, or high-temperature performance, DMLS is the appropriate technology. SLS and MJF are preferred for durable nylon-based polymer components, while SLA excels in high-resolution, non-metallic prototypes.

From CAD to Part: The Process

Honyo Prototype Steel 3D Printing Process Overview

Honyo Prototype utilizes Laser Powder Bed Fusion (LPBF) for precision steel additive manufacturing, primarily with 316L stainless steel and 17-4PH precipitation-hardening stainless steel. Our streamlined workflow ensures technical rigor and rapid turnaround while maintaining aerospace and medical-grade quality standards. Below is the detailed sequence from initial upload to final delivery.

Upload CAD

Clients submit watertight, manifold 3D CAD files in STEP, IGES, or native formats via our secure customer portal. Minimum wall thickness requirements (0.4 mm for 316L, 0.5 mm for 17-4PH) and overhang angle limitations (<45° without supports) are enforced at this stage. The system validates file integrity and automatically checks for non-manifold edges or self-intersections, rejecting non-compliant submissions with specific error logs to prevent downstream delays.

AI Quote Generation

Within 15 minutes of CAD upload, our proprietary AI engine analyzes geometry, material selection, and requested quantity to generate a binding quote. This system evaluates build volume utilization, support structure density, and thermal distortion risk using historical machine data. Pricing includes material cost (quoted per cm³), machine time, and standard post-processing (stress relief, support removal). The quote details achievable as-built surface roughness (Ra 12–25 μm) and tolerances (±0.1 mm for features <50 mm), with options to upgrade to precision finishing.

DFM Analysis

A dedicated manufacturing engineer performs a manual Design for Additive Manufacturing review within 24 hours of quote acceptance. This phase focuses on optimizing part orientation to minimize supports, identifying critical surfaces requiring machining allowances, and verifying compliance with ASTM F75/F138 standards for medical applications. We provide a formal DFM report with actionable recommendations—such as adding escape holes for powder evacuation or modifying thin features for improved thermal stability—and revise the quote if structural changes are required. Client approval is mandatory before proceeding.

Production

Approved designs enter our certified LPBF production queue using EOS M 290 or M 400 systems in ISO Class 8 cleanrooms. Build parameters are validated per material-specific PBF protocols (e.g., 316L: 300 W laser, 60 μm layer thickness, 800 mm/s scan speed). Real-time melt pool monitoring ensures defect detection, with full build chamber inerting (oxygen < 250 ppm). Post-build, parts undergo:

Support removal via band sawing and wire EDM

Stress relief annealing (316L: 1050°C/1hr, 17-4PH: 1040°C/1hr)

Precision bead blasting (Ra 3.2 μm) or CNC machining for critical interfaces

All steel components receive PMI verification via handheld XRF and 100% dimensional inspection against CAD using CMM or optical scanning.

Delivery

Final parts ship with comprehensive documentation:

Material test reports (ASTM E8 tensile, E566 chemical)

Heat treatment certificates with traceable furnace logs

Dimensional inspection report (AS9102 format available)

First article inspection for production runs

Standard lead time is 7–10 business days from DFM approval. Parts are packaged in anti-static, humidity-controlled containers with desiccant, labeled per AS9145 requirements. Expedited delivery (5 days) includes real-time production tracking via our client portal.

This integrated process reduces time-to-part by 40% compared to industry averages while ensuring full traceability from raw powder to certified delivery, meeting ITAR, ISO 13485, and NADCAP requirements for regulated sectors.

Start Your Project

Interested in high-precision steel 3D printing for your next project? Contact Susan Leo at [email protected] to discuss your requirements.

Our advanced manufacturing facility in Shenzhen offers rapid prototyping and low-volume production with tight tolerances, excellent surface finish, and fast turnaround times.

Leverage our expertise in metal additive manufacturing to accelerate your product development cycle. Reach out today for a quote and technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.