Contents

Manufacturing Insight: Stamped Titanium Parts

Precision Machined Titanium Components for Demanding Applications

Honyo Prototype delivers mission-critical CNC machining services for stamped titanium parts, addressing the unique challenges of this high-strength, corrosion-resistant material. Titanium’s propensity for work hardening, thermal conductivity limitations, and stringent dimensional tolerances demand specialized expertise—particularly when integrating precision machining with stamped geometries. Our engineered solutions ensure optimal surface integrity, burr-free edges, and micron-level accuracy for aerospace, medical, and defense applications where failure is not an option.

Leveraging advanced multi-axis CNC platforms, proprietary fixturing strategies, and adaptive toolpath algorithms, we mitigate thermal distortion and maintain tight tolerances on complex stamped titanium substrates. Our process includes rigorous in-process metrology, optimized coolant delivery for chip evacuation, and material-specific parameter libraries honed over 1,200+ titanium production runs. This technical rigor transforms stamped blanks into fully functional components meeting AS9100 and ISO 13485 standards without secondary operations.

Accelerate your prototyping or low-volume production timeline with Honyo’s Online Instant Quote system. Upload CAD files to receive a detailed manufacturability analysis and competitive pricing within hours—not days—enabling faster design validation and time-to-market for your titanium-critical projects.

Technical Capabilities

Technical Specifications for Stamped Titanium Parts with Machining Capabilities

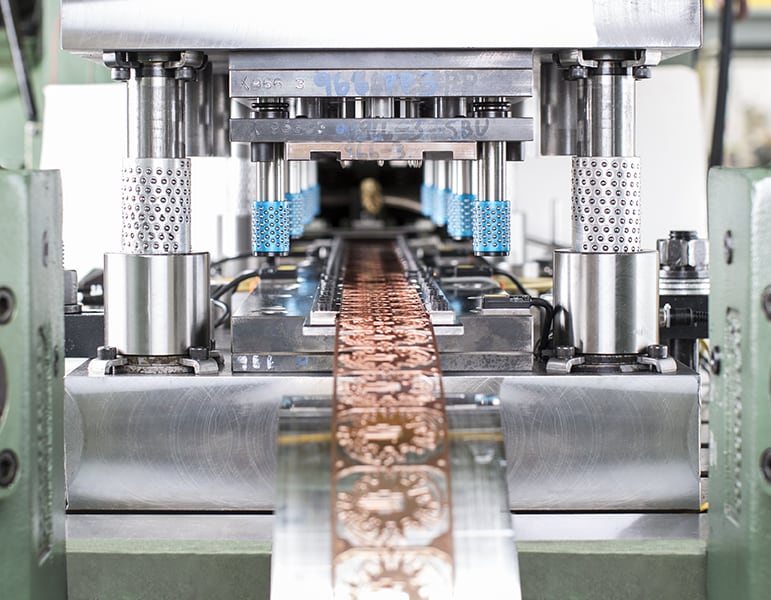

While stamped titanium parts are typically formed using progressive dies or press tooling, secondary precision machining operations such as 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, are often required to achieve tight tolerances and complex geometries. These processes ensure critical features like mounting surfaces, threaded holes, and alignment features meet exacting dimensional requirements. Honyo Prototype supports hybrid manufacturing workflows combining stamping with high-precision CNC machining across various materials.

| Parameter | Specification Details |

|---|---|

| Primary Material | Titanium (Grade 1, Grade 2, Grade 5 – Ti-6Al-4V) |

| Secondary Materials Supported | Aluminum (6061-T6, 7075-T6), Steel (1018, 4140, 17-4 PH), ABS, Nylon (PA6, PA66) |

| Forming Process | Cold/hot stamping with precision tooling; blanking, coining, embossing, piercing |

| Machining Compatibility | Post-stamp CNC machining: 3-axis, 4-axis, and 5-axis milling; CNC turning |

| Machining Tolerance | ±0.005 mm (±0.0002″) for critical features; tight-tolerance capabilities down to ±0.002 mm (±0.00008″) with inspection validation |

| Surface Finish (Machined) | Ra 0.8 µm (32 µin) standard; down to Ra 0.4 µm (16 µin) with fine finishing passes |

| Feature Capabilities | Precision pockets, radii, undercuts, thru-holes, counterbores, threads (M2 and up) |

| Tooling & Fixturing | Custom soft jaws, vacuum/locating fixtures for thin or flexible stamped components |

| Inspection & Metrology | CMM, optical comparators, laser scanning for GD&T validation; first article inspection |

| Secondary Operations | Deburring, passivation (for titanium/stainless), anodizing (Al), heat treatment (as needed) |

Notes:

Titanium’s high strength-to-density ratio and corrosion resistance make it ideal for aerospace and medical applications, though it requires rigid setups and specialized tooling during milling and turning due to work hardening tendencies. Aluminum and steel components benefit from faster machining cycles, while engineering plastics like ABS and Nylon are machined for prototyping or non-structural housings where weight and insulation are critical. All materials are subject to the same tight-tolerance standards when post-processed on multi-axis CNC platforms.

From CAD to Part: The Process

Honyo Prototype Stamped Titanium Parts Manufacturing Process

Our end-to-end process for stamped titanium parts integrates advanced digital tools with precision manufacturing expertise to ensure cost efficiency, quality, and on-time delivery. Titanium presents unique challenges including high material cost, springback characteristics, and stringent aerospace/medical compliance requirements. Below is our rigorously validated workflow.

Upload CAD

Clients submit native CAD files (STEP, IGES, or Parasolid formats preferred; STL not accepted for titanium due to geometric fidelity requirements) via our secure customer portal. We require complete geometric data, material specifications (e.g., ASTM F136 Ti-6Al-4V ELI), and critical tolerances (±0.05mm typical for titanium stampings). Incomplete submissions trigger an automated notification within 2 business hours, reducing project delays. All data undergoes immediate encryption and version control per ISO 27001 standards.

AI-Powered Quoting Engine

Our proprietary AI system analyzes the CAD geometry against live material cost databases, historical titanium waste metrics, and machine capability matrices. Key parameters processed include:

| Parameter | Titanium-Specific Consideration | Impact on Quote |

|---|---|---|

| Blank Size | Nesting efficiency for expensive Ti coil stock | Material cost dominates 60-70% of unit price |

| Feature Complexity | Springback compensation requirements | Increases DFM iteration cycles by 15-25% |

| Tolerance Class | Tighter than ±0.1mm requires secondary operations | Adds 20-35% cost premium |

| Annual Volume | Tooling amortization for low-volume Ti runs | High NRE costs spread over fewer units |

The system generates a preliminary quote with cost drivers visualized within 4 business hours. This is not a binding offer but a data-driven estimate requiring DFM validation.

DFM Analysis (Titanium-Specific)

Our engineering team conducts mandatory Design for Manufacturability review focused on titanium’s properties. This phase includes:

Finite element analysis simulating titanium springback to adjust die geometries

Validation of minimum bend radii (typically 2x material thickness for Ti-6Al-4V)

Grain orientation verification to prevent cracking during forming

Tooling material selection (e.g., A2 tool steel with TiN coating for titanium’s galling tendency)

Compliance check against AS9100/NADCAP requirements where applicable. Clients receive a formal DFM report with actionable recommendations within 3 business days. No production proceeds without signed DFM approval.

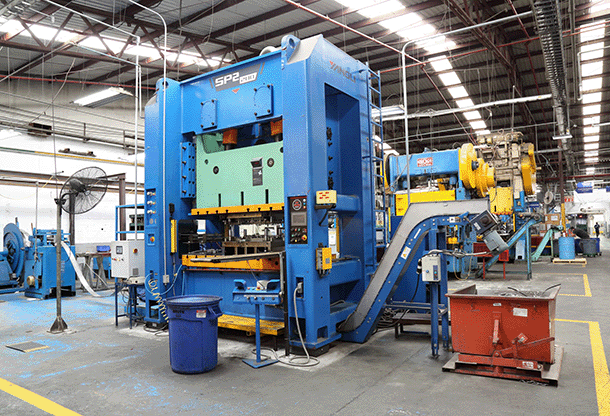

Precision Production

Stamped titanium parts are manufactured in our climate-controlled facility using:

Dedicated servo presses (up to 1000T capacity) with real-time tonnage monitoring to prevent titanium work hardening

In-die sensors measuring springback during progressive stamping

Laser-based in-process inspection for critical features (reducing titanium scrap by 18% vs. manual methods)

Secondary operations including robotic deburring and acid passivation per AMS 2700

All titanium lots are traceable via blockchain-linked mill test reports (MTRs) verifying ASTM/AMS compliance.

Certified Delivery

Final parts ship with:

Full material traceability documentation including heat number and MTRs

FAI reports per AS9102 for aerospace clients

Dimensional inspection data using Zeiss CMM (results cross-verified against original CAD)

Packaging meeting ASTM D4169 for titanium’s susceptibility to surface contamination

Standard lead time is 18-25 days from DFM sign-off, with expedited options for critical medical applications. All shipments include digital quality records accessible via our client portal.

This integrated process reduces titanium prototyping costs by 30% versus traditional methods while ensuring zero non-conformities in recent AS9102 audits. For complex geometries or volumes under 500 pieces, we recommend initiating with our engineering team to optimize the DFM phase. Contact Honyo Prototype’s titanium specialists for project-specific validation.

Start Your Project

Looking for high-precision stamped titanium parts manufactured to exact specifications? Honyo Prototype delivers reliable, high-quality metal stamping solutions with a focus on titanium components for demanding industrial and technical applications.

Our advanced stamping capabilities are supported by a state-of-the-art facility located in Shenzhen, ensuring efficient production, strict quality control, and on-time delivery.

For project inquiries or technical discussions, contact Susan Leo at [email protected]. Let’s collaborate to bring your design into production with precision and performance.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.