Contents

Manufacturing Insight: Stainless Steel Type Chart

Material Selection Precision for Optimal Machinability

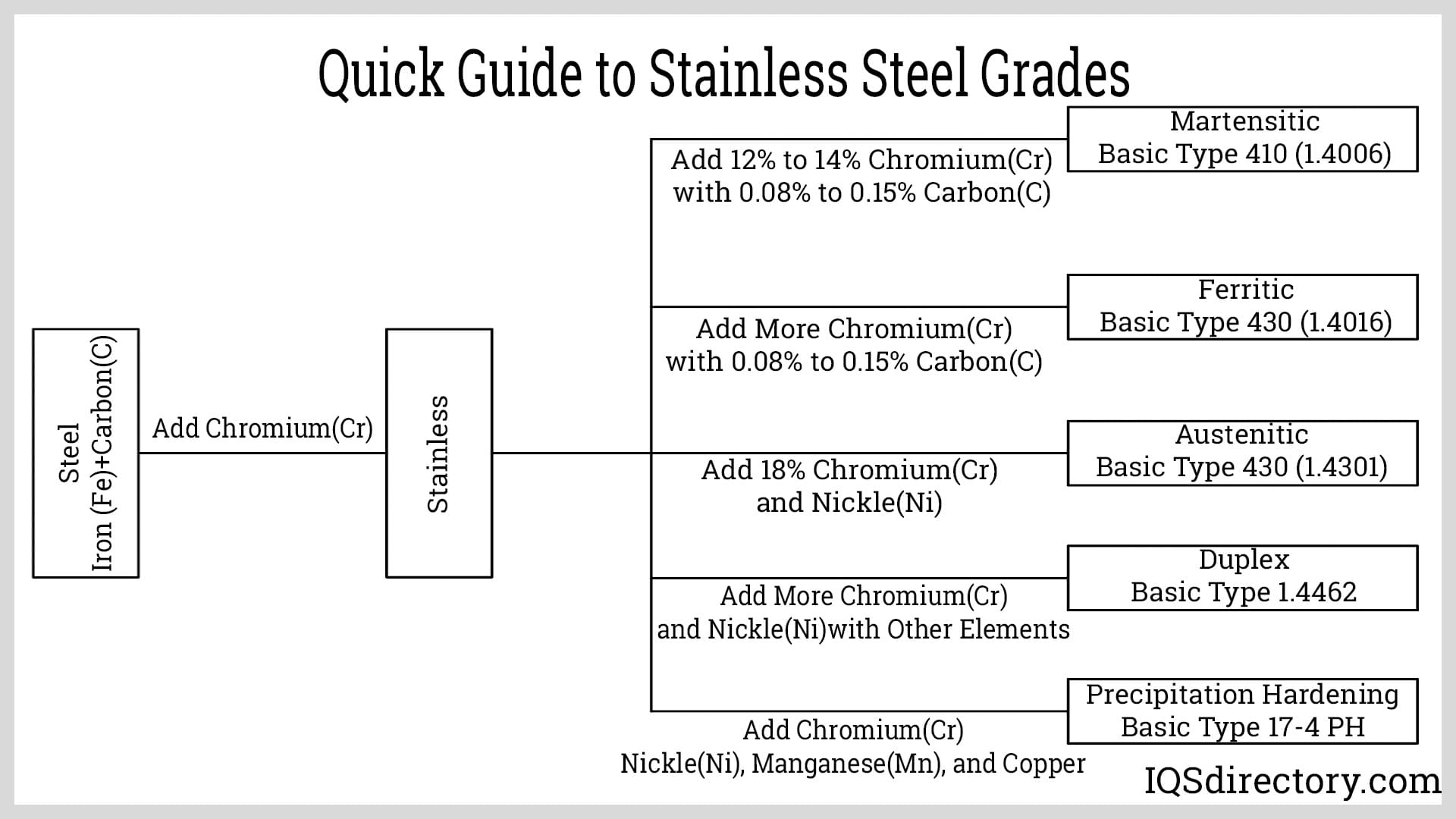

Selecting the appropriate stainless steel grade is a critical engineering decision that directly impacts part performance, corrosion resistance, and manufacturability. At Honyo Prototype, our CNC machining expertise spans the full spectrum of stainless alloys—from standard 304 and 316 austenitic grades to specialized 17-4 PH precipitation-hardening variants—ensuring your design intent translates flawlessly into high-tolerance, production-ready components. We understand that material properties like work hardening rates, thermal conductivity, and chip formation behavior dictate machining parameters, tooling strategies, and secondary finishing requirements.

Honyo’s Engineering-Driven Machining Capabilities

Our ISO 9001-certified facility leverages advanced 3-, 4-, and 5-axis CNC systems with sub-micron repeatability to machine even the most challenging stainless grades. By integrating material science insights with process optimization, we mitigate common issues such as galling in 303 or weld decay sensitivity in 304L, delivering consistent dimensional accuracy and surface integrity. This technical proficiency reduces lead times, minimizes scrap, and ensures compliance with ASTM, AMS, and customer-specific material certifications.

Navigate Material Complexity with Confidence

The stainless steel type chart below provides a concise technical reference for key grades, highlighting mechanical properties, corrosion resistance profiles, and machinability ratings relative to free-machining 303. Use this resource to align your application requirements with the optimal alloy—whether prioritizing marine-grade pitting resistance (316/L), high-strength aerospace needs (15-5 PH), or medical biocompatibility (316LVM).

Accelerate Your Prototyping Timeline

Ready to transform your stainless steel component design into reality? Honyo’s Online Instant Quote platform delivers precise cost and lead time estimates in under 60 seconds. Simply upload your STEP or IGES file to receive a manufacturability analysis and competitive pricing—enabling faster iteration from concept to functional prototype. Begin your project at honyoprototype.com/quote.

Technical Capabilities

Stainless steel type charts are essential reference tools in precision manufacturing environments, particularly for 3/4/5-axis milling and turning operations requiring tight tolerances. These charts typically outline the compatibility, machinability, and performance characteristics of various stainless steel grades when processed alongside other common engineering materials such as aluminum, carbon steel, ABS, and nylon. The following table summarizes key technical specifications and considerations relevant to high-precision CNC machining applications at Honyo Prototype.

| Material | Typical Stainless Steel Grades | Machinability Rating (Relative) | Recommended Tooling | Max Tolerance Capability (Typical) | Key Considerations for 3/4/5-Axis Milling & Turning |

|---|---|---|---|---|---|

| Aluminum (e.g., 6061, 7075) | N/A (non-steel) | Excellent (100%) | Carbide or diamond-coated end mills, sharp cutting edges | ±0.005 mm – ±0.0125 mm | Low melting point; high chip load; minimal thermal deformation; ideal for complex 5-axis contours |

| Carbon Steel (e.g., 1018, 4140) | N/A (non-stainless) | Good (50–65%) | TiAlN-coated carbide inserts, rigid tool holders | ±0.01 mm – ±0.025 mm | Generates significant heat; requires flood coolant; higher tool wear than aluminum |

| Stainless Steel – Austenitic (e.g., 303, 304, 316) | 303, 304, 316, 316L | Fair (40–45%) | High-performance carbide with AlTiN coating, variable helix end mills | ±0.01 mm – ±0.02 mm | Work hardening tendency; requires consistent feed rates; ideal for tight-tolerance medical and aerospace parts |

| Stainless Steel – Martensitic (e.g., 410, 420, 440C) | 410, 420, 440C | Poor to Fair (25–35%) | Polycrystalline diamond (PCD) or ceramic inserts for hardened grades; rigid setups | ±0.01 mm – ±0.025 mm | High hardness (especially 440C); often pre-hardened; used in high-wear applications; slow speeds required |

| ABS (Thermoplastic) | N/A | Excellent (90–100%) | Sharp high-speed steel or uncoated carbide, low rake tools | ±0.05 mm – ±0.1 mm (material-dependent) | Low melting point; prone to melting if overheated; minimal clamping force required |

| Nylon (Polyamide) | N/A | Good to Excellent (80–95%) | Polished carbide tools, high rake angles | ±0.05 mm – ±0.15 mm | High thermal expansion; hygroscopic; requires dry machining; low stiffness affects form stability |

Notes on Tight Tolerance Machining:

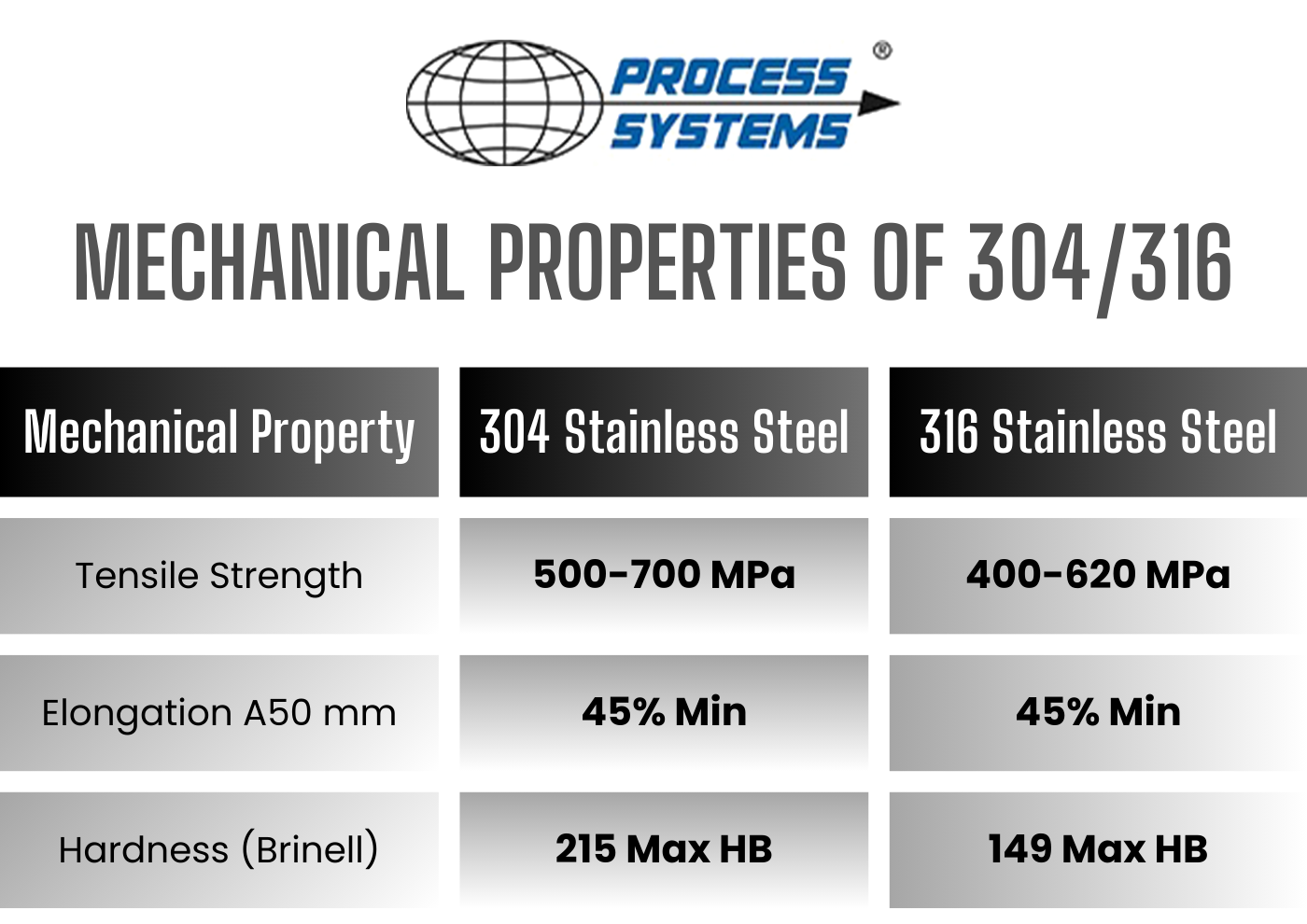

Achieving tolerances below ±0.01 mm in stainless steel (especially 316 and 440C) requires thermal stability, high spindle accuracy, and vibration-damped machine platforms.

Multi-axis synchronization (4/5-axis) demands precise tool path planning to avoid tool deflection and maintain surface finish in deep cavities or undercuts.

Material selection impacts fixturing strategy—ABS and nylon require non-marring, low-pressure clamps, while steel and stainless benefit from mechanical vices with high rigidity.

Coolant type and delivery (flood vs. mist vs. through-spindle) significantly affect tool life and dimensional consistency, particularly in continuous stainless steel cutting.

This specification guide supports Honyo Prototype’s capability in delivering high-accuracy machined components across diverse material families, ensuring optimal process selection and repeatability in complex CNC operations.

From CAD to Part: The Process

Honyo Prototype Stainless Steel Manufacturing Process Overview

Honyo Prototype executes a streamlined, technology-driven workflow for stainless steel components, integrating material-specific expertise at every phase. This process ensures precision, cost efficiency, and compliance with ASTM/AMS standards for grades such as 304, 316, and 17-4PH. Below is the detailed sequence:

Upload CAD

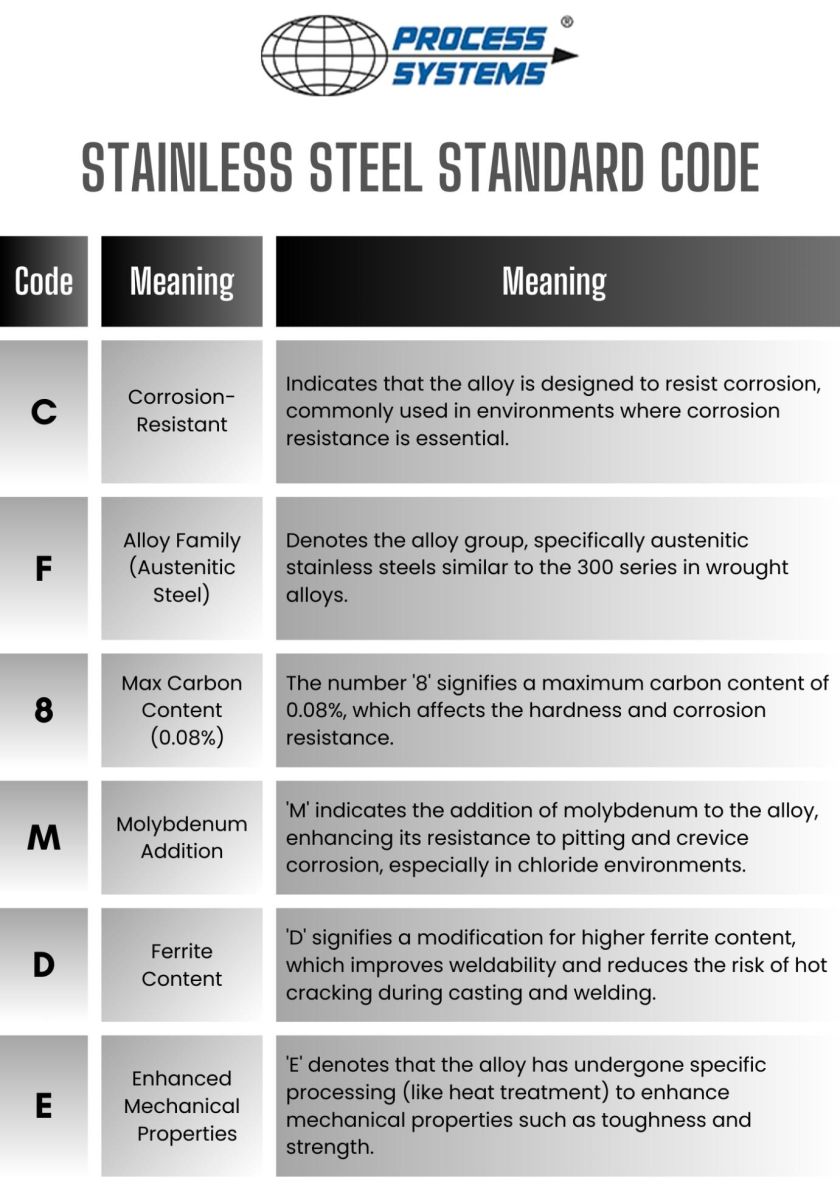

Clients submit 3D CAD files (STEP, IGES, or native formats) via our secure portal. Our system immediately validates file integrity and identifies stainless steel-specific parameters, including wall thickness, feature complexity, and surface finish requirements. Material grade selection is cross-referenced against Honyo’s internal stainless steel type chart, which maps mechanical properties, corrosion resistance, and machinability for common alloys. This chart ensures alignment with client specifications and prevents downstream material mismatches.

AI Quote Generation

Honyo’s proprietary AI engine analyzes the CAD geometry alongside real-time variables: stainless steel market pricing (LME-linked), scrap rates, and grade-specific processing costs. The algorithm factors in critical nuances like 316L’s higher nickel content affecting weldability or 17-4PH’s precipitation-hardening requirements. Within 2 hours, clients receive a granular cost breakdown, lead time estimate, and material certification options (e.g., MTRs per ASTM A240). No manual intervention is required, eliminating human error in initial pricing.

DFM Analysis

Our DFM team conducts a stainless steel-optimized review, focusing on material behavior during fabrication. Key checks include:

Avoiding tool chatter in 303 (sulfur-added) grades during milling

Verifying minimum bend radii for 304/304L to prevent micro-cracking

Assessing heat-affected zone risks for welded 316L assemblies

Recommending stress-relief annealing for complex geometries

Clients receive actionable feedback within 24 hours, with tolerance adjustments and feature modifications proposed to reduce costs by 15–30% while maintaining ISO 2768-mK standards.

Production Execution

Stainless steel parts enter a dedicated production cell with grade-segregated tooling to prevent cross-contamination. Critical protocols include:

CNC machining with cryogenic cooling for 304/316 to minimize work hardening

Laser cutting using nitrogen assist gas for oxide-free edges

Electropolishing baths calibrated for specific alloy compositions

In-process CMM verification at 20% and 80% completion stages

All operations comply with NADCAP audit trails, with real-time production data accessible via client portal.

Delivery and Documentation

Finished components undergo final QA per ASTM A480, including pitting corrosion tests for marine-grade alloys. Every shipment includes:

Dimensional report with GD&T verification

Material test reports (MTRs) traceable to heat number

Certificate of Conformance (CoC) with RoHS/REACH compliance

Packaging certified for salt-spray resistance during transit

Standard delivery is 7–12 business days for prototypes, with expedited options. Logistics partners provide GPS-tracked shipments with humidity-controlled containers for critical applications.

Stainless Steel Grade Reference

| Grade | Key Properties | Common Applications | Honyo Processing Notes |

|———|—————————————–|—————————|——————————————–|

| 304/L | General corrosion resistance, formable | Food equipment, enclosures | Avoid chloride exposure; anneal post-weld |

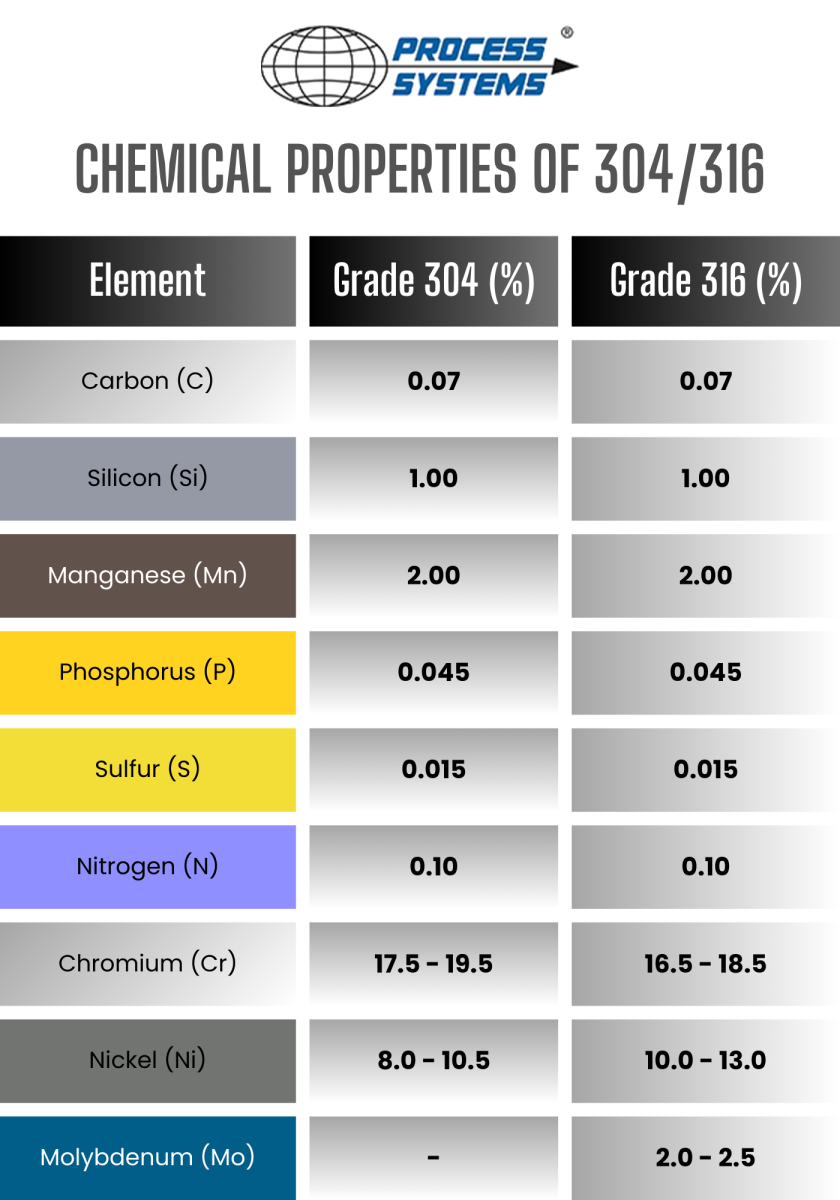

| 316/L | Enhanced pitting resistance (Mo 2-3%) | Marine, pharmaceutical | Use low-carbon grade; purge weld zones |

| 17-4PH | High strength, martensitic hardening | Aerospace fittings | Requires H900/H1025 heat treatment |

| 410 | Magnetic, moderate corrosion resistance | Valves, cutlery | Preheat to 200°C for welding |

This end-to-end process leverages Honyo’s material science expertise to transform stainless steel designs into certified, production-ready components with zero tolerance for grade-related defects. Clients benefit from reduced iteration cycles and guaranteed material integrity from quotation through delivery.

Start Your Project

For detailed technical guidance on selecting the right stainless steel type for your application, refer to our comprehensive stainless steel type chart. This resource is designed to help engineers and procurement teams make informed material decisions based on corrosion resistance, strength, temperature tolerance, and manufacturability.

To request a downloadable version or discuss custom material specifications for your next project, contact Susan Leo at [email protected]. Our precision manufacturing facility is located in Shenzhen, enabling rapid prototyping and scalable production with strict quality control aligned to international standards.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.