Introduction: Navigating the Global Market for stainless steel torsion spring

The global market for stainless steel torsion springs presents both opportunities and challenges for international B2B buyers. Sourcing high-quality torsion springs that meet specific application requirements can be daunting, especially when navigating suppliers across diverse regions such as Africa, South America, the Middle East, and Europe. This guide aims to streamline that process by providing comprehensive insights into various types of stainless steel torsion springs, their applications, and key factors to consider when selecting suppliers.

In the pages that follow, you will find detailed sections on the different types of torsion springs available, ranging from standard models to custom designs tailored for unique applications. We will delve into the critical aspects of supplier vetting, ensuring that you choose reliable partners who deliver quality products on time. Additionally, we will explore cost considerations, helping you balance quality with budget constraints without compromising on performance.

By equipping you with the necessary knowledge and tools, this guide empowers B2B buyers to make informed purchasing decisions. With a focus on the unique needs of buyers from regions like Brazil and Saudi Arabia, we aim to facilitate smoother transactions and foster long-lasting supplier relationships. Whether you’re looking to enhance product performance or ensure durability in challenging environments, understanding the global landscape of stainless steel torsion springs is essential for your business success.

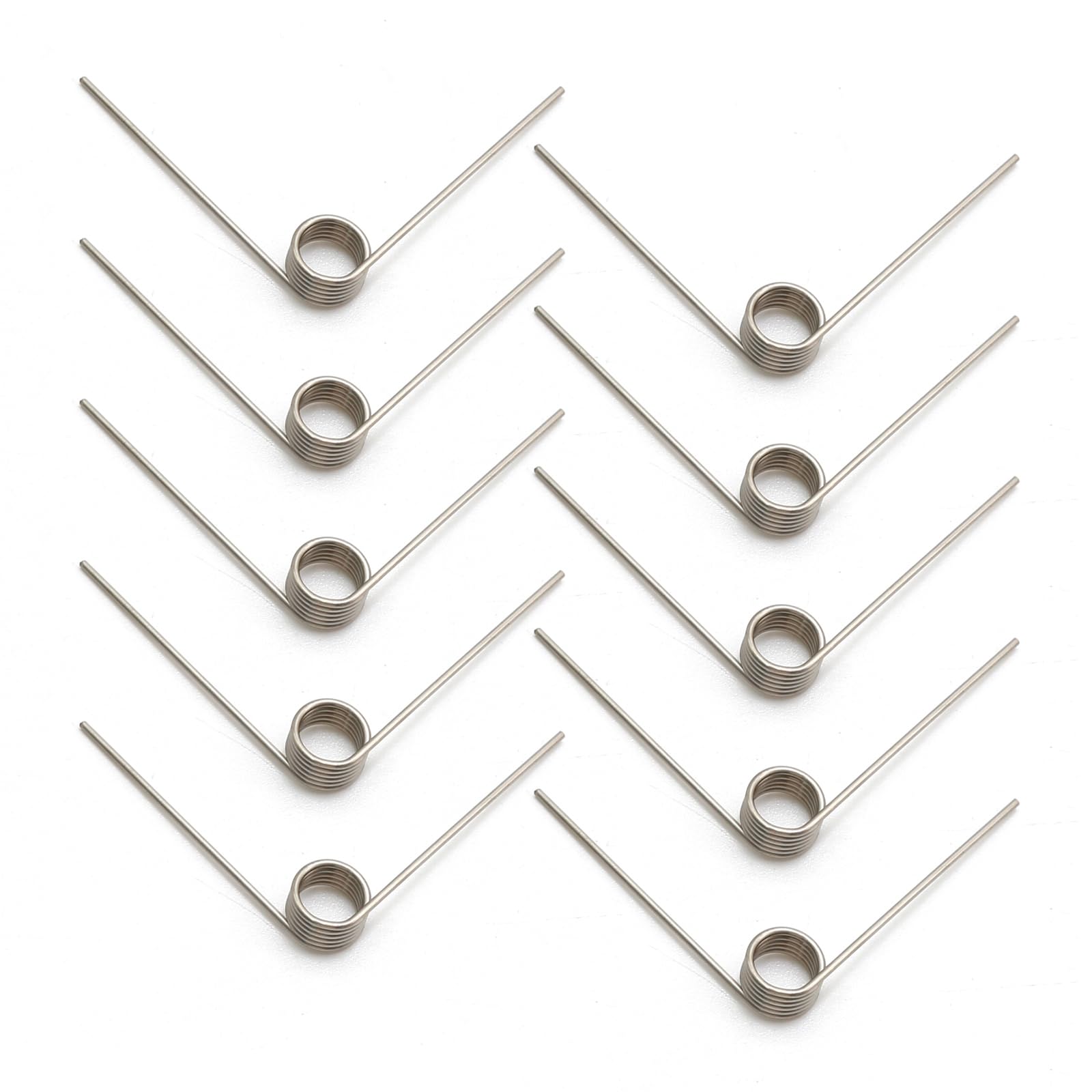

Understanding stainless steel torsion spring Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Torsion Springs | Made from 302/304 stainless steel, various sizes | General machinery, automotive, furniture | Pros: Versatile; Cons: May require customization for specific applications. |

| Heavy-Duty Torsion Springs | Thicker wire diameter, higher torque capacity | Industrial equipment, heavy machinery | Pros: Increased durability; Cons: Higher cost may deter some buyers. |

| Custom Torsion Springs | Tailored dimensions and specifications | Specialized machinery, niche applications | Pros: Perfect fit for unique needs; Cons: Longer lead times for production. |

| Corrosion-Resistant Torsion Springs | Enhanced coatings for extreme environments | Marine, chemical processing, outdoor equipment | Pros: Excellent longevity in harsh conditions; Cons: Higher initial investment. |

| Garage Door Torsion Springs | Specifically designed for garage doors, various sizes | Residential and commercial garage doors | Pros: Optimized for specific applications; Cons: Limited to garage door use. |

What are Standard Torsion Springs and Their Applications?

Standard torsion springs are commonly manufactured using 302 or 304 stainless steel, which provides a balance of strength and flexibility. These springs come in various sizes and dimensions, making them suitable for a wide range of applications, including general machinery, automotive components, and furniture. When purchasing, buyers should consider the required specifications, such as wire diameter and coil count, as these factors influence performance and compatibility with existing systems.

How Do Heavy-Duty Torsion Springs Differ from Standard Variants?

Heavy-duty torsion springs are characterized by their thicker wire diameters and higher torque capacities, making them ideal for demanding industrial applications. They are commonly used in heavy machinery and equipment that require robust performance under significant loads. While they offer increased durability and reliability, buyers should be prepared for a higher cost compared to standard options. Assessing the specific torque requirements and environmental conditions is essential for ensuring optimal performance.

What Benefits Do Custom Torsion Springs Provide to Businesses?

Custom torsion springs are designed to meet specific dimensions and performance criteria, making them invaluable for specialized machinery and niche applications. This tailored approach allows businesses to optimize their equipment for unique operational needs. However, buyers should be aware of the longer lead times associated with custom manufacturing. It is crucial to communicate precise specifications to ensure that the springs meet all operational requirements without compromising on quality.

Why Choose Corrosion-Resistant Torsion Springs for Harsh Environments?

Corrosion-resistant torsion springs are engineered with enhanced coatings to withstand extreme environmental conditions, such as those found in marine or chemical processing applications. These springs offer excellent longevity, making them a wise investment for businesses operating in harsh settings. While the initial investment may be higher, the cost savings from reduced maintenance and replacement needs can justify the expense. Buyers should evaluate the specific corrosive elements present in their operational environment to select the appropriate spring.

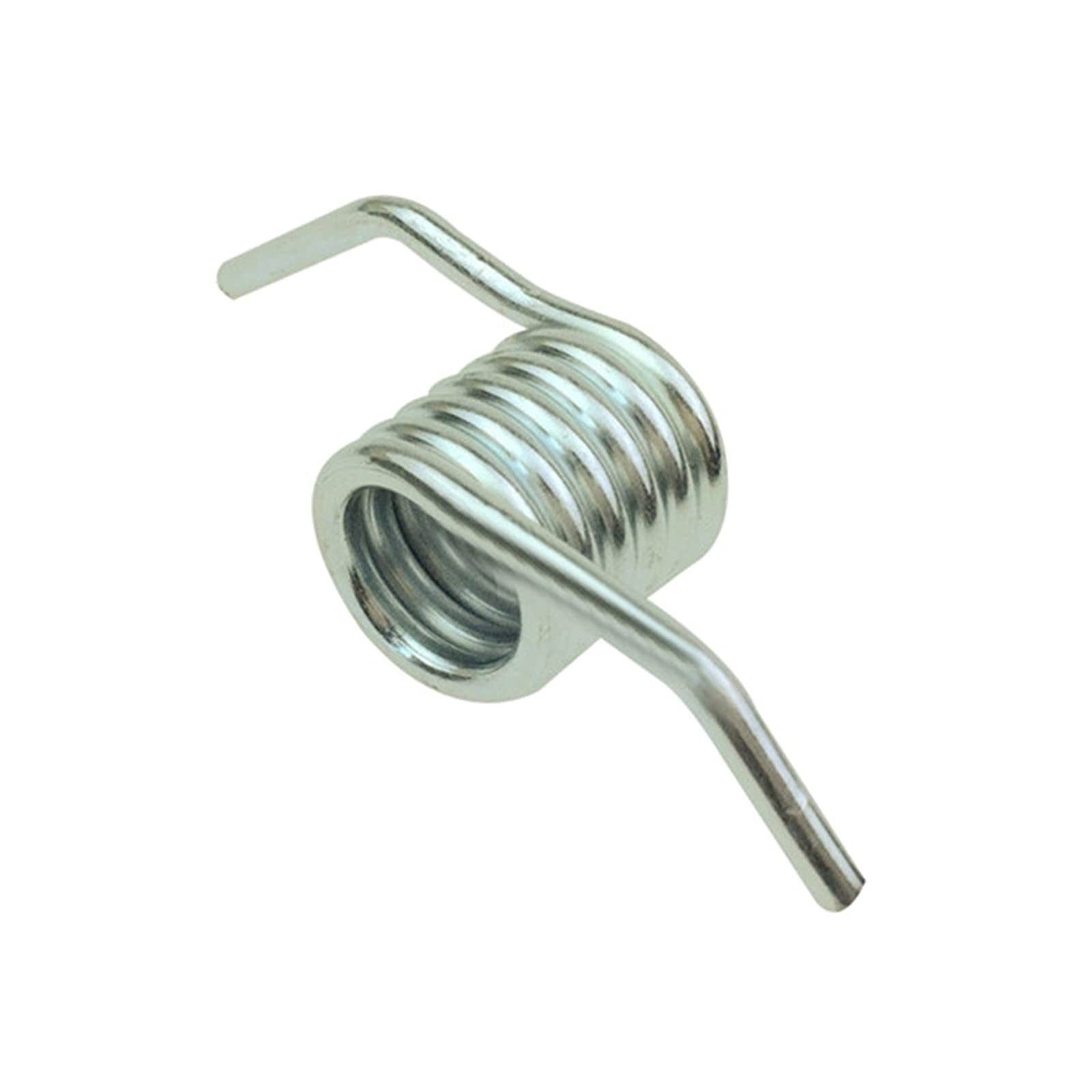

What Are the Key Features of Garage Door Torsion Springs?

Garage door torsion springs are specifically designed to facilitate the smooth operation of residential and commercial garage doors. These springs come in various sizes and winding configurations to match different door types and weights. Their tailored design enhances functionality and safety, making them a popular choice for both homeowners and business owners. While they are optimized for specific applications, buyers should ensure they select the correct size and specifications to avoid compatibility issues.

Key Industrial Applications of stainless steel torsion spring

| Industry/Sector | Specific Application of stainless steel torsion spring | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Suspension systems in vehicles | Enhances vehicle stability and performance | Ensure compliance with automotive standards and durability requirements. |

| Aerospace | Control mechanisms in aircraft | Critical for safety and reliability in flight | Sourcing from certified manufacturers to meet stringent aerospace regulations. |

| Manufacturing Equipment | Machinery for material handling | Increases operational efficiency and reduces downtime | Custom specifications for load and torque requirements are essential. |

| Construction | Garage doors and automated access systems | Provides long-lasting performance in harsh environments | Focus on corrosion resistance and appropriate sizing for specific installations. |

| Renewable Energy | Wind turbine mechanisms | Contributes to the efficiency and longevity of turbines | Consider sourcing for high-tensile strength and environmental resistance. |

How are stainless steel torsion springs utilized in the automotive industry?

In the automotive sector, stainless steel torsion springs are integral to suspension systems, where they support vehicle stability and performance. By providing necessary resistance against forces during movement, these springs help maintain optimal alignment and handling. For international buyers, particularly in regions like Africa and South America, sourcing springs that comply with local automotive safety standards is crucial, ensuring durability and performance under diverse road conditions.

What role do stainless steel torsion springs play in aerospace applications?

In aerospace applications, stainless steel torsion springs are vital in control mechanisms, such as flaps and landing gear systems. These springs must meet rigorous safety and reliability standards due to their critical role in flight operations. Buyers in the Middle East and Europe should prioritize sourcing from manufacturers with aerospace certifications to guarantee compliance with industry regulations and ensure the springs can withstand extreme environmental conditions.

Why are stainless steel torsion springs important in manufacturing equipment?

Within the manufacturing sector, stainless steel torsion springs are used in machinery designed for material handling, providing essential force and torque for smooth operation. Their ability to enhance efficiency and reduce downtime is vital for businesses looking to optimize production processes. When sourcing, buyers should focus on custom specifications that cater to specific load and torque requirements, ensuring the springs can handle the demands of the machinery.

How do stainless steel torsion springs benefit construction applications?

In construction, stainless steel torsion springs are often found in garage doors and automated access systems. Their durability and corrosion resistance make them ideal for environments exposed to harsh weather conditions. For B2B buyers in regions like Brazil and Saudi Arabia, it is essential to consider the spring’s sizing and material properties to ensure long-lasting performance and reliability in their specific installations.

What advantages do stainless steel torsion springs offer in renewable energy applications?

Stainless steel torsion springs are critical components in wind turbine mechanisms, where they contribute to the efficiency and longevity of the turbines. These springs must withstand high-tensile forces and environmental stressors, making sourcing from reputable manufacturers crucial. Buyers should prioritize springs with high corrosion resistance and appropriate strength to ensure optimal performance in renewable energy applications, particularly in regions with varying climatic conditions.

3 Common User Pain Points for ‘stainless steel torsion spring’ & Their Solutions

Scenario 1: Inconsistent Quality and Performance Issues

The Problem: B2B buyers often face challenges with the quality and reliability of stainless steel torsion springs. Inconsistencies in manufacturing can lead to variations in performance, where some springs may not meet the required specifications, resulting in equipment failures or suboptimal functionality. This inconsistency can stem from various factors, including poor material quality, inadequate manufacturing processes, or lack of proper quality control measures. Such issues not only disrupt production schedules but can also lead to increased costs due to replacements and repairs.

The Solution: To mitigate these quality issues, it is crucial for buyers to establish strong relationships with reputable suppliers who prioritize quality assurance. When sourcing stainless steel torsion springs, buyers should request detailed specifications and certifications that verify the materials used, such as compliance with ASTM standards. Additionally, conducting site visits or audits of potential suppliers can provide insights into their manufacturing processes and quality control practices. Implementing a robust vendor evaluation process can further ensure that only those suppliers who demonstrate consistent quality are selected. Regularly testing springs upon delivery for torque and deflection can help catch any discrepancies early, ensuring that only high-quality products are utilized in production.

Scenario 2: Difficulty in Sizing and Specification

The Problem: Another common pain point for B2B buyers is the challenge of accurately sizing and specifying stainless steel torsion springs for their applications. Incorrect specifications can lead to poor fitment, inadequate torque, or failure to meet design requirements, which can cause significant delays and additional costs in production. The complexity of torsion spring design, including variables such as wire diameter, leg length, and coil count, can complicate the selection process, particularly for buyers who may not have extensive technical knowledge.

The Solution: To address these sizing and specification challenges, buyers should invest in a comprehensive understanding of torsion spring mechanics and applications. Collaborating with engineers or utilizing design software that allows for accurate spring modeling can streamline the selection process. Additionally, many suppliers offer online tools or consultation services to help buyers identify the right specifications based on their specific application needs. When placing orders, buyers should provide detailed information regarding the operational environment and load requirements, enabling suppliers to recommend the most suitable springs. Creating a standardized specification sheet for all spring requirements can also enhance clarity and ensure that all parties are aligned on expectations.

Scenario 3: Long Lead Times and Supply Chain Delays

The Problem: In today’s global market, B2B buyers frequently contend with long lead times and supply chain disruptions, particularly for specialized components like stainless steel torsion springs. Such delays can severely impact production schedules, leading to missed deadlines and lost revenue. Factors contributing to these delays may include fluctuating demand, shipping issues, or inadequate inventory levels from suppliers, which can be particularly problematic for buyers in regions like Africa and South America, where logistics can be more challenging.

The Solution: To alleviate the impact of lead times and supply chain issues, buyers should proactively manage their inventory and supply relationships. Establishing agreements with multiple suppliers can create a safety net, allowing for quicker turnaround times should one supplier face delays. Implementing a just-in-time inventory system can also help maintain optimal stock levels while minimizing excess. Furthermore, buyers should consider ordering stainless steel torsion springs in bulk or setting up blanket purchase orders to secure pricing and ensure availability. Regular communication with suppliers regarding their inventory status and lead times can also provide valuable insights, allowing buyers to plan accordingly and avoid production halts.

Strategic Material Selection Guide for stainless steel torsion spring

When selecting materials for stainless steel torsion springs, it’s essential to consider various factors including performance characteristics, manufacturing complexities, and compliance with international standards. Below is an analysis of four common materials used in the production of stainless steel torsion springs, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of 302 Stainless Steel for Torsion Springs?

302 stainless steel is a widely used material for torsion springs due to its excellent balance of strength and corrosion resistance. It can withstand temperatures up to 870°C (1600°F) and offers good mechanical properties. This material is particularly resistant to oxidation and is suitable for applications in various environments, including marine and industrial settings.

Pros: The main advantages of 302 stainless steel include its high tensile strength and ductility, making it ideal for applications requiring significant deformation. Additionally, its corrosion resistance ensures longevity in harsh conditions.

Cons: However, 302 stainless steel can be more expensive than other materials, and its manufacturing process may require specialized techniques to achieve the desired spring characteristics.

Impact on Application: 302 stainless steel is compatible with a wide range of media, making it suitable for applications in automotive, aerospace, and industrial machinery.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with ASTM standards, particularly ASTM A313, which governs the specifications for stainless steel wire.

How Does 304 Stainless Steel Compare for Torsion Springs?

304 stainless steel is another popular choice for torsion springs, known for its excellent corrosion resistance and formability. It can handle temperatures up to 870°C (1600°F) and is often used in food processing and medical applications due to its non-reactive nature.

Pros: The key advantage of 304 stainless steel is its versatility, making it suitable for a wide range of applications. Its resistance to pitting and crevice corrosion is particularly beneficial in environments exposed to chlorides.

Cons: On the downside, 304 stainless steel has lower tensile strength compared to 302, which may limit its use in high-stress applications. Additionally, it can be more challenging to machine, increasing manufacturing complexity.

Impact on Application: This material is ideal for applications requiring hygiene and cleanliness, such as in the food and beverage industry.

Considerations for International Buyers: Compliance with international standards like DIN 1.4301 is crucial for buyers in Europe and the Middle East to ensure quality and performance.

What Are the Benefits of 316 Stainless Steel for Torsion Springs?

316 stainless steel is often referred to as marine-grade stainless steel due to its superior corrosion resistance, particularly against chlorides and saline environments. It can withstand temperatures up to 870°C (1600°F) and is used in highly corrosive environments.

Pros: The primary advantage of 316 stainless steel is its exceptional durability and resistance to corrosion, making it ideal for marine and chemical processing applications.

Cons: However, this material is significantly more expensive than 302 and 304 stainless steels, which may not be feasible for all projects. Its higher cost can impact overall project budgets.

Impact on Application: 316 stainless steel is particularly suitable for applications in the oil and gas industry, as well as in marine environments where exposure to saltwater is common.

Considerations for International Buyers: Buyers should be aware of compliance with ASTM A313 and other relevant standards to ensure product quality.

How Does Music Wire Compare to Stainless Steel for Torsion Springs?

Music wire, while not stainless steel, is frequently used for torsion springs due to its high tensile strength and excellent fatigue resistance. It is typically used in applications where corrosion resistance is less critical.

Pros: The main advantage of music wire is its cost-effectiveness and high performance in terms of tensile strength, making it suitable for various mechanical applications.

Cons: The downside is its susceptibility to rust and corrosion, which limits its use in environments where exposure to moisture is a concern.

Impact on Application: Music wire is often used in applications like automotive components and general machinery.

Considerations for International Buyers: Buyers in regions with high humidity or corrosive environments should prioritize stainless steel options over music wire to ensure longevity.

Summary Table

| Material | Typical Use Case for stainless steel torsion spring | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 302 Stainless Steel | Automotive, Aerospace, Industrial Machinery | High tensile strength and ductility | Higher cost, specialized manufacturing | Medium |

| 304 Stainless Steel | Food processing, Medical applications | Excellent corrosion resistance | Lower tensile strength, machining complexity | Medium |

| 316 Stainless Steel | Marine, Chemical processing applications | Superior corrosion resistance | Significantly higher cost | High |

| Music Wire | Automotive components, General machinery | Cost-effective, high tensile strength | Susceptible to rust and corrosion | Low |

This strategic material selection guide provides insights into the various options available for stainless steel torsion springs, helping international B2B buyers make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for stainless steel torsion spring

What Are the Main Stages in the Manufacturing Process of Stainless Steel Torsion Springs?

The manufacturing of stainless steel torsion springs involves several critical stages, each contributing to the final product’s performance and durability. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Torsion Spring Manufacturing?

The first step in the manufacturing process is the careful selection and preparation of the raw materials, typically 302 or 304 stainless steel, known for their excellent corrosion resistance and mechanical properties. Manufacturers often source these materials from reputable suppliers to ensure consistency in quality. The steel wire is then cut to the required lengths, and its diameter is measured to maintain precision.

What Techniques Are Used in the Forming Process?

Once the materials are prepared, the forming process begins. This involves coiling the stainless steel wire into the desired shape. Various techniques can be employed, such as cold coiling or hot coiling, depending on the specific requirements of the torsion spring. Cold coiling is generally preferred for smaller springs, as it allows for greater precision and a smoother finish, while hot coiling can be used for larger springs that require more force to shape.

During this stage, the spring is also subjected to a series of mechanical processes, including bending and twisting, to achieve the required torque and deflection characteristics. Advanced machinery, often computer-controlled, is employed to ensure high accuracy in the dimensions and angles of the coils.

How Is Assembly Conducted in the Manufacturing of Torsion Springs?

After the springs are formed, they undergo an assembly process, which may involve attaching any necessary fittings or components, such as cones or brackets, that enhance the spring’s functionality. This step is crucial for applications where the torsion spring will be integrated into larger systems, such as garage doors or machinery.

Quality control measures are initiated at this stage to ensure that all components meet design specifications before proceeding to the finishing process.

What Finishing Techniques Are Applied to Stainless Steel Torsion Springs?

The finishing stage includes treatments to enhance the spring’s performance and longevity. Common techniques include surface treatments, such as passivation, to improve corrosion resistance, and shot peening, which enhances fatigue strength. These processes are vital for ensuring that the springs can withstand harsh environments and prolonged use.

What Quality Assurance Measures Are Important for Stainless Steel Torsion Springs?

Quality assurance (QA) is a critical aspect of the manufacturing process for stainless steel torsion springs. It ensures that the final product meets both international and industry-specific standards, providing confidence to B2B buyers regarding the reliability and safety of their purchases.

Which International Standards Should Buyers Be Aware Of?

Many manufacturers adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with this standard indicates that a manufacturer has established a robust quality management process, ensuring consistent product quality. In addition, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for oil and gas applications may also apply, depending on the intended use of the springs.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are established throughout the manufacturing process. The key checkpoints include:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Ongoing inspections are conducted during the manufacturing process to identify any deviations from specifications early on. This includes monitoring dimensions, torque specifications, and surface quality.

- Final Quality Control (FQC): After production, each batch of torsion springs undergoes comprehensive testing to verify that they meet all specifications and standards before they are packaged and shipped.

What Common Testing Methods Are Used for Quality Assurance?

Testing methods for stainless steel torsion springs typically include:

- Torque Testing: To measure the spring’s ability to store and release energy effectively.

- Deflection Testing: To determine how much the spring can be deflected without permanent deformation.

- Fatigue Testing: To assess the spring’s durability and performance under repeated loading conditions.

- Corrosion Testing: To evaluate the resistance of the spring material to various corrosive environments.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control measures is crucial for ensuring product reliability. Here are some methods to consider:

What Audit Processes Should Buyers Implement?

Conducting supplier audits is an effective way to assess a manufacturer’s quality control processes. This involves reviewing the supplier’s quality management system, production capabilities, and compliance with international standards. Buyers should request access to audit reports and certifications to gauge the supplier’s commitment to quality.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These inspections can be particularly valuable for buyers who may not have the resources to conduct their audits. Third-party inspectors can verify compliance with international standards and provide detailed reports on the quality of the products being manufactured.

What Documentation Should Buyers Request from Suppliers?

Buyers should request detailed documentation from suppliers, including quality assurance reports, test results, and compliance certificates. This documentation serves as proof of the supplier’s adherence to quality standards and can be essential for resolving any disputes that may arise post-purchase.

Conclusion: Ensuring Quality in the Purchase of Stainless Steel Torsion Springs

Understanding the manufacturing processes and quality assurance measures for stainless steel torsion springs is essential for B2B buyers. By focusing on critical stages such as material preparation, forming, assembly, and finishing, along with rigorous quality control checkpoints, buyers can ensure they procure reliable and durable products. Implementing thorough verification processes, including audits and third-party inspections, will further enhance the confidence in their supply chain, ensuring that their applications perform optimally.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stainless steel torsion spring’

In the competitive landscape of B2B sourcing, finding the right stainless steel torsion spring requires a systematic approach. This guide aims to provide international buyers with actionable steps to ensure a successful procurement process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the torsion springs meet your application requirements. Consider factors such as material type (e.g., 302/304 stainless steel), dimensions (inside and outside diameter), coil count, and wind direction. Document these specifications to communicate effectively with potential suppliers.

Step 2: Identify Your Application Needs

Understanding the specific applications for your torsion springs will help narrow down your options. Different industries—such as automotive, aerospace, and manufacturing—may have unique requirements regarding load capacity, corrosion resistance, and operational environment. Make a list of your application scenarios to guide your selection.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, it’s vital to conduct a thorough evaluation of potential suppliers. Look for company profiles, product catalogs, and customer testimonials to assess their reliability and expertise. Request references from buyers in similar industries to ensure the supplier has a proven track record of delivering quality products.

- Key Factors to Check:

- Years of experience in the industry

- Certifications (e.g., ISO 9001) that demonstrate quality management

- Geographic proximity to reduce shipping times and costs

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of the torsion springs for testing. This step is critical to verify that the springs meet your specifications and quality standards. Conduct tests to assess factors such as torque, deflection, and overall durability under operational conditions.

Step 5: Review Pricing and Payment Terms

Price is a significant factor in any procurement decision. Compare quotes from multiple suppliers while considering the total cost of ownership, which includes shipping, duties, and potential tariffs. Additionally, clarify payment terms to avoid any surprises later; options might include upfront payments, net terms, or letters of credit.

Step 6: Check for After-Sales Support and Warranty

A good supplier should offer robust after-sales support, including installation guidance and warranty coverage. Review the warranty terms to understand the conditions for returns or replacements. This is especially important for torsion springs, which may require adjustments or replacements due to wear over time.

Step 7: Finalize Your Order and Confirm Delivery Timelines

Once you have made your selection, finalize your order by confirming all details, including specifications, pricing, and delivery timelines. Ensure that you have a written agreement that outlines these aspects to prevent misunderstandings. Monitor the order’s progress to ensure timely delivery, which is crucial for maintaining your project schedules.

By following this practical sourcing checklist, B2B buyers can streamline their procurement process for stainless steel torsion springs, ensuring they select the right components for their specific needs while mitigating risks associated with supplier selection.

Comprehensive Cost and Pricing Analysis for stainless steel torsion spring Sourcing

What Are the Key Cost Components for Stainless Steel Torsion Springs?

When sourcing stainless steel torsion springs, understanding the cost structure is crucial for B2B buyers. The primary components of the cost include:

-

Materials: The choice of stainless steel, such as 302 or 304 grades, significantly impacts pricing due to variations in corrosion resistance, strength, and overall quality. Higher-grade materials typically command a premium.

-

Labor: Labor costs are influenced by the complexity of manufacturing processes and the skill level required. Customization or intricate designs may necessitate more skilled labor, thus increasing costs.

-

Manufacturing Overhead: This includes costs associated with equipment maintenance, energy consumption, and facility expenses. Efficient manufacturing practices can help mitigate these overheads.

-

Tooling: The initial investment in tooling for custom torsion springs can be substantial. However, this cost can be amortized over larger production runs, making it more economical in high-volume scenarios.

-

Quality Control (QC): Ensuring the springs meet industry standards and specifications involves rigorous testing and quality assurance processes. This can add to the overall cost but is essential for maintaining reliability.

-

Logistics: Shipping and handling costs vary by destination and can be influenced by factors such as weight, volume, and transportation mode. For international buyers, customs duties and tariffs must also be considered.

-

Margin: Suppliers typically include a profit margin that reflects their operational costs and market positioning. This can vary widely based on the supplier’s reputation and the competitiveness of the market.

How Do Pricing Influencers Affect the Cost of Torsion Springs?

Several factors can influence the pricing of stainless steel torsion springs:

-

Volume/MOQ: Minimum Order Quantities (MOQs) can significantly affect pricing. Higher volumes often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs against potential discounts for bulk purchases.

-

Specifications and Customization: Custom springs tailored to specific applications may incur additional design and manufacturing costs. Standard sizes and specifications typically offer more competitive pricing.

-

Material Quality and Certifications: Springs that require specific certifications (e.g., ISO, ASTM) for quality assurance can be more expensive. Buyers should weigh the importance of certifications against their project requirements.

-

Supplier Factors: The supplier’s location, production capabilities, and reputation can all impact price. Local suppliers may reduce shipping costs but may have higher material costs, while international suppliers may offer competitive pricing but involve higher logistics costs.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting overall costs.

What Tips Can Help Buyers Optimize Costs for Stainless Steel Torsion Springs?

For B2B buyers, particularly from Africa, South America, the Middle East, and Europe, optimizing costs is essential. Consider the following strategies:

-

Negotiation: Leverage your purchasing power by negotiating prices, especially when placing large orders or establishing long-term relationships with suppliers.

-

Cost Efficiency: Analyze the Total Cost of Ownership (TCO), which includes purchase price, shipping, maintenance, and replacement costs. This broader perspective can lead to better decision-making.

-

Pricing Nuances: Be aware of seasonal trends or market fluctuations that may affect pricing. Staying informed can provide leverage in negotiations and help identify the best purchasing times.

-

Supplier Diversification: Engaging with multiple suppliers can reduce dependency on a single source and provide leverage in price negotiations. It also helps in ensuring continuity in supply.

In conclusion, understanding the cost structure, pricing influencers, and strategic negotiation techniques can significantly impact the procurement of stainless steel torsion springs for international B2B buyers. Always consider indicative pricing and market conditions when making purchasing decisions.

Alternatives Analysis: Comparing stainless steel torsion spring With Other Solutions

Exploring Alternatives to Stainless Steel Torsion Springs: A Comparative Analysis

In the quest for effective and durable solutions in mechanical applications, stainless steel torsion springs are a popular choice due to their exceptional performance and corrosion resistance. However, it is essential for B2B buyers to consider alternative solutions that may also meet their specific requirements. This analysis compares stainless steel torsion springs with two viable alternatives: composite leaf springs and plastic torsion springs.

Comparison Table

| Comparison Aspect | Stainless Steel Torsion Spring | Composite Leaf Spring | Plastic Torsion Spring |

|---|---|---|---|

| Performance | High torque and deflection capabilities; excellent fatigue resistance | Good performance in lightweight applications; flexible and durable | Moderate torque; limited deflection; less durable than metal options |

| Cost | Higher initial investment due to material and manufacturing | Moderate cost; cost-effective for volume production | Lower cost; economical for low-load applications |

| Ease of Implementation | Requires precise installation; may need specific tools | Generally easy to install; adaptable to various designs | Simple installation; lightweight and easy to handle |

| Maintenance | Low maintenance; resistant to corrosion | Low maintenance; susceptible to environmental factors | Low maintenance; may degrade under UV exposure |

| Best Use Case | Heavy-duty applications requiring high torque and durability | Automotive and aerospace industries; applications needing lightweight solutions | Light-duty applications in consumer products or toys |

Detailed Breakdown of Alternatives

Composite Leaf Springs

Composite leaf springs are increasingly used in the automotive industry for their lightweight and flexible properties. They outperform traditional steel springs in applications where weight reduction is critical, such as in electric vehicles. Their composite material offers resilience against corrosion and fatigue. However, while they provide good performance for lighter loads, they may not withstand the same levels of torque and deflection as stainless steel torsion springs in heavy-duty scenarios.

Plastic Torsion Springs

Plastic torsion springs present a cost-effective alternative, especially suitable for low-load applications such as in toys, small appliances, or lightweight machinery. They are easy to install and handle due to their lightweight nature, making them user-friendly. However, their performance is limited compared to metal springs, particularly in terms of torque and deflection capacity. Additionally, they may not offer the same durability, especially under extreme temperature conditions or UV exposure, which could lead to degradation over time.

Conclusion: How to Choose the Right Spring for Your Needs

When selecting the right solution for your mechanical applications, consider factors such as performance requirements, budget constraints, and the specific environment in which the spring will operate. Stainless steel torsion springs excel in heavy-duty applications, offering superior durability and performance. In contrast, composite leaf springs may serve better in applications prioritizing weight reduction, while plastic torsion springs can be a suitable choice for low-load scenarios where cost is a significant concern. By carefully assessing your operational needs and the characteristics of each alternative, you can make an informed decision that aligns with your project goals and budget.

Essential Technical Properties and Trade Terminology for stainless steel torsion spring

What Are the Key Technical Properties of Stainless Steel Torsion Springs?

Stainless steel torsion springs are critical components in various applications, ranging from automotive to industrial machinery. Understanding their essential technical properties can aid B2B buyers in making informed purchasing decisions. Here are some key specifications to consider:

-

Material Grade (302/304 Stainless Steel)

Stainless steel torsion springs are often made from 302 or 304 grades, known for their excellent corrosion resistance and tensile strength. This property is vital for applications exposed to moisture or corrosive environments, ensuring durability and reducing maintenance costs. For international buyers in humid regions like parts of Africa or South America, selecting the right material is crucial for long-term performance. -

Wire Diameter

The wire diameter influences the spring’s strength and load-bearing capacity. Common diameters range from 0.105 inches (2.67 mm) to larger sizes depending on the application. A thicker wire diameter typically means a stronger spring, which is essential for high-load applications. B2B buyers should assess the load requirements of their specific use cases to select an appropriately sized spring. -

Coil Count and Configuration

The number of coils directly affects the spring’s torque and deflection characteristics. For instance, a torsion spring with eight coils may provide a specific torque rating, making it suitable for particular applications such as garage doors or machinery. Understanding the configuration helps buyers match the spring to their operational needs. -

Maximum Torque Rating

This specification indicates the maximum twisting force the spring can withstand before failure. Torque ratings are typically expressed in inch-pounds or Newton-millimeters. For applications that require precise control, selecting a spring with the appropriate torque rating is essential to avoid premature failure or malfunction. -

Deflection Angle

The deflection angle refers to the maximum angle the spring can twist without losing its functional properties. This is crucial in applications where movement is continuous, as excessive deflection can lead to fatigue and failure. Buyers should consider their application’s operational limits to ensure compatibility.

Which Trade Terms Should B2B Buyers Understand When Sourcing Torsion Springs?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts that are used in another company’s end products. Understanding OEM specifications can help buyers ensure compatibility and quality when sourcing torsion springs for their applications. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest order amount a supplier will accept. Knowing the MOQ is essential for budgeting and inventory management, especially for international buyers who may be looking to minimize costs while ensuring adequate supply. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers. This is particularly important for large orders or custom springs, allowing buyers to compare options and negotiate better terms. -

Incoterms

International Commercial Terms (Incoterms) define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms helps buyers mitigate risks and manage costs effectively in international transactions. -

Lead Time

This term indicates the amount of time it takes for an order to be processed and shipped. Knowing the lead time is crucial for project planning and ensuring that timelines are met, especially in industries where downtime can be costly.

By grasping these technical properties and trade terminologies, B2B buyers can navigate the procurement process more effectively, ensuring they select the right stainless steel torsion springs for their needs.

Navigating Market Dynamics and Sourcing Trends in the stainless steel torsion spring Sector

What are the Current Market Dynamics and Key Trends in the Stainless Steel Torsion Spring Sector?

The global market for stainless steel torsion springs is witnessing significant growth, driven by increasing demand across various industries, including automotive, aerospace, and construction. Key trends influencing this sector include advancements in manufacturing technologies, such as automation and precision engineering, which enhance production efficiency and product quality. Furthermore, the proliferation of e-commerce platforms is transforming how B2B buyers source these components, allowing for quicker access to a broader range of products and suppliers.

International buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly prioritizing suppliers that offer a blend of competitive pricing and reliable quality. This trend is particularly evident in markets like Brazil and Saudi Arabia, where local industries are expanding rapidly. Buyers are also seeking suppliers with robust inventory management systems, ensuring timely delivery of products like stainless steel torsion springs. This responsiveness is critical, as delays in supply chains can significantly impact production schedules.

Emerging technologies, such as IoT and AI, are beginning to play a role in the sourcing process, allowing companies to better manage inventories, predict demand fluctuations, and streamline procurement processes. As the market evolves, international buyers must stay informed about these technological advancements to enhance their sourcing strategies and maintain competitive advantages.

How is Sustainability and Ethical Sourcing Shaping the Stainless Steel Torsion Spring Market?

Sustainability is becoming a central focus in the stainless steel torsion spring sector, with increasing pressure on manufacturers to minimize environmental impacts. Ethical sourcing practices are gaining prominence, as companies recognize the importance of transparent supply chains. B2B buyers are now more inclined to partner with suppliers who demonstrate a commitment to sustainability, including the use of recycled materials and environmentally friendly manufacturing processes.

The environmental impact of stainless steel production, particularly concerning energy consumption and emissions, is prompting many businesses to seek suppliers that prioritize green certifications. Certifications such as ISO 14001 (Environmental Management) and the use of materials that comply with environmental standards are becoming vital criteria in the supplier selection process. Buyers are also looking for manufacturers who can provide documentation on the lifecycle assessment of their products, ensuring that the springs they source have a reduced carbon footprint.

Incorporating sustainable practices not only meets regulatory requirements but also enhances brand reputation and consumer trust. As the global market continues to evolve, companies that proactively adopt sustainable practices will likely gain a competitive edge in the increasingly conscientious marketplace.

What is the Historical Context of Stainless Steel Torsion Springs in B2B Markets?

The use of torsion springs dates back to the early 19th century, primarily in mechanical applications where rotational force was necessary. The introduction of stainless steel in the mid-20th century revolutionized the torsion spring market, providing enhanced durability and corrosion resistance. This innovation allowed for wider applications across various sectors, including automotive and industrial machinery.

As industries evolved, so did the manufacturing processes for stainless steel torsion springs. Advances in technology have led to more precise manufacturing techniques, improving the performance characteristics of these springs. Today, stainless steel torsion springs are integral components in numerous applications, from garage doors to complex machinery, reflecting their versatility and importance in modern engineering. Understanding this historical context can help B2B buyers appreciate the advancements in quality and technology that have shaped the current market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of stainless steel torsion spring

1. How do I choose the right stainless steel torsion spring for my application?

Selecting the appropriate stainless steel torsion spring involves considering several factors, including load requirements, spring dimensions, and environmental conditions. Assess the torque specifications and deflection angles needed for your application. Additionally, ensure the spring material, such as 302 or 304 stainless steel, provides adequate corrosion resistance for your environment. Consulting technical data sheets and engaging with manufacturers can help clarify which specifications best meet your needs.

2. What are the advantages of using stainless steel torsion springs over other materials?

Stainless steel torsion springs offer superior corrosion resistance, making them ideal for applications exposed to moisture or chemicals. Their durability ensures a longer lifespan, reducing maintenance costs and replacement frequency. Furthermore, stainless steel springs maintain strength and performance under varying temperatures, which is crucial for international markets with diverse climates. This combination of features makes them a preferred choice for industries ranging from automotive to aerospace.

3. What is the minimum order quantity (MOQ) for stainless steel torsion springs?

Minimum order quantities can vary significantly among suppliers. Typically, MOQs range from a few dozen to several hundred units, depending on the manufacturer and the specific spring design. It’s advisable to inquire directly with potential suppliers about their MOQ policies, as some may offer flexibility for first-time buyers or bulk orders. Understanding these terms can aid in your planning and budget allocation.

4. How can I vet suppliers of stainless steel torsion springs for international trade?

When vetting suppliers, consider their industry reputation, certifications, and experience in the market. Look for suppliers with ISO certifications, which indicate adherence to quality management standards. Additionally, request references from previous clients, especially those in your region, to gauge reliability. It’s also beneficial to verify their production capabilities and lead times, ensuring they can meet your demand consistently.

5. What customization options are available for stainless steel torsion springs?

Many manufacturers offer customization options for stainless steel torsion springs, including variations in size, shape, winding direction, and material grades. You can also specify unique torque ratings and deflection angles tailored to your application. Discussing your specific requirements with suppliers allows them to provide tailored solutions that meet your operational needs while maintaining performance and durability.

6. What payment terms should I expect when sourcing stainless steel torsion springs internationally?

Payment terms can differ widely depending on the supplier and the nature of the transaction. Common terms include net 30 or net 60 days, requiring payment within that timeframe after receiving the invoice. For new relationships, suppliers may request upfront payment or a deposit, especially for custom orders. Always clarify payment options, including wire transfers, letters of credit, or escrow services, to ensure a secure transaction.

7. How do I ensure quality assurance for my stainless steel torsion springs?

Quality assurance can be ensured by requesting detailed inspection reports and certifications from your supplier. Many reputable manufacturers perform rigorous testing, including tensile strength and fatigue tests, to confirm product integrity. Additionally, consider implementing a quality control process where you can conduct inspections upon receiving shipments. Establishing clear communication about quality expectations with your supplier is essential for maintaining standards.

8. What logistics considerations should I keep in mind when importing stainless steel torsion springs?

When importing, consider shipping methods, lead times, and customs regulations in your country. Evaluate the best shipping options that balance cost and delivery speed, whether by air or sea. Familiarize yourself with import duties and taxes to avoid unexpected expenses. Collaborating with a logistics partner experienced in international trade can streamline the process and ensure compliance with all regulations, facilitating a smooth import experience.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Stainless Steel Torsion Spring Manufacturers & Suppliers List

1. Century Spring – TO-1123CS Left-Hand Spring

Domain: centuryspring.com

Registered: 1996 (29 years)

Introduction: {‘SKU’: ‘TO-1123CS’, ‘Material’: ‘302/304 Stainless Steel’, ‘Wind Direction’: ‘Left-hand’, ‘Inside Diameter’: ‘0.562 inches’, ‘Outside Diameter’: ‘0.772 inches’, ‘Body Length’: ‘1.04 inches’, ‘Leg Length’: ‘3.5 inches’, ‘Wire Diameter’: ‘0.105 inches’, ‘Mandrel Diameter’: ‘0.46 inches’, ‘Total Coils’: ‘8’, ‘Rotational Angle’: ‘180 degrees’, ‘Max Torque’: ’17 inch-pounds’, ‘Rate’: ‘0.1641 lbf-in/de…

2. McMaster – Stainless Steel Torsion Springs

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Stainless Steel Torsion Springs, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. MW Components – Torsion Springs

Domain: mwcomponents.com

Registered: 2017 (8 years)

Introduction: Torsion Springs available in Stainless Steel and other materials. Part of a broader category of springs including Custom Springs, Hot Wound Springs, Coiled Springs, Compression Springs, Extension Springs, Automotive Springs, and more. MW Components offers a variety of spring types and related products, emphasizing custom solutions and quick shipping for aerospace and military specifications.

4. Stainless Garage Door Parts – Torsion Spring 2 ID x .192 Wire

Domain: stainlessgaragedoorparts.com

Registered: 2014 (11 years)

Introduction: [{‘name’: ‘Stainless Garage Door Torsion Spring, 2″ ID. x .192 Wire x 18″ Left Wound with Cones’, ‘sale_price’: ‘$235.99’, ‘regular_price’: ‘$337.13’, ‘savings’: ‘$101.14’}, {‘name’: ‘Stainless Garage Door Torsion Spring, 2″ ID. x .192 Wire x 18″ Right Wound with Cones’, ‘sale_price’: ‘$235.99’, ‘regular_price’: ‘$337.13’, ‘savings’: ‘$101.14’}, {‘name’: ‘Stainless Garage Door Torsion Spring, 2″ I…

5. Industrial Springs – Stainless Steel 302 Compression Springs

Domain: industrial-springs.com

Registered: 2005 (20 years)

Introduction: {“material”:”Stainless steel 302″,”wire_diameter_mm”:0.30,”external_diameter_mm”:[2.36,2.59,2.77,4.22,4.32],”internal_diameter_mm”:[1.76,1.99,2.17,3.62,3.72],”max_shaft_mm”:[1.40,1.57,1.70,2.77],”elastic_coils_pcs”:[2.25,8.75,5.00,3.00,4.75],”length_of_leg_mm”:[9.50,12.70],”max_turning_degrees”:[90.00,270.00,180.00],”leg_position”:[1.00,2.00,3.00],”max_torque_N_mm”:5.31}

6. MISUMI – Torsion Springs

Domain: us.misumi-ec.com

Registered: 2007 (18 years)

Introduction: Torsion springs are a type of wire spring that receive a twisting moment around the coil. They can be classified into close-wound and pitch-wound types. Key features include:

– Selection of arm angles: 90-, 135-, or 180-degrees based on mounting location and method.

– Reduction of design space and labor compared to compression and tension springs.

– Important specifications to consider: free le…

7. Mr. Spring – Torsion Spring MT070-01-RH-SS

Domain: springs.mrspring.com

Registered: 1997 (28 years)

Introduction: {‘item_number’: ‘MT070-01-RH-SS’, ‘outside_diameter’: ‘0.595 Inch’, ‘wire_diameter’: ‘0.07 Inch’, ‘material’: ‘Stainless Steel’, ‘type’: ‘Torsion Spring’, ‘deflection’: ’90 °’, ‘torque’: ‘7.47 In-Lbs’, ‘leg_length’: ‘2’, ‘mandrel_size’: ‘0.375’, ‘axial_space’: ‘0.42’, ‘total_coils’: ‘4.25’, ‘price’: ‘$8.98’, ‘quantity_discounts’: [{‘quantity_range’: ’10 – 24′, ‘price’: ‘$8.98’}, {‘quantity_range’:…

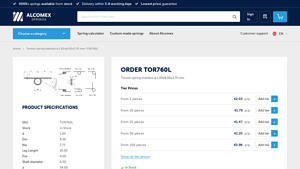

8. Alcomex – Torsion Spring Stainless ø 1.00×8.00×3.75 mm

Domain: webshop.alcomexsprings.com

Registered: 2017 (8 years)

Introduction: {‘name’: ‘Torsion spring stainless ø 1,00×8,00×3,75 mm-TOR760L’, ‘sku’: ‘TOR760L’, ‘price’: ‘€2.39’, ‘stock_status’: ‘In Stock’, ‘dimensions’: {‘diameter’: ‘1.00 mm’, ‘outer_diameter’: ‘8.00 mm’, ‘wire_diameter’: ‘2.75 mm’, ‘leg_length’: ‘35.00 mm’, ‘shaft_diameter’: ‘6.00 mm’, ‘position’: ‘4.00 mm’, ‘a’: ‘54.00 mm’, ‘M’: ‘127.00 mm’, ‘R’: ‘2.36 mm’}, ‘winding_direction’: ‘left’, ‘material’: ‘stai…

Strategic Sourcing Conclusion and Outlook for stainless steel torsion spring

As the demand for stainless steel torsion springs continues to rise across diverse industries, strategic sourcing emerges as a pivotal factor for international B2B buyers. By leveraging reliable suppliers with robust inventory management and efficient logistics, businesses can ensure timely access to high-quality components. The exceptional durability and corrosion resistance of stainless steel torsion springs make them ideal for applications ranging from automotive to industrial machinery, particularly in challenging environments found in regions like Africa, South America, the Middle East, and Europe.

Understanding the specifications and performance metrics—such as torque ratings and coil configurations—enables buyers to make informed decisions that align with their operational needs. Additionally, considering suppliers that offer customization options can enhance the adaptability of products to specific applications.

Looking ahead, the landscape of stainless steel torsion spring sourcing is set to evolve with advances in manufacturing technologies and an increasing focus on sustainability. B2B buyers are encouraged to engage with suppliers who prioritize quality, support, and innovation. By doing so, businesses can position themselves for success in an increasingly competitive market. Explore your options today and secure the components that will drive your projects forward.