Contents

Manufacturing Insight: Stainless Steel Torsion Spring

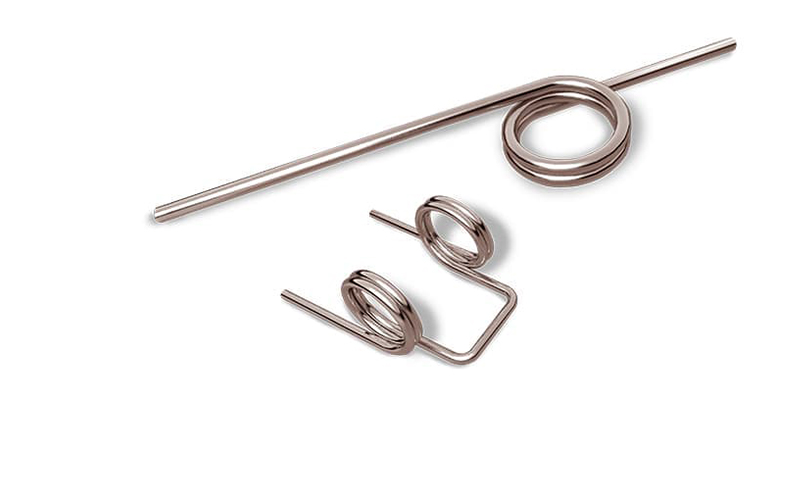

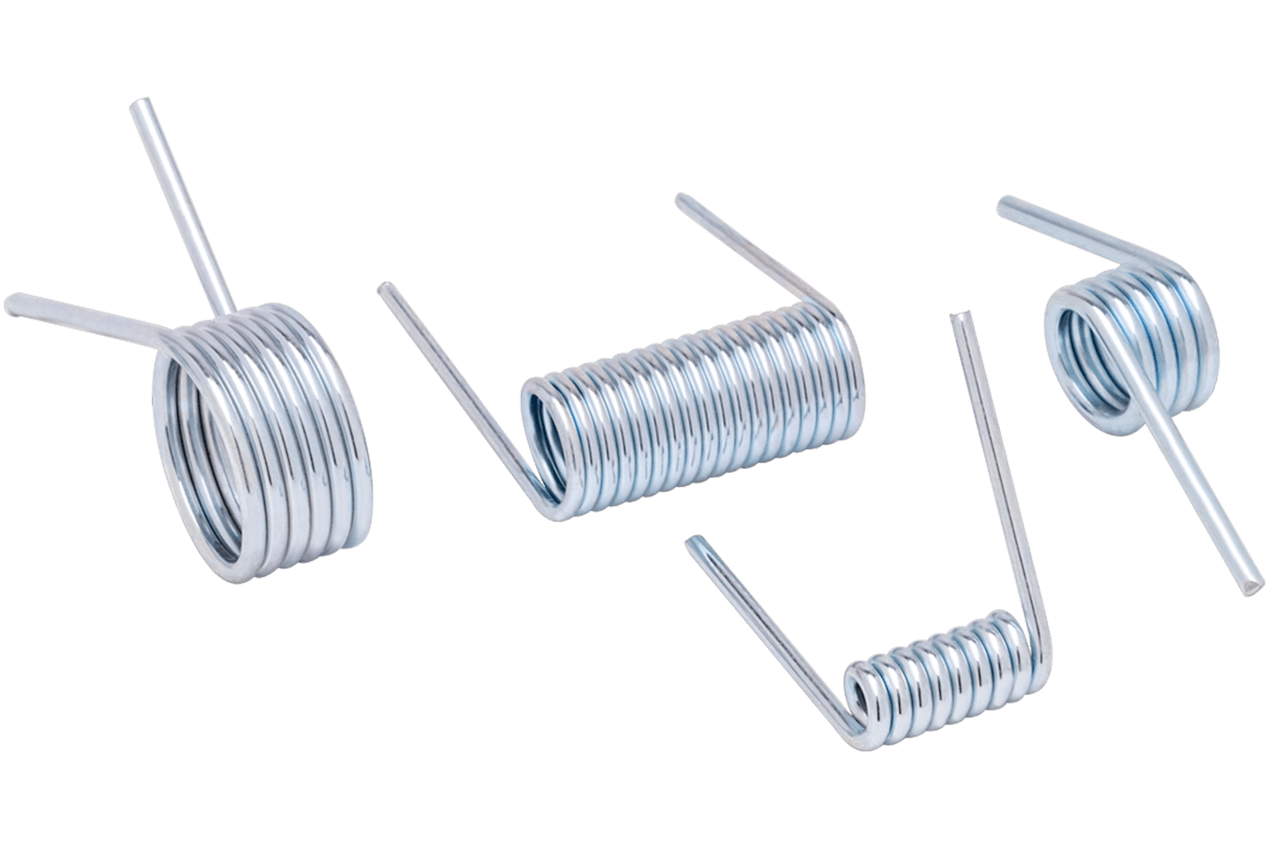

Precision Stainless Steel Torsion Springs Engineered for Demanding Applications

Honyo Prototype delivers mission-critical stainless steel torsion springs through advanced CNC machining processes designed for uncompromising precision and repeatability. Our engineering team leverages multi-axis CNC Swiss turning and milling centers to manufacture springs meeting exact torque specifications, angular deflection requirements, and fatigue life expectations across industries including medical devices, aerospace systems, and industrial automation. Material integrity is ensured through strict control of 304, 316, and 17-4 PH stainless steel grades, with capabilities spanning wire diameters from 0.2mm to 8.0mm and tight tolerances down to ±0.025mm. Every component undergoes rigorous in-process metrology and final inspection against ASME Y14.5 geometric dimensioning standards to guarantee performance under cyclic loading.

Accelerate your development timeline with Honyo Prototype’s Online Instant Quote platform, providing detailed manufacturing feedback and lead time estimates within minutes for stainless steel torsion spring designs. Upload CAD files directly to receive actionable insights on manufacturability, material optimization, and cost drivers—enabling faster iteration from prototype to production without sacrificing the dimensional accuracy or material properties essential for torsional reliability.

Technical Capabilities

The term “stainless steel torsion spring” refers to a mechanical component designed to store and release angular energy or to apply a torque or rotational force. However, torsion springs are typically manufactured using wire forming processes rather than 3/4/5-axis milling or turning, which are subtractive machining methods more appropriate for complex geometries in solid stock. That said, certain precision components related to spring housings, fixtures, or integrated assemblies may require multi-axis CNC machining with tight tolerances.

Below is a technical overview focused on the machining capabilities relevant to components associated with torsion spring applications, including material compatibility and precision machining parameters.

| Parameter | Description |

|---|---|

| Primary Machining Processes | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning |

| Typical Applications | Precision spring retainers, actuator housings, medical device components |

| Tight Tolerance Capability | ±0.0002″ (±0.005 mm) for critical dimensions; GD&T controls as required |

| Surface Finish | Ra 16–32 μin standard; down to Ra 8 μin with fine finishing passes |

| Materials – Machinability | Stainless Steel (304, 316): Moderate; requires carbide tooling and cooling |

| Aluminum (6061, 7075): Excellent; high MRR, ideal for prototypes | |

| Steel (1018, 4140): Good; higher tool wear vs. aluminum | |

| ABS: Good; low melting point; requires sharp tools and low heat buildup | |

| Nylon (PA6, PA66): Moderate; prone to deformation; needs rigid fixturing | |

| Tooling Recommendations | High-performance carbide end mills; coolant-through tools for deep pockets |

| Fixturing | Vacuum, tombstone, or modular fixturing for 5-axis; collet chucks for turning |

| Common Finishes | Passivation (stainless steel), anodizing (aluminum), bead blasting, polishing |

| Quality Control | CMM inspection, optical comparators, surface roughness testers |

Note: While torsion springs themselves are not typically milled or turned, Honyo Prototype supports high-precision machining of mating or structural components from stainless steel and other materials, ensuring tight integration and functional performance in final assemblies.

From CAD to Part: The Process

Honyo Prototype Stainless Steel Torsion Spring Manufacturing Process

Our end-to-end process for stainless steel torsion springs begins with secure CAD file submission through our encrypted client portal. We accept native formats including STEP AP203/214, IGES, and Parasolid, with strict validation for geometric accuracy and critical torsion spring parameters such as leg angles, center diameter, and torque requirements. Incomplete geometry or ambiguous tolerances trigger an immediate notification for client clarification to prevent downstream delays.

The AI-powered quoting engine analyzes the CAD model against real-time material costs, machine availability, and process constraints specific to stainless steel alloys like 302, 304, or 17-4PH. It calculates precise raw material consumption based on wire diameter and coil count while factoring in stainless steel’s work hardening characteristics during coiling. The system generates a detailed quote within 2 hours, including cost breakdowns for secondary operations such as stress relief tempering and passivation, with clear annotations of any geometric risks like undercut legs or excessive torsional stress concentrations.

During Design for Manufacturability (DFM) review, our senior process engineers conduct a rigorous analysis focused on stainless steel’s unique challenges. We verify mandrel diameter compatibility to prevent surface scratches, assess coil winding tension parameters to avoid residual stress-induced set loss, and confirm heat treatment specifications to mitigate stress corrosion cracking risks. Critical checks include validating minimum bend radii against the alloy’s ductility limits and ensuring leg geometries allow for automated coiling without secondary forming. Clients receive a formal DFM report with actionable recommendations, such as adjusting leg length tolerances from ±0.1mm to ±0.25mm to accommodate stainless steel springback.

Production executes on CNC coiling machines with in-process monitoring of spring index and torque consistency. Stainless steel wire undergoes strict lot traceability per ASTM A313, with coiling performed under controlled tension to manage work hardening. All springs undergo mandatory stress relief at 450±10°C for 30 minutes followed by quenching, then passivation in nitric acid per ASTM A967 to remove free iron and enhance corrosion resistance. Final inspection includes torque testing per ISO 10243 using calibrated fixtures, surface roughness verification (Ra ≤ 0.8µm), and 100% visual inspection for micro-cracks.

Delivery includes ISO 13485-compliant documentation: material certs with full traceability, heat treatment records, and first-article inspection reports. Springs are packaged in anti-tarnish VCI paper with desiccant inside rigid containers to prevent set loss during transit. Typical lead time from CAD upload to shipment is 10–15 business days for quantities under 5,000 pieces, with expedited options available for critical applications. We maintain real-time shipment tracking and proactive delay notifications through our client portal.

Start Your Project

Looking for high-quality stainless steel torsion springs for your next project? Honyo Prototype manufactures precision-engineered springs at our state-of-the-art facility in Shenzhen, China. Built for durability and consistent performance, our torsion springs are ideal for demanding applications across automotive, industrial, and medical industries.

For quotes, custom designs, or technical specifications, contact Susan Leo directly at [email protected]. Let us support your prototyping and low-volume production needs with fast turnaround and strict quality control.

Contact:

Susan Leo

Email: [email protected]

Factory Location: Shenzhen, China

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.