Contents

Manufacturing Insight: Stainless Steel Stamp

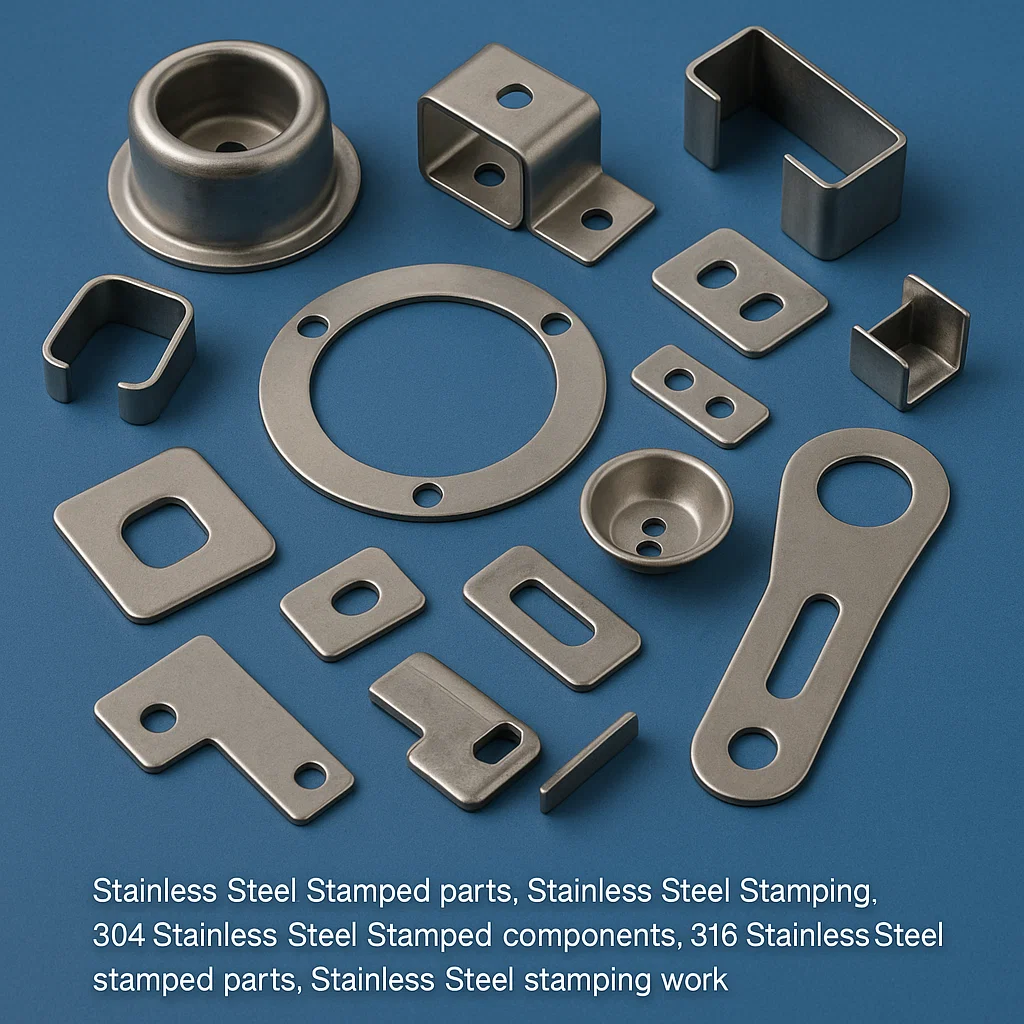

Honyo Prototype CNC Machining for Precision Stainless Steel Stamps

Honyo Prototype delivers high-precision stainless steel stamps engineered for demanding industrial applications, including part identification, branding, and tooling. Our advanced CNC machining capabilities ensure exact dimensional accuracy, tight tolerances down to ±0.005 mm, and superior surface finishes critical for consistent impression quality. We specialize in machining corrosion-resistant stainless steel grades like 304 and 316, optimizing material integrity to prevent deformation during high-force stamping operations. Each component undergoes rigorous in-process inspection to guarantee burr-free edges and repeatability, whether for prototyping or low-volume production runs.

Accelerate your project timeline with Honyo’s Online Instant Quote system. Upload your 3D CAD file to receive a detailed, binding quotation in seconds—no manual submission delays. Our platform provides transparent pricing, lead time estimates, and real-time design feedback, streamlining procurement from initial concept to certified delivery. For engineers requiring rapid iteration or mission-critical stamping solutions, Honyo combines technical expertise with digital efficiency to eliminate bottlenecks in your supply chain. Upload your design today to validate manufacturability and secure immediate pricing.

Technical Capabilities

Technical specifications for a stainless steel stamp used in precision manufacturing environments require high dimensional accuracy, surface finish quality, and durability. These stamps are typically machined using 3, 4, or 5-axis CNC milling systems, often combined with turning operations for hybrid features. They are designed to produce consistent impressions on various materials including Aluminum, Steel, ABS, and Nylon, particularly in prototyping and low-volume production applications at Honyo Prototype.

The stamp must maintain tight tolerances to ensure repeatability and part integrity. Multi-axis milling allows for complex geometries and undercuts, while CNC turning ensures precise cylindrical alignment when required. Surface treatments such as passivation or coating may be applied to enhance wear resistance.

Below is a summary of key technical parameters and performance characteristics:

| Parameter | Specification |

|---|---|

| Machining Process | 3-axis, 4-axis, and 5-axis CNC milling; CNC turning (for rotational symmetry or hybrid features) |

| Tolerance Range | ±0.005 mm to ±0.025 mm depending on geometry and material |

| Surface Finish (Ra) | 0.8 µm to 3.2 µm (polished finishes available upon request) |

| Stamp Material | Stainless Steel (typically AISI 304, 316, or 17-4 PH for enhanced hardness) |

| Target Materials for Impression | Aluminum (soft and hard alloys), Mild and tool steel, ABS (thermoplastic), Nylon (PA6, PA66) |

| Hardness (Stamp) | 50–58 HRC (heat-treated variants used for steel impression applications) |

| Feature Complexity | Capable of engraving logos, serial numbers, barcodes, and precision datum features |

| Fixturing & Alignment | Precision ground reference surfaces; compatible with modular workholding systems |

| Applications | Part identification, branding, datum marking, functional texturing |

| Quality Control | Inspected via CMM, optical comparators, and surface profilometry |

This specification ensures compatibility with high-mix, high-precision manufacturing workflows, supporting industries such as aerospace, medical devices, and automotive prototyping.

From CAD to Part: The Process

Honyo Prototype Stainless Steel Stamping Process Overview

Honyo Prototype delivers precision stainless steel stamped components through a rigorously controlled digital workflow optimized for material-specific challenges. This process ensures geometric accuracy, material integrity, and cost efficiency for grades including 304, 316, and 430 stainless steel. Below is the end-to-end sequence.

CAD Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, or Parasolid) via our secure portal. Our system immediately checks for dimensional completeness, unit consistency, and geometric validity. Stainless steel stamping requires explicit material thickness and grade specifications; missing parameters trigger automated client notification to prevent downstream errors. Only validated files proceed to quoting.

AI-Powered Quoting Engine

Proprietary AI algorithms analyze the CAD geometry against real-time production constraints. The system calculates material utilization efficiency, progressive die complexity, machine time, and secondary operations (e.g., coining, coining, or heat treatment). Stainless steel-specific factors include tool wear rates, springback compensation requirements, and lubrication needs. Quotes detail cost drivers like scrap rate projections and tolerance-driven cycle time adjustments, typically generated within 2 business hours.

Engineering-Led DFM Analysis

Every stainless steel part undergoes mandatory Design for Manufacturability (DFM) review by our tooling engineers. This phase identifies critical stainless steel challenges: excessive thinning in deep draws, burr formation at high shear rates, and stress-induced warpage. Key parameters are validated against material limits:

| Parameter | Stainless Steel Requirement | Honyo Action |

|---|---|---|

| Minimum Bend Radius | ≥ 0.8T for 304/316 | Flag designs <0.6T for redesign consultation |

| Hole-to-Edge Distance | ≥ 1.5T | Reject if <1.2T; propose alternative layout |

| Tolerance (±) | ±0.05mm standard | Note GD&T callouts requiring secondary ops |

| Grain Direction Critical | Yes for formed features | Verify alignment in flat pattern |

Engineers collaborate with clients to resolve conflicts, optimizing for manufacturability without compromising function. This step reduces prototyping iterations by 70% based on historical data.

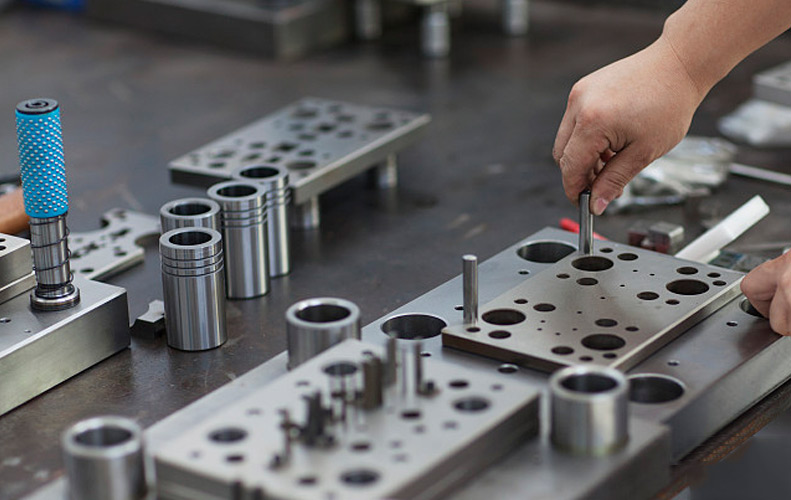

Precision Production Execution

Approved designs move to our stamping floor equipped with CNC servo presses (25-300 tons) featuring hardened tool steels (D2/A2) and coated punches to combat stainless galling. Key production controls include:

Material is tension-levelled pre-feed to eliminate coil set. In-die sensors monitor tonnage and part ejection in real time, with automatic shutdown if force deviates >5% from baseline. All 300-series parts undergo in-process deburring via vibratory finishing to meet edge quality standards. Statistical process control (SPC) tracks critical dimensions at 30-minute intervals, with Cpk ≥1.33 required for release.

Quality-Certified Delivery

Final inspection validates conformance to ASME Y14.5 using CMM and optical comparators. Stainless steel parts receive passivation per ASTM A967 and a material test report (MTR) tracing chemical composition. Components are vacuum-sealed with VCI paper to prevent flash rust during transit. Standard lead time is 10-15 business days from DFM approval, with real-time shipment tracking provided. All deliveries include a full quality package: FAIR, dimensional report, and RoHS compliance documentation.

Start Your Project

Looking for high-precision stainless steel stamping solutions? Partner with Honyo Prototype for reliable, low-volume production and rapid prototyping.

Our in-house manufacturing facility in Shenzhen ensures tight tolerances, fast turnaround, and consistent quality for your custom stainless steel stamping needs.

Contact Susan Leo directly at [email protected] to discuss your project requirements and get a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.