Contents

Manufacturing Insight: Stainless Steel Screws In Aluminium

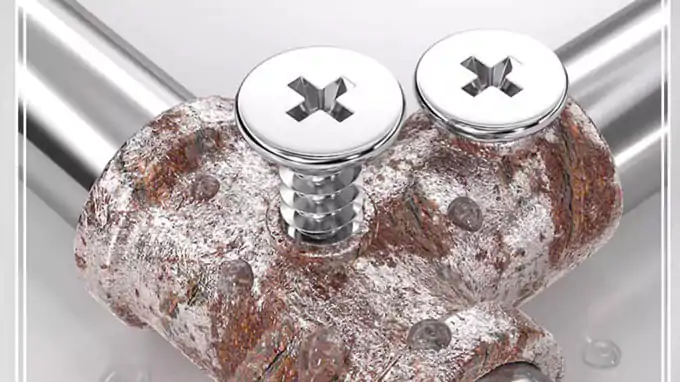

Precision Integration of Stainless Steel Screws in Aluminum Assemblies

The inherent galvanic incompatibility between stainless steel fasteners and aluminum substrates presents a critical engineering challenge, often leading to accelerated corrosion, joint failure, and compromised structural integrity in demanding applications. At Honyo Prototype, we address this complexity head-on through advanced CNC machining expertise, ensuring seamless and reliable integration without sacrificing performance or longevity.

Our specialized manufacturing process leverages tightly controlled tolerances, precision-machined interface geometries, and material-specific surface treatments to mitigate galvanic effects while maintaining optimal clamping force and dimensional stability. Every stainless steel screw hole, counterbore, and thread engagement in aluminum components is produced using state-of-the-art multi-axis CNC equipment, adhering to stringent aerospace and industrial standards for repeatability and quality. This capability is essential for sectors where failure is not an option, including robotics, medical devices, and high-performance automotive systems.

Honyo Prototype delivers engineered solutions that transform design intent into robust, production-ready assemblies. Eliminate quoting delays and accelerate your development cycle with our Online Instant Quote system—providing accurate, real-time pricing and lead times for custom-machined stainless steel screw-in-aluminum components within minutes. Experience the precision and reliability that define Honyo’s CNC machining services, engineered for reliability from prototype to volume production.

Technical Capabilities

Technical specifications for stainless steel screws used in aluminum components, particularly within high-precision manufacturing environments involving 3/4/5-axis milling and turning operations, require careful consideration of material compatibility, dimensional accuracy, and environmental resistance. These fasteners are commonly used in aerospace, medical, and automation industries where tight tolerances (typically ±0.005 mm to ±0.025 mm) and repeatable performance are critical.

The integration of dissimilar materials—such as stainless steel screws with aluminum substrates—requires attention to galvanic corrosion, thermal expansion differences, and thread engagement length. Additional considerations arise when assembling with non-metallic materials like ABS or nylon, which demand controlled torque and often inserts for durability.

Below is a comparative technical overview of materials involved in such assemblies:

| Material | Typical Grade/Type | Machinability | Thermal Expansion (µm/m·K) | Tensile Strength (MPa) | Hardness (HB) | Key Considerations in Milling & Turning |

|---|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | Excellent | 23–24 | 310 (6061), 570 (7075) | 95–150 | High precision achievable; prone to galling with steel; requires sharp tooling and proper coolants to avoid built-up edge |

| Stainless Steel (Screws) | 304, 316, 17-4 PH | Moderate to Poor | 16–18 | 505–1000 | 150–330 | Causes tool wear in multi-axis operations; 17-4 PH used for high strength and tight tolerance; passivation recommended |

| ABS | Standard, High Impact | Excellent | 70–100 | 35–50 | 80–100 | Low melting point; requires low feed rates and sharp cutting tools; often used for enclosures or prototypes |

| Nylon (PA6, PA66) | Reinforced or unfilled | Good | 80–120 | 70–85 | 85–110 | Susceptible to moisture absorption; needs dry machining; used for insulating or non-conductive inserts |

For tight tolerance applications, stainless steel screws (especially precision-ground variants) are pre-machined to close tolerances (h6 to h9) and often used with threaded inserts in aluminum or plastics to prevent thread stripping. In 3/4/5-axis milling setups, alignment and perpendicularity must be maintained during tapping operations to ensure proper screw fitment and avoid cross-threading.

When integrating with ABS or nylon, heat generated during screw installation must be minimized—considering cold-forming or pre-tapped holes with reduced thread percentages. In high-cycle environments, PEM® or heat-staked inserts are recommended for nylon and ABS to maintain thread integrity.

Environmental sealing and anti-corrosion measures such as PTFE coating on stainless screws or anodizing aluminum parts are standard practices to mitigate galvanic effects in humid or outdoor applications.

From CAD to Part: The Process

Honyo Prototype Stainless Steel Screws in Aluminum Manufacturing Process

Honyo Prototype executes precise manufacturing for stainless steel screws in aluminum components through a rigorously controlled five-phase workflow. This process specifically addresses material compatibility challenges such as galvanic corrosion and thermal expansion differentials inherent in dissimilar metal assemblies.

Upload CAD

Clients initiate the process by uploading native or neutral-format CAD files (STEP, IGES, Parasolid) via Honyo’s secure portal. Our system validates file integrity and extracts critical parameters including screw thread specifications (e.g., M3x0.5), hole callouts, aluminum alloy grade (e.g., 6061-T6), and geometric tolerances. Material interaction zones are automatically tagged for corrosion risk assessment in subsequent stages.

AI Quote

Honyo’s proprietary AI quoting engine analyzes the CAD geometry, material specifications, and production context to generate an instant technical and commercial proposal. For stainless-aluminum interfaces, the AI flags:

Required corrosion mitigation strategies (e.g., insulating coatings, isolating washers)

Thread engagement depth validation against aluminum’s lower shear strength

Estimated secondary operation costs (e.g., thread inserts, anodizing masking)

The quote includes granular cost breakdowns and lead time projections within 2 business hours.

DFM (Design for Manufacturability)

Our engineering team conducts a mandatory DFM review focusing on stainless-aluminum interface integrity. Key actions include:

Verifying minimum thread engagement depth (typically 1.5x screw diameter in aluminum to prevent pull-out)

Recommending corrosion prevention methods based on environmental exposure

Adjusting hole tolerances to accommodate aluminum’s higher thermal expansion coefficient

Confirming compatibility with stainless steel fastener grades (e.g., A2/A4) to minimize galvanic potential

The DFM report documents all modifications with annotated CAD markups and technical justifications.

Production

Manufacturing adheres to AS9100-certified protocols with material-specific controls:

Aluminum components undergo precision drilling/tapping with coolant optimization to prevent galling

Stainless steel screws are pre-treated with Dacromet or Geomet coatings where specified

Critical assemblies use non-conductive PTFE washers or nylon inserts per DFM requirements

In-process metrology validates thread pitch diameter (GO/NO-GO gauges) and hole positional accuracy

Strict segregation of stainless and aluminum tooling prevents cross-contamination

Delivery

Final assemblies undergo functional testing per client specifications (e.g., torque-to-failure validation on sample screws). Components are packaged with VCI paper and humidity indicators to prevent in-transit corrosion. All deliverables include:

First-article inspection reports (FAIR) with CMM data for critical features

Material certification for both stainless screws (ASTM F593) and aluminum substrates

Traceability documentation linking screws to certified lots

Environmental compliance certificates (RoHS, REACH)

Corrosion Mitigation Strategy Comparison

| Method | Application Context | Cost Impact | Lead Time Impact |

|———————–|—————————————–|————-|——————|

| Isolating Washers | Indoor/low-moisture environments | +3-5% | None |

| Dacromet Coating | Marine/industrial exposure | +12-15% | +2 days |

| Threaded Inserts | High-vibration applications | +18-22% | +3 days |

| Anodizing + Sealant | Critical aerospace/military components | +25-30% | +5 days |

This integrated approach ensures stainless steel screws achieve reliable, long-term performance in aluminum assemblies while maintaining Honyo’s standard 99.2% first-pass yield rate. Process deviations are mitigated through real-time SPC monitoring, with all corrosion prevention measures validated per ASTM B117 salt spray testing protocols where required.

Start Your Project

Looking for high-quality stainless steel screws in aluminium components? Honyo Prototype offers precision manufacturing solutions with tight tolerances and consistent quality. Our factory in Shenzhen ensures fast turnaround and reliable production for your prototyping and low-volume manufacturing needs.

Contact Susan Leo at [email protected] to discuss your project requirements and get a competitive quote today.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.