Contents

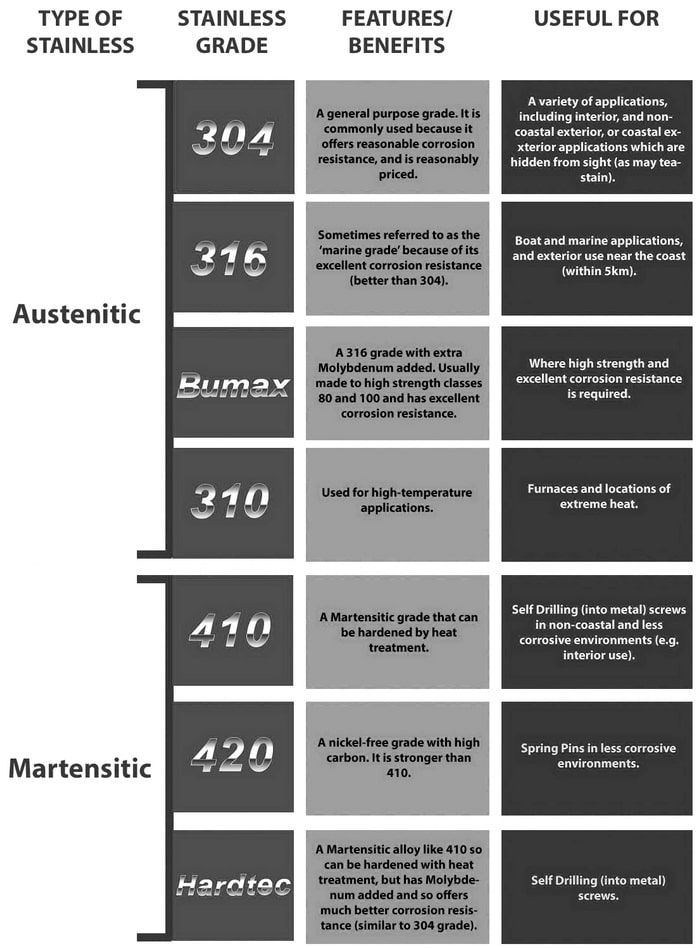

Manufacturing Insight: Stainless Steel Quality Chart

Stainless Steel Quality Chart for Precision CNC Machined Components

Honyo Prototype delivers exceptional CNC machining capabilities specifically engineered for demanding stainless steel applications including 304, 316/L, 17-4PH, and custom alloys. Our advanced multi-axis milling and turning centers achieve tight tolerances down to ±0.005mm while maintaining critical surface finishes and dimensional stability, even with challenging material properties like work hardening and thermal sensitivity. Rigorous in-process inspections and material traceability protocols ensure every component meets stringent aerospace, medical, and industrial specifications without compromise.

This quality chart provides definitive reference data on achievable tolerances, surface roughness parameters, and metallurgical integrity across common stainless steel grades under Honyo’s controlled machining processes. Leverage our Online Instant Quote system to upload CAD files and receive detailed manufacturability feedback alongside competitive pricing within hours—accelerating your prototyping and low-volume production timelines without sacrificing quality assurance. Reference this chart during design validation to optimize part geometry for cost-effective, high-integrity stainless steel fabrication.

Technical Capabilities

Stainless Steel Quality Chart – Technical Specifications for Precision Machining

The following table outlines key technical specifications and performance characteristics relevant to stainless steel when processed using 3-axis, 4-axis, and 5-axis milling, as well as CNC turning operations. Emphasis is placed on tight tolerance capabilities, surface finish, and compatibility with common engineering materials including Aluminum, Steel, ABS, and Nylon. These parameters are critical for high-precision prototyping and production at Honyo Prototype.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Tight Tolerance Capability | Compatible Materials |

|---|---|---|---|---|---|---|

| Max Working Axes | 3 (X, Y, Z) | 4 (X, Y, Z, A or B) | 5 (X, Y, Z, A, B or C) | 2 (X, Z) + C-axis optional | ±0.005 mm (±0.0002″) | Stainless Steel, Aluminum, Steel, ABS, Nylon |

| Typical Surface Finish (Ra) | 1.6 – 3.2 µm | 1.6 – 2.4 µm | 0.8 – 1.6 µm | 0.8 – 1.6 µm | Achievable on critical surfaces | Varies by material and toolpath strategy |

| Positioning Accuracy | ±0.01 mm | ±0.01 mm | ±0.005 mm | ±0.005 mm | Up to ±0.002 mm with calibration | Stainless Steel: high repeatability |

| Repeatability | ±0.008 mm | ±0.008 mm | ±0.003 mm | ±0.003 mm | Critical for multi-setup parts | Aluminum: excellent; ABS: moderate |

| Spindle Speed Range | 8,000 – 20,000 RPM | 8,000 – 20,000 RPM | 10,000 – 24,000 RPM | 3,000 – 12,000 RPM | High speed improves finish | Nylon: requires reduced feed rates |

| Tool Holders | ISO 30 / HSK-E32 | ISO 30 / HSK-E32 | HSK-F63 / CAT-40 | Capto C6 / ISO 50 | High rigidity for precision | ABS: prone to melting if overheated |

| Coolant Options | Flood, Mist, Air Blast | Flood, Mist | Flood, Through-Spindle | Flood, Mist | Essential for stainless steel | Steel and stainless: require lubrication |

| Typical Applications | Flat geometries, prismatic parts | Index features, angled holes | Complex contours, aerospace molds | Shafts, bushings, fittings | ±0.01 mm standard; tighter upon request | Multi-material assemblies supported |

Notes on Material Behavior:

Stainless steel (e.g., 304, 316) exhibits high work-hardening rates and lower thermal conductivity, requiring optimized toolpaths and tooling (e.g., carbide with PVD coatings). Aluminum offers higher machinability with faster feed rates and excellent surface finish. Carbon steel and alloy steels demand rigid setups due to higher cutting forces. ABS and Nylon, while machinable, require careful control of feed and speed to avoid burring or melting, especially in tight tolerance zones.

All processes are supported with CMM inspection and first-article reporting to validate dimensional compliance per ISO 2768-mK or custom GD&T requirements.

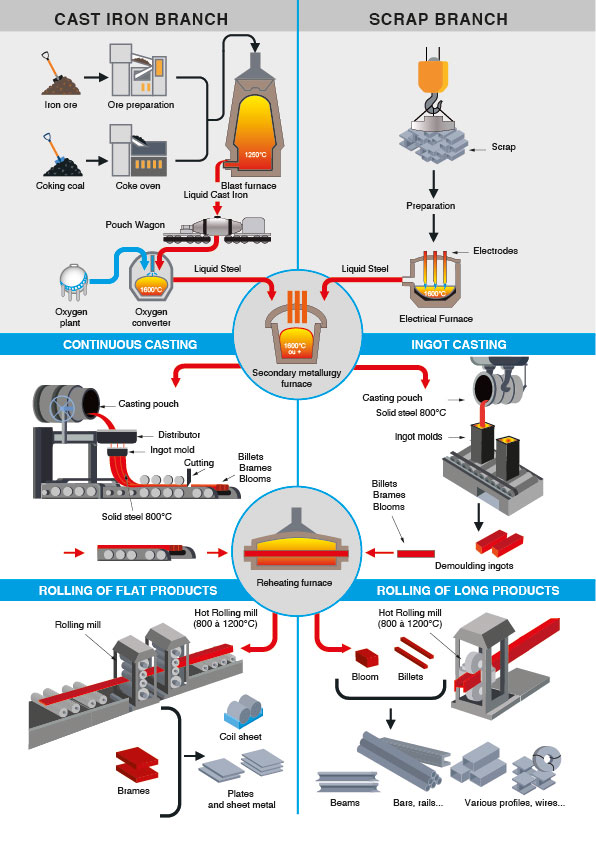

From CAD to Part: The Process

Honyo Prototype implements a rigorous stainless steel quality management system integrated throughout our end-to-end manufacturing workflow. This system ensures material integrity, dimensional accuracy, and compliance with industry standards for every stainless steel component we produce. The process begins with CAD file submission and extends through to final delivery, with specific quality checkpoints tailored to stainless steel properties such as corrosion resistance, weld integrity, and surface finish requirements.

Upon CAD file upload, our platform initiates material-specific validation. The system cross-references the requested stainless steel grade (e.g., 304, 316, 17-4PH) against design geometry, tolerance specifications, and functional requirements. Critical factors like minimum wall thickness for pressure applications or weld joint accessibility are automatically flagged for review. This initial screening prevents downstream issues related to material selection or geometric feasibility in stainless steel fabrication.

The AI-powered quoting engine then generates not only cost and lead time estimates but also a preliminary quality risk assessment. Our algorithms analyze over 15 years of stainless steel production data, identifying potential failure points such as stress concentrations in thin sections, inadequate draft angles for casting, or surface finish conflicts with specified Ra values. The quote includes explicit quality considerations like required NDT methods or post-weld heat treatment needs based on the alloy and application.

During the DFM (Design for Manufacturability) phase, our engineering team conducts stainless steel-specific reviews. Key checks include:

Material grade verification against environmental exposure requirements

Weld preparation design validation per ASME BPVC Section IX

Machining tolerance feasibility given stainless steel’s work-hardening characteristics

Surface finish compatibility with cleaning/passivation processes

Corrosion risk assessment for dissimilar metal contact points

This phase produces a formal DFM report with actionable recommendations, often reducing quality-related rework by 40-60% through early intervention.

Production executes under our ISO 9001-certified quality management system with stainless steel-specific controls:

Raw material certification verification (mill test reports traceable to heat number)

In-process dimensional checks using calibrated CMMs with temperature compensation

Weld procedure specification (WPS) adherence monitoring with real-time weld parameter logging

Controlled atmosphere during welding to prevent chromium carbide precipitation

Automated surface inspection for scratches, pits, or heat tint using machine vision

All critical parameters are digitally recorded in our traceability system, creating an immutable quality ledger for each component.

Final delivery includes comprehensive documentation meeting industry-specific requirements:

Material test reports with full chemical composition and mechanical properties

Dimensional inspection reports showing actual vs. nominal measurements

Weld maps with NDT results (RT/UT/PT) where applicable

Passivation validation documentation per ASTM A967

Certificate of Conformance with explicit reference to purchase order specifications

This digital quality package remains accessible through our client portal for the component’s entire lifecycle, supporting audits and maintenance activities.

Our integrated approach ensures stainless steel components meet stringent performance demands while minimizing supply chain risks. The system’s predictive capabilities, built on extensive stainless steel production data, consistently achieve first-pass yield rates exceeding 98.5% for qualified designs. This methodology transforms quality from a final inspection checkpoint into a continuous engineering discipline embedded at every process stage.

Start Your Project

Download the stainless steel quality chart to make informed decisions on material selection for your next precision manufacturing project. For technical specifications and custom material recommendations, contact Susan Leo at [email protected]. Our ISO-certified factory in Shenzhen ensures consistent quality, tight tolerances, and fast turnaround for prototypes and production runs. Let Honyo Prototype be your trusted partner in high-performance metal fabrication.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.