Contents

Manufacturing Insight: Stainless Steel Pulley Wheel

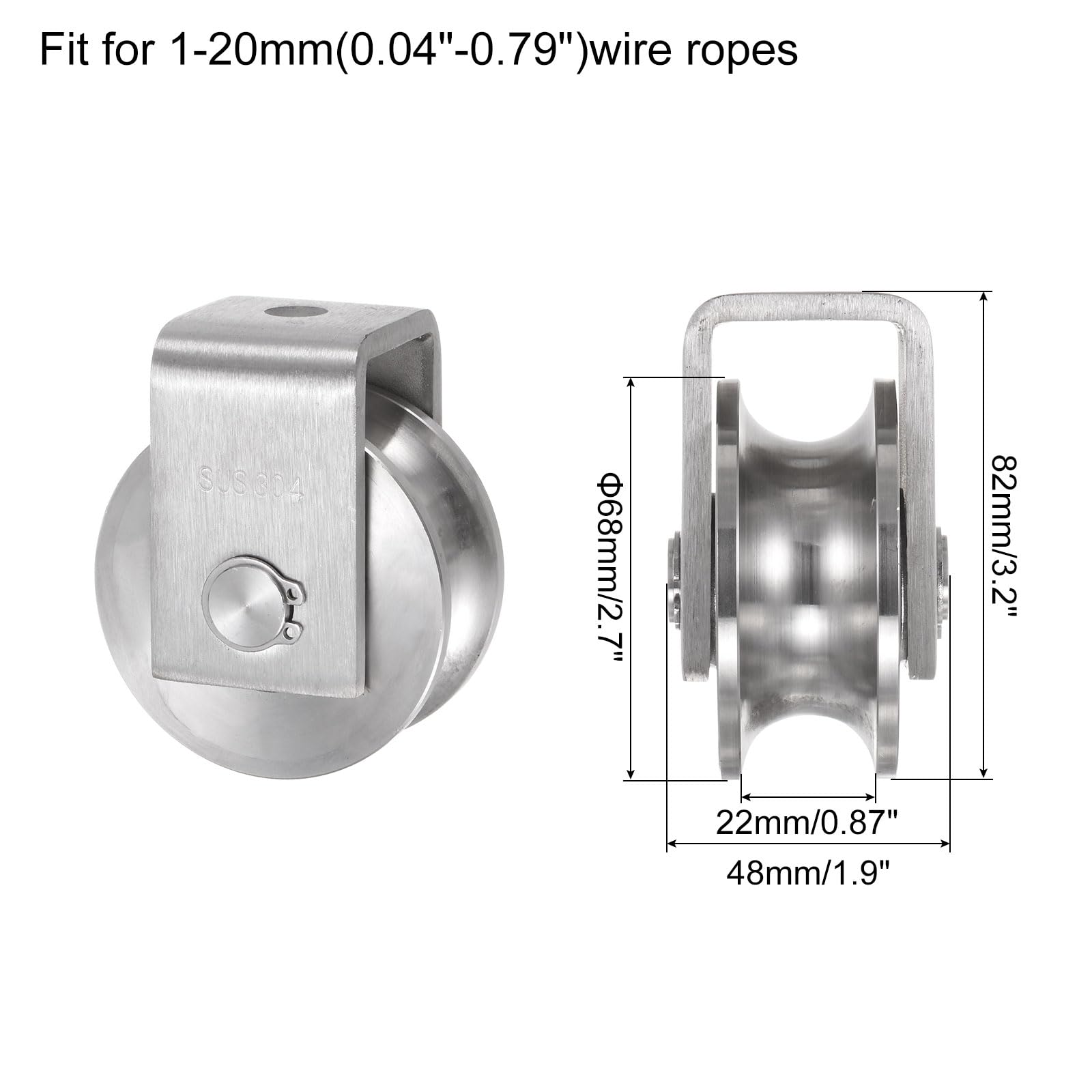

Precision Stainless Steel Pulley Wheels Engineered for Demanding Applications

Honyo Prototype delivers mission-critical stainless steel pulley wheels through advanced CNC machining, engineered to withstand corrosive environments, high loads, and continuous operation. Our ISO 9001-certified processes transform 304 and 316 stainless steel billets into components meeting exacting tolerances down to ±0.005 mm and surface finishes as fine as Ra 0.8 μm. This precision ensures optimal belt tracking, reduced wear, and extended service life in industrial conveyors, material handling systems, and aerospace mechanisms where failure is not an option.

Leveraging 5-axis milling and turning centers with in-process metrology, we eliminate secondary operations and tooling costs typically associated with complex pulley geometries. Every component undergoes rigorous first-article inspection against ASME Y14.5 GD&T standards, with full traceability from raw material certification to final packaging. Our engineers collaborate directly with clients to refine designs for manufacturability—optimizing weight, balancing critical rotational masses, and integrating custom features like anodized keyways or laser-etched identifiers without compromising structural integrity.

Accelerate your prototyping or low-volume production with Honyo’s Online Instant Quote platform. Upload your STEP or IGES file to receive a detailed manufacturing assessment and competitive pricing within 15 seconds—no sales calls required. This digital workflow, backed by 15+ years of precision machining expertise, ensures your stainless steel pulley wheels move from concept to certified hardware faster than industry standards.

Material & Process Specifications

| Parameter | Capability |

|———————|——————————–|

| Material Grades | ASTM A276 304, 304L, 316, 316L |

| Tolerance Range | ±0.005 mm to ±0.05 mm |

| Surface Finish | Ra 0.4 μm to 3.2 μm |

| Max Work Envelope | Ø 300 mm x 200 mm height |

| Lead Time | As fast as 5 business days |

Technical Capabilities

Stainless steel pulley wheels are precision-engineered components commonly used in motion control systems, automation, and power transmission applications. When manufactured using 3/4/5-axis CNC milling and turning processes, these pulleys achieve tight tolerances and high repeatability essential for performance-critical environments. While the primary material is stainless steel, similar pulley designs may be prototyped or produced using aluminum, steel (carbon or alloy), ABS, and nylon depending on mechanical, environmental, and cost requirements.

Below is a comparative technical specification table outlining key attributes relevant to CNC manufacturing processes and material selection:

| Feature | Stainless Steel Pulley Wheel | Aluminum Variant | Carbon/Alloy Steel Variant | ABS Plastic Variant | Nylon (Polyamide) Variant |

|---|---|---|---|---|---|

| Typical Material Grade | 303, 304, or 17-4 PH Stainless Steel | 6061-T6 or 7075-T6 | 1045, 4140 | ABS (FDM or CNC-grade) | PA6 or PA66 |

| Manufacturing Process | 3/4/5-axis CNC milling, CNC turning | 3/4/5-axis CNC milling, turning | CNC turning, milling | CNC milling, FDM printing | CNC milling, injection molding |

| Typical Tolerance | ±0.005 mm to ±0.025 mm (tight tolerance) | ±0.01 mm to ±0.05 mm | ±0.01 mm to ±0.025 mm | ±0.05 mm to ±0.1 mm | ±0.05 mm to ±0.1 mm |

| Surface Finish (Ra) | 0.8 – 1.6 µm (machined), polish optional | 1.6 – 3.2 µm | 1.6 – 3.2 µm | 6.3 – 12.5 µm (as-machined) | 3.2 – 6.3 µm |

| Hardness (Typical) | 85–95 HRB (17-4 PH up to 40 HRC) | 30–35 HRC | 50–60 HRC (after heat treat) | < 100 MPa (tensile) | 70–80 MPa (tensile) |

| Machinability | Moderate (free-machining 303 better) | Excellent | Good (requires tool wear care) | Good | Moderate (gummy at high speed) |

| Corrosion Resistance | High | Moderate (anodizing improves) | Low (requires coating) | High (chemical resistant) | High (moisture sensitive) |

| Weight (Density) | ~7.9 g/cm³ | ~2.7 g/cm³ | ~7.8 g/cm³ | ~1.04 g/cm³ | ~1.13 g/cm³ |

| Typical Applications | Industrial automation, food, medical | Prototypes, lightweight systems | High-load, industrial drives | Prototypes, low-load guides | Wear pads, low-noise systems |

| Post-Processing Options | Passivation, electropolish, deburring | Anodizing, bead blasting | Plating, black oxide | Vapor polishing, painting | Dry running, moisture conditioning |

Note: Tight tolerance stainless steel pulley wheels benefit significantly from multi-axis CNC capabilities, allowing complex groove geometries, precise bore alignment, and secondary features like mounting holes or timing teeth to be machined in a single setup—reducing cumulative error and improving runout performance. Material selection should consider load, speed, environmental exposure, and lifecycle requirements.

From CAD to Part: The Process

Honyo Prototype Stainless Steel Pulley Wheel Manufacturing Process

Honyo Prototype executes a streamlined, technology-driven workflow for stainless steel pulley wheel production, ensuring precision, cost efficiency, and rapid turnaround. The process begins with CAD submission and concludes with certified delivery, integrating AI and engineering validation at critical stages. Below is a detailed technical breakdown:

Upload CAD

Customers submit 3D models in native or neutral formats (STEP, IGES, Parasolid) via Honyo’s secure client portal. The system validates geometric integrity, units, and file completeness. For stainless steel pulleys, material specification (e.g., ASTM A276 304/L or 316/L) must be explicitly defined in the CAD metadata or accompanying RFQ documentation. Non-conforming submissions trigger automated feedback within 2 business hours.

AI-Powered Quoting

Honyo’s proprietary AI engine processes the CAD geometry, material selection, and quantity to generate an instant quote. The algorithm factors in real-time stainless steel market pricing, machine hour costs for CNC milling/turning, secondary operations (e.g., heat treatment, passivation), and geometric complexity metrics like feature density and tolerance severity. Quotes include granular cost breakdowns for material, machining, finishing, and QA, with accuracy validated against historical production data. Typical quote generation time: ≤15 minutes.

Engineering DFM Analysis

All stainless steel pulley designs undergo mandatory Design for Manufacturability review by Honyo’s senior manufacturing engineering team. This phase identifies and resolves stainless-specific challenges:

| DFM Check Parameter | Stainless Steel-Specific Focus Areas |

|---|---|

| Material Utilization | Minimizing 304/316 billet waste; optimizing bar stock diameter for OD |

| Machinability Constraints | Avoiding thin-web features prone to chatter; mitigating galling in threaded bores |

| Tolerance Feasibility | Verifying GD&T callouts align with ±0.005mm achievable on CNC lathes |

| Post-Processing Needs | Specifying passivation per ASTM A967 for corrosion resistance |

Engineers collaborate with clients to refine designs—e.g., modifying sharp internal corners to reduce stress concentration or adjusting surface finishes to eliminate unnecessary polishing costs. DFM report delivery: 1–2 business days.

Production Execution

Approved designs move to Honyo’s climate-controlled facility. Stainless steel pulleys are manufactured under strict protocols:

Machining: High-pressure coolant CNC turning/milling centers (e.g., DMG MORI CTX beta 1250) with carbide tooling optimized for 304/316. All operations maintain ≤0.002mm runout on critical diameters.

Secondary Operations: Stress-relieving at 900°C (for 304) or 1010°C (for 316), followed by citric acid passivation. Optional electropolishing for ultra-smooth surfaces (Ra ≤0.4μm).

In-Process QA: Real-time CMM checks at 20% production intervals; batch traceability via laser-etched serial numbers.

Typical lead time: 7–12 days for quantities ≤500 units, excluding material procurement.

Certified Delivery

Final inspection includes:

Full geometric validation against original CAD using Zeiss CONTURA CMM

Material certificate verification (mill test reports)

Passivation efficacy testing per ASTM A380

Salt spray testing (optional, per ASTM B117)

Components are packaged in VCI film with desiccant, shipped with comprehensive documentation (inspection reports, CoC, CoA), and tracked via Honyo’s logistics portal. Standard delivery includes 24-hour shipment notification with real-time GPS tracking for global clients.

This integrated process ensures stainless steel pulley wheels meet aerospace, medical, and industrial OEM specifications while reducing time-to-prototype by 40% versus traditional manufacturers. All stages adhere to ISO 9001:2015 and IATF 16949 standards.

Start Your Project

Looking for high-quality stainless steel pulley wheels manufactured to precise specifications? Contact Susan Leo at [email protected] to discuss your project requirements.

Honyo Prototype operates a dedicated manufacturing facility in Shenzhen, leveraging advanced production capabilities and strict quality control to deliver durable, corrosion-resistant pulley wheels for demanding industrial applications.

Whether you need custom dimensions, low-volume prototypes, or high-volume production, our engineering team supports tailored solutions with fast turnaround times.

Reach out today to request a quote or technical consultation.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.