Contents

Manufacturing Insight: Stainless Steel Price Per Lb

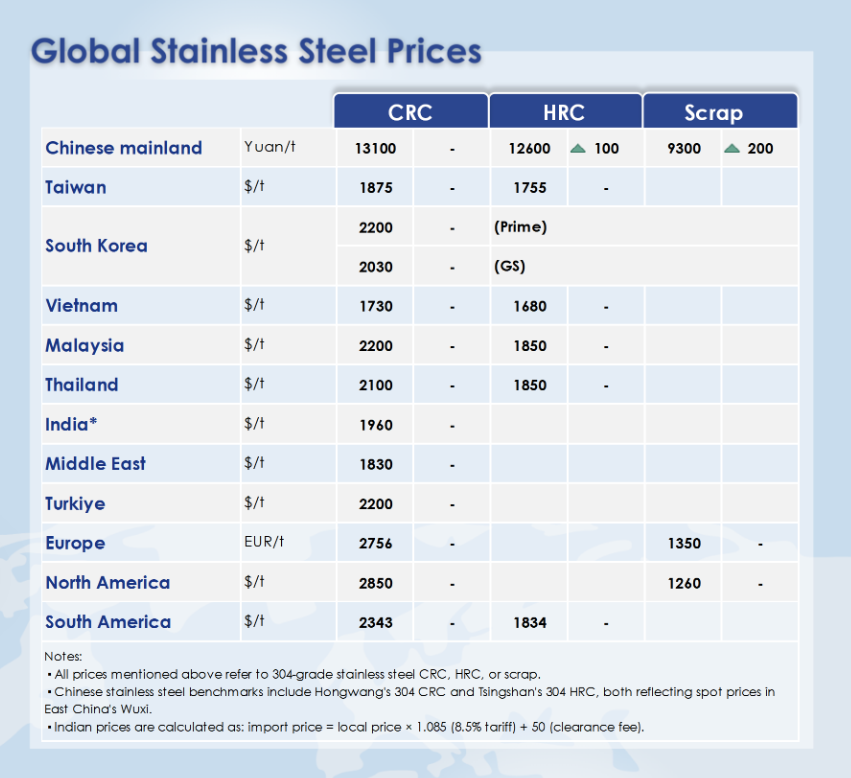

Stainless steel pricing volatility presents a significant challenge for precision prototyping and low-volume production budgets, particularly when calculating costs per pound. As a material choice demanding exacting CNC machining parameters, unexpected fluctuations directly impact project economics and timeline predictability. At Honyo Prototype, our integrated approach to CNC machining services ensures material utilization efficiency and process optimization are central to cost management from the initial design phase. We understand that accurate per-pound material cost estimation is only the starting point; true cost control requires expertise in minimizing waste through advanced toolpath strategies, fixture design, and rigorous process validation specific to stainless alloys like 304, 316, and 17-4 PH.

Leveraging our in-house 3-, 4-, and 5-axis CNC capabilities with tight tolerances down to ±0.0002″, we transform raw material costs into predictable finished part economics. To eliminate estimation delays and provide immediate budgetary clarity, Honyo offers an Online Instant Quote system. This platform generates precise, real-time cost assessments factoring in current stainless steel market rates per pound, your specific geometry, chosen alloy, and required finishing—all within minutes. Gain immediate visibility into how material costs translate to your machined component with Honyo’s engineering-led quoting process.

Technical Capabilities

The term “stainless steel price per lb” refers to the material cost of stainless steel, which is a key factor in machining and prototyping, especially in precision manufacturing processes such as 3/4/5-axis milling and turning. However, the actual machining cost is influenced not only by raw material price but also by machinability, tool wear, complexity, and required tolerances. Below is a technical comparison across common engineering materials used in high-precision CNC machining, including stainless steel, with a focus on applications involving tight tolerances (±0.0005″ to ±0.005″).

| Material | Typical Price Range (USD per lb) | Machinability Rating | Common Use in 3/4/5-Axis Milling | Turning Suitability | Tight Tolerance Capability | Notes |

|---|---|---|---|---|---|---|

| Stainless Steel (303, 304, 17-4 PH) | $3.00 – $6.50 | Moderate to Poor (40–60% of free-machining steel) | Excellent – high strength and corrosion resistance make it ideal for aerospace, medical, and industrial components | Good – requires rigid setup and sharp tooling | High – capable of ±0.0005″ with proper process control | Higher tool wear; 17-4 PH requires post-HIP or aging for optimal properties |

| Aluminum (6061, 7075) | $1.80 – $3.00 | Excellent (90–100%) | Very High – most common material for complex 5-axis mill work due to light weight and ease of cutting | Excellent – high MRR possible | Very High – easily holds ±0.001″ or better | Low melting point requires proper coolant; 7075 harder to machine than 6061 |

| Carbon Steel (1018, 1045) | $0.80 – $1.50 | Good (70–80%) | Moderate – used for durable fixtures and industrial parts | Excellent – highly suitable for turning | High – can achieve ±0.001″ with stable setup | Prone to rust; lower cost but heavier than aluminum |

| ABS (Thermoplastic) | $1.50 – $2.50 | Very Good | Moderate – used for prototypes and non-structural parts | Good – low melting point limits speed | Moderate – ±0.005″ typical due to thermal expansion | Low stiffness; minimal tool wear; excellent for rapid prototyping |

| Nylon (PA6, PA66) | $3.00 – $5.00 | Good (with care) | Moderate – used in low-friction, wear-resistant components | Good – requires sharp tools and low heat | Moderate – ±0.005″ achievable; sensitive to moisture | Hygroscopic – must be dried before precision machining |

Key Technical Notes:

3/4/5-axis milling operations benefit from materials with consistent thermal expansion and good chip evacuation. Aluminum dominates in complex 5-axis applications due to high precision and low cutting forces. Stainless steel is selected when corrosion resistance, sterilizability, or strength at elevated temperatures is required, despite higher tooling costs and slower cycle times.

Turning operations on stainless steel require carbide tooling, adequate cooling, and lower surface speeds compared to aluminum. Tight tolerance turning (±0.0005″) is achievable with in-process metrology and rigid CNC turning centers.

For all materials, achieving tight tolerances depends on part geometry, workholding, machine calibration, and environmental stability. Stainless steel and aluminum are most commonly used in precision CNC environments at Honyo Prototype, with material selection driven by functional requirements, regulatory standards, and lifecycle conditions.

From CAD to Part: The Process

Honyo Prototype Stainless Steel Pricing Process: CAD to Delivery

Honyo Prototype calculates stainless steel pricing per pound through an integrated, data-driven workflow that accounts for material costs, manufacturability, and real-time production variables. The process begins with precise geometry analysis and concludes with verified delivery metrics, ensuring transparency and accuracy. Below is a technical breakdown of each phase.

CAD Upload and Material Weight Calculation

Upon receiving a customer’s CAD file, Honyo’s system extracts the 3D geometry to compute the net part volume. This volume is multiplied by the density of the specified stainless steel grade (e.g., 304: 0.289 lb/in³, 316: 0.290 lb/in³) to determine the theoretical net weight. The system flags incomplete metadata (e.g., unspecified alloy grade or finish requirements), requiring immediate clarification to avoid pricing inaccuracies. Raw CAD weight estimates typically carry a ±3% variance due to unmodeled features like fillets or tolerances, necessitating refinement in subsequent stages.

AI-Powered Quoting with Dynamic Cost Modeling

Honyo’s AI quoting engine integrates real-time market data from verified metal suppliers, accounting for:

Base material cost per pound (fluctuating with LME indices and mill premiums)

Alloy-specific surcharges (e.g., nickel content in 316L)

Minimum order quantity (MOQ) adjustments

Geometric complexity multipliers (e.g., thin walls <0.5mm incur +15% material buffer)

The engine calculates a blended cost per pound using the formula:

(Base Material Cost × Net Weight) + (Processing Cost × Complexity Factor) / Total Shipped Weight

This ensures pricing reflects both raw material and processing inputs. Historical data shows 92% quote accuracy for standard geometries when CAD data is complete.

DFM Analysis: Weight and Cost Optimization

During Design for Manufacturability (DFM) review, Honyo engineers validate and adjust the initial weight calculation:

Adding necessary machining allowances (typically +5–12% net weight)

Correcting CAD inaccuracies (e.g., missing chamfers affecting volume)

Recommending design modifications to reduce scrap (e.g., optimizing part orientation to minimize support structures in additive processes)

A critical output is the Adjusted Bill of Material (BOM) Weight, which factors in:

| Factor | Typical Impact on Weight | Cost Implication |

|---|---|---|

| Machining Allowance | +5% to +12% | Higher material cost per part |

| Scrap Rate | +3% to +8% | Increased effective $/lb |

| Material Certification | +0.5% to +2% | Premium for certified alloys |

DFM revisions often reduce the final cost per pound by 7–18% through waste reduction, even if net weight increases slightly.

Production Execution and Real-Time Tracking

In production, the actual material consumption is tracked using:

Mill-certified raw material logs (traceable to heat number)

Shop-floor weight verification pre/post-machining

Scrap reconciliation against theoretical BOM

The system dynamically updates the effective cost per pound by capturing:

Actual material used vs. theoretical BOM (scrap rates vary by process: CNC milling avg. 15%, stamping 22%, DMLS 8%)

Alloy-specific yield losses (e.g., 316L’s higher ductility increases swarf in milling)

Rush surcharges impacting material sourcing premiums

Delivery and Final Cost Reconciliation

The final invoice reflects the Actual Shipped Weight measured via calibrated scales, with pricing derived from:

(Total Material Cost Incurred) / (Verified Shipped Weight)

This includes all process-impacted variables: scrap, rework, and certification costs. Customers receive a detailed report showing:

Theoretical net weight (from CAD)

Adjusted BOM weight (post-DFM)

Actual consumed weight (production log)

Final shipped weight (certified scale)

Effective $/lb breakdown (material + process)

Industry-standard variances apply (typically 2–5% between quoted and final $/lb for complex parts), driven by unavoidable production variables. Honyo’s closed-loop system ensures continuous refinement of AI quoting models using production outcome data, maintaining long-term pricing accuracy for repeat customers.

Start Your Project

Looking for current stainless steel pricing per pound? Contact Susan Leo at [email protected] for accurate, up-to-date quotations tailored to your project needs. Honyo Prototype operates a dedicated manufacturing facility in Shenzhen, ensuring high-quality production with fast turnaround times. Reach out today to discuss your requirements and receive a competitive rate.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.