Contents

Manufacturing Insight: Stainless Steel Price Per Kilo

Understanding Stainless Steel Price Per Kilo in Precision CNC Machining

Material costs significantly impact prototyping and low-volume production budgets, particularly with stainless steel where per-kilo pricing fluctuates due to alloy composition, market volatility, and supplier surcharges. While raw material expenses are a visible factor, the true cost driver in precision components often lies in machining complexity—not just the base metal rate. At Honyo Prototype, we optimize this equation through advanced CNC machining capabilities that minimize waste and maximize efficiency, transforming volatile stainless steel pricing into predictable project outcomes.

Our 5-axis milling and turning centers handle grades like 304, 316, and 17-4 PH with tight tolerances down to ±0.005mm, reducing secondary operations and scrap rates. This engineering-focused approach ensures your investment covers precision—not just kilograms—by leveraging strategic toolpath planning and in-process quality control. For immediate clarity on how material costs integrate with machining value, utilize our Online Instant Quote system. Input your CAD file and specifications to receive a transparent, all-inclusive cost breakdown within hours, reflecting real-time material variables alongside process efficiencies unique to Honyo’s manufacturing ecosystem.

Request your quote today to experience cost control beyond the per-kilo metric.

Technical Capabilities

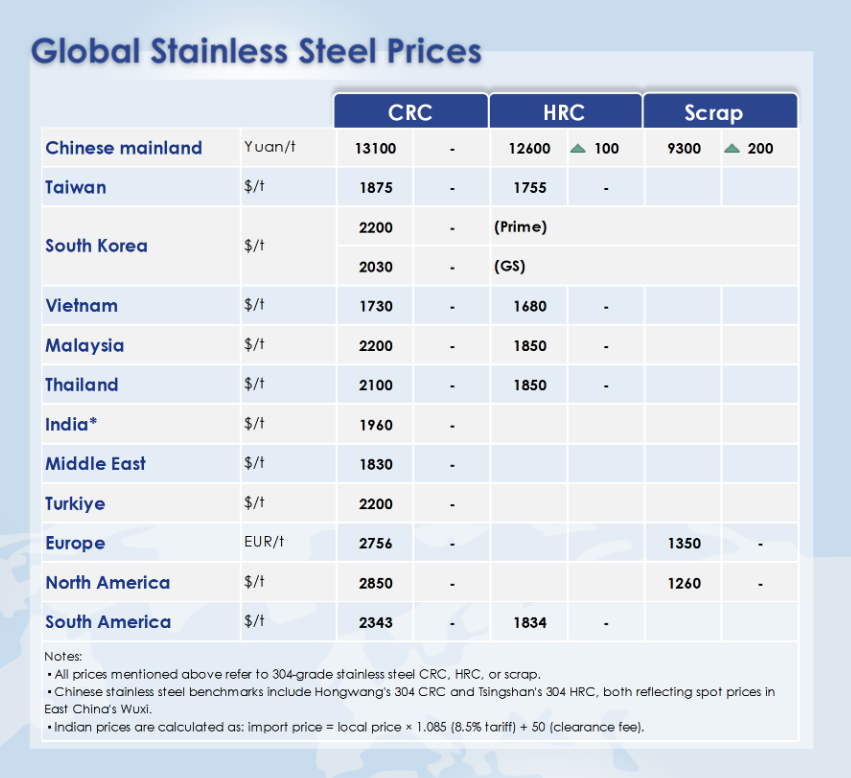

Stainless steel pricing per kilogram is influenced by several factors including alloy composition, grade (e.g., 304, 316, 17-4 PH), market volatility, and fabrication complexity. When used in high-precision CNC machining processes such as 3-, 4-, and 5-axis milling and turning, additional cost drivers include tight tolerances (±0.005 mm to ±0.025 mm), surface finish requirements, and setup complexity. While stainless steel typically ranges from $3.00 to $6.50 per kilogram in raw material form (depending on grade and region), the effective cost in precision machining applications must account for machining time, tool wear, and yield losses.

Below is a comparative technical and cost overview of stainless steel and other commonly machined materials in the context of precision CNC manufacturing:

| Material | Typical Price Range (USD/kg) | Machinability Rating | Common Grades Used | Typical Tolerance (CNC) | Suitability for 3/4/5-Axis Milling | Suitability for Turning | Notes |

|---|---|---|---|---|---|---|---|

| Stainless Steel | $3.00 – $6.50 | Low to Moderate (40–60% of B1112 steel) | 304, 316, 17-4 PH, 440C | ±0.01 mm – ±0.025 mm | Excellent – high rigidity and precision achievable | Excellent – good chip formation with proper tooling | Higher tool wear; slower feed rates; passivation often required |

| Aluminum | $2.50 – $4.00 | High (Excellent machinability) | 6061, 7075, 2024 | ±0.005 mm – ±0.025 mm | Excellent – lightweight, high MRR | Excellent – low cutting forces | Preferred for rapid prototyping and complex 5-axis parts |

| Carbon Steel | $1.00 – $2.50 | Moderate | 1018, 1045, 4140 | ±0.01 mm – ±0.05 mm | Good – but prone to warping if not stress-relieved | Excellent | Requires post-machining coating for corrosion resistance |

| ABS (Plastic) | $1.80 – $3.00 | Very High | ABS M30, ABS Plus | ±0.05 mm – ±0.1 mm | Good – limited by rigidity and heat deflection | Good – low melting point | Used for non-structural prototypes; low thermal conductivity |

| Nylon (PA6, PA66) | $3.50 – $6.00 | Moderate to Low | Nylon 6, Nylon 6/6, Glass-filled | ±0.05 mm – ±0.2 mm | Fair – prone to deformation due to moisture absorption | Fair – requires sharp tools and stable fixturing | Hygroscopic – must be dried before machining; excellent wear resistance |

Notes on Precision Machining Context:

In 3-, 4-, and 5-axis milling operations, material stability and predictability are critical. Stainless steel offers superior dimensional stability and strength under load, making it ideal for aerospace, medical, and high-performance industrial components requiring tight tolerances. However, its low thermal conductivity and high work-hardening rate increase machining time and tooling costs.

While raw stainless steel may be moderately priced, the total cost per machined part often exceeds that of aluminum due to longer cycle times and higher tooling consumption. For prototypes or low-volume production, aluminum is frequently selected for cost-efficiency and speed, whereas stainless steel is chosen when corrosion resistance, strength, or regulatory compliance (e.g., FDA, ISO) are mandatory.

At Honyo Prototype, material selection is optimized based on functional requirements, environmental exposure, and production volume, with stainless steel reserved for applications where performance justifies the higher effective machining cost.

From CAD to Part: The Process

Honyo Prototype employs a structured, technology-driven workflow to determine and communicate stainless steel pricing, ensuring transparency and accuracy for prototype manufacturing. The process centers on material cost as a primary driver but integrates comprehensive manufacturing intelligence. Crucially, the quoted price per kilogram reflects projected material consumption after accounting for design efficiency and production realities, not merely raw material spot pricing.

The process begins when a client uploads a native or neutral format CAD file to our secure portal. Our proprietary AI quotation engine immediately performs geometric analysis to calculate the precise net weight of the stainless steel component. This calculation uses the specific alloy density (e.g., 304: 8.0 g/cm³, 316: 8.03 g/cm³) applied to the solid model volume. Simultaneously, the AI accesses real-time global stainless steel market data feeds, adjusted for our bulk purchasing agreements and current logistics costs, establishing the base material cost per kilogram. This initial AI-generated quote provides a rapid estimate of the material-inclusive price per kilogram, typically within minutes.

Following the initial quote, the design undergoes rigorous Design for Manufacturability (DFM) analysis by our engineering team. This step critically refines the material cost projection. Engineers assess manufacturability, identifying opportunities to minimize waste through optimized nesting, toolpath strategies, and fixture design. They evaluate if design modifications could reduce raw material usage (e.g., simplifying geometries, reducing wall thickness within functional limits) or allow substitution to a more cost-effective alloy grade without compromising requirements. The DFM phase may adjust the initial quoted weight and price per kilogram based on achievable yield rates and process-specific material consumption, ensuring the final price reflects actual production conditions.

Upon client approval of the DFM recommendations and quote, production commences. Material is cut from certified stainless steel stock (304, 316, etc.), with precise weighing occurring at multiple stages: incoming stock verification, pre-machining blank preparation, and final part inspection. Actual consumed material weight is meticulously tracked. The final invoice reconciles the initial quoted price per kilogram with the verified net part weight and any agreed-upon DFM adjustments. Minor variances within standard industry tolerances (typically ±3%) are absorbed per our terms; significant deviations trigger client consultation.

Key stainless steel alloy cost factors influencing the final price per kilogram include:

| Alloy Grade | Primary Cost Drivers | Typical Relative Cost Factor |

|---|---|---|

| 304 / 304L | Base grade, high chromium/nickel content, market volatility | 1.0x (Baseline) |

| 316 / 316L | Added molybdenum for corrosion resistance, higher raw material cost | 1.15x – 1.25x |

| 17-4 PH | Precipitation hardening, complex heat treatment requirements | 1.3x – 1.5x |

| Duplex (e.g., 2205) | Higher alloy content (Cr, Ni, Mo, N), specialized processing | 1.4x – 1.8x |

The final delivered price per kilogram represents a synthesized value incorporating real-time material commodities pricing, geometrically precise net weight, DFM-optimized yield, and Honyo’s manufacturing expertise. This integrated approach ensures clients receive a realistic, defensible cost projection that aligns with actual production outcomes, minimizing billing discrepancies and fostering trust in our prototyping partnership.

Start Your Project

For accurate and up-to-date stainless steel pricing per kilo, contact Susan Leo at [email protected]. As a trusted manufacturing partner based in Shenzhen, Honyo Prototype delivers high-quality stainless steel components with competitive material sourcing and in-house production capabilities. Reach out today to request a quote or discuss your project requirements.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.