Contents

Manufacturing Insight: Stainless Steel Milling

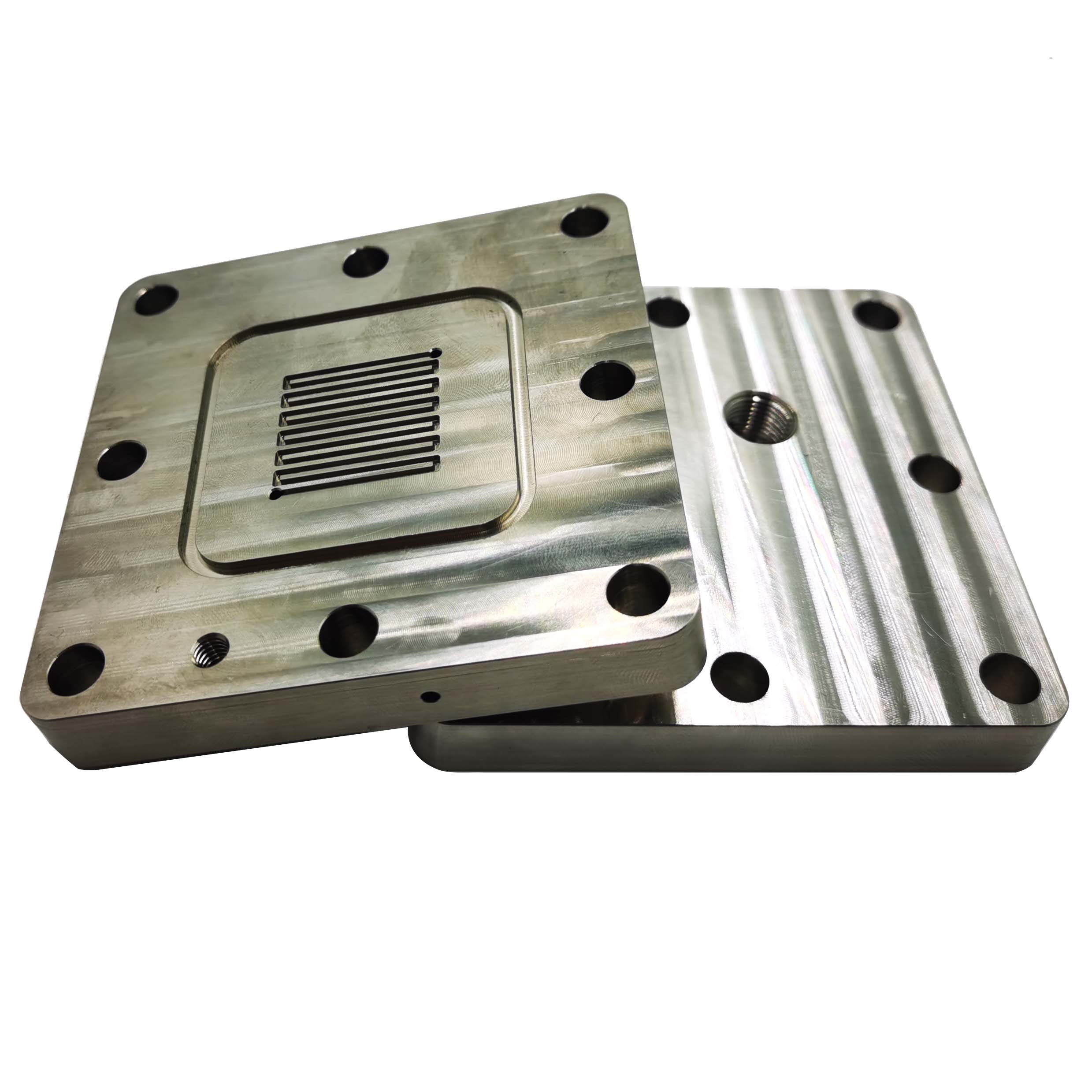

Precision Stainless Steel Milling for Demanding Applications

Stainless steel presents unique machining challenges due to its work hardening characteristics, abrasive nature, and thermal conductivity constraints. Achieving tight tolerances and superior surface finishes requires specialized tooling, optimized coolant strategies, and deep metallurgical expertise to prevent deformation or tool degradation. At Honyo Prototype, our CNC milling processes are engineered specifically for corrosion-resistant alloys, including 304, 316, 17-4 PH, and duplex grades, ensuring dimensional accuracy within ±0.0002 inches and surface finishes down to Ra 0.8 µm.

Advanced Capabilities for Mission-Critical Components

Our multi-axis CNC milling centers integrate high-rigidity spindles, adaptive toolpath algorithms, and in-process probing to maintain consistency across complex geometries—from medical implants to aerospace brackets. We mitigate thermal distortion through controlled cutting parameters and proprietary fixturing, while rigorous material traceability and first-article inspection (FAI) per AS9102 standards guarantee compliance for regulated industries. This precision eliminates secondary operations, reducing lead times without compromising integrity in high-stress environments.

Accelerate Your Project Timeline with Real-Time Quoting

Engineers and procurement teams can now access Honyo’s technical expertise instantly. Upload your STEP or IGES files to our Online Instant Quote platform for validated manufacturability feedback and competitive pricing within minutes—not days. This seamless integration of engineering insight and digital efficiency ensures your stainless steel prototypes or low-volume production parts move from design to delivery faster, with zero compromise on quality.

| Material Grade | Typical Tolerance (±in) | Max. Part Size (in) | Lead Time (Prototype) |

|---|---|---|---|

| 304/304L | 0.0002 | 24 × 18 × 12 | 5–7 business days |

| 316/316L | 0.0002 | 24 × 18 × 12 | 5–7 business days |

| 17-4 PH | 0.0003 | 20 × 16 × 10 | 6–8 business days |

| Duplex 2205 | 0.0003 | 20 × 16 × 10 | 6–8 business days |

Partner with Honyo Prototype to transform stainless steel design challenges into high-performance realities, backed by data-driven manufacturing and immediate quoting transparency.

Technical Capabilities

Stainless Steel Milling – Technical Specifications

Stainless steel milling involves precision material removal processes conducted on advanced CNC machining platforms, including 3-axis, 4-axis, and 5-axis milling systems, as well as CNC turning centers. These operations are optimized for tight-tolerance components used in aerospace, medical, and industrial applications. While stainless steel is the primary focus, the same equipment and methodologies are often applied to other materials such as aluminum, carbon steel, ABS, and nylon, with adjustments to cutting parameters.

The following table outlines the technical specifications and capabilities relevant to multi-axis milling and turning of stainless steel and associated materials, emphasizing tight-tolerance performance.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning | Typical Tight Tolerance (±) |

|---|---|---|---|---|---|

| Max Work Envelope (mm) | 600 x 400 x 300 | 600 x 400 x 300 + rotary (360° indexing) | 500 x 400 x 350 + dual rotary (A/B or A/C) | Ø300 x 500 length | – |

| Spindle Speed (RPM) | 8,000 – 24,000 | 8,000 – 20,000 | 10,000 – 30,000 | 3,000 – 12,000 | – |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm | – |

| Repeatability | ±0.003 mm | ±0.003 mm | ±0.002 mm | ±0.003 mm | – |

| Tool Changer Capacity | 16 – 30 tools | 20 – 30 tools | 24 – 40 tools | 8 – 12 tools (live tooling) | – |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 1.6 µm | 0.4 – 1.6 µm | 0.8 – 1.6 µm | – |

| Stainless Steel (e.g., 304, 316) | Yes – Carbide tools, coolant-through, SFM: 100–150 | Yes – Indexing for undercuts | Yes – Continuous contouring, minimal setups | Yes – High-pressure coolant, rigid tooling | ±0.010 mm (standard), ±0.005 mm (high precision) |

| Aluminum (6061, 7075) | Yes – High-speed cutting, SFM: 800–1200 | Yes – Fast indexing, light cuts | Yes – High feed rates, minimal tool wear | Yes – High RPM, sharp tools | ±0.005 mm achievable |

| Carbon Steel (1018, 4140) | Yes – Moderate speeds, rigid setup | Yes – Controlled depth cuts | Yes – Multi-face access | Yes – Hard turning options | ±0.010 mm |

| ABS (Thermoplastic) | Yes – Low cutting forces, no coolant | Yes – Vacuum fixturing | Yes – 5-axis contouring for complex shapes | Limited – Soft material, chip control | ±0.05 mm (due to thermal expansion) |

| Nylon (PA6, PA66) | Yes – Sharp tools, controlled feed | Yes – Avoid melting with low heat | Yes – Precision profiling | Yes – Peeling strategy, low RPM | ±0.05 mm |

Notes on Tight Tolerances:

Achieving tolerances down to ±0.005 mm requires thermal stability, precision metrology (e.g., CMM verification), and process validation. Stainless steel presents challenges due to work hardening and low thermal conductivity, necessitating optimized toolpaths, high-performance coatings (e.g., TiAlN), and consistent coolant application. 5-axis milling reduces setup variation, enabling tighter overall tolerances on complex geometries. Non-metals like ABS and nylon require adjusted parameters to manage deflection and thermal expansion.

All processes are supported by CAD/CAM programming (e.g., Siemens NX, Mastercam) and in-process probing for first-article inspection and batch consistency.

From CAD to Part: The Process

Honyo Prototype Stainless Steel Milling Process Overview

Honyo Prototype executes stainless steel milling through a rigorously defined workflow designed for speed, precision, and manufacturability assurance. The process begins with CAD file submission and concludes with certified delivery, integrating automated systems with engineering expertise at critical stages.

CAD Upload and Validation

Clients initiate the process by uploading native or neutral CAD formats (STEP, IGES, Parasolid) via our secure portal. Our system performs immediate geometric validation, checking for non-manifold edges, unit inconsistencies, and minimum feature size compliance relative to stainless steel machining capabilities. Unsupported formats trigger an automated request for conversion, minimizing intake delays. All files undergo encryption and version control per ISO 27001 standards.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system, which analyzes part topology, material grade requirements, and geometric complexity. The algorithm calculates machine time based on toolpath simulation, accounts for stainless steel-specific factors (e.g., reduced feed rates for 17-4PH vs. 304, coolant requirements for 316L), and factors in fixture complexity. Quotes include granular cost breakdowns for material, machining, finishing, and inspection within 2 business hours, with tolerance-driven pricing adjustments.

Engineering-Led DFM Analysis

Every quote triggers mandatory Design for Manufacturability review by Honyo’s senior manufacturing engineers. This phase focuses on stainless steel challenges:

Identifying thin walls prone to chatter or deflection requiring adaptive toolpaths

Flagging internal radii below 0.5mm that necessitate specialized tooling

Verifying hole depth-to-diameter ratios exceeding 4:1 to prevent chip evacuation issues

Recommending stress-relief annealing steps for complex geometries in martensitic grades

Engineers collaborate with clients via annotated markups to resolve conflicts, optimizing for cost without compromising functional requirements. No part proceeds to production without DFM sign-off.

Precision Milling Production

Approved designs move to our climate-controlled CNC facility. Stainless steel milling employs:

3-axis and 5-axis vertical machining centers with 24,000 RPM spindles and HSK-63 tooling

Titanium-aluminum-nitride (TiAlN) coated carbide end mills optimized for stainless alloys

Through-spindle coolant (70 bar) to manage heat and prevent work hardening

In-process probing for feature verification per ASME Y14.5

Critical parameters are dynamically adjusted based on real-time force monitoring to maintain surface integrity. All stainless steel grades adhere to strict handling protocols to avoid cross-contamination.

Common stainless steel grades processed and their machining characteristics:

| Grade | Key Properties | Machining Notes | Typical Applications |

|---|---|---|---|

| 304/304L | Austenitic, 18-8 chromium-nickel | Moderate work hardening; requires sharp tools and consistent feeds | Food equipment, chemical tanks |

| 316/316L | Molybdenum-enhanced corrosion resistance | Higher tendency for built-up edge; low-RPM finishing recommended | Marine hardware, medical implants |

| 17-4 PH | Precipitation-hardening | Pre-heat treat to H900 condition for optimal machinability | Aerospace fittings, valves |

| 440C | High-carbon martensitic | Extreme tool wear; requires rigid setup and minimal depth of cut | Bearings, cutting tools |

Quality-Controlled Delivery

Post-machining, parts undergo CMM validation against critical dimensions (reporting to ±0.005mm), surface roughness testing (Ra ≤ 0.8µm standard), and visual inspection for burrs or micro-fractures. Stainless steel components receive passivation per ASTM A967 and are packaged in VCI paper within static-dissipative containers. Delivery includes full traceability: material certs (mill test reports), first-article inspection data, and process parameter logs. Standard lead time is 8–12 business days from DFM approval, with expedited options available.

This integrated workflow ensures stainless steel components meet stringent industry requirements while minimizing time-to-part through validated digital continuity from design to shipment.

Start Your Project

Looking for precision stainless steel milling services? Honyo Prototype offers high-accuracy CNC milling of stainless steel components with fast turnaround times. Our manufacturing facility in Shenzhen is equipped with advanced machinery and staffed by experienced engineers to ensure tight tolerances and superior surface finishes.

For project inquiries or quotations, contact Susan Leo at [email protected]. We support prototyping and low-to-mid volume production runs with strict quality control and on-time delivery. Partner with us for reliable, cost-effective stainless steel machining solutions from China.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.