Contents

Manufacturing Insight: Stainless Steel Laser Cutting Service

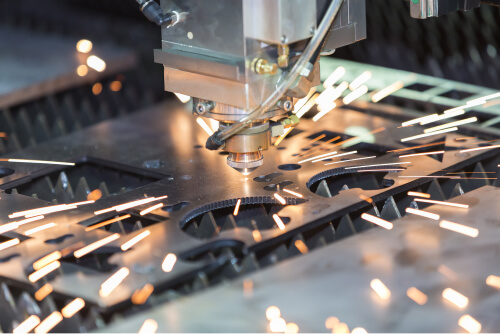

Precision Stainless Steel Laser Cutting Services from Honyo Prototype

Honyo Prototype delivers high-precision stainless steel laser cutting services engineered for demanding industrial applications. Our advanced fiber laser systems process grades including 304, 316, and duplex stainless steels with exceptional accuracy, achieving tolerances of ±0.1 mm and clean edges requiring minimal secondary finishing. This capability ensures structural integrity and corrosion resistance critical for aerospace, medical, and fluid handling components where material performance is non-negotiable.

Complementing our laser cutting expertise, Honyo integrates these services within a comprehensive CNC machining ecosystem. Complex projects benefit from seamless transitions between laser cutting, multi-axis milling, turning, and finishing—all managed under one roof with unified quality control. This holistic approach eliminates supply chain fragmentation, reduces lead times by up to 30%, and maintains strict adherence to ISO 9001 standards across all fabrication stages.

Accelerate your prototyping or low-volume production with our Online Instant Quote platform. Upload CAD files in minutes to receive detailed pricing, manufacturability feedback, and lead time estimates—no manual RFQ delays. This digital workflow empowers engineering teams to iterate faster while leveraging Honyo’s technical rigor in stainless steel fabrication and precision machining.

Technical Capabilities

Honyo Prototype offers advanced stainless steel laser cutting services integrated with precision 3, 4, and 5-axis CNC milling and turning operations to support complex geometries and tight tolerance requirements. Our capabilities are optimized for a variety of engineering-grade materials including stainless steel, aluminum, carbon steel, ABS, and nylon. These processes are ideal for rapid prototyping, low-volume production, and high-precision component manufacturing.

The following table outlines the technical specifications for our laser cutting and complementary CNC machining services:

| Parameter | Specification Detail |

|---|---|

| Laser Cutting Thickness Range (Stainless Steel) | 0.5 mm – 25 mm |

| Laser Cutting Accuracy | ±0.1 mm |

| Laser Kerf Width | 0.1 mm – 0.3 mm (dependent on thickness and power) |

| Supported Materials | Stainless Steel (304, 316, 430), Aluminum (6061, 7075), Carbon Steel, ABS, Nylon (PA6, PA66) |

| CNC Milling Capabilities | 3-axis, 4-axis, and 5-axis simultaneous machining |

| Turning Capabilities | CNC turning with live tooling, diameter range: 2 mm – 300 mm |

| Tight Tolerance Machining | ±0.005 mm (for critical features, with proper design and material selection) |

| Surface Finish (As-Machined) | Ra 1.6 µm standard; down to Ra 0.4 µm with polishing or grinding |

| Maximum Work Envelope (5-Axis Milling) | 1200 mm × 800 mm × 600 mm |

| Maximum Turning Length | 1000 mm |

| Tooling & Fixturing | Custom modular fixturing for high repeatability and minimal setup error |

| Quality Control | In-process and final inspection using CMM, optical comparators, and surface roughness testers |

| Lead Time | As fast as 3–5 days for prototypes, depending on complexity and material availability |

Our integrated approach allows seamless transition from laser-cut blanks to fully machined components with tight tolerances and superior surface integrity. Material selection is evaluated for machinability, structural requirements, and environmental resistance to ensure optimal performance in end-use applications.

From CAD to Part: The Process

Honyo Prototype executes stainless steel laser cutting services through a rigorously defined digital workflow designed for precision, speed, and manufacturability assurance. This integrated process eliminates traditional bottlenecks while maintaining stringent quality control for industrial clients requiring rapid prototyping or low-volume production.

CAD File Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, DXF, DWG) via our secure customer portal. Our system automatically validates geometric integrity, layer structure, and unit consistency. Non-native formats undergo automated conversion with dimensional cross-checking to prevent import errors. File acceptance triggers immediate notification, with rejected uploads specifying exact correction requirements within 15 minutes. This phase ensures downstream processes operate on technically sound geometry.

AI-Powered Instant Quoting

Upon file validation, proprietary AI algorithms analyze part geometry, material specifications, and nesting efficiency against live machine capacity data. The system generates a comprehensive quote within 90 seconds, detailing cost breakdown by material consumption, machine runtime, and secondary operations. Critical parameters include edge quality class (VDI 3406), kerf allowance, and heat-affected zone projections. Quotes remain valid for 72 hours and include real-time production slot availability. Human engineering oversight validates all AI outputs for complex geometries or non-standard materials.

Engineering-Led DFM Analysis

Every quoted job undergoes mandatory Design for Manufacturability review by our certified manufacturing engineers. This phase identifies potential fabrication risks including minimum feature spacing violations, unsupported geometries causing thermal distortion, and suboptimal nesting patterns affecting yield. Clients receive a DFM report with actionable recommendations—such as adjusting internal radii or consolidating features—prior to production commitment. This step typically reduces post-cut rework by 65% and is conducted collaboratively via integrated mark-up tools within 4 business hours.

Precision Laser Cutting Production

Approved jobs enter our production queue with strict adherence to material certifications and process parameters. We utilize 15kW fiber laser systems with integrated fume extraction and real-time power monitoring for consistent cut quality across all stainless grades. Material handling follows AS9100-compliant protocols with full traceability from raw sheet to finished part.

Material processing capabilities are summarized below:

| Material Grade | Thickness Range | Max Sheet Size | Typical Tolerance |

|---|---|---|---|

| 304/304L SS | 0.5mm – 25mm | 1500x3000mm | ±0.1mm |

| 316/316L SS | 0.5mm – 20mm | 1500x3000mm | ±0.1mm |

| 430 SS | 0.8mm – 16mm | 1250x2500mm | ±0.15mm |

| 17-4PH SS | 1.0mm – 12mm | 1000x2000mm | ±0.1mm (solution treated) |

All cuts undergo in-process verification via machine-mounted cameras checking critical dimensions at 500mm intervals. Secondary operations like deburring or edge rounding are performed per client specifications using automated finishing cells.

Quality-Controlled Delivery

Completed parts undergo final inspection against ASME Y14.5 GD&T standards with first-article reports provided for production runs. Dimensional verification uses calibrated CMMs with 3D scanning for complex contours. Parts ship in ESD-safe packaging with serialized traceability tags, accompanied by material certs and inspection documentation. Standard delivery is 5–7 business days from DFM approval, with expedited 72-hour options available. Real-time shipment tracking integrates with client ERP systems via API, while our logistics partners maintain ISO 28199-compliant handling for stainless components to prevent surface contamination.

This closed-loop process delivers certified stainless steel components with 99.2% on-time delivery performance, reducing time-to-prototype by 40% compared to conventional fabrication vendors through seamless digital integration between engineering and production systems.

Start Your Project

Looking for precision stainless steel laser cutting services? Honyo Prototype delivers high-accuracy, high-quality results with fast turnaround times. Our state-of-the-art laser cutting equipment ensures clean, burr-free edges and tight tolerances for a wide range of industrial applications.

All manufacturing is performed at our Shenzhen factory, where strict quality control and advanced processing capabilities meet international standards.

For quotes and project inquiries, contact Susan Leo at [email protected]. Let us support your prototyping and production needs with reliable, cost-effective solutions.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.