Introduction: Navigating the Global Market for stainless steel grease fittings

In today’s competitive industrial landscape, sourcing high-quality stainless steel grease fittings can pose a significant challenge for B2B buyers, particularly those operating in harsh environments. These components are essential for maintaining machinery and equipment, ensuring optimal performance and longevity. However, the global market is flooded with various options, making it crucial for international buyers from regions such as Africa, South America, the Middle East, and Europe—particularly Brazil and Saudi Arabia—to make informed purchasing decisions.

This comprehensive guide serves as a valuable resource for navigating the complexities of stainless steel grease fittings. We delve into the different types available, including straight, angled, and specialty fittings, as well as their specific applications across industries. Additionally, we provide insights into supplier vetting, enabling buyers to identify reputable manufacturers and distributors that meet stringent quality standards. Cost considerations, including pricing trends and bulk purchasing strategies, are also discussed to aid in budget planning.

By equipping B2B buyers with essential knowledge and actionable insights, this guide empowers them to make strategic choices that enhance operational efficiency and reduce maintenance costs. Whether you’re looking to improve equipment reliability or expand your supplier network, understanding the intricacies of stainless steel grease fittings is vital for sustaining business growth in a global marketplace.

Understanding stainless steel grease fittings Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Straight Zerk Fitting | Direct connection, typically 1/8″ or 1/4″ threads | Machinery lubrication, automotive | Pros: Easy installation; Cons: Limited to straight access. |

| 45-Degree Angle Zerk Fitting | Angled design for tighter spaces | Construction equipment, industrial tools | Pros: Flexible installation; Cons: May require more grease. |

| 90-Degree Angle Zerk Fitting | Right-angle design for restricted access | Heavy machinery, agricultural equipment | Pros: Ideal for tight spots; Cons: Can be harder to align. |

| Metric Grease Zerk Fitting | Available in metric sizes like M8 and M10 | European machinery, automotive | Pros: Compatibility with metric systems; Cons: Limited availability. |

| 1/4″ Drive Zerk Fitting | Designed for use with grease guns | General machinery, automotive | Pros: Efficient lubrication; Cons: Requires compatible tools. |

What are the Characteristics of Straight Zerk Fittings?

Straight Zerk fittings are characterized by their direct line connection, typically featuring either 1/8″ or 1/4″ threaded ends. They are commonly used in applications where access is straightforward and can accommodate a standard grease gun. For B2B buyers, the ease of installation makes them an attractive option for routine maintenance in machinery and automotive sectors. However, their utility may be limited in spaces that require angled fittings.

How Do 45-Degree Angle Zerk Fittings Enhance Functionality?

The 45-degree angle Zerk fittings are designed to provide flexibility in installation, making them suitable for machinery and tools that operate in confined spaces. Their angled design allows for easier access when aligning grease guns. B2B buyers in construction and industrial sectors will find these fittings advantageous, although they may require more grease to fill the joint adequately compared to straight fittings.

Why Choose 90-Degree Angle Zerk Fittings?

90-degree angle Zerk fittings offer a right-angle connection, which is particularly useful in areas with limited access. This design is ideal for heavy machinery and agricultural equipment where operational efficiency is critical. B2B buyers should consider that while these fittings are effective in tight spaces, they may pose alignment challenges during installation, necessitating careful handling.

What are the Advantages of Metric Grease Zerk Fittings?

Metric grease Zerk fittings, such as those with M8 or M10 thread sizes, cater specifically to European machinery and automotive applications. Their compatibility with metric systems makes them essential for businesses operating in or importing from regions that predominantly use metric measurements. However, buyers should be aware that these fittings may have limited availability compared to standard sizes, which can affect procurement.

How Do 1/4″ Drive Zerk Fittings Optimize Lubrication?

1/4″ drive Zerk fittings are specially designed for use with grease guns, facilitating efficient lubrication processes across various machinery types. Their design allows for a secure fit that minimizes grease wastage, making them ideal for general machinery and automotive applications. For B2B buyers, the requirement for compatible tools can be a downside, but the efficiency gained often outweighs this consideration.

Key Industrial Applications of stainless steel grease fittings

| Industry/Sector | Specific Application of stainless steel grease fittings | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine & Offshore | Lubrication of ship machinery and equipment | Enhanced durability against corrosion in saltwater environments | Compliance with marine standards; corrosion resistance; availability of various fitting types |

| Agriculture | Maintenance of agricultural machinery | Improved equipment longevity and reduced downtime | Compatibility with existing equipment; availability of metric and imperial sizes |

| Construction & Heavy Equipment | Lubrication of cranes and earth-moving equipment | Increased operational efficiency and reliability | High-pressure ratings; ability to withstand harsh environmental conditions; ease of installation |

| Food Processing | Lubrication in food-grade machinery | Ensures hygiene and compliance with safety regulations | FDA compliance; non-reactive materials; easy cleaning and maintenance |

| Automotive | Maintenance of assembly line robots and machinery | Reduces wear and tear, improving production efficiency | Precision engineering; compatibility with various grease types; global sourcing options |

In the marine and offshore sector, stainless steel grease fittings are crucial for lubricating machinery and equipment on ships. These fittings are designed to withstand harsh saltwater environments, providing reliable performance and longevity. Buyers in this sector must prioritize corrosion resistance and compliance with marine standards, ensuring that the fittings can endure the rigors of maritime operations.

In agriculture, these fittings are employed in the maintenance of tractors and other agricultural machinery. By facilitating efficient lubrication, they help extend the lifespan of equipment and minimize downtime during critical harvest periods. Buyers should consider compatibility with existing machinery and the availability of both metric and imperial sizes to ensure seamless integration.

Within the construction and heavy equipment industry, stainless steel grease fittings are vital for the lubrication of cranes and earth-moving equipment. Their ability to operate under high pressure and extreme conditions enhances equipment reliability and efficiency. Sourcing considerations include high-pressure ratings and durability to withstand the challenging environments typical of construction sites.

In food processing, stainless steel grease fittings are essential for maintaining hygiene in food-grade machinery. They help ensure compliance with safety regulations while allowing for easy cleaning and maintenance. Buyers must ensure that the fittings meet FDA compliance and are made from non-reactive materials to prevent contamination.

Finally, in the automotive sector, these fittings are used to maintain assembly line robots and machinery, which are critical for production efficiency. The use of stainless steel fittings reduces wear and tear, thereby enhancing the overall performance of the production line. Buyers should focus on precision engineering and compatibility with various grease types, ensuring that sourcing options are globally available to support international operations.

3 Common User Pain Points for ‘stainless steel grease fittings’ & Their Solutions

Scenario 1: Difficulties with Corrosion in Harsh Environments

The Problem:

Many B2B buyers dealing with machinery or equipment in harsh environments—such as marine, mining, or chemical processing industries—often face issues with grease fittings corroding quickly. Traditional grease fittings made from carbon steel may fail under such conditions, leading to costly repairs and equipment downtime. This corrosion not only jeopardizes the integrity of the grease fittings but can also lead to contamination of the lubricants, ultimately affecting equipment performance.

The Solution:

Opt for stainless steel grease fittings, particularly those made from Type 303 stainless steel, which offer superior corrosion resistance compared to carbon steel alternatives. When sourcing these fittings, ensure they are specifically designed for high-corrosion applications. Verify that the supplier provides detailed specifications on the material composition and performance ratings for various environmental conditions. Additionally, consider using fittings with protective coatings or finishes designed to enhance their durability in extreme environments. Regular maintenance checks and lubrication schedules will further prolong the lifespan of these fittings, ensuring that your machinery remains operational and efficient.

Scenario 2: Compatibility Issues with Existing Equipment

The Problem:

B2B buyers often encounter compatibility issues when trying to integrate new stainless steel grease fittings with existing machinery. Different thread sizes and types, such as NPT or metric, can complicate installation. This mismatch can lead to leaks, inefficient lubrication, and ultimately, equipment failure, resulting in significant operational disruptions.

The Solution:

Before purchasing stainless steel grease fittings, conduct a thorough inventory of your existing machinery to identify the required specifications, including thread size, type, and fitting angles (straight, 45°, or 90°). Work with suppliers who offer a comprehensive range of fittings and can provide guidance on compatibility. Consider sourcing a variety pack that includes multiple sizes and angles to ensure you have the right fittings on hand for different applications. Utilizing thread adapters can also bridge compatibility gaps without the need for extensive machinery modifications, ensuring smooth integration and reducing potential downtime.

Scenario 3: Inefficient Lubrication Processes Leading to Downtime

The Problem:

In many industrial settings, inefficient lubrication processes can lead to excessive downtime. Traditional grease fittings often require multiple attempts to connect the grease gun properly, resulting in wasted time and spilled lubricant. This inefficiency not only affects productivity but can also lead to increased operational costs due to the need for additional lubricant and potential damage to machinery.

The Solution:

Invest in high-quality stainless steel grease fittings designed to minimize leakage and enhance the ease of connection with grease guns. Look for fittings that feature a positive locking mechanism to prevent disconnection under pressure, such as those offered by LockNLube. This design allows operators to quickly and securely attach the grease gun, ensuring that lubrication is applied efficiently without spills. Additionally, implementing a structured lubrication schedule with designated personnel responsible for lubrication tasks can streamline the process. Training staff on best practices for using stainless steel grease fittings will further optimize efficiency, leading to reduced downtime and increased equipment reliability.

Strategic Material Selection Guide for stainless steel grease fittings

What Are the Key Materials Used in Stainless Steel Grease Fittings?

When selecting stainless steel grease fittings for industrial applications, understanding the materials used is crucial. The choice of material affects performance, durability, and cost, especially for international B2B buyers. Here, we analyze four common materials used in stainless steel grease fittings: Type 303 stainless steel, Type 440 stainless steel, Type 316 stainless steel, and carbon steel with stainless steel plating.

How Does Type 303 Stainless Steel Perform in Grease Fittings?

Type 303 stainless steel is widely utilized in grease fittings due to its excellent machinability and moderate corrosion resistance. It can withstand temperatures up to 1,600°F (870°C) and pressures typically found in lubrication systems.

Pros: The primary advantage of Type 303 is its ease of machining, making it cost-effective for mass production. It is suitable for general-purpose applications where exposure to corrosive environments is limited.

Cons: However, its corrosion resistance is inferior compared to other stainless steel grades, making it less suitable for harsh environments, such as marine applications.

Impact on Application: Type 303 is compatible with various lubricants but may not perform well in applications involving aggressive chemicals.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local standards, as Type 303 may not meet stringent corrosion resistance requirements in coastal areas.

What Are the Benefits of Using Type 440 Stainless Steel?

Type 440 stainless steel is known for its high strength and hardness, making it ideal for applications requiring durability. It can handle temperatures up to 1,500°F (815°C) and offers improved corrosion resistance compared to Type 303.

Pros: The high hardness provides excellent wear resistance, making it suitable for heavy-duty applications.

Cons: The downside is its brittleness, which can lead to cracking under high-stress conditions.

Impact on Application: Type 440 is compatible with various media but may not be ideal for high-pressure applications due to its brittleness.

Considerations for International Buyers: Buyers should consider the availability of Type 440 fittings and their compliance with standards such as ASTM and DIN, especially in Europe.

Why Choose Type 316 Stainless Steel for Grease Fittings?

Type 316 stainless steel is often regarded as the best option for grease fittings exposed to corrosive environments. It can withstand temperatures up to 1,600°F (870°C) and offers superior corrosion resistance, particularly against chlorides.

Pros: Its durability and resistance to pitting make it suitable for marine and chemical processing applications.

Cons: The primary drawback is its higher cost compared to other stainless steel types, which may be a concern for budget-sensitive projects.

Impact on Application: Type 316 is compatible with a wide range of lubricants and is ideal for applications in harsh environments.

Considerations for International Buyers: Buyers should verify that Type 316 fittings meet local compliance standards, especially in industries with stringent regulations.

What Role Does Carbon Steel with Stainless Steel Plating Play?

Carbon steel grease fittings with stainless steel plating are a cost-effective alternative for applications where corrosion resistance is not the primary concern. They can handle moderate temperatures and pressures.

Pros: The plating provides a protective layer that enhances corrosion resistance while keeping manufacturing costs low.

Cons: The main limitation is that the underlying carbon steel can corrode if the plating is compromised.

Impact on Application: These fittings are suitable for less demanding applications but may fail in highly corrosive environments.

Considerations for International Buyers: Buyers should ensure that the plating meets local standards and is suitable for the intended application, especially in humid or coastal regions.

Summary Table of Material Selection for Stainless Steel Grease Fittings

| Material | Typical Use Case for stainless steel grease fittings | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Type 303 Stainless Steel | General-purpose applications | Excellent machinability | Limited corrosion resistance | Medium |

| Type 440 Stainless Steel | Heavy-duty applications | High strength and wear resistance | Brittle under high stress | Medium |

| Type 316 Stainless Steel | Marine and chemical processing applications | Superior corrosion resistance | Higher cost | High |

| Carbon Steel with Stainless Steel Plating | Moderate-duty applications | Cost-effective | Corrosion risk if plating is compromised | Low |

This guide provides a comprehensive overview of the materials used in stainless steel grease fittings, aiding international B2B buyers in making informed decisions based on their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for stainless steel grease fittings

What Are the Key Stages in the Manufacturing Process of Stainless Steel Grease Fittings?

The manufacturing of stainless steel grease fittings involves several critical stages, each essential for ensuring the final product meets quality and performance standards. These stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Is Raw Material Selected and Processed?

The first step in manufacturing stainless steel grease fittings is selecting high-quality raw materials. Typically, Type 303 stainless steel is used for its excellent corrosion resistance and machinability. This material is then cut into appropriate sizes and shapes, followed by processes like annealing to relieve stress and improve ductility. This preparation phase is crucial, as the quality of the raw material directly impacts the performance and longevity of the fittings.

What Techniques Are Employed in the Forming Process?

Once the materials are prepared, they undergo various forming techniques. Common methods include precision machining, forging, and stamping, depending on the design requirements. Precision machining ensures that the fittings have exact dimensions and tolerances, which is vital for their proper function in lubrication systems. For example, a CNC lathe may be used to create the intricate threads required for proper sealing and attachment.

How Are Stainless Steel Grease Fittings Assembled?

After forming, the components are assembled. This may involve the integration of springs and balls, often made from different grades of stainless steel, to ensure durability and optimal performance. The assembly process must be executed with precision to avoid leaks and ensure that the fittings function correctly under pressure.

What Finishing Processes Are Used to Enhance Durability?

The final stage in manufacturing is finishing, which may include processes like polishing, passivation, and coating. Polishing enhances the aesthetic appeal and can improve resistance to corrosion by providing a smoother surface. Passivation, on the other hand, removes free iron from the surface and enhances the protective oxide layer, further increasing corrosion resistance. Additional coatings may also be applied for specific environments, such as marine applications.

How Is Quality Assurance Implemented in the Production of Stainless Steel Grease Fittings?

Quality assurance (QA) is integral to the manufacturing process, ensuring that every stainless steel grease fitting meets international standards and customer specifications. This process typically adheres to recognized international standards such as ISO 9001 and industry-specific certifications like CE and API.

What International Standards Should B2B Buyers Be Aware Of?

ISO 9001 sets a framework for quality management systems, focusing on customer satisfaction and continuous improvement. Compliance with this standard indicates that a manufacturer has a robust quality management system in place. Additionally, industry-specific certifications like CE mark compliance for products sold in Europe and API standards for oil and gas applications are crucial for B2B buyers to consider, particularly when sourcing internationally.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) involves several checkpoints throughout the manufacturing process, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Any substandard materials are rejected to prevent defects in the final product.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are performed to monitor critical dimensions and features. This proactive approach helps identify issues early, minimizing waste and rework.

-

Final Quality Control (FQC): Before shipping, each batch of stainless steel grease fittings undergoes thorough testing, including pressure tests and dimensional inspections. This final check ensures that the products meet all performance criteria.

What Common Testing Methods Are Used to Ensure Quality?

Several testing methods are employed to verify the integrity and functionality of stainless steel grease fittings. Common tests include:

- Pressure Testing: Ensures that fittings can withstand operational pressures without leaking.

- Salt Spray Testing: Assesses corrosion resistance by exposing fittings to a saline environment.

- Dimensional Inspection: Uses calipers and gauges to verify that components meet specified tolerances.

These testing methods are crucial for ensuring that the fittings perform reliably in their intended applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers adhere to stringent quality control practices, B2B buyers should consider conducting audits and requesting detailed quality assurance reports.

What Should Be Included in Supplier Audits?

When auditing potential suppliers, buyers should evaluate the following:

- Quality Management System Documentation: Review ISO certifications and quality manuals.

- Process Control Records: Examine records of manufacturing processes, including inspection and testing data.

- Non-Conformance Reports: Investigate how suppliers handle defects and the corrective actions they implement.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These inspections help ensure compliance with international standards and can be particularly valuable for buyers in regions like Africa, South America, the Middle East, and Europe, where local regulations may vary.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers should be aware of specific nuances when it comes to quality control. For instance, documentation requirements may differ across regions, and understanding local standards is crucial for compliance. Additionally, language barriers can complicate communication regarding quality expectations, so it is advisable to work with suppliers who provide clear and comprehensive documentation in multiple languages.

By understanding the manufacturing processes and quality assurance practices involved in stainless steel grease fittings, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stainless steel grease fittings’

In the quest for high-quality stainless steel grease fittings, B2B buyers must navigate a range of factors to ensure they make informed purchasing decisions. This step-by-step sourcing guide aims to equip you with the essential considerations and actions required to procure these critical components effectively.

Step 1: Define Your Technical Specifications

Understanding the precise requirements for your stainless steel grease fittings is vital. Consider the application, required thread size, and whether you need straight or angled fittings. Additionally, assess environmental factors such as temperature ranges and exposure to corrosive substances to determine the appropriate grade of stainless steel.

Step 2: Research Quality Standards and Compliance

Investigate the quality standards applicable to stainless steel grease fittings in your region. Look for certifications such as ISO 9001 or ASTM specifications that ensure product reliability and durability. Compliance with local regulations is also crucial, especially in regions with stringent manufacturing guidelines.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a strong reputation for quality and reliability, and verify their experience in manufacturing stainless steel components.

- Supplier Reviews: Check online reviews and testimonials.

- Industry Experience: Assess how long they have been in the market and their familiarity with your specific needs.

Step 4: Request Samples for Testing

Always request samples of the grease fittings before placing a bulk order. Testing samples for compatibility with your equipment and confirming the quality of materials used can prevent costly mistakes later. Assess aspects such as the fitting’s strength, corrosion resistance, and ease of installation.

Step 5: Negotiate Terms and Conditions

Once you identify a preferred supplier, negotiate favorable terms and conditions. Discuss pricing, payment options, delivery timelines, and warranty provisions. Be clear about your expectations regarding quality assurance and after-sales support to ensure a smooth procurement process.

Step 6: Confirm Shipping and Logistics

Understanding the logistics involved in shipping your order is essential, especially for international buyers. Confirm shipping methods, lead times, and costs. Ensure that the supplier can provide tracking information and is compliant with export regulations in their country.

Step 7: Establish a Relationship for Future Needs

Building a solid relationship with your supplier can lead to better pricing, priority service, and tailored solutions for your future needs. Regular communication can foster trust and facilitate smoother transactions down the line, especially if your requirements evolve.

By following this checklist, B2B buyers can make informed decisions when sourcing stainless steel grease fittings, ensuring that they select the right products for their applications while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for stainless steel grease fittings Sourcing

What Are the Key Cost Components for Sourcing Stainless Steel Grease Fittings?

When evaluating the cost structure of stainless steel grease fittings, several components come into play. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

Materials represent a significant portion of the cost, with stainless steel (commonly Type 303 or 440) being the most prevalent due to its superior corrosion resistance. This is particularly important in harsh environments, making the choice of material crucial.

Labor costs include the workforce required for both production and quality assurance. Manufacturing overhead encompasses utilities, equipment depreciation, and facility maintenance that support production processes. Tooling costs involve the initial investment in molds and dies necessary for producing various fitting designs.

Quality Control is essential in ensuring that the fittings meet industry standards, which may involve additional costs for testing and certification. Logistics costs include shipping, warehousing, and handling, which can vary significantly based on the geographic location of both suppliers and buyers. Finally, the margin added by suppliers reflects their operational costs and profit expectations.

How Do Price Influencers Affect the Cost of Stainless Steel Grease Fittings?

Several factors influence the pricing of stainless steel grease fittings. Volume and Minimum Order Quantity (MOQ) play a critical role; larger orders typically reduce per-unit costs due to economies of scale. Specifications and customization can also affect pricing, as tailored solutions may require additional engineering and production time.

The choice of materials directly impacts cost; higher-grade stainless steels or additional coatings will increase prices. Quality certifications (such as ISO) can also elevate costs but are crucial for ensuring reliability and compliance in regulated industries.

Supplier factors, such as reputation, reliability, and geographical location, can influence pricing. Suppliers located closer to the buyer may offer lower logistics costs, while established brands might charge a premium for their proven quality. Lastly, Incoterms can affect the total price by defining the responsibilities of buyers and sellers regarding shipping and handling costs.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing?

To achieve cost-efficiency when sourcing stainless steel grease fittings, buyers should consider a few strategic approaches. Negotiation is vital; understanding market rates and being prepared to discuss terms can lead to better pricing.

Consider the Total Cost of Ownership (TCO) instead of just the purchase price. TCO includes maintenance, operational efficiency, and potential downtime costs. Investing in higher-quality fittings may result in lower long-term expenses due to reduced failure rates and maintenance needs.

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, it is essential to understand pricing nuances. Currency fluctuations, import duties, and tariffs can significantly impact final costs. Thus, staying informed about these factors and considering local suppliers can lead to more favorable pricing.

Lastly, buyers should seek multiple quotes and compare them not only on price but also on quality and service. This comparative analysis can uncover hidden costs and help negotiate better terms, ensuring a comprehensive understanding of what drives the price of stainless steel grease fittings.

Disclaimer on Indicative Prices

It is important to note that the prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and changes in material costs. Buyers should conduct thorough market research and engage directly with suppliers for the most accurate and current pricing information.

Alternatives Analysis: Comparing stainless steel grease fittings With Other Solutions

Exploring Alternatives to Stainless Steel Grease Fittings

When it comes to lubrication systems, stainless steel grease fittings are a popular choice due to their durability and corrosion resistance. However, there are alternative solutions available that may better suit specific applications or budget constraints. This analysis aims to provide a comparative overview of stainless steel grease fittings against two viable alternatives: plastic grease fittings and traditional manual grease guns.

Comparison Table

| Comparison Aspect | Stainless Steel Grease Fittings | Plastic Grease Fittings | Traditional Manual Grease Guns |

|---|---|---|---|

| Performance | High durability and corrosion resistance; suitable for harsh environments | Moderate performance; not suitable for extreme conditions | Variable performance based on user technique; effective for manual applications |

| Cost | Higher initial investment; long-term savings due to durability | Lower upfront cost; may require more frequent replacements | Low initial cost; ongoing costs for grease tubes |

| Ease of Implementation | Simple installation; compatible with standard equipment | Easy to install; limited to specific applications | Requires manual operation; requires user skill for effective lubrication |

| Maintenance | Low maintenance; resistant to wear and tear | Moderate maintenance; can degrade over time | Requires regular maintenance and user attention |

| Best Use Case | Ideal for industrial machinery in corrosive environments | Suitable for light-duty applications and non-critical systems | Best for small-scale operations and occasional use |

In-Depth Look at Alternatives

Plastic Grease Fittings

Plastic grease fittings are lightweight and cost-effective, making them an attractive option for non-critical applications. They are easy to install and can be used in environments where corrosion is not a significant concern. However, their performance may be compromised in extreme conditions, leading to potential failures in lubrication over time. For businesses operating in less demanding environments, plastic fittings can provide adequate service at a lower cost, but they may require more frequent replacements, impacting long-term value.

Traditional Manual Grease Guns

Traditional manual grease guns offer a versatile lubrication solution that does not rely on fittings. These tools allow users to apply grease directly to machinery, making them ideal for small operations or maintenance tasks. However, the effectiveness of manual grease guns is highly dependent on the user’s skill level. Inconsistent application can lead to under-lubrication or over-lubrication, which may cause premature wear or damage to machinery. While manual grease guns have a lower initial cost, businesses need to consider ongoing expenses related to grease and potential equipment wear.

How to Choose the Right Solution for Your Needs

When selecting between stainless steel grease fittings and alternative solutions, B2B buyers should assess their specific operational requirements. Consider factors such as the environment where the fittings will be used, the frequency of maintenance, and the total cost of ownership over time. For operations in corrosive environments or where durability is paramount, stainless steel grease fittings may offer the best long-term value. Conversely, for applications with lower demands or budget constraints, plastic fittings or manual grease guns could provide adequate performance without the higher initial investment. Ultimately, the right choice will align with the unique needs of the business while balancing performance, cost, and maintenance considerations.

Essential Technical Properties and Trade Terminology for stainless steel grease fittings

What Are the Key Technical Properties of Stainless Steel Grease Fittings?

Understanding the essential technical properties of stainless steel grease fittings is crucial for B2B buyers. These specifications influence product performance, durability, and suitability for various applications.

1. Material Grade

Stainless steel grease fittings are typically made from Type 303 stainless steel, known for its excellent corrosion resistance and machinability. This grade is essential in industries such as marine, automotive, and heavy machinery, where exposure to moisture and aggressive chemicals is common. Selecting the right material ensures longevity and reduces maintenance costs.

2. Thread Size and Type

Thread specifications, such as 1/8″-27 NPT or 1/4″-28 SAE, dictate compatibility with various grease guns and fittings. A proper thread size ensures a secure connection, preventing leaks and ensuring efficient lubrication. Buyers must consider these measurements to avoid costly errors in assembly or maintenance.

3. Working Pressure

The working pressure rating indicates the maximum pressure the fitting can withstand without failure. Most stainless steel grease fittings are designed to handle pressures of up to 5,000 psi or more. Understanding this property helps buyers select fittings that will perform reliably in high-stress environments, enhancing equipment reliability and reducing downtime.

4. Temperature Range

Stainless steel grease fittings can operate within specific temperature ranges, often between -20°F to 300°F (-29°C to 149°C). This range is critical for applications exposed to extreme temperatures, ensuring the fitting remains functional and does not degrade under stress. Buyers should confirm that the fittings meet the thermal requirements of their specific application.

5. Finish and Coating

The finish, such as passivation or electropolishing, enhances corrosion resistance and reduces friction. A high-quality finish can significantly extend the lifespan of the fittings, making them more suitable for harsh environments. B2B buyers should prioritize fittings with superior finishes to minimize wear and maintenance.

What Common Trade Terms Should B2B Buyers Know About Stainless Steel Grease Fittings?

Familiarity with industry terminology can streamline purchasing processes and enhance communication with suppliers.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that can be marketed under another company’s brand. Understanding this term helps buyers identify suppliers that can provide fittings specifically designed to meet their unique operational needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for B2B buyers who need to understand inventory requirements and cost implications. Suppliers often set MOQs based on production costs, and knowing this can help buyers negotiate better terms or plan their orders more effectively.

3. RFQ (Request for Quotation)

An RFQ is a formal document requesting pricing and terms from suppliers for specific products. This process is essential for buyers looking to compare offers and negotiate contracts. A well-prepared RFQ can lead to cost savings and better supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. They specify who pays for shipping, insurance, and tariffs, which is vital for B2B buyers engaging in cross-border purchases. Understanding these terms ensures clarity in logistics and helps avoid unexpected costs.

5. Lead Time

Lead time is the period between placing an order and receiving the product. This term is crucial for supply chain planning, particularly in industries where timely maintenance is critical. Buyers should inquire about lead times to ensure they can meet operational deadlines.

In conclusion, grasping the technical properties and trade terminology related to stainless steel grease fittings is vital for B2B buyers. These insights help in making informed purchasing decisions that align with operational needs and enhance equipment reliability.

Navigating Market Dynamics and Sourcing Trends in the stainless steel grease fittings Sector

What Are the Current Market Dynamics and Key Trends for Stainless Steel Grease Fittings?

The global market for stainless steel grease fittings is driven by the increasing demand for durable and corrosion-resistant components across various industries, including automotive, manufacturing, and marine applications. As companies prioritize reliability and longevity in machinery maintenance, the adoption of stainless steel fittings is on the rise. Emerging technologies, such as 3D printing and advanced manufacturing processes, are also reshaping sourcing trends by enabling customization and reducing lead times. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers who can provide high-quality products with flexible customization options.

In addition to the conventional supply chain, buyers are leveraging digital platforms for sourcing, allowing for more efficient comparisons of products and prices. The trend towards e-commerce in B2B transactions is empowering buyers to make informed decisions based on real-time data and customer reviews. Furthermore, the emphasis on safety and compliance with international standards is driving companies to partner with manufacturers that adhere to rigorous quality control processes. As businesses expand into emerging markets, understanding regional preferences and local regulations becomes essential for effective sourcing.

How Is Sustainability and Ethical Sourcing Transforming the Stainless Steel Grease Fittings Sector?

Sustainability and ethical sourcing are increasingly becoming focal points for B2B buyers in the stainless steel grease fittings sector. The environmental impact of production processes, including energy consumption and waste generation, is a significant concern. Buyers are now prioritizing suppliers that utilize eco-friendly practices and materials, such as recycled stainless steel or low-impact manufacturing methods. This shift not only supports environmental goals but also aligns with the growing consumer demand for sustainable products.

Moreover, ethical supply chains are crucial for maintaining brand reputation and customer loyalty. Companies are expected to demonstrate transparency in their sourcing practices, ensuring that all components are procured responsibly. Certifications such as ISO 14001 (Environmental Management) and materials labeled as eco-friendly can serve as indicators of a supplier’s commitment to sustainability. For international buyers, especially those in developed markets, partnering with manufacturers that uphold these standards can provide a competitive edge, enhancing their corporate social responsibility (CSR) initiatives.

What Is the Brief History and Evolution of Stainless Steel Grease Fittings in B2B Applications?

The evolution of stainless steel grease fittings can be traced back to the need for enhanced durability and corrosion resistance in lubrication systems. Initially, traditional carbon steel fittings dominated the market; however, their limitations in harsh environments led to the development of stainless steel alternatives. The introduction of Type 303 and Type 440 stainless steel revolutionized the sector by offering improved performance in corrosive settings, such as marine and industrial applications.

Over the years, technological advancements have further refined the manufacturing processes, enabling the production of more complex shapes and sizes tailored to specific applications. The integration of precision engineering has also enhanced the reliability and functionality of grease fittings, making them essential components in machinery maintenance. Today, stainless steel grease fittings are recognized for their longevity and efficiency, solidifying their role in modern industrial practices and maintenance strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of stainless steel grease fittings

-

How do I choose the right stainless steel grease fitting for my application?

Selecting the appropriate stainless steel grease fitting involves considering several factors such as the type of machinery, the operating environment, and the specific lubrication requirements. Assess the thread size and type, such as 1/4″-28 or 1/8″-27, to ensure compatibility with existing systems. Additionally, consider the angle of the fitting (straight, 45°, or 90°) to ensure proper alignment for grease application. Lastly, evaluate the environmental conditions; for instance, if the fittings will be exposed to high corrosion, opting for high-grade stainless steel (like Type 303) is recommended. -

What are the advantages of stainless steel grease fittings compared to other materials?

Stainless steel grease fittings offer superior corrosion resistance compared to traditional carbon steel options, making them ideal for harsh environments, including marine and industrial applications. They are less prone to rust and degradation, which enhances the longevity of the fittings and reduces maintenance costs. Additionally, stainless steel fittings maintain their structural integrity under extreme temperatures and pressures, ensuring reliable performance. This durability translates to fewer replacements and lower overall costs for businesses, especially those operating in challenging conditions. -

What is the typical minimum order quantity (MOQ) for stainless steel grease fittings?

The minimum order quantity for stainless steel grease fittings varies by supplier but typically ranges from 100 to 1,000 units. Factors influencing MOQ include the supplier’s production capabilities, the specific product type, and whether the fittings are standard or customized. It’s advisable to discuss your requirements with potential suppliers to negotiate favorable terms. For larger orders, many suppliers offer tiered pricing, allowing for cost savings as order volumes increase, which can be beneficial for businesses looking to stock up. -

How can I verify the quality of stainless steel grease fittings from international suppliers?

To ensure the quality of stainless steel grease fittings, request certification documents such as ISO 9001 or material test reports that confirm compliance with international standards. Conducting a factory audit, if feasible, can provide insights into the supplier’s manufacturing processes and quality control measures. Additionally, sourcing samples before placing a bulk order allows you to assess the fittings’ durability and performance firsthand. Establishing a good line of communication with suppliers and reading reviews or testimonials from other buyers can also help gauge reliability. -

What payment terms are commonly offered by suppliers of stainless steel grease fittings?

Payment terms for stainless steel grease fittings can vary significantly based on the supplier’s policies and the buyer’s creditworthiness. Common arrangements include full payment upfront, a 30% deposit with the balance due before shipment, or net 30/60 terms after delivery. International buyers should also consider currency exchange rates and transaction fees when negotiating terms. It’s advisable to establish clear terms in a contract to protect both parties and ensure that payment methods are secure, such as using letters of credit or escrow services. -

How do I handle shipping and logistics for stainless steel grease fittings purchased internationally?

When sourcing stainless steel grease fittings internationally, it’s crucial to understand the logistics involved. Collaborate with a reliable freight forwarder experienced in handling industrial goods to ensure timely and safe delivery. Discuss shipping methods, such as air freight for speed or sea freight for cost-effectiveness, depending on your urgency. Additionally, factor in customs clearance processes and potential tariffs or duties that may apply. Establishing a clear timeline for delivery and tracking shipments can help manage expectations and prevent delays. -

Can I customize stainless steel grease fittings to meet specific requirements?

Yes, many suppliers offer customization options for stainless steel grease fittings, allowing you to tailor products to your specific needs. Customization may include alterations in thread size, fitting angles, or even special coatings for enhanced corrosion resistance. When requesting custom fittings, provide detailed specifications and drawings to ensure accuracy. Keep in mind that customization may lead to longer lead times and higher costs, so it’s essential to discuss these factors with the supplier to align expectations. -

What should I consider when evaluating potential suppliers of stainless steel grease fittings?

When evaluating suppliers for stainless steel grease fittings, consider their industry experience, product quality, and manufacturing capabilities. Research their reputation by checking customer reviews and testimonials, and inquire about certifications that demonstrate compliance with international standards. Assess their communication responsiveness and willingness to provide technical support. Additionally, ensure they have a robust supply chain management system to handle your orders efficiently. Building a strong relationship with a trustworthy supplier can lead to better terms and reliable service in the long run.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Stainless Steel Grease Fittings Manufacturers & Suppliers List

1. Zerks Plus – Stainless Steel Grease Fittings

Domain: zerksplus.com

Registered: 2014 (11 years)

Introduction: Stainless Steel Grease Fittings designed for marine and corrosive environments. Features include two notches in the hex for easy identification. Product offerings include various types of Zerk fittings such as: 1/4 inch Drive Stainless Steel Straight Zerk Fitting, 1/8-27 NPT Stainless Steel 45° Grease Zerk Fitting, M8 x 1.25mm Straight Stainless Metric Grease Zerk Fitting, M8 x 1mm Straight Stainl…

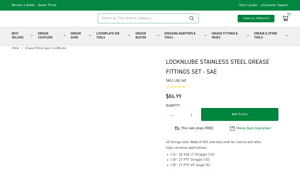

2. LockNLube – Stainless Steel Grease Fittings Set

Domain: locknlube.com

Registered: 2013 (12 years)

Introduction: LockNLube Stainless Steel Grease Fittings Set – SAE

SKU: LNL140

Price: $86.99 (Regular price: $89.99)

Total fittings: 40

Material: 303 stainless steel (suitable for marine and high-corrosion applications)

Fitting types:

– 1/4″- 28 SAE LT Straight (10)

– 1/8″- 27 PTF Straight (10)

– 1/8″- 27 PTF 45° Angle (5)

– 1/8″- 27 PTF 90° Angle (5)

– 1/4″- 28 SAE LT 90° Angle (5)

– 1/4″- 28 SAE LT 45° Angle (…

3. McMaster – Stainless Steel Grease Fittings

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Stainless Steel Grease Fittings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. American Lube – Stainless Steel Grease Fittings

Domain: americanlube.com

Registered: 1997 (28 years)

Introduction: Stainless Steel Grease Fittings are designed for harsh and highly corrosive environments. They are made from 303 stainless steel for the body and head, with a stainless steel stress relieving spring and ball. All fittings have a single notch identification mark on the hexagonal corners. Key items include:

– Item 777-1401: Type Straight, Thread Size 1/4″, Length .82″

– Item 777-142801: Type Straig…

5. SAE Products – Stainless Steel Grease Fittings

Domain: saeproducts.com

Registered: 2001 (24 years)

Introduction: Stainless Steel Grease Fittings, also known as Stainless Steel Zerk Fittings or Stainless Steel Lubrication Fittings, are designed to withstand severe and corrosive environments, offering greater corrosion resistance than traditional carbon steel grease fittings. They are made from Type 303 stainless steel for fitting bodies, Type 440 stainless steel for balls, and Type 302 stainless steel for tem…

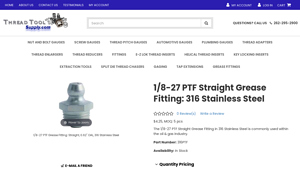

6. Thread Tool Supply – 1/8-27 PTF Straight Grease Fitting

Domain: threadtoolsupply.com

Registered: 2009 (16 years)

Introduction: {“Product Name”: “1/8-27 PTF Straight Grease Fitting”, “Material”: “316 Stainless Steel”, “Thread Size”: “1/8-27”, “Overall Length”: “0.62 inch (15.7mm)”, “Shank Length”: “0.25 inch (6.4mm)”, “Hex Size”: “11mm”, “Head Angle”: “Straight”, “Thread Type”: “PTF Spl Extra Short”, “Ball Check Valve”: “Yes”, “Heat Treated”: “8000 PSI”, “RoHS Compliant”: “Yes”, “Industry Spec”: “SAE J534”, “Country of Ori…

7. Tacoma Screw – Stainless Steel Grease Fittings

Domain: tacomascrew.com

Registered: 1999 (26 years)

Introduction: This company, Tacoma Screw – Stainless Steel Grease Fittings, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for stainless steel grease fittings

In navigating the complexities of sourcing stainless steel grease fittings, international B2B buyers must prioritize quality, durability, and cost-efficiency. The inherent advantages of stainless steel—such as enhanced corrosion resistance and longevity—make these fittings an optimal choice for harsh environments prevalent in industries across Africa, South America, the Middle East, and Europe.

Strategic sourcing not only ensures access to reliable suppliers but also fosters stronger partnerships that can lead to better pricing and service conditions. By leveraging regional insights and understanding local market dynamics, buyers can make informed decisions that align with their operational needs and budget constraints.

As you move forward, consider the diverse range of stainless steel grease fittings available, from various sizes to specialized designs. Investing in high-quality fittings can significantly reduce maintenance costs and equipment downtime.

In conclusion, the demand for robust, corrosion-resistant solutions will continue to grow. Equip your business for success by exploring strategic sourcing options that cater to your specific requirements. Engage with trusted suppliers, and position your operations to benefit from the resilience and efficiency that stainless steel grease fittings offer.