Contents

Manufacturing Insight: Stainless Steel Cost Per Tonne

Material Cost Context in Precision Manufacturing

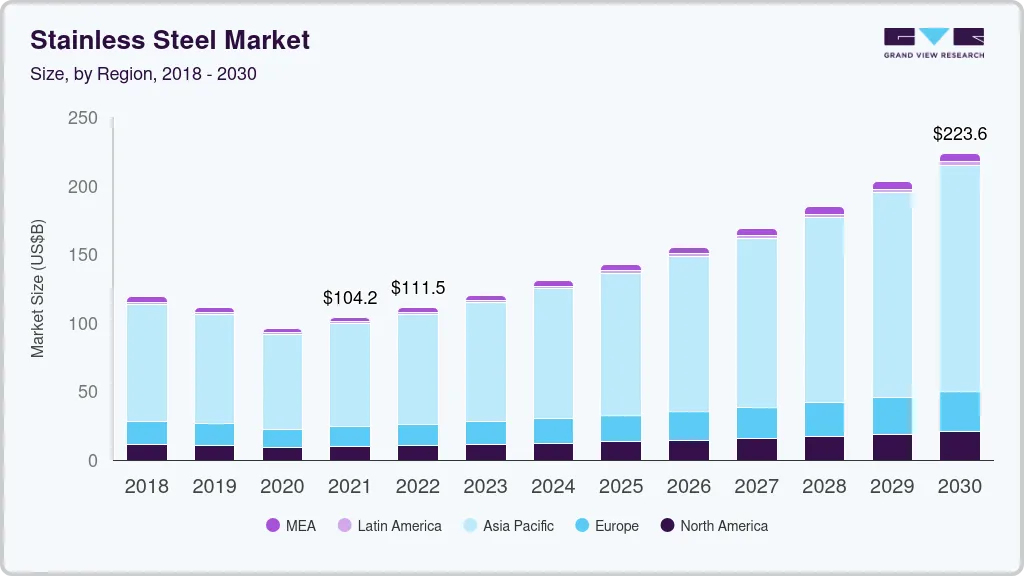

Understanding stainless steel cost per tonne is fundamental to strategic material selection for prototyping and low-volume production. Global market dynamics, alloy composition variables like 304 versus 316 grades, and supply chain volatility directly impact project budgets. At Honyo Prototype, we recognize that raw material expenditure constitutes a significant portion of total part cost, particularly for high-integrity components requiring corrosion resistance and mechanical strength.

Precision Machining Value Beyond Raw Material Pricing

Our CNC machining services mitigate cost pressures through advanced material utilization strategies. High-precision 3-, 4-, and 5-axis milling and turning minimize waste via optimized nesting, near-net-shape processing, and tolerance-driven waste reduction. This engineering approach ensures you pay only for the material transformed into functional geometry—not excess scrap. Our ISO 9001-certified processes maintain strict adherence to dimensional accuracy while maximizing yield from each stainless steel billet or bar stock.

Accelerated Cost Transparency with Online Instant Quote

Eliminate estimation delays with Honyo’s Online Instant Quote platform. Upload your STEP or IGES file to receive a detailed machining cost breakdown within minutes—including real-time material cost calculations based on current stainless steel market rates per tonne. This tool integrates alloy-specific pricing, geometric complexity, and finishing requirements to deliver actionable budget intelligence before project kickoff.

Strategic Partnership for Cost-Effective Prototyping

We transform material cost variables into predictable engineering outcomes. Contact Honyo Prototype to leverage our CNC expertise and digital quoting system for stainless steel components where precision, speed, and cost control intersect.

Technical Capabilities

Stainless steel cost per tonne is influenced by material grade, machining complexity, and required tolerances. When considering precision manufacturing processes such as 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, the overall cost structure includes raw material pricing, machining time, tool wear, and quality control—especially under tight tolerance requirements (±0.005 mm to ±0.05 mm). Below is a comparative technical and cost analysis across common engineering materials used in prototyping and low-to-mid volume production at Honyo Prototype.

| Material | Typical Grade | Density (g/cm³) | Machinability Rating | Avg. Raw Material Cost (USD per Tonne) | Machining Complexity (3/4/5-Axis) | Tight Tolerance Feasibility | Notes |

|---|---|---|---|---|---|---|---|

| Stainless Steel | 304 / 316 | 8.0 | Moderate | 2,800 – 4,200 | High – Very High | Excellent | High tool wear; slower feed rates; excellent corrosion resistance; ideal for medical, aerospace, and food-grade applications |

| Aluminum | 6061 / 7075 | 2.7 | Excellent | 2,500 – 3,500 | Low – Moderate | Excellent | Fast machining cycles; low tool wear; lightweight; common in aerospace and consumer electronics |

| Carbon Steel | 1045 / 4140 | 7.8 | Good | 900 – 1,400 | Moderate | Very Good | Higher strength than stainless; prone to corrosion; often used in industrial components |

| ABS | Commercial Grade | 1.05 | Very Good | 2,000 – 2,800 | Low | Good | Thermoplastic; ideal for functional prototypes; limited thermal and structural performance |

| Nylon | PA6 / PA66 | 1.13 | Good | 3,000 – 4,500 | Moderate | Good | High toughness and wear resistance; hygroscopic; used in gears and bushings |

Key Observations:

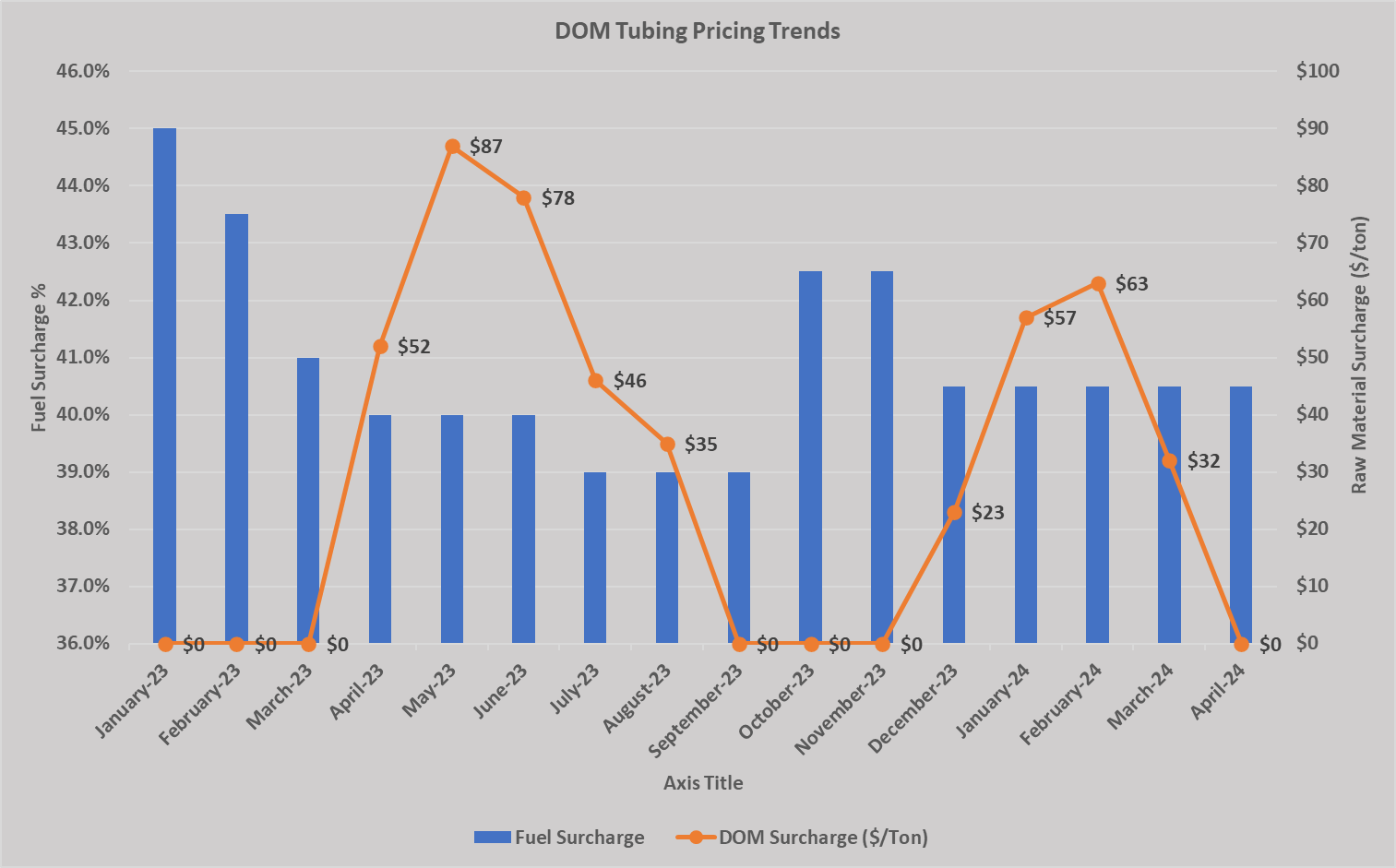

Stainless steel commands a higher per-tonne cost compared to aluminum and carbon steel, but its performance in tight tolerance applications justifies the expense in critical industries. 5-axis milling of stainless steel requires high-precision CNC machines with rigid setups and specialized tooling (e.g., carbide end mills with coolant through-spindle), increasing operational costs. In contrast, aluminum’s superior machinability reduces cycle times and tooling expenses, making it cost-effective despite similar raw material pricing.

For turning operations, stainless steel also demands slower spindle speeds and higher cutting forces, impacting throughput. Tight tolerance finishing (e.g., for hydraulic fittings or aerospace brackets) often requires multi-step inspection using CMMs or laser probes, further affecting unit cost.

ABS and nylon, while higher per tonne than carbon steel, are typically used in lower volumes and require less complex tool paths. Their lower density reduces material usage per part, but dimensional stability under tight tolerance can be challenging due to thermal expansion and moisture absorption.

At Honyo Prototype, material selection is optimized based on functional requirements, production volume, and geometric complexity—ensuring cost efficiency without compromising precision.

From CAD to Part: The Process

Honyo Prototype does not calculate or quote a standalone stainless steel cost per tonne as a final deliverable metric. Instead, the base material cost per tonne is a critical input variable within our comprehensive quotation and manufacturing process. The process you described focuses on how we integrate real-time material costs with engineering and production factors to generate an accurate part-specific price. Here is our technical workflow:

Upload CAD

The customer submits a detailed 3D CAD model with specified material grade (e.g., 304, 316L stainless steel). Our system extracts key geometric data including volume, bounding box dimensions, and surface area. Crucially, this step identifies the net usable material volume required for the part, excluding any internal voids or non-manufacturable features.

AI Quote

Our proprietary AI engine initiates cost modeling using three primary inputs: the extracted net material volume, current global stainless steel market pricing (sourced from LME and major mill indices updated hourly), and regional scrap value recovery rates. The AI calculates a theoretical raw material cost using the formula:

(Net Part Volume × Material Density) × (Current Market Price per Tonne – Scrap Recovery Value per Tonne)

This represents the baseline material cost before processing. However, the AI simultaneously factors in historical data on yield loss for similar geometries, machine setup costs, and standard machining time estimates. The output is a preliminary quote where material cost typically constitutes 30-50% of the total, depending on part complexity.

DFM (Design for Manufacturability)

During engineering review, our team analyzes material utilization efficiency. We identify opportunities to reduce effective material cost through:

Nesting optimization to minimize sheet waste

Adjusting wall thicknesses within tolerance limits

Recommending alternative grades if 316L is over-specified for the application

Proposing design modifications to reduce machining time (which indirectly lowers the material cost allocation per part by improving throughput)

This phase often reduces the effective material cost per part by 15-25% through waste reduction, even if the base tonnage price remains fixed.

Production

Actual material consumption is tracked using IoT-enabled saws and CNC systems that record:

Precise raw stock usage (including kerf loss)

Verified scrap weight for recycling reconciliation

Real-time yield against the DFM-optimized plan

The final material cost per part is dynamically adjusted based on measured consumption. For example, if 1.2 tonnes of raw stock produces 0.95 tonnes of finished parts (79% yield), the effective material cost per finished tonne is calculated as:

(1.2 tonnes × Purchase Price) / 0.95 tonnes

This figure is always higher than the base market price due to inherent process losses.

Delivery

The customer receives a detailed cost breakdown with the shipment. Material cost is reported as a line item derived from actual consumed stock, not theoretical tonnage. Below is a representative cost structure for a typical stainless steel prototype part:

| Cost Component | Percentage of Total Cost | Notes |

|---|---|---|

| Base Material (as purchased) | 35% | Adjusted for actual yield loss |

| Machining Labor | 25% | Highly dependent on part complexity |

| CNC Machine Depreciation | 20% | Amortized over machine lifecycle |

| Quality Assurance | 12% | Includes material certification tests |

| Logistics | 8% | Varies by destination and urgency |

This integrated approach ensures transparency while accounting for engineering realities. Quoting a naked “cost per tonne” would misrepresent the true manufacturing economics, as material efficiency and processing costs dominate the final price structure. Our clients benefit from accurate, defensible pricing that reflects actual production physics rather than oversimplified commodity metrics.

Start Your Project

Looking for up-to-date pricing on stainless steel per tonne? Contact Susan Leo at [email protected] for accurate, real-time quotations tailored to your project needs. As a trusted manufacturing partner with a fully operational factory in Shenzhen, Honyo Prototype ensures competitive material sourcing, precision fabrication, and reliable delivery—ideal for prototyping and low to high-volume production runs. Reach out today to streamline your supply chain with expert support from our team.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.