Contents

Manufacturing Insight: Stainless Steel Comparison Chart

Material Selection Complexity in Precision Manufacturing

Selecting the optimal stainless steel grade for CNC machined components demands careful evaluation of corrosion resistance, mechanical properties, weldability, and machinability. Misalignment between material specifications and application requirements can lead to premature part failure, increased production costs, or extended lead times. At Honyo Prototype, our engineering team leverages deep metallurgical expertise to guide clients through this critical decision process, ensuring material choices align with functional demands and manufacturability constraints.

Honyo’s CNC Machining Excellence

We specialize in high-precision CNC milling and turning of stainless steel alloys, including 303, 304/L, 316/L, 17-4 PH, and 416 grades. Our advanced 5-axis machining centers, coupled with in-house material certification and stringent QA protocols, deliver components meeting tight tolerances (±0.0002″) and superior surface finishes. By integrating material science with precision manufacturing, we optimize part performance while minimizing waste and cycle times—critical for prototyping and low-volume production runs.

Accelerate Your Project Timeline

To streamline your sourcing workflow, Honyo provides an Online Instant Quote platform. Upload your 3D CAD file, specify your stainless steel grade and quantities, and receive a detailed manufacturability analysis with competitive pricing in under 60 seconds. This tool eliminates traditional quoting bottlenecks, allowing engineering teams to validate design feasibility and budget parameters before formal procurement.

Utilize the stainless steel comparison chart below to evaluate key properties, then leverage our instant quoting system to transition seamlessly from material selection to production-ready solutions. Honyo Prototype: Where material intelligence meets precision execution.

Technical Capabilities

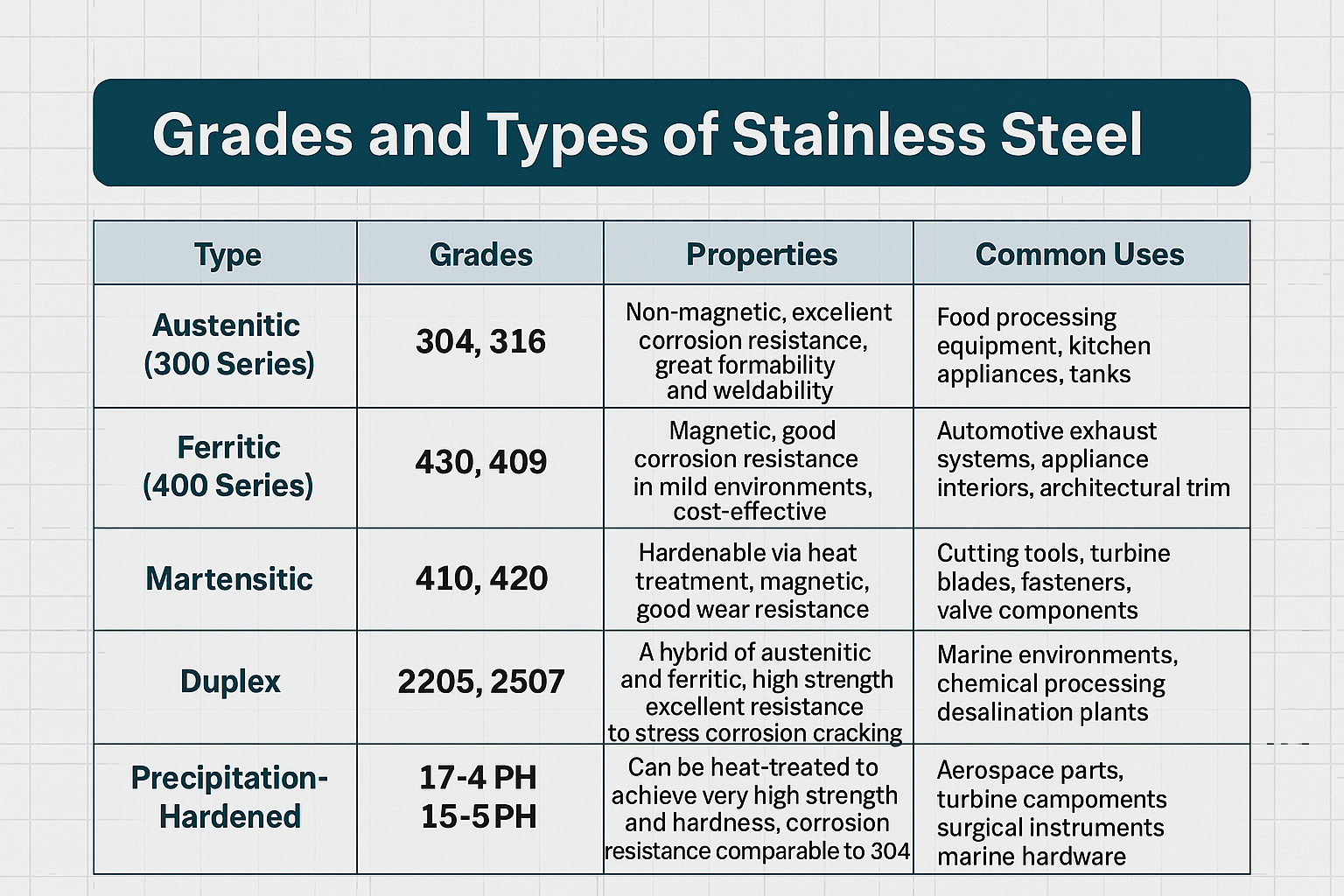

The following technical specifications outline a comparison of stainless steel grades commonly used in precision CNC machining processes including 3-axis, 4-axis, and 5-axis milling, as well as CNC turning. These operations are frequently employed for manufacturing components requiring tight tolerances (±0.0002″ to ±0.001″). While the focus is on stainless steel, comparative notes are included for Aluminum, Carbon Steel, ABS, and Nylon to provide context across material families.

| Property / Material | 303 Stainless Steel | 304 Stainless Steel | 316 Stainless Steel | 17-4 PH Stainless Steel | Aluminum 6061-T6 | Carbon Steel (1018) | ABS (Acrylonitrile Butadiene Styrene) | Nylon (PA6/PA66) |

|---|---|---|---|---|---|---|---|---|

| Machinability Rating | 78% | 45% | 42% | 30% | 90% | 55% | Excellent (easy to machine) | Good (slightly gummy) |

| Typical Tolerance (±) | 0.0005″ – 0.001″ | 0.0005″ – 0.001″ | 0.0005″ – 0.001″ | 0.0002″ – 0.0005″ | 0.0005″ – 0.001″ | 0.001″ | 0.005″ – 0.010″ | 0.005″ – 0.010″ |

| Surface Finish (Ra µin) | 16 – 32 | 32 – 64 | 32 – 64 | 16 – 32 | 16 – 32 | 32 – 125 | 64 – 125 | 64 – 125 |

| Corrosion Resistance | Moderate (sulfides reduce resistance) | Good (general purpose) | Excellent (chloride resistant) | Good (passivates well) | Good (with anodizing) | Poor (requires coating) | Fair | Poor (hygroscopic) |

| Tensile Strength (psi) | 70,000 | 73,000 | 75,000 | 150,000 | 45,000 | 63,000 | 6,000 | 9,000 – 11,000 |

| Hardness (HB) | 160 – 180 | 150 – 170 | 150 – 170 | 330 – 380 | 95 | 125 | 80 | 80 – 100 |

| Common Applications | Fasteners, shafts, fittings | Food processing, enclosures | Marine, chemical, medical | Aerospace, tooling, molds | Enclosures, brackets, prototypes | Structural parts, shafts | Prototypes, jigs, consumer parts | Gears, wear components |

| 5-Axis Milling Suitability | Moderate (chip control critical) | Challenging (work hardening) | Challenging (work hardening) | Difficult (high hardness) | Excellent (light cuts, high speed) | Moderate (requires rigid setup) | Excellent (low cutting forces) | Good (requires chip control) |

| Turning Suitability | Good (free-machining) | Fair (requires sharp tools) | Fair (requires sharp tools) | Poor (requires carbide, low speeds) | Excellent (high RPM possible) | Good (stable cutting) | Excellent | Good |

| Thermal Stability | High | High | High | High | Moderate | High | Low (softens easily) | Low (absorbs moisture & heat) |

Notes on Tight Tolerance Machining:

17-4 PH stainless steel is preferred for high-precision, tight-tolerance applications requiring both strength and moderate corrosion resistance, especially in aerospace and medical fields. Its age-hardening capability allows post-machining heat treatment with minimal distortion.

303 stainless steel is often selected for complex turned parts due to its sulfur content improving machinability, though at the expense of weldability and slight reduction in corrosion resistance.

Aluminum 6061-T6 is ideal for rapid prototyping and lightweight precision components, offering excellent dimensional stability and ease of achieving tight tolerances in multi-axis milling.

ABS and Nylon are typically used for non-structural prototypes, jigs, and fixtures. While they can be machined to moderate tolerances, their hygroscopic nature and lower thermal resistance limit use in high-precision or high-temperature environments.

For 5-axis stainless steel milling, rigid setups, high-pressure coolant, and optimized toolpaths are essential to manage work hardening and tool wear, especially in 304 and 316 grades.

This comparison supports material selection for high-accuracy CNC manufacturing at Honyo Prototype, balancing machinability, performance, and application requirements.

From CAD to Part: The Process

Honyo Prototype executes stainless steel component projects through a rigorously defined workflow that integrates material science expertise with digital manufacturing intelligence. The process begins when a client uploads a CAD file to our secure portal, triggering immediate material analysis. Our AI quoting engine specifically evaluates stainless steel grade implications—comparing 304, 316, 17-4PH, and other alloys against geometric complexity, tolerance requirements, and functional demands. This initial assessment quantifies cost differentials between grades while flagging potential manufacturability risks such as work hardening during machining or weld decay in sensitized zones.

Following AI quotation, the Design for Manufacturability (DFM) phase commences with dedicated metallurgical review. Our engineers perform granular stainless steel property comparisons across critical parameters:

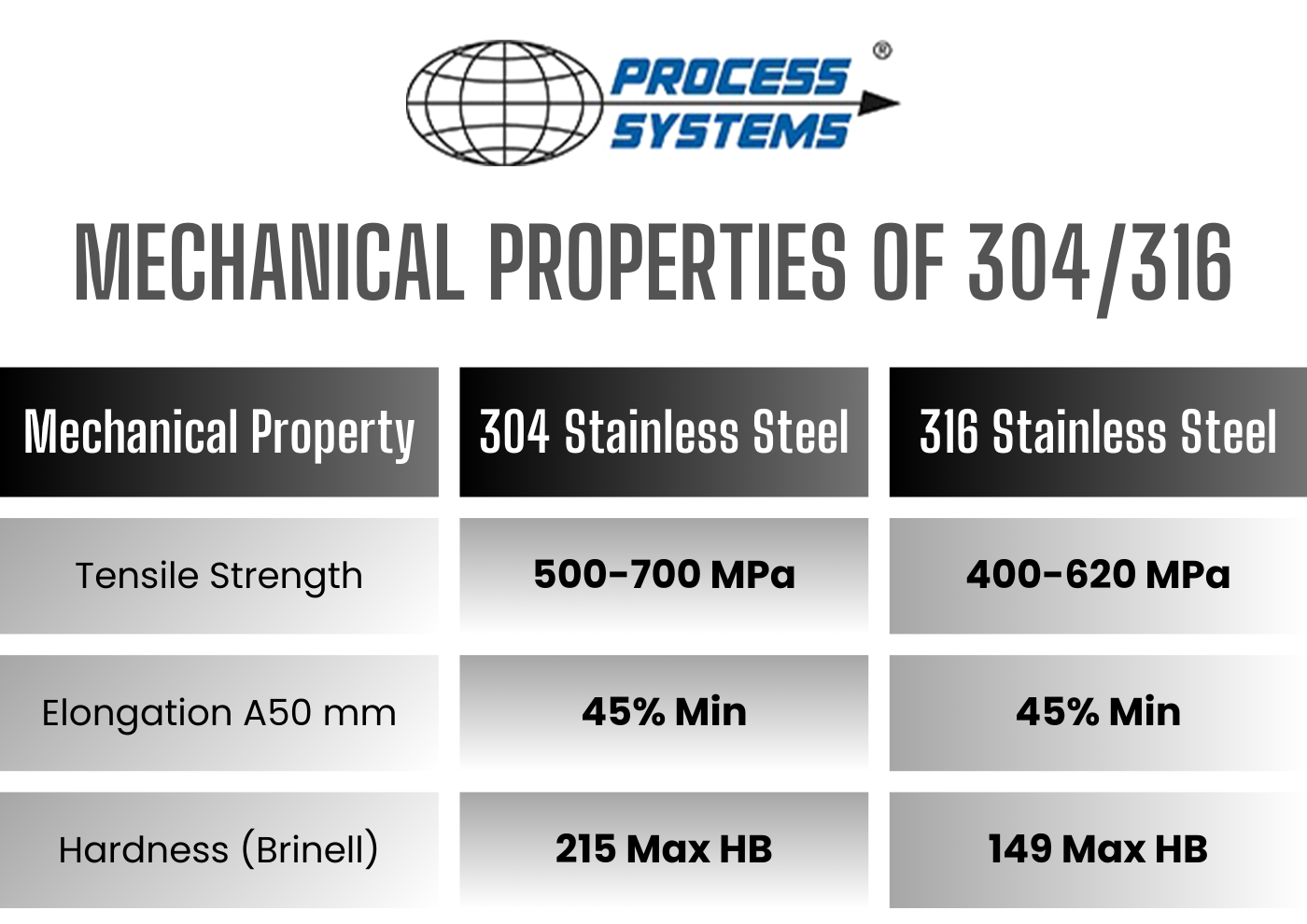

| Property | 304 Stainless | 316 Stainless | 17-4PH Stainless | Relevance to DFM |

|---|---|---|---|---|

| Corrosion Resistance | Moderate | High (Mo 2-3%) | Moderate | Determines passivation requirements and welding procedures for chloride exposure |

| Machinability | 70% of 1212 steel | 60% of 1212 steel | 45% of 1212 steel | Impacts tool selection, feed rates, and surface finish expectations |

| Thermal Conductivity | 16.2 W/m·K | 16.3 W/m·K | 27.6 W/m·K | Affects heat dissipation during welding and distortion control |

| Yield Strength | 205 MPa | 215 MPa | 1000 MPa | Dictates fixturing requirements and post-machining stress relief needs |

This comparative analysis directly informs actionable DFM recommendations. For instance, if the CAD geometry includes thin-walled features exposed to saltwater, the system will mandate 316 over 304 despite 18-22% cost premium, with specific notes on avoiding heat-affected zone corrosion. Similarly, complex internal geometries may trigger substitution suggestions to free-machining grades like 303 where corrosion resistance permits.

Upon DFM approval, production leverages grade-specific process parameters. CNC machining centers automatically load optimized toolpaths accounting for stainless steel’s galling tendencies, while welding cells implement ASTM A380-compliant procedures with argon shielding gas tailored to each alloy. Throughout fabrication, in-process inspections verify material conformance per ASTM A240 standards using handheld XRF analyzers. Final delivery includes full material traceability documentation with mill test reports, dimensional certification, and surface roughness validation against the original CAD specifications. This end-to-end integration of material intelligence ensures stainless steel components meet both functional requirements and economic targets without compromising on performance integrity.

Start Your Project

View our comprehensive stainless steel comparison chart to select the optimal material for your manufacturing needs. Contact Susan Leo at [email protected] for technical specifications, material certifications, and project consultation.

Honyo Prototype operates a precision manufacturing facility in Shenzhen, China, specializing in rapid prototyping, CNC machining, and low-volume production using high-grade stainless steel alloys.

Let us help you make an informed material choice—reach out today for expert support and fast turnaround.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.