Introduction: Navigating the Global Market for stainless steel cnc machining services

Navigating the complexities of sourcing stainless steel CNC machining services can pose significant challenges for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. Companies often grapple with finding reliable suppliers who can deliver high-quality, precision-engineered parts that meet stringent industry standards. This comprehensive guide aims to demystify the procurement process by exploring the diverse types of stainless steel CNC machining services available, their applications across various industries, and the critical factors to consider when vetting suppliers.

In this guide, we will delve into the key aspects of stainless steel machining, including the different stainless steel alloys suitable for various applications—from medical instruments to aerospace components. We will also address essential topics such as cost considerations, lead times, and quality certifications, ensuring that you are equipped to make informed purchasing decisions. By providing actionable insights and practical tips, this guide empowers international buyers to navigate the global market with confidence, helping them select the right partners and optimize their supply chain strategies. Whether you’re in Brazil seeking robust manufacturing solutions or in Saudi Arabia looking for precision parts, this resource is designed to enhance your sourcing effectiveness and drive operational success.

Understanding stainless steel cnc machining services Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Milling | High precision, multi-axis capabilities for complex shapes | Aerospace components, medical devices, custom machinery | Pros: High accuracy; Cons: Longer lead times for complex designs. |

| CNC Turning | Rotational machining for cylindrical parts | Shafts, bolts, fittings, automotive components | Pros: Efficient for round parts; Cons: Limited to specific geometries. |

| CNC Laser Cutting | Uses high-powered lasers for cutting intricate designs | Signage, brackets, decorative elements | Pros: Clean cuts, minimal material waste; Cons: Not suitable for thick materials. |

| CNC Waterjet Cutting | Utilizes high-pressure water jets to cut various materials | Aerospace, automotive, and architectural applications | Pros: Can cut thick materials; Cons: Slower than other methods. |

| CNC Sheet Metal Fabrication | Processes flat sheets into specific shapes and designs | Enclosures, frames, and brackets for various industries | Pros: Cost-effective for large volumes; Cons: Limited to sheet metal thicknesses. |

What are the Key Characteristics of CNC Milling in Stainless Steel Machining?

CNC milling is characterized by its ability to produce complex shapes with high precision using multi-axis machines. This method is particularly suitable for creating intricate components required in industries such as aerospace and medical devices. When purchasing CNC milling services, buyers should consider the machine’s capabilities, the experience of the machinists, and the lead times for complex parts.

How Does CNC Turning Differ from Other Machining Processes?

CNC turning focuses on machining cylindrical components by rotating the workpiece against a stationary cutting tool. This method is ideal for producing shafts, bolts, and other rounded parts commonly found in automotive and industrial applications. Buyers should evaluate the supplier’s ability to handle different diameters and lengths, as well as the quality of surface finishes achievable through turning processes.

What Advantages Does CNC Laser Cutting Offer for Stainless Steel Parts?

CNC laser cutting is renowned for its precision in cutting intricate designs with minimal material waste. This method is particularly effective for creating detailed signage and decorative elements. When considering laser cutting services, buyers should assess the thickness of materials that can be processed and the potential for post-processing finishes, as well as turnaround times for custom designs.

Why Choose CNC Waterjet Cutting for Thick Materials?

CNC waterjet cutting employs high-pressure water jets to slice through various materials, making it an excellent choice for thick stainless steel components. This method is versatile and can be used across multiple industries, including aerospace and architecture. B2B buyers should focus on the supplier’s ability to handle large-scale projects and the precision tolerances they can achieve with waterjet technology.

How Does CNC Sheet Metal Fabrication Benefit Large-Scale Production?

CNC sheet metal fabrication is designed for processing flat sheets into specific shapes, making it cost-effective for large production runs. Common applications include manufacturing enclosures and frames for various industries. Buyers should consider the supplier’s experience with different metal thicknesses and their capabilities for secondary processes, such as welding or finishing, to ensure that all project requirements are met efficiently.

Key Industrial Applications of stainless steel cnc machining services

| Industry/Sector | Specific Application of stainless steel cnc machining services | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Devices | Manufacturing of surgical instruments and implants | High precision and biocompatibility, ensuring patient safety and regulatory compliance | Certifications (ISO, FDA), material traceability, rapid prototyping capabilities |

| Aerospace | Production of structural components and fasteners | Lightweight yet strong materials that meet stringent safety standards | Compliance with aerospace standards (AS9100), lead time, and part complexity |

| Food and Beverage | Creation of processing equipment and containers | Corrosion resistance and ease of cleaning, ensuring hygiene and compliance with food safety regulations | Material certifications (food-grade), surface finish requirements, and durability |

| Automotive | Fabrication of engine parts and chassis components | Enhanced strength and performance, contributing to vehicle safety and efficiency | Tolerance specifications, volume requirements, and delivery schedules |

| Heavy Machinery | Parts for construction and agricultural equipment | Durability and resistance to harsh environments, reducing downtime and maintenance costs | Customization options, bulk pricing, and logistical support for international shipping |

How Are Stainless Steel CNC Machining Services Utilized in Medical Devices?

In the medical sector, stainless steel CNC machining services are critical for producing precision surgical instruments and implants. These components must meet rigorous biocompatibility and sterilization standards to ensure patient safety. International buyers, particularly from regions like South America and the Middle East, should prioritize suppliers with ISO certifications and robust material traceability. Rapid prototyping capabilities are also essential, allowing for quick iterations and compliance with evolving medical regulations.

What Role Does CNC Machining Play in the Aerospace Industry?

Stainless steel CNC machining services are integral to the aerospace industry, where they are used to manufacture lightweight yet robust structural components and fasteners. These parts must adhere to stringent safety and performance standards, such as AS9100 certification. For B2B buyers in Europe and Africa, sourcing from certified suppliers that can handle complex designs and provide quick turnaround times is crucial to meet project deadlines and ensure compliance with international aerospace regulations.

Why Is Stainless Steel Important in the Food and Beverage Industry?

In the food and beverage sector, stainless steel CNC machining is employed to create processing equipment and containers that are both durable and easy to clean. The corrosion resistance of stainless steel ensures hygiene and compliance with food safety regulations. Buyers from regions like Brazil and Saudi Arabia should consider suppliers who offer food-grade material certifications and can meet specific surface finish requirements to maintain product integrity and safety.

How Does CNC Machining Enhance Automotive Manufacturing?

The automotive industry relies on stainless steel CNC machining for fabricating critical engine parts and chassis components. The high strength and durability of stainless steel contribute to enhanced vehicle safety and performance. For international buyers, especially in emerging markets, it’s essential to work with suppliers who can meet precise tolerance specifications and accommodate varying volume requirements, ensuring timely delivery and cost-effectiveness.

What Are the Advantages of Using CNC Machining in Heavy Machinery?

In heavy machinery applications, stainless steel CNC machining services are utilized to produce parts for construction and agricultural equipment. The durability and resistance of stainless steel to harsh environments significantly reduce maintenance costs and downtime. Buyers should look for suppliers that offer customization options and competitive bulk pricing, along with logistical support for efficient international shipping, ensuring a seamless supply chain.

3 Common User Pain Points for ‘stainless steel cnc machining services’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

The Problem: One of the most pressing challenges faced by B2B buyers in the stainless steel CNC machining industry is the inconsistency in part quality from different suppliers. This can lead to unexpected delays in production schedules, increased costs due to rework or scrapped parts, and ultimately, a negative impact on customer satisfaction. Buyers may struggle to establish quality standards that all suppliers meet, especially when sourcing internationally from regions like Africa or South America where manufacturing standards may vary widely.

The Solution: To overcome this issue, B2B buyers should prioritize working with ISO-certified suppliers who demonstrate a commitment to quality management systems. Before finalizing any contracts, buyers should request detailed quality assurance processes, including material certifications and examples of past work that meet their specifications. Utilizing platforms that aggregate certified suppliers can help streamline this process. Additionally, establishing clear communication channels and setting precise quality benchmarks in the initial stages of the project can lead to more reliable outcomes. Regular audits and feedback loops should also be part of the partnership to ensure ongoing compliance with quality standards.

Scenario 2: High Costs and Long Lead Times

The Problem: Another common pain point for B2B buyers is the high costs associated with stainless steel CNC machining and the long lead times often experienced when ordering custom parts. This issue is particularly pronounced in industries such as aerospace and medical, where precision and reliability are paramount. Buyers may find themselves facing unexpected budget overruns and delayed product launches due to these factors, which can hinder their competitive edge.

The Solution: To mitigate high costs and long lead times, buyers should consider employing a dual-sourcing strategy. This involves working with multiple suppliers to compare prices and lead times, which can foster competitive pricing while ensuring faster turnaround times. Additionally, leveraging online CNC machining services that provide instant quotes and real-time inventory checks can help buyers make informed decisions quickly. Implementing advanced design for manufacturability (DFM) practices early in the design process can also reduce complexities, leading to lower production costs and faster lead times. Engaging with suppliers who offer rapid prototyping services can further enable faster iterations and minimize delays.

Scenario 3: Challenges in Material Selection and Specification

The Problem: Many B2B buyers encounter difficulties when it comes to selecting the right stainless steel alloy and specifying the correct machining parameters for their projects. With various stainless steel types available—each with its unique properties—buyers may find it challenging to choose the most suitable material for their specific application, leading to performance issues or product failures down the line.

The Solution: To address this challenge, buyers should invest time in understanding the properties of different stainless steel alloys and how they relate to their project requirements. Collaborating with suppliers who offer expert consultation services can provide invaluable insights into material selection. Buyers should also utilize comprehensive material comparison guides and request samples to evaluate the suitability of different alloys for their applications. Implementing a systematic approach to specifying machining parameters—such as tolerances, finishes, and post-machining treatments—can help align supplier capabilities with project needs. By fostering open dialogue and seeking technical assistance during the design phase, buyers can ensure optimal material selection and specifications, leading to successful project outcomes.

Strategic Material Selection Guide for stainless steel cnc machining services

What Are the Key Properties of Common Stainless Steel Alloys for CNC Machining?

When selecting materials for stainless steel CNC machining services, it is essential to understand the properties of different stainless steel alloys. Here, we analyze four common materials: Stainless Steel 303, 304, 316, and 17-4PH. Each alloy has unique characteristics that can significantly impact product performance, manufacturing complexity, and suitability for specific applications.

How Does Stainless Steel 303 Perform in CNC Machining?

Stainless Steel 303 is known for its excellent machinability and is often chosen for parts that require extensive machining. It has a tensile strength of 75-90 ksi and an elongation of 35-50%. This alloy is highly resistant to corrosion, making it suitable for applications in the food and beverage industry.

Pros: The primary advantage of 303 is its superior machinability, which allows for faster production times and lower machining costs. It is also non-magnetic and has good weldability.

Cons: However, its corrosion resistance is not as high as other alloys, such as 316, making it less suitable for harsh environments.

Impact on Application: It is ideal for components like fasteners and fittings that require intricate shapes but may not be suitable for marine applications due to lower corrosion resistance.

Considerations for International Buyers: Buyers should ensure compliance with ASTM standards and consider local regulations regarding food safety when using 303 in food-related applications.

What Makes Stainless Steel 304 a Preferred Choice for Many Applications?

Stainless Steel 304 is one of the most widely used stainless steel alloys, valued for its excellent corrosion resistance and good formability. It has a tensile strength of 99 ksi and an elongation of 52%. This alloy is commonly used in industries ranging from food processing to medical devices.

Pros: The key advantage of 304 is its versatility and resistance to oxidation and corrosion, making it suitable for a wide range of environments. Its ability to be easily welded and formed adds to its appeal.

Cons: On the downside, it is less resistant to pitting corrosion compared to 316, which may limit its use in highly corrosive environments.

Impact on Application: 304 is suitable for applications like kitchen equipment, storage tanks, and piping systems, where corrosion resistance is essential.

Considerations for International Buyers: Compliance with ISO and ASTM standards is critical, especially in the food and medical sectors, where hygiene and safety are paramount.

Why Choose Stainless Steel 316 for Corrosive Environments?

Stainless Steel 316 is renowned for its high corrosion resistance, especially against chlorides and other aggressive environments. With a tensile strength of 85 ksi and an elongation of 56%, it is often used in marine and chemical processing applications.

Pros: The primary advantage of 316 is its exceptional resistance to pitting and crevice corrosion, making it ideal for harsh environments. It also maintains strength at elevated temperatures.

Cons: The downside is that 316 is typically more expensive than 304 and 303, which may affect budget considerations for large projects.

Impact on Application: It is commonly used in marine applications, chemical processing equipment, and medical devices, where exposure to corrosive substances is a concern.

Considerations for International Buyers: Buyers in regions with stringent maritime or chemical regulations should ensure compliance with relevant standards, such as ASTM A240.

What Are the Benefits of Using Stainless Steel 17-4PH?

Stainless Steel 17-4PH is a precipitation-hardening alloy known for its high strength and excellent corrosion resistance. It has a tensile strength of 150 ksi and is often used in aerospace and high-stress applications.

Pros: The key advantage of 17-4PH is its ability to achieve high strength through heat treatment, allowing for thinner and lighter components without sacrificing durability.

Cons: However, its higher manufacturing complexity and cost can be a limitation for some applications.

Impact on Application: This alloy is ideal for aerospace components, valve bodies, and other high-stress applications where strength is critical.

Considerations for International Buyers: Compliance with aerospace standards, such as AS9100, is crucial for buyers in the aerospace sector, particularly in Europe and North America.

Summary Table of Stainless Steel Alloys for CNC Machining

| Material | Typical Use Case for stainless steel cnc machining services | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel 303 | Fasteners, fittings, food industry components | Excellent machinability | Lower corrosion resistance | Medium |

| Stainless Steel 304 | Kitchen equipment, storage tanks, piping systems | Versatile, good corrosion resistance | Less resistant to pitting than 316 | Medium |

| Stainless Steel 316 | Marine applications, chemical processing equipment | Exceptional corrosion resistance | Higher cost compared to 304 and 303 | High |

| Stainless Steel 17-4PH | Aerospace components, high-stress applications | High strength through heat treatment | Higher manufacturing complexity and cost | High |

This strategic material selection guide provides critical insights for international B2B buyers, enabling informed decisions when choosing stainless steel alloys for CNC machining services.

In-depth Look: Manufacturing Processes and Quality Assurance for stainless steel cnc machining services

What Are the Main Stages of Manufacturing for Stainless Steel CNC Machining Services?

The manufacturing process for stainless steel CNC machining services involves several critical stages: material preparation, forming, assembly, and finishing. Each of these stages contributes to the overall quality and precision of the final product.

Material Preparation: How Is Stainless Steel Readied for Machining?

The first step in the manufacturing process is material preparation. Stainless steel is available in various grades, each with specific properties suited for different applications. Buyers should consider materials such as Stainless Steel 304, 316, or 17-4PH, depending on the strength, corrosion resistance, and machinability required for their projects.

Once the appropriate grade is selected, it is typically cut into manageable sizes using saws or shears. This is followed by the inspection of the material to ensure it meets the specified standards before proceeding to machining. Proper material preparation is crucial as it lays the foundation for a successful machining operation.

What Techniques Are Used in the Forming Stage of CNC Machining?

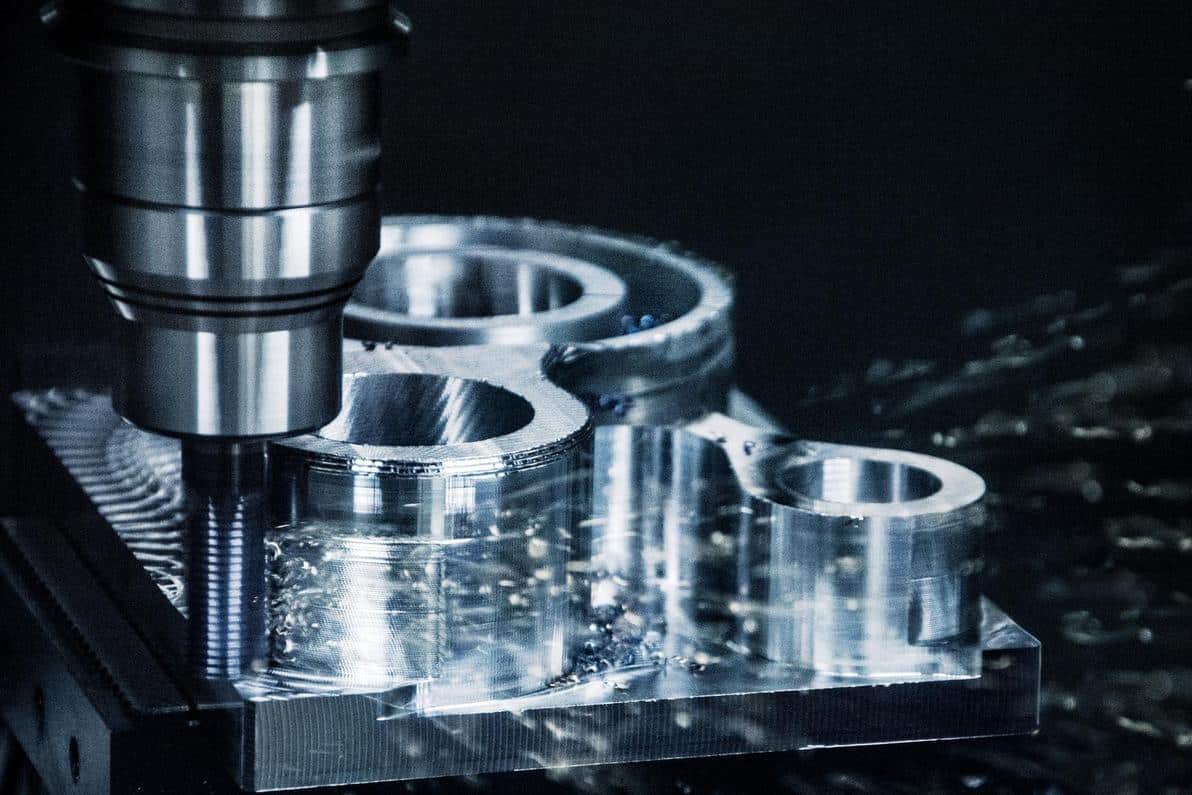

The forming stage employs advanced CNC (Computer Numerical Control) technology to shape stainless steel into the desired components. This process can involve various techniques, including milling, turning, and drilling, which are performed by highly precise machines.

CNC machines can operate in multiple axes, allowing for complex geometries and intricate designs. For example, 5-axis machining enables the production of parts with complicated contours and tight tolerances, which are essential in industries like aerospace and medical devices. The use of CAD (Computer-Aided Design) software ensures that the machining process adheres closely to the specified dimensions and tolerances.

How Are Components Assembled During the Manufacturing Process?

Following machining, the next step is assembly, if applicable. In many cases, stainless steel parts are produced as standalone components. However, when multiple parts are required to function together, assembly becomes critical. This stage may involve welding, fastening, or other joining techniques, depending on the design requirements.

Quality assurance during assembly is vital, as any misalignment or improper joining can lead to product failure. Therefore, it is essential that assemblers follow strict guidelines and specifications to ensure a reliable final product.

What Finishing Techniques Are Commonly Used in Stainless Steel Machining?

Finishing techniques enhance the aesthetic and functional properties of stainless steel parts. Common finishing processes include polishing, passivation, and coating. Polishing improves the surface finish, providing a smooth and shiny appearance, which is particularly desirable in medical and consumer products.

Passivation is a chemical treatment that enhances corrosion resistance by removing free iron and other contaminants from the surface. Coating may be applied to further improve corrosion resistance or to add specific properties, such as wear resistance. The choice of finishing technique should align with the end-use requirements of the component.

What Quality Assurance Measures Are Essential for CNC Machining Services?

Quality assurance (QA) is a fundamental component of the manufacturing process, ensuring that the final products meet the specified standards and requirements. For international B2B buyers, understanding the relevant quality standards and checkpoints is crucial.

Which International Standards Are Relevant for Quality Assurance in CNC Machining?

ISO 9001:2015 is a widely recognized quality management standard that outlines the requirements for an effective quality management system (QMS). Companies that are ISO-certified demonstrate their commitment to quality and continuous improvement. Other standards such as ISO 13485 (for medical devices) and AS9100 (for aerospace) may also be applicable depending on the industry.

In addition to ISO certifications, industry-specific standards like CE marking (for products sold in the European Economic Area) and API (for oil and gas equipment) can provide further assurance of quality. Buyers should inquire about their suppliers’ certifications and compliance with these standards to ensure product reliability.

What Are the Key Quality Control Checkpoints in CNC Machining?

Quality control in CNC machining typically includes several checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC involves inspecting raw materials and components before they are used in production, ensuring they meet the necessary specifications.

- IPQC focuses on monitoring the manufacturing process to detect any deviations from quality standards during production. This may include periodic checks of dimensions, tolerances, and surface finish.

- FQC is the final inspection before products are shipped. It ensures that all parts meet the specified criteria and are free from defects.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify a supplier’s quality control measures. Conducting audits of the supplier’s facilities can provide valuable insights into their processes and adherence to quality standards. Additionally, requesting quality reports, inspection certificates, and documentation of previous audits can help assess the supplier’s reliability.

Third-party inspections can also be beneficial, particularly for international transactions. Engaging an independent inspection agency ensures that the products meet the agreed-upon specifications and quality standards before shipment.

What Nuances Should International Buyers Consider Regarding Quality Assurance?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality assurance in CNC machining is vital. Different regions may have varying standards and regulations that affect product quality and compliance.

Buyers should be aware of potential language barriers and cultural differences that may impact communication with suppliers. Establishing clear specifications and quality expectations upfront can mitigate misunderstandings. It is also advisable to stay informed about international shipping regulations and tariffs that may affect the cost and delivery of products.

In conclusion, ensuring high-quality stainless steel CNC machining services requires a comprehensive understanding of the manufacturing processes and quality assurance measures. By focusing on these critical areas, B2B buyers can make informed decisions and establish successful partnerships with suppliers across the globe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘stainless steel cnc machining services’

Introduction

This practical sourcing guide is designed to help international B2B buyers navigate the complexities of procuring stainless steel CNC machining services. By following this checklist, you can ensure that you select a reliable supplier that meets your technical requirements while optimizing quality, cost, and delivery timelines.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for effective communication with potential suppliers. This includes detailing dimensions, tolerances, and material grades, such as whether you require Stainless Steel 304, 316, or other alloys. Accurate specifications help prevent misunderstandings and ensure that the finished parts meet your functional and quality expectations.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in stainless steel CNC machining. Look for companies with a proven track record in your industry and those that possess relevant certifications such as ISO 9001:2015 or AS9100D. Utilize online directories, trade shows, and industry networks to gather a list of potential candidates.

Step 3: Evaluate Supplier Capabilities

Before making a decision, assess each supplier’s machining capabilities. Verify their equipment, technology (e.g., 3-axis, 4-axis, or 5-axis CNC machines), and production capacity. Understanding their capabilities will help you gauge whether they can handle your project’s complexity and volume requirements.

Step 4: Verify Supplier Certifications

It’s essential to ensure that your chosen suppliers maintain relevant industry certifications. Certifications such as ISO 13485 for medical devices or IATF 16949 for automotive applications indicate a commitment to quality management. Request copies of their certifications and check their compliance with international standards.

Step 5: Request Quotes and Compare Pricing

Once you’ve shortlisted suppliers, request detailed quotes that include pricing, lead times, and payment terms. Compare these quotes carefully, not just on price but also on the value offered, such as post-production services, shipping options, and warranty policies. Keep in mind that the lowest price may not always equate to the best value.

Step 6: Review Past Performance and References

Ask suppliers for case studies or references from previous clients, especially those in similar industries or projects. Reviewing their past performance can provide insights into their reliability, quality of work, and ability to meet deadlines. Don’t hesitate to reach out to these references to gain firsthand feedback.

Step 7: Establish Communication Protocols

Effective communication is vital throughout the machining process. Set clear expectations regarding timelines, updates, and points of contact. Establishing a communication plan will help mitigate potential issues and ensure that both parties are aligned on project goals and progress.

By following these steps, B2B buyers can confidently source stainless steel CNC machining services that align with their technical needs and business objectives.

Comprehensive Cost and Pricing Analysis for stainless steel cnc machining services Sourcing

What Are the Key Cost Components in Stainless Steel CNC Machining Services?

When sourcing stainless steel CNC machining services, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The type of stainless steel alloy significantly impacts costs. Common grades like 304 and 316 offer a balance of machinability and corrosion resistance, influencing overall pricing. Higher-grade materials, such as 17-4PH, may incur additional costs due to their enhanced properties.

-

Labor: Skilled labor is required for CNC machining, which can vary in cost depending on the region and the machinist’s expertise. Labor costs also encompass programming CNC machines and overseeing the machining process.

-

Manufacturing Overhead: This includes expenses related to facility operations, utilities, and maintenance of machinery. Overhead costs can differ widely based on geographic location and the efficiency of the machining facility.

-

Tooling: The cost of tools and fixtures necessary for machining operations can be substantial, especially for custom parts. Tooling costs are often amortized over the production run, which makes them critical for high-volume orders.

-

Quality Control (QC): Ensuring that parts meet specified tolerances and quality standards involves inspection and testing, which adds to the overall cost. Certifications such as ISO 9001 can also influence pricing.

-

Logistics: Shipping and handling costs are significant, particularly for international orders. Incoterms and shipping methods can impact lead times and final pricing.

-

Margin: Suppliers will typically apply a margin to cover risks, business operations, and profit. Understanding this aspect can help buyers negotiate better terms.

How Do Price Influencers Affect the Cost of Stainless Steel CNC Machining?

Several factors influence the pricing of stainless steel CNC machining services:

-

Volume/MOQ: Higher order volumes often lead to reduced unit costs, as setup and tooling costs are distributed over more parts. Conversely, small batch sizes may incur higher per-part costs due to increased setup times.

-

Specifications and Customization: Custom designs and specific tolerances can drive costs up. Providing detailed specifications and optimized designs can help mitigate these expenses.

-

Material Quality and Certifications: Parts requiring specific certifications or advanced materials will typically be more expensive. Buyers should assess the necessity of certifications based on their industry requirements.

-

Supplier Factors: Different suppliers may offer varying pricing structures based on their operational efficiencies, geographic location, and market positioning. Building long-term relationships can sometimes yield better pricing.

-

Incoterms: The chosen Incoterms can significantly affect logistics costs. Buyers should be clear about responsibilities for shipping, insurance, and tariffs, especially in international transactions.

What Negotiation Strategies Can Buyers Employ for Cost-Efficiency?

When sourcing stainless steel CNC machining services, B2B buyers can implement several strategies to achieve cost efficiency:

-

Negotiate Volume Discounts: Discuss potential discounts for larger orders upfront. Suppliers are often willing to negotiate when it means securing a larger volume of business.

-

Optimize Designs: Collaborate with suppliers to ensure designs are optimized for manufacturability. This can reduce machining time and lower costs.

-

Evaluate Total Cost of Ownership (TCO): Consider not only the initial costs but also the long-term implications of part durability, maintenance, and replacement. A more expensive part may ultimately offer better value.

-

Understand Pricing Nuances: International buyers, particularly from regions like Africa, South America, and the Middle East, should be aware of how tariffs, currency fluctuations, and regional supply chain dynamics can affect pricing.

Are There Any Disclaimer Considerations for Indicative Prices?

It’s crucial for buyers to understand that prices for stainless steel CNC machining services can vary widely based on the factors discussed. The indicative prices provided by suppliers may change due to market conditions, material costs, and specific project requirements. Buyers should always request updated quotes and clarify all terms before proceeding with orders to ensure alignment on expectations and budget.

Alternatives Analysis: Comparing stainless steel cnc machining services With Other Solutions

Understanding Alternatives in Stainless Steel CNC Machining Services

When considering the optimal manufacturing process for stainless steel components, it is crucial to evaluate alternatives to CNC machining. Different methodologies can offer varying benefits in terms of performance, cost, and application suitability. This analysis compares stainless steel CNC machining services with two viable alternatives: additive manufacturing and traditional machining processes.

Comparison Table

| Comparison Aspect | Stainless Steel CNC Machining Services | Additive Manufacturing (3D Printing) | Traditional Machining (Manual) |

|---|---|---|---|

| Performance | High precision and repeatability | Moderate precision; depends on technology used | Variable precision; skilled labor-dependent |

| Cost | Moderate to high; lower for high volumes | Generally lower for small batches; can be high for large parts | Often lower for simple parts; higher for complex designs |

| Ease of Implementation | Requires CAD design and CNC setup | Simple design upload; no tooling required | Requires skilled labor and tooling setup |

| Maintenance | Low; mostly machine upkeep | Low; maintenance of 3D printer | High; tools and machines require regular maintenance |

| Best Use Case | High-strength applications in industries like aerospace and medical | Rapid prototyping and low-volume production | Custom parts and repairs in low-tech industries |

What Are the Pros and Cons of Additive Manufacturing?

Additive manufacturing, commonly known as 3D printing, allows for the creation of parts layer by layer from a digital model. One of its most significant advantages is the ability to produce complex geometries that would be challenging or impossible with traditional methods. It is particularly beneficial for rapid prototyping and low-volume production due to its minimal setup time and reduced waste. However, the precision of 3D printing can vary significantly based on the specific technology used (e.g., FDM, SLA, SLS) and may not achieve the same level of strength and durability as stainless steel CNC machining. Additionally, material choices are limited compared to the wide range of stainless steel alloys available for CNC machining.

How Does Traditional Machining Compare to Stainless Steel CNC Machining Services?

Traditional machining encompasses manual processes such as milling, turning, and drilling, often operated by skilled machinists. While it can be cost-effective for simple parts, it generally lacks the precision and repeatability offered by CNC machining. This method is labor-intensive and requires significant setup time, especially for complex parts. Maintenance costs can also be higher due to the need for regular servicing of tools and machines. Traditional machining is suitable for custom parts and repairs in less demanding applications, making it a viable option when precision is not the top priority.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting the appropriate manufacturing method, B2B buyers should consider several factors, including the required precision, production volume, complexity of the part, and budget constraints. Stainless steel CNC machining is ideal for high-strength applications that demand accuracy and consistency, particularly in industries such as aerospace and medical. Alternatively, if the goal is rapid prototyping or creating complex geometries with lower initial costs, additive manufacturing may be the better choice. For simpler, low-volume projects or repairs, traditional machining could suffice. Ultimately, understanding the specific project requirements and potential trade-offs between methods will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for stainless steel cnc machining services

What Are the Key Technical Properties of Stainless Steel CNC Machining Services?

Understanding the essential technical properties of stainless steel is crucial for B2B buyers engaging in CNC machining services. Here are some of the most critical specifications:

Material Grade: What Is Its Importance in CNC Machining?

Stainless steel is categorized into various grades, each with unique properties suited for different applications. Common grades include 304, 316, and 17-4PH. For instance, 304 stainless steel offers excellent corrosion resistance and is ideal for food and beverage applications, while 316 provides enhanced resistance to chlorides, making it suitable for marine environments. Selecting the appropriate grade ensures that the final product meets the specific performance and durability requirements of your industry.

Tolerance: How Does It Affect the Quality of Machined Parts?

Tolerance refers to the permissible limit of variation in a physical dimension. It is vital for ensuring that parts fit together correctly and function as intended. In CNC machining, typical tolerances for metals range from ±0.005 inches to tighter specifications of ±0.001 inches. Understanding tolerances helps buyers specify their requirements accurately, ultimately affecting the part’s functionality, assembly, and lifespan.

Surface Finish: Why Is It Critical for Aesthetic and Functional Properties?

The surface finish of a machined part can significantly impact its performance and appearance. Common finishes include “as-machined,” which has a rougher texture, and polished finishes that enhance corrosion resistance and aesthetics. Buyers should specify the required surface finish to ensure the final product meets industry standards and client expectations, especially in sectors like aerospace and medical where both function and appearance are critical.

Ductility: What Role Does It Play in Machining?

Ductility is the ability of a material to deform under tensile stress, which is particularly important in machining operations. Stainless steel typically has high ductility, allowing it to be formed into complex shapes without cracking. This property is essential for industries that require intricate designs, such as automotive and aerospace, where component integrity is paramount.

What Are Common Trade Terms in Stainless Steel CNC Machining?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms you should know:

What Does OEM Mean in the Context of CNC Machining?

OEM stands for Original Equipment Manufacturer. In the CNC machining context, it refers to companies that produce parts or components that are then used in another company’s end product. Understanding OEM relationships can help buyers identify potential suppliers who can meet their specific design and production needs.

MOQ: What Is It and Why Does It Matter?

MOQ, or Minimum Order Quantity, is the smallest number of units a supplier is willing to produce or sell. For B2B buyers, understanding MOQs is crucial for inventory management and budgeting. Suppliers may set MOQs to ensure cost-effectiveness in production, which can influence your purchasing strategy.

RFQ: How Does It Facilitate the Procurement Process?

RFQ stands for Request for Quotation. This document is used by buyers to solicit pricing and terms from suppliers for specific products or services. Submitting an RFQ allows you to compare offers from different suppliers, ensuring you receive competitive pricing and terms that align with your project requirements.

Incoterms: Why Are They Important for International Trade?

Incoterms, or International Commercial Terms, are a set of predefined commercial terms published by the International Chamber of Commerce (ICC). They clarify the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers navigate logistics and understand their obligations, ensuring smooth cross-border transactions.

By grasping these technical properties and industry terms, B2B buyers can make informed decisions when selecting stainless steel CNC machining services that align with their operational needs and project specifications.

Navigating Market Dynamics and Sourcing Trends in the stainless steel cnc machining services Sector

What Are the Current Market Dynamics and Key Trends in Stainless Steel CNC Machining Services?

The global market for stainless steel CNC machining services is experiencing robust growth, driven by several key factors. First, the increasing demand for high-strength, corrosion-resistant materials across various industries such as aerospace, automotive, and medical is propelling the need for stainless steel components. This trend is particularly pronounced in regions like Africa, South America, the Middle East, and Europe, where industrialization efforts are ramping up.

Technological advancements in CNC machining processes are also transforming the landscape. Innovations such as 5-axis machining, automated quoting systems, and the integration of AI for predictive maintenance are enhancing efficiency and precision. B2B buyers can now leverage platforms that offer instant quotes, lead time estimates, and design feedback, making the sourcing process faster and more transparent.

Emerging trends such as digital manufacturing and the rise of Industry 4.0 are reshaping supply chain dynamics. Buyers are increasingly looking for suppliers who can provide not only quality products but also flexible production capabilities, such as small-batch runs and rapid prototyping. Moreover, the emphasis on just-in-time manufacturing is influencing sourcing strategies, encouraging businesses to partner with CNC machining service providers who can offer reliable and quick turnaround times.

How Is Sustainability Influencing Sourcing Trends in Stainless Steel CNC Machining Services?

Sustainability has become a critical consideration in the sourcing of stainless steel CNC machining services. The environmental impact of manufacturing processes is under scrutiny, prompting B2B buyers to prioritize suppliers who demonstrate a commitment to sustainable practices. This includes the use of recycled materials, energy-efficient manufacturing techniques, and waste reduction strategies.

Ethical sourcing is gaining traction as businesses recognize the importance of transparent supply chains. Buyers are increasingly interested in suppliers who can provide certifications that affirm their adherence to environmental and social responsibility standards. Certifications such as ISO 14001 for environmental management and other ‘green’ labels can serve as indicators of a supplier’s commitment to sustainability.

Additionally, the availability of eco-friendly materials, including stainless steel alloys with lower carbon footprints, is becoming a deciding factor in procurement decisions. By aligning sourcing strategies with sustainability goals, B2B buyers can not only reduce their environmental impact but also enhance their brand reputation and meet regulatory requirements.

What Is the Historical Context of Stainless Steel CNC Machining Services?

The evolution of stainless steel CNC machining services can be traced back to the development of CNC technology in the mid-20th century. Initially, machining processes relied heavily on manual labor, which limited precision and scalability. The introduction of computer numerical control (CNC) revolutionized manufacturing by allowing for greater automation and accuracy.

As industries began to recognize the benefits of stainless steel—such as its strength, durability, and resistance to corrosion—the demand for CNC machining services grew. Over the decades, advancements in materials science and machining technology have further enhanced the capabilities of CNC machining, enabling the production of increasingly complex parts for diverse applications. Today, stainless steel CNC machining is integral to many high-tech industries, illustrating the material’s enduring value in modern manufacturing.

This historical context not only highlights the technological advancements in the sector but also underscores the importance of adapting to market trends and buyer demands in an ever-evolving landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of stainless steel cnc machining services

-

How do I select the right supplier for stainless steel CNC machining services?

Choosing the right supplier involves several key steps. First, assess their industry experience, particularly with stainless steel. Verify their certifications, such as ISO 9001 or AS9100, which indicate quality management standards. Additionally, review their portfolio to gauge their machining capabilities and previous projects. Request references and check reviews from other B2B clients to ensure reliability and quality. Finally, consider their communication responsiveness and logistical capabilities, especially if you’re sourcing from international suppliers. -

What are the common applications for stainless steel CNC machined parts?

Stainless steel CNC machining is widely used across various industries due to its strength and corrosion resistance. Common applications include medical instruments, aerospace components, automotive parts, and food processing equipment. The material’s durability makes it ideal for producing intricate machine parts, gears, and heavy construction equipment. Understanding your specific application will help you choose the appropriate stainless steel grade and machining process, ensuring optimal performance and longevity. -

What are the minimum order quantities (MOQs) for stainless steel CNC machining services?

Minimum order quantities can vary significantly among suppliers. Some may offer low MOQs for prototyping or small-batch production, while others might require larger quantities for cost efficiency. When sourcing internationally, it’s essential to clarify MOQs upfront, as this can impact shipping and production costs. If your needs are small, look for suppliers that specialize in rapid prototyping or flexible manufacturing solutions to meet your requirements without incurring unnecessary expenses. -

What payment terms should I expect when sourcing internationally?

Payment terms can differ widely based on supplier policies and the nature of the transaction. Common options include upfront deposits, payment upon delivery, or net terms (e.g., net 30 or net 60 days). For international transactions, consider using secure payment methods like letters of credit or escrow services to mitigate risks. Always clarify payment terms before finalizing contracts and ensure they align with your cash flow and budget management strategies. -

How can I ensure quality assurance in my stainless steel CNC machined parts?

Quality assurance can be maintained through several practices. First, verify that the supplier follows recognized quality standards, such as ISO certifications. Request detailed documentation, including material certifications and inspection reports, for the parts produced. Additionally, consider conducting third-party inspections or audits to ensure compliance with specifications. Establish clear communication regarding tolerances and quality expectations during the design phase to minimize discrepancies in the final product. -

What should I know about the logistics of international shipping for CNC machined parts?

When planning for international shipping, consider factors such as shipping methods, customs duties, and delivery timelines. Ensure your supplier has experience with international logistics and can provide options that suit your timeline and budget. Discuss who will handle customs clearance, as this can affect delivery times. Additionally, request quotes that include all shipping costs upfront to avoid unexpected expenses. Understanding local regulations in your destination country can also streamline the import process. -

What types of stainless steel are most commonly used in CNC machining?

The most commonly used stainless steel grades in CNC machining include 304, 316, and 17-4PH. Stainless steel 304 offers excellent corrosion resistance and is ideal for general applications, while 316 provides superior resistance in harsher environments, making it suitable for marine and chemical applications. 17-4PH is a precipitation-hardening steel known for its high strength and hardness, often used in aerospace and heavy-duty applications. Selecting the right alloy depends on your specific application requirements and environmental conditions. -

How do I request a quote for stainless steel CNC machining services?

To request a quote, start by preparing detailed specifications for your project, including material type, dimensions, tolerances, and finish requirements. Many suppliers offer online quoting tools where you can upload CAD files for a more accurate estimate. Be clear about your timeline and any specific requirements you may have. Once you submit your request, follow up with the supplier to discuss any questions they might have, ensuring that you receive a comprehensive and tailored quote for your needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Stainless Steel Cnc Machining Services Manufacturers & Suppliers List

1. Protolabs – Stainless Steel CNC Machining

Domain: protolabs.com

Registered: 2006 (19 years)

Introduction: Stainless Steel CNC Machining for custom parts. Key benefits include excellent machinability, outstanding uniformity, corrosion and oxidation resistance, leading to longer product life and lower total cost. Applications include medical instruments, machine parts, gears, parts for tractors, heavy construction equipment, and vacuum and pressure vessels. Available stainless steel alloys include 303, …

2. Hubs – Custom Stainless Steel CNC Services

Domain: hubs.com

Registered: 1998 (27 years)

Introduction: Stainless steel CNC services for custom stainless steel parts. Key features include:

– High tensile strength, corrosion and temperature resistance.

– Excellent mechanical properties, accuracy, and repeatability.

– Available materials include:

– Stainless steel 304/304L (1.4301/1.4307)

– Stainless steel 316/316L (1.4401/1.4404)

– Stainless steel 303 (1.4305)

– Stainless Steel 17-4 PH (1.454…

3. Action Stainless & Alloys – CNC Machining Services

Domain: actionstainless.com

Registered: 1999 (26 years)

Introduction: CNC Lathe and Mill services offered by Action Stainless & Alloys include precision machining for various materials. The company utilizes advanced CNC technology to ensure high accuracy and efficiency in production. They cater to a wide range of industries, providing custom solutions tailored to specific client needs. The services are suitable for both small and large production runs, emphasizing q…

4. RAM Tool – Custom CNC Machining Services for Stainless Steel Parts

Domain: ramtoolinc.com

Registered: 1999 (26 years)

Introduction: RAM Tool provides custom CNC machining services for stainless steel parts, utilizing advanced CAD design software and various CNC machining centers. Key stainless steel alloys processed include 15-5, 17-4, 304, 316, and 420. The company specializes in producing parts for industries such as aerospace, medical, automotive, and oil & gas. Services offered include 5-axis machining, CNC milling, CNC bo…

5. PCBWay – CNC Machining & 3D Printing Services

Domain: pcbway.com

Registered: 2012 (13 years)

Introduction: CNC Machining Service: Includes CNC Milling (3-, 4-, & full 5-axis) and CNC Turning. 3D Printing Service: Offers various methods including Stereolithography (SLA), Digital Light Processing (DLP), Fused Deposition Modeling (FDM), Selective Laser Melting (SLM), Selective Laser Sintering (SLS), PolyJet (PJ), and Vacuum Casting (VC). Sheet Metal Fabrication: Services include Laser Cutting and Bending….

Strategic Sourcing Conclusion and Outlook for stainless steel cnc machining services

In the evolving landscape of manufacturing, strategic sourcing for stainless steel CNC machining services presents a multitude of benefits for international B2B buyers. The exceptional machinability, corrosion resistance, and durability of stainless steel make it an ideal choice for various applications across industries such as medical, aerospace, and automotive. By leveraging advanced CNC technologies and a diverse range of stainless steel alloys, businesses can ensure high-quality, cost-effective solutions tailored to their specific needs.

As global markets continue to expand, particularly in regions like Africa, South America, the Middle East, and Europe, the importance of establishing reliable partnerships with certified machining suppliers cannot be overstated. These partnerships not only streamline production processes but also enhance product quality and reduce lead times, ultimately contributing to a competitive edge in the marketplace.

Looking ahead, international buyers should actively seek out suppliers who offer robust quality assurance measures, rapid prototyping capabilities, and flexible production options. Embracing these strategic sourcing practices will be pivotal in navigating the complexities of the global supply chain and fostering innovation. Engage with trusted CNC machining partners today to unlock the potential of stainless steel in your manufacturing operations.