Contents

Manufacturing Insight: Stainless Steel 3D Printing

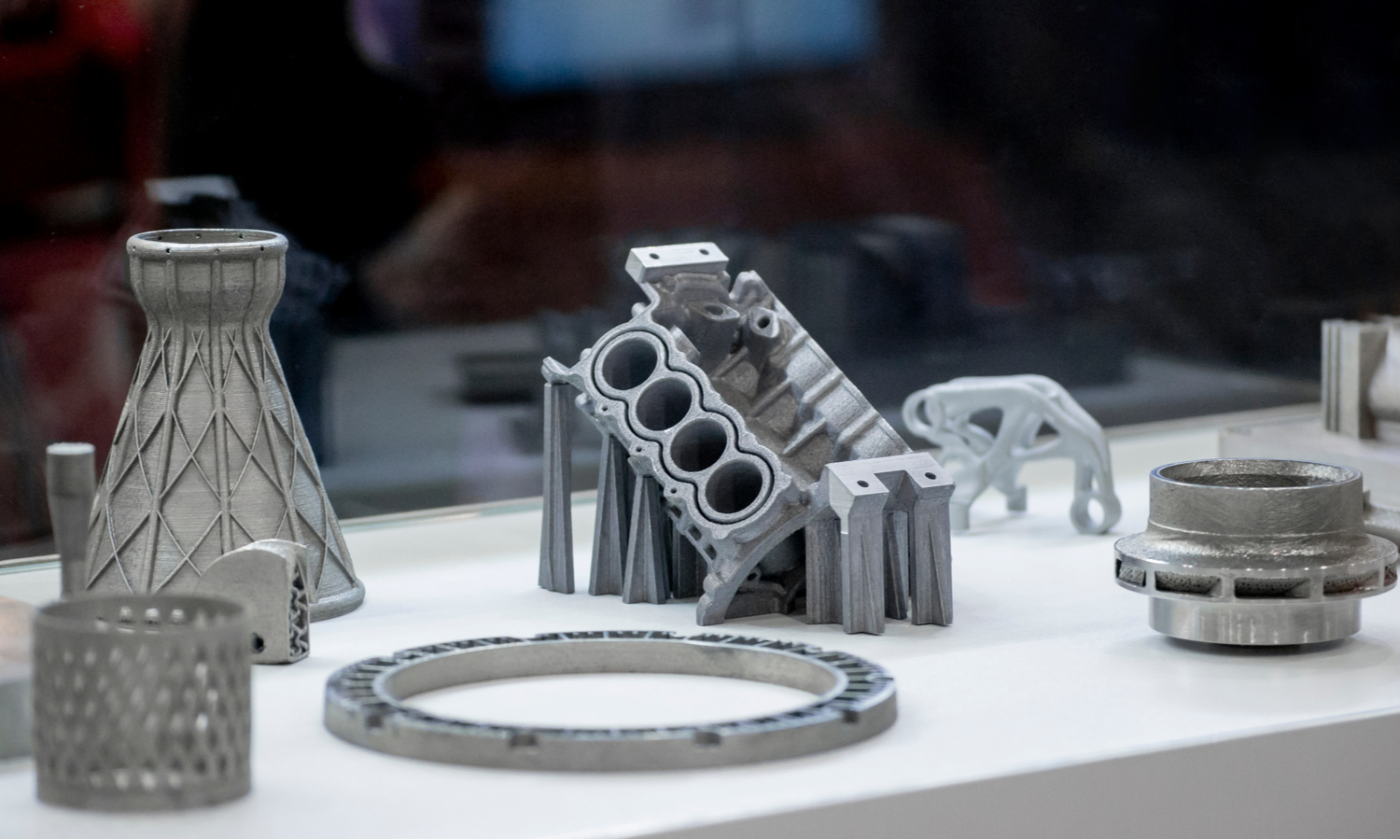

Industrial-Grade Stainless Steel 3D Printing Solutions from Honyo Prototype

Honyo Prototype delivers precision-engineered stainless steel components through advanced industrial additive manufacturing, meeting the rigorous demands of aerospace, medical, and high-performance industrial sectors. Our metal 3D printing services leverage state-of-the-art laser powder bed fusion technology to produce complex geometries in materials like 316L and 17-4 PH stainless steel, achieving exceptional mechanical properties, corrosion resistance, and surface finish unattainable through traditional methods. We maintain strict process control and in-house metallurgical expertise to ensure part integrity, dimensional accuracy, and repeatability for functional prototypes and end-use production.

Engineered for manufacturing scalability, our stainless steel printing solutions support rapid iteration and low-volume production without tooling constraints. Accelerate your development cycle with Honyo Prototype’s seamless integration of design validation, certified material processing, and post-build thermal treatment. Initiate your project immediately using our Online Instant Quote system, providing real-time cost and lead time estimates for qualified stainless steel 3D printing jobs, streamlining procurement for engineering teams.

Technical Capabilities

Stainless steel 3D printing is primarily associated with metal additive manufacturing processes such as Direct Metal Laser Sintering (DMLS), while technologies like Stereolithography (SLA), Selective Laser Sintering (SLS), and Multi Jet Fusion (MJF) are typically used for polymers or other metals. Below is a technical comparison of these processes with respect to their applicability to stainless steel and other common materials.

| Process | Primary Materials | Compatible with Stainless Steel | Typical Layer Thickness | Dimensional Accuracy | Surface Finish (Ra) | Build Volume Range (approx.) | Key Characteristics |

|---|---|---|---|---|---|---|---|

| SLA (Stereolithography) | Photopolymer resins (e.g., standard, engineering, castable) | No | 25–100 μm | ±0.1 mm | 0.5–1.0 μm | 145 x 145 x 185 mm to 1500 x 750 x 500 mm | High-resolution parts; not suitable for metals; excellent for visual prototypes and molds |

| SLS (Selective Laser Sintering) | Nylon (PA11, PA12), TPU, composites | No (standard process) | 80–120 μm | ±0.3 mm | 10–20 μm | 200 x 200 x 180 mm to 700 x 380 x 580 mm | Functional polymer parts; good mechanical properties; no support structures needed |

| MJF (Multi Jet Fusion) | Nylon (PA12), glass-filled nylon, TPU | No | 80–100 μm | ±0.3 mm | 5–15 μm | 380 x 280 x 380 mm | Faster than SLS; uniform mechanical properties; high-density functional parts |

| DMLS (Direct Metal Laser Sintering) | Stainless steel (e.g., 17-4 PH, 316L), titanium, aluminum, Inconel | Yes (core material) | 20–50 μm | ±0.1 mm | 10–20 μm (as-built); lower with post-processing | 250 x 250 x 325 mm to 500 x 400 x 400 mm | Full-density metal parts; high strength; complex geometries; aerospace and medical applications |

Notes on Material Compatibility:

Stainless Steel: Used almost exclusively in DMLS/SLM (Laser Beam Melting) processes. Common grades include 316L (corrosion-resistant) and 17-4 PH (precipitation-hardened for high strength).

Aluminum: Processed via DMLS using alloys such as AlSi10Mg; lightweight and thermally conductive; not used in SLA, SLS, or MJF.

Steel (Tool Steel, Maraging Steel): Also processed using DMLS; not compatible with polymer-based systems.

ABS (Acrylonitrile Butadiene Styrene): A thermoplastic not directly printable via SLS or MJF; however, ABS-like properties can be mimicked using high-performance nylons or composite materials in SLS/MJF.

Nylon (PA12, PA11): Primary material for SLS and MJF; offers good mechanical performance, chemical resistance, and durability; not applicable to DMLS or SLA.

In summary, stainless steel 3D printing is best achieved through DMLS technology. SLA, SLS, and MJF are polymer-focused processes and do not support stainless steel printing. Each process offers distinct advantages depending on the application, material requirements, and production volume.

From CAD to Part: The Process

Honyo Prototype executes stainless steel 3D printing through a rigorously controlled technical workflow designed for precision, repeatability, and manufacturability assurance. Our process integrates advanced automation with expert engineering oversight at critical stages to ensure optimal outcomes for demanding industrial applications.

CAD File Upload and Validation

Clients initiate the process by uploading native CAD files (STEP, IGES, or Parasolid formats preferred) via our secure customer portal. Our system performs immediate geometric validation, checking for manifold errors, minimum feature compliance relative to stainless steel powder bed processes (typically ≥ 0.4mm for SLS/DMLS), and watertightness. Non-conforming files trigger automated feedback detailing specific geometry issues before proceeding, preventing downstream delays.

AI-Powered Quoting Engine

Validated CAD data feeds into our proprietary AI quoting system. This engine calculates build time, material consumption (accounting for part density and support structure requirements), machine utilization, and post-processing labor. Material cost factors include specific stainless steel alloy pricing (e.g., 316L, 17-4PH), powder recycling rates, and energy consumption metrics. The AI cross-references historical production data from thousands of stainless steel builds to predict potential failure risks, generating a technically grounded quote with lead time estimates within 2 business hours. Human oversight validates AI outputs for complex geometries.

Engineering-Led DFM Analysis

All quotes undergo mandatory Design for Manufacturability (DFM) review by our senior AM engineers. This phase identifies critical stainless steel-specific concerns:

Overhang angles requiring support structures (threshold typically 45° for 316L)

Wall thickness optimization to prevent warpage during cooling (minimum 0.8mm recommended)

Internal channel accessibility for powder removal

Thermal stress concentration points requiring lattice structures

Build orientation impact on surface finish and mechanical properties

Engineers provide actionable revision suggestions via annotated reports, not merely rejection notices. Client approval of DFM recommendations is required before production release.

Stainless Steel Production Execution

Approved builds enter our certified production environment using industrial-grade EOS M 290 or SLM 280 systems. Key process controls include:

Argon atmosphere maintained at < 500ppm oxygen

Layer thickness optimized per alloy (20-50μm)

Real-time melt pool monitoring via coaxial cameras

In-situ temperature mapping for thermal management

Post-build, parts undergo standardized stainless steel post-processing:

1. Controlled powder removal in inert atmosphere cabinets

2. Support structure removal via band saw or wire EDM

3. Stress relief annealing per AMS 5643 specifications

4. Optional HIP treatment for critical aerospace components

5. Precision machining of critical interfaces

6. Surface finishing (vibratory, bead blast, or electro-polish)

Quality-Controlled Delivery

Each shipment includes comprehensive documentation:

First Article Inspection report with CMM data (AS9102 format available)

Material test certificates traceable to heat number

Process parameter logs from build chamber

Post-processing validation records

Parts are packaged in anti-corrosion VCI bags with humidity indicators. Standard lead time is 7-10 business days from DFM approval, with expedited options validated through our capacity planning dashboard.

Critical stainless steel alloy properties achieved through this process include:

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| 316L | 550-650 | 250-350 | 30-45 | Excellent (marine) | Marine components, medical implants |

| 17-4PH | 1000-1300 | 850-1000 | 12-18 | Good (mild env.) | Aerospace brackets, tooling |

This integrated approach ensures Honyo delivers fully qualified stainless steel AM components meeting ASTM F75, ISO/ASTM 52900, and industry-specific regulatory requirements while minimizing time-to-part for our engineering partners.

Start Your Project

Looking for high-precision stainless steel 3D printing for your next project? Honyo Prototype offers advanced metal additive manufacturing services with fast turnaround and strict quality control. Our in-house facility in Shenzhen ensures cost-effective production and seamless scalability from prototype to pilot run.

Contact Susan Leo today at [email protected] to discuss your design requirements and receive a competitive quote.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.