Introduction: Navigating the Global Market for ss 303 hardness

In the competitive landscape of global manufacturing, sourcing stainless steel that meets specific hardness requirements is a critical challenge for B2B buyers, particularly when considering materials like ss 303 hardness. This guide aims to demystify the complexities surrounding AISI Type 303 stainless steel, providing valuable insights into its properties, applications, and advantages for various industries. From understanding the mechanical and thermal properties to exploring the nuances of supplier vetting and cost considerations, this comprehensive resource is designed to empower international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Nigeria and Germany.

As industries increasingly rely on stainless steel for its durability and resistance to corrosion, making informed purchasing decisions becomes paramount. This guide not only outlines the technical specifications and performance characteristics of ss 303 but also highlights best practices in supplier selection and negotiation strategies. By equipping buyers with the knowledge to evaluate different suppliers and products effectively, we aim to facilitate successful sourcing processes that meet project timelines and budget constraints. Ultimately, this resource is your go-to tool for navigating the global market for ss 303 hardness, ensuring that you secure the right materials for your business needs while maximizing value.

Understanding ss 303 hardness Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cold Drawn | Higher hardness, improved surface finish, and dimensional accuracy. | Precision components, fasteners, valves | Pros: Excellent machinability; Cons: Higher cost due to processing. |

| Annealed | Lower hardness, increased ductility, and improved corrosion resistance. | General fabrication, automotive parts | Pros: Easier to work with; Cons: Weaker mechanical properties. |

| Hardened | Enhanced hardness and strength through heat treatment. | Cutting tools, wear-resistant applications | Pros: Superior durability; Cons: Reduced machinability. |

| 303 Se | Contains selenium for improved machinability and surface finish. | Aerospace, medical devices | Pros: Enhanced machinability; Cons: Slightly lower corrosion resistance compared to standard 303. |

| 303 S | Standard grade with balanced hardness and corrosion resistance. | Food processing, chemical handling | Pros: Versatile and widely available; Cons: Moderate strength compared to hardened variants. |

What Are the Characteristics of Cold Drawn SS 303 Hardness?

Cold drawn SS 303 exhibits a higher hardness due to the cold drawing process, which enhances its surface finish and dimensional accuracy. This variant is ideal for precision components such as fasteners and valves, where tight tolerances are crucial. Buyers should consider the higher costs associated with this processing method, but the benefits in performance and appearance often justify the investment.

How Does Annealed SS 303 Compare in Terms of Ductility?

Annealed SS 303 is characterized by lower hardness levels, resulting in increased ductility and improved corrosion resistance. This makes it suitable for general fabrication and automotive parts, where ease of machining is essential. While its mechanical properties may be weaker than those of hardened variants, the ease of processing and flexibility can be advantageous in various applications.

What Advantages Does Hardened SS 303 Offer for B2B Applications?

Hardened SS 303 is achieved through a heat treatment process that significantly enhances hardness and strength. It is particularly useful in applications requiring high durability, such as cutting tools and wear-resistant components. However, buyers should note that the increased hardness can lead to reduced machinability, which may affect production timelines and costs.

What Are the Benefits of Using 303 Se Stainless Steel?

303 Se stainless steel includes selenium, which improves machinability and surface finish. This variant is commonly used in aerospace and medical devices, where precision is critical. While it offers enhanced machinability, buyers should be aware that it may have slightly lower corrosion resistance compared to standard 303, necessitating careful consideration based on application requirements.

Why Choose Standard 303 S for Versatility?

Standard 303 S stainless steel provides a balanced combination of hardness and corrosion resistance, making it a versatile choice for various applications, including food processing and chemical handling. Its widespread availability makes it a practical option for buyers. However, its moderate strength compared to hardened variants may require consideration depending on the specific demands of the application.

Key Industrial Applications of ss 303 hardness

| Industry/Sector | Specific Application of ss 303 hardness | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Precision machined components | High corrosion resistance and durability | Ensure compliance with automotive standards and specifications. |

| Oil & Gas | Fasteners and fittings | Enhanced strength under high-pressure conditions | Evaluate the hardness and corrosion resistance for specific environments. |

| Food Processing | Equipment parts and tools | Non-reactive surface with easy cleaning | Confirm compliance with food safety regulations and standards. |

| Aerospace | Structural components | High strength-to-weight ratio | Focus on material certification and performance in extreme conditions. |

| Medical Devices | Surgical instruments | Sterilizable, corrosion-resistant properties | Verify compatibility with medical regulations and standards. |

How is ss 303 hardness utilized in the Automotive Industry?

In the automotive sector, ss 303 hardness is critical for manufacturing precision machined components such as fasteners, bushings, and brackets. The hardness of this stainless steel grade contributes to its ability to withstand harsh conditions, including exposure to fluids and high temperatures. For international buyers, particularly those in Africa and Europe, sourcing components that meet specific automotive standards is essential to ensure safety and performance. Additionally, buyers should consider the supplier’s ability to provide certified materials that comply with industry regulations.

What role does ss 303 hardness play in the Oil & Gas Industry?

In the oil and gas industry, ss 303 hardness is often utilized in the production of fasteners and fittings that must endure extreme pressure and corrosive environments. The hardness of this stainless steel allows for the manufacture of reliable components that maintain integrity under challenging conditions. For buyers from regions such as South America and the Middle East, it is crucial to assess the material’s performance in specific applications, such as offshore drilling or pipeline construction. Suppliers should provide detailed information on the hardness and corrosion resistance of their products.

Why is ss 303 hardness important in Food Processing?

In food processing, ss 303 hardness is valued for its non-reactive properties, making it ideal for equipment parts and tools that come into contact with food products. The hardness ensures durability and resistance to wear, facilitating a longer lifespan for equipment. For international buyers, particularly in regions with strict food safety regulations, verifying that the sourced materials comply with these standards is vital. Suppliers should provide documentation proving that their products meet health and safety guidelines.

How does ss 303 hardness benefit the Aerospace Sector?

The aerospace industry benefits from ss 303 hardness by using it in structural components where a high strength-to-weight ratio is necessary. The hardness contributes to the material’s ability to withstand the rigorous demands of flight, including temperature fluctuations and mechanical stress. Buyers, especially those in Europe, need to prioritize sourcing from manufacturers who can certify that their materials meet aerospace industry standards and can perform under extreme conditions.

What advantages does ss 303 hardness offer for Medical Devices?

In the medical device industry, ss 303 hardness is essential for manufacturing surgical instruments that require corrosion resistance and the ability to be sterilized. The hardness ensures that these instruments maintain their sharpness and structural integrity over time. Buyers in Africa and other regions must ensure that their suppliers adhere to medical regulations, providing materials that are not only hard but also safe for patient use. This includes verifying the quality assurance processes of the manufacturers.

3 Common User Pain Points for ‘ss 303 hardness’ & Their Solutions

Scenario 1: Difficulty in Maintaining Consistent Hardness Levels

The Problem:

B2B buyers often encounter challenges related to the variability in hardness levels of SS 303 stainless steel due to differences in manufacturing processes or material batches. Inconsistent hardness can lead to complications during machining or forming operations, resulting in increased production costs, delays, and potential failures in end-use applications. For industries such as automotive or aerospace, where precision is paramount, this inconsistency can jeopardize product integrity and lead to costly rework or recalls.

The Solution:

To ensure consistent hardness levels, buyers should prioritize sourcing SS 303 from reputable suppliers who adhere to strict quality control measures and industry standards, such as ASTM or ISO certifications. Before placing orders, it’s beneficial to request detailed material certifications and hardness test reports that verify compliance with the specified hardness levels. Additionally, establishing long-term relationships with suppliers can facilitate better traceability of material batches and enhance communication regarding any potential changes in material properties. Implementing rigorous in-house testing protocols during incoming inspections can further mitigate risks associated with variability in hardness.

Scenario 2: Challenges with Machining SS 303 Stainless Steel

The Problem:

Machining SS 303 can present unique difficulties, particularly when it comes to managing tool wear and achieving desired surface finishes. Buyers may find that while SS 303 is designed for improved machinability, factors such as hardness levels, cutting tool material, and machining parameters can significantly impact production efficiency. Inadequate cutting tools or incorrect machining speeds can lead to increased tool wear, reduced productivity, and higher operational costs.

The Solution:

To effectively address these machining challenges, buyers should invest in high-quality cutting tools specifically designed for stainless steel applications, such as carbide or high-speed steel tools with appropriate coatings. Furthermore, conducting thorough pre-production trials to determine optimal cutting speeds, feeds, and depths can help identify the most efficient machining parameters. Regularly monitoring tool performance and implementing predictive maintenance strategies can also enhance operational efficiency. Collaborating with tool manufacturers for technical support can provide additional insights into best practices for machining SS 303, ensuring better outcomes and reduced costs.

Scenario 3: Corrosion Resistance and Environmental Factors Affecting Hardness

The Problem:

B2B buyers often face the issue of corrosion resistance in SS 303, which, while known for its good corrosion resistance, can still be susceptible to environmental factors, especially in humid or corrosive settings. Over time, exposure to such conditions can lead to pitting or stress corrosion cracking, which may compromise the material’s hardness and overall performance. This is particularly critical for applications in marine or chemical processing environments.

The Solution:

To combat corrosion-related issues, buyers should consider specifying SS 303 with additional alloying elements or opt for surface treatments that enhance corrosion resistance. For instance, electropolishing or passivation processes can significantly improve the surface quality and resistance to corrosion. Additionally, buyers should evaluate the environmental conditions where the material will be used and consider switching to higher-grade stainless steels, such as SS 316, if the application involves exposure to harsh environments. Regular maintenance and inspections can help identify any early signs of corrosion, allowing for timely interventions before significant damage occurs.

Strategic Material Selection Guide for ss 303 hardness

What Are the Key Properties of AISI Type 303 Stainless Steel?

AISI Type 303 stainless steel is renowned for its excellent machinability and corrosion resistance, making it a popular choice in various industries. It typically contains 18% chromium and 9% nickel, which contribute to its durability and resistance to oxidation. The hardness of AISI Type 303 is measured at approximately 228 Brinell, which indicates a balance between strength and ductility. This material performs well in environments with moderate temperatures and pressures, making it suitable for applications like fasteners, fittings, and various components in machinery.

What Are the Advantages and Disadvantages of Using AISI Type 303?

Pros:

– Machinability: AISI Type 303 is one of the easiest stainless steels to machine, which can lead to lower manufacturing costs and faster production times.

– Corrosion Resistance: It offers good resistance to a variety of corrosive environments, making it suitable for food processing, chemical handling, and marine applications.

– Ductility: The material can withstand deformation, which is beneficial for components that require bending or shaping.

Cons:

– Cost: While generally affordable, it can be more expensive than lower-grade stainless steels, which may affect budget-sensitive projects.

– Not Ideal for High-Temperature Applications: AISI Type 303 has limitations in high-temperature environments, which may necessitate alternative materials for certain applications.

How Does AISI Type 303 Impact Specific Applications?

The compatibility of AISI Type 303 with various media makes it a versatile choice for many applications. Its resistance to rust and corrosion ensures longevity in environments exposed to moisture or chemicals. However, its performance diminishes in extreme heat or highly acidic conditions, which could lead to material degradation. Therefore, it is essential for buyers to evaluate the specific conditions under which the material will be used.

What Should International B2B Buyers Consider When Selecting AISI Type 303?

For international B2B buyers, compliance with regional standards is crucial. AISI Type 303 adheres to various international standards such as ASTM, DIN, and JIS, which may vary by region. Buyers from Africa, South America, the Middle East, and Europe should ensure that the material meets local regulations and quality standards. Additionally, understanding the supply chain logistics, including import tariffs and shipping times, can significantly impact procurement decisions.

Summary Table of Material Selection for AISI Type 303

| Material | Typical Use Case for ss 303 hardness | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| AISI Type 303 | Fasteners, fittings, and machinery parts | Excellent machinability and corrosion resistance | Not suitable for high-temperature applications | Medium |

| AISI Type 304 | Food processing equipment | Higher corrosion resistance than 303 | More expensive than Type 303 | High |

| AISI Type 316 | Marine applications, chemical processing | Superior corrosion resistance, especially against chlorides | Higher cost and more difficult to machine | High |

| AISI Type 430 | Automotive trim and appliances | Cost-effective and good corrosion resistance | Lower strength and ductility than austenitic grades | Low |

This table summarizes the key considerations for B2B buyers when selecting materials with similar hardness to AISI Type 303, offering insights into their applications, advantages, disadvantages, and relative costs.

In-depth Look: Manufacturing Processes and Quality Assurance for ss 303 hardness

What Are the Key Manufacturing Processes for SS 303 Hardness?

The manufacturing of SS 303 stainless steel involves several critical stages, each designed to ensure the final product meets specific hardness and quality requirements. Understanding these stages can help B2B buyers make informed decisions when sourcing SS 303 products.

How Is Material Prepared for SS 303 Stainless Steel?

The first step in the manufacturing process is material preparation, which involves selecting high-quality raw materials. SS 303 typically consists of iron, chromium, nickel, and sulfur. The material is often sourced from reputable suppliers who can provide documentation on the chemical composition and mechanical properties.

Once the raw materials are selected, they undergo melting and refining processes. This may involve electric arc furnaces or induction melting techniques to achieve the desired alloy composition. The molten steel is then cast into ingots or billets, which are cooled and shaped for further processing.

What Forming Techniques Are Used in SS 303 Manufacturing?

After material preparation, the next stage is forming. Common techniques for shaping SS 303 include hot rolling and cold drawing.

-

Hot Rolling involves heating the billets above their recrystallization temperature, allowing them to be easily shaped into desired forms. This method is beneficial for producing larger sections and reducing material defects.

-

Cold Drawing is utilized to achieve finer tolerances and enhanced surface finishes. This process pulls the material through a die, which not only shapes it but also increases its strength and hardness through strain hardening.

Both techniques are crucial in achieving the desired hardness levels, with cold-drawn SS 303 typically reaching a hardness of around 228 Brinell, making it suitable for various applications.

What Are the Finishing Processes for SS 303 Products?

Finishing processes are essential to ensure the final product meets the required specifications for hardness and surface quality. Common finishing techniques include:

-

Annealing: This heat treatment process helps relieve stresses introduced during forming, ensuring a consistent hardness throughout the material. It is particularly important for achieving the desired mechanical properties in SS 303.

-

Surface Treatment: Processes like pickling and passivation are used to enhance corrosion resistance. This not only improves the aesthetic appeal of the final product but also extends its service life in corrosive environments.

-

Machining: For applications requiring precise dimensions, machining operations such as turning, milling, or grinding are performed. These processes also help achieve the desired surface finish and tolerances.

How Is Quality Assurance Implemented in SS 303 Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for SS 303 stainless steel. Effective QA ensures that the material meets international standards and customer specifications.

What International Standards Are Relevant for SS 303 Quality Assurance?

Several international standards govern the quality assurance processes in the manufacturing of SS 303. Key standards include:

-

ISO 9001: This standard focuses on quality management systems, ensuring that organizations consistently meet customer and regulatory requirements. It emphasizes continuous improvement and customer satisfaction.

-

ASTM Standards: Various ASTM specifications outline the requirements for stainless steel products, including mechanical properties, chemical composition, and testing methods.

-

CE Marking: For products sold in Europe, CE marking indicates compliance with EU safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are essential throughout the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. Documentation such as certificates of analysis should be reviewed.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are performed to ensure that processes remain within defined parameters. This may include monitoring temperatures during annealing or measuring hardness at various stages.

-

Final Quality Control (FQC): Before shipping, a comprehensive inspection is conducted. This includes testing for mechanical properties, dimensional accuracy, and surface quality. Common testing methods for SS 303 include hardness tests (Brinell, Rockwell), tensile strength tests, and visual inspections.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must ensure that their suppliers adhere to strict quality control measures. Here are effective strategies to verify supplier QC:

What Audits and Reports Should Buyers Request?

-

Supplier Audits: Conducting regular audits of suppliers allows buyers to assess compliance with quality standards and practices. This can include reviewing production processes, quality control measures, and employee training programs.

-

Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s QC processes. This should include results from mechanical testing, chemical analysis, and any corrective actions taken in response to non-conformities.

How Can Third-Party Inspections Enhance Confidence?

Engaging third-party inspection agencies can add an extra layer of assurance. These agencies are independent and can provide unbiased assessments of the supplier’s compliance with quality standards. They can perform on-site inspections, testing, and certification, ensuring that the products meet the required specifications.

What Nuances Should International B2B Buyers Consider?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital.

-

Documentation Requirements: Different regions may have varying documentation requirements for imports. Buyers should familiarize themselves with local regulations and ensure that suppliers provide all necessary certifications.

-

Cultural and Communication Factors: Effective communication is crucial in international transactions. Buyers should establish clear expectations regarding quality standards and timelines to avoid misunderstandings.

-

Logistics and Supply Chain Considerations: Understanding the logistics involved in transporting SS 303 products can impact quality. Buyers should consider factors such as temperature control during shipping, which can affect material properties.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance protocols for SS 303 hardness is essential for B2B buyers. By focusing on material preparation, forming techniques, finishing processes, and robust quality control measures, buyers can ensure they source high-quality stainless steel products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ss 303 hardness’

Introduction

This practical sourcing guide aims to assist international B2B buyers in procuring stainless steel 303 (SS 303) with specific hardness requirements. With its excellent machinability and corrosion resistance, SS 303 is a popular choice in various industrial applications. This checklist will help you navigate the procurement process effectively, ensuring you select the right material and supplier for your needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring that the SS 303 material meets your application’s requirements. Consider the desired hardness level, tensile strength, and elongation properties, which are critical for performance in specific environments. For instance, the hardness of SS 303 typically ranges from 160 to 228 Brinell, depending on its treatment, so specify whether you need cold-drawn or annealed forms.

Step 2: Research Industry Standards and Certifications

Familiarize yourself with relevant industry standards and certifications that apply to SS 303. Look for compliance with ASTM, ASME, and other recognized organizations, which ensure that the material meets specific quality and safety requirements. Certification can also indicate a supplier’s commitment to quality management systems, which is crucial for long-term reliability.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct a thorough evaluation. Request detailed company profiles, including case studies and references from clients in similar industries or regions. Assess their production capabilities and quality assurance processes to ensure they can consistently deliver the required SS 303 hardness specifications.

Step 4: Request Material Test Reports

Always request material test reports from your suppliers. These documents should include data on hardness, tensile strength, and other mechanical properties tested under standard conditions. Verified test reports provide confidence that the SS 303 you’re sourcing meets your technical specifications and industry standards.

Step 5: Negotiate Terms and Conditions

Engage in negotiations with potential suppliers to clarify terms and conditions, including pricing, delivery schedules, and payment terms. Establishing clear terms upfront can prevent misunderstandings later in the process. Ensure that both parties agree on the specifications and any penalties for non-compliance with quality standards.

Step 6: Assess Logistics and Supply Chain Reliability

Evaluate the logistics capabilities of your chosen supplier. Consider factors such as shipping times, customs handling, and local market conditions that could affect delivery. Reliable supply chain management is essential to minimize delays and ensure you receive your SS 303 on time, especially when working on tight deadlines.

Step 7: Plan for Quality Control Upon Receipt

Once the SS 303 material is delivered, implement a quality control plan to verify that it meets your specifications. Conduct inspections and tests on the received material, comparing the results against the initial requirements and test reports. This step is crucial to ensure that the material will perform as expected in your applications, safeguarding your investment and reputation.

Comprehensive Cost and Pricing Analysis for ss 303 hardness Sourcing

When considering the sourcing of SS 303 hardness, understanding the comprehensive cost structure is essential for B2B buyers. The total cost comprises several key components, each influencing the final pricing of this material.

What Are the Main Cost Components for SS 303 Hardness?

-

Materials: The primary cost driver in sourcing SS 303 hardness is the raw material itself. The composition includes chromium, nickel, and sulfur, among other elements, which are subject to market fluctuations. Prices can vary based on global supply and demand, impacting the overall cost.

-

Labor: Labor costs encompass the workforce involved in manufacturing and processing the stainless steel. Factors such as local wage rates and skill levels can significantly affect these expenses. For instance, regions with higher labor costs may see an increase in the overall price of SS 303 products.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize these overhead costs, making it crucial for buyers to assess the production capabilities of potential suppliers.

-

Tooling: The cost of tooling is essential for custom specifications. If specialized tools are required to produce specific shapes or sizes of SS 303, these costs will be reflected in the final price. Buyers should inquire about tooling costs when seeking customized solutions.

-

Quality Control (QC): Ensuring that SS 303 meets specified hardness and other mechanical properties involves rigorous testing and quality assurance processes. The expenses related to these activities can vary based on the complexity of testing required.

-

Logistics: Transportation and shipping costs can be significant, especially for international buyers. Factors such as distance, mode of transport, and customs duties play a role in logistics costs. Understanding these elements can help buyers make informed decisions about their sourcing strategy.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on the supplier’s business model and market position. Buyers should be aware of this when negotiating prices.

How Do Price Influencers Affect SS 303 Hardness Costs?

Several factors can influence the pricing of SS 303 hardness:

-

Volume/MOQ: Minimum Order Quantities (MOQ) can significantly impact unit prices. Larger orders often lead to lower per-unit costs, creating an incentive for buyers to consolidate their purchases.

-

Specifications and Customization: Custom specifications may require additional processing or materials, increasing costs. Buyers should balance their need for customization with cost-effectiveness.

-

Materials Quality and Certifications: The quality of the raw materials and any certifications (e.g., ISO, ASTM) can influence pricing. Higher quality materials typically command a premium.

-

Supplier Factors: Supplier reputation, reliability, and location can affect pricing. Established suppliers may have more stable pricing, while newer entrants might offer lower prices to attract business.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can dictate shipping responsibilities and costs, influencing the total landed cost of the product.

What Are the Best Negotiation Tips for B2B Buyers Sourcing SS 303 Hardness?

-

Understand Total Cost of Ownership (TCO): Buyers should evaluate not just the upfront costs but the long-term implications of sourcing decisions, including maintenance and operational costs.

-

Leverage Volume Discounts: Consider consolidating orders or partnering with other businesses to meet higher MOQ thresholds for better pricing.

-

Compare Multiple Suppliers: Solicit quotes from various suppliers to gauge the market price and negotiate better terms based on comparative data.

-

Clarify Specifications Early: Clearly define specifications and quality requirements upfront to avoid unexpected costs later in the sourcing process.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and preferential treatment in future transactions.

Disclaimer

Prices for SS 303 hardness can vary widely based on market conditions and specific requirements. Buyers should conduct thorough research and obtain multiple quotes to ensure they receive fair pricing reflective of their unique needs.

Alternatives Analysis: Comparing ss 303 hardness With Other Solutions

Introduction to Alternative Solutions for SS 303 Hardness

When evaluating materials for industrial applications, it is essential to consider alternatives to AISI Type 303 stainless steel, particularly regarding hardness. While SS 303 is known for its excellent machinability and moderate corrosion resistance, other materials may offer distinct advantages depending on specific application requirements. This analysis compares SS 303 hardness with two viable alternatives: SS 304 and SS 316 stainless steels, allowing B2B buyers to make informed decisions based on their unique needs.

Comparison Table

| Comparison Aspect | SS 303 Hardness | SS 304 Hardness | SS 316 Hardness |

|---|---|---|---|

| Performance | Brinell: 228 | Brinell: 201 | Brinell: 217 |

| Cost | Moderate | Moderate | Higher |

| Ease of Implementation | Easy to machine | Easy to machine | Moderate, requires more care |

| Maintenance | Low | Low | Low |

| Best Use Case | General machining | Food and beverage industry | Marine and chemical applications |

Detailed Breakdown of Alternatives

1. SS 304 Stainless Steel

SS 304 stainless steel is a widely used material known for its balance of strength, corrosion resistance, and ease of fabrication. With a lower hardness value (Brinell 201), it is slightly softer than SS 303, which can be advantageous in applications requiring more ductility. This makes it ideal for environments such as food and beverage processing, where hygiene and ease of cleaning are paramount. However, its lower hardness may lead to quicker wear in high-stress applications compared to SS 303.

2. SS 316 Stainless Steel

SS 316 is often considered a premium stainless steel due to its enhanced corrosion resistance, particularly against chlorides and other harsh environments. With a Brinell hardness of 217, it provides a good balance between strength and ductility. This makes it a preferred choice for marine applications and chemical processing. However, the higher cost and slightly more complex machining process can be a drawback for some buyers. Its resilience in demanding environments justifies its use in critical applications where failure is not an option.

Conclusion: Choosing the Right Solution for Your Needs

In selecting the right stainless steel for your application, consider the specific requirements of your project, including performance, cost, and environmental conditions. SS 303 offers excellent machinability and moderate hardness, making it suitable for general applications. On the other hand, SS 304 is ideal for food-related uses, while SS 316 excels in highly corrosive environments. By carefully evaluating these factors, B2B buyers can make a well-informed decision that aligns with their operational objectives and budget constraints.

Essential Technical Properties and Trade Terminology for ss 303 hardness

What Are the Key Technical Properties of SS 303 Hardness?

-

Material Grade

SS 303, also known as AISI Type 303, is an austenitic stainless steel known for its excellent machinability. It contains approximately 18% chromium and 9% nickel, making it resistant to corrosion and oxidation. For B2B buyers, selecting the right material grade is crucial for ensuring the longevity and reliability of components in various industrial applications, especially in environments that demand high performance. -

Hardness Levels

The hardness of SS 303 is measured using several scales, including Brinell (228 HB), Knoop (251 HK), Rockwell B (96 HRB), and Vickers (240 HV). These hardness metrics indicate the material’s resistance to deformation and wear. Understanding hardness is essential for manufacturers and OEMs (Original Equipment Manufacturers) to ensure that components can withstand operational stresses and maintain structural integrity. -

Tensile Strength

SS 303 exhibits a tensile strength of approximately 690 MPa (100,000 psi) and a yield strength of 415 MPa (60,200 psi). This property defines the maximum load the material can handle without permanent deformation. Buyers should consider tensile strength when selecting materials for applications requiring high strength and durability, such as fasteners and structural components. -

Elongation at Break

With an elongation at break of around 40%, SS 303 demonstrates good ductility, allowing it to be formed into various shapes without fracturing. This is particularly advantageous in applications where complex geometries are needed. For B2B customers, understanding elongation helps in assessing how well the material can be processed or fabricated into finished goods. -

Density and Thermal Properties

The density of SS 303 is about 8 g/cc (0.289 lb/in³), and it has a melting point ranging from 1400 to 1420 °C (2550 to 2590 °F). These properties are vital for applications involving high temperatures or specific weight requirements. B2B purchasers should evaluate these properties to ensure compatibility with their intended use, especially in industries like aerospace and automotive.

What Are Common Trade Terms Related to SS 303 Hardness?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM specifications is critical for buyers to ensure that the components they source meet the necessary quality and performance standards. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ helps in budgeting and inventory management, especially when sourcing specialized materials like SS 303. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. This is an essential step in the procurement process, allowing buyers to compare costs and ensure they receive competitive pricing for SS 303 materials. -

Incoterms (International Commercial Terms)

These are a set of predefined commercial terms used in international trade, defining responsibilities of buyers and sellers. Familiarity with Incoterms is crucial for B2B transactions involving SS 303, as they clarify shipping responsibilities, risk transfer, and cost allocation. -

Heat Treatment

Heat treatment refers to the controlled heating and cooling of materials to alter their physical and sometimes chemical properties. For SS 303, understanding how heat treatment affects hardness and other mechanical properties is essential for manufacturers to achieve desired performance characteristics. -

Machinability

This term describes how easily a material can be machined to create desired shapes and features. SS 303 is noted for its excellent machinability, making it a preferred choice for parts requiring intricate designs. For B2B buyers, evaluating machinability ensures efficiency in production processes and cost-effectiveness in manufacturing.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing SS 303 hardness materials, ensuring they meet both their operational needs and quality standards.

Navigating Market Dynamics and Sourcing Trends in the ss 303 hardness Sector

What Are the Key Trends Affecting the Global ss 303 Hardness Market?

The ss 303 hardness market is experiencing a dynamic transformation influenced by several global drivers. Key trends include the increasing demand for high-performance materials in various industries such as automotive, aerospace, and manufacturing, particularly in regions like Africa, South America, the Middle East, and Europe. The rise of advanced manufacturing technologies, including 3D printing and automation, is reshaping sourcing strategies, enabling manufacturers to optimize production processes and reduce lead times.

Moreover, international buyers are placing greater emphasis on sourcing materials that not only meet stringent performance specifications but also offer competitive pricing. This has led to an increased focus on supply chain resilience, with businesses seeking reliable suppliers who can ensure consistent quality and delivery. The integration of digital procurement platforms is becoming prevalent, allowing buyers to streamline their sourcing processes and engage with suppliers in real-time, thereby enhancing transparency and efficiency.

Another emerging trend is the shift towards customization and specialized applications for ss 303 hardness, which is particularly relevant for sectors requiring tailored solutions. As industries evolve, the demand for materials that can withstand extreme conditions while maintaining mechanical integrity is driving innovation in the market.

How Can Sustainability and Ethical Sourcing Influence Your B2B Purchasing Decisions?

Sustainability and ethical sourcing are increasingly critical factors for B2B buyers, particularly in the context of ss 303 hardness. The environmental impact of stainless steel production, which often involves energy-intensive processes and significant carbon emissions, is prompting companies to seek suppliers who prioritize sustainable practices. This includes the use of recycled materials and energy-efficient manufacturing methods, which can significantly reduce the carbon footprint of ss 303 products.

Ethical supply chains are equally important, as buyers are becoming more vigilant about labor practices and sourcing transparency. Companies are encouraged to partner with suppliers who adhere to international labor standards and are committed to responsible sourcing. Certifications like ISO 14001 for environmental management and Fair Trade certifications can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Furthermore, the demand for ‘green’ certifications and eco-friendly materials is growing. Buyers can differentiate themselves in the marketplace by sourcing ss 303 hardness materials that are certified for sustainability, thereby appealing to environmentally conscious customers and enhancing their brand reputation.

What Is the Historical Context of ss 303 Hardness in B2B Applications?

The development of ss 303 hardness can be traced back to the late 20th century when the need for corrosion-resistant materials with improved machinability became paramount in various industries. AISI Type 303 was specifically engineered as an austenitic stainless steel to address these needs, featuring a sulfur addition that enhances its machinability without significantly compromising corrosion resistance. This made it a preferred choice for manufacturers of precision components, fasteners, and intricate parts in sectors ranging from automotive to medical devices.

Over the years, advancements in production techniques and material science have further optimized ss 303, leading to its widespread adoption across global markets. As industries continue to evolve, the relevance of ss 303 hardness remains strong, driven by its unique combination of mechanical properties and adaptability for specialized applications. As such, understanding its historical context is essential for B2B buyers who are looking to make informed sourcing decisions in a competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of ss 303 hardness

1. How do I determine the appropriate hardness level for SS 303 in my application?

To determine the appropriate hardness level for SS 303, consider the specific requirements of your application, including mechanical stress, environmental exposure, and manufacturing processes. SS 303 typically has a Brinell hardness of 228 and a Rockwell B hardness of 96. If you require enhanced machinability or wear resistance, you may opt for a hardened version. Collaborating with a materials engineer can also provide insights tailored to your unique needs, ensuring that you select the right hardness for optimal performance.

2. What are the key differences between SS 303 and SS 304 hardness?

SS 303 and SS 304 differ in their chemical compositions and mechanical properties. SS 303 contains sulfur, which enhances machinability but can lead to slightly lower corrosion resistance compared to SS 304. The hardness levels are also comparable, with SS 303 generally exhibiting a Brinell hardness of around 228, while SS 304 typically has a hardness of about 201. Understanding these differences is crucial for selecting the right stainless steel grade based on your project’s requirements.

3. What are the minimum order quantities (MOQs) for sourcing SS 303 hardness materials?

Minimum order quantities (MOQs) for SS 303 materials can vary significantly among suppliers. Generally, MOQs can range from as low as 100 kg to several tons, depending on the supplier’s inventory policies and production capabilities. When sourcing internationally, it’s advisable to discuss your specific needs with potential suppliers to negotiate MOQs that align with your purchasing strategy and project scale.

4. How can I vet suppliers for SS 303 hardness materials?

Vetting suppliers for SS 303 hardness materials involves several steps. Start by researching their reputation through customer reviews and industry certifications. Request references from previous clients and assess their experience in your specific market, particularly in regions like Africa or South America. Additionally, inquire about their quality assurance processes, production capacity, and adherence to international standards to ensure they meet your requirements.

5. What payment terms should I expect when sourcing SS 303 internationally?

Payment terms for international sourcing of SS 303 can vary widely but typically include options like upfront payment, letter of credit, or net 30/60 days upon delivery. It’s essential to negotiate terms that provide security for both parties. Consider using escrow services for large transactions to mitigate risks. Always confirm the payment methods accepted by the supplier, especially when dealing with international transactions, to ensure a smooth payment process.

6. What quality assurance measures should I look for in SS 303 suppliers?

When sourcing SS 303, ensure that suppliers implement rigorous quality assurance measures. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Suppliers should provide material test certificates (MTCs) that detail the hardness, chemical composition, and mechanical properties of the materials. Additionally, inquire about their inspection processes and whether they conduct third-party audits to validate product quality.

7. How do logistics and shipping impact the procurement of SS 303 hardness materials?

Logistics and shipping play a critical role in the procurement of SS 303 materials, especially for international buyers. Consider factors such as lead times, shipping methods, and potential customs duties. Efficient logistics can significantly affect delivery timelines and costs. Work with suppliers who have experience in international shipping and can provide detailed shipping options, including freight forwarding and customs clearance assistance, to streamline the process.

8. What customization options are available for SS 303 hardness products?

Customization options for SS 303 products can include variations in size, shape, and finishing processes tailored to your specific needs. Many suppliers offer machining services to achieve desired tolerances and surface finishes. It’s advisable to communicate your requirements clearly during the sourcing process, including any specific applications or performance criteria. Requesting samples or prototypes can also help ensure that the customized product meets your expectations before placing a larger order.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Ss 303 Hardness Manufacturers & Suppliers List

1. MatWeb – AISI Type 303 Stainless Steel

Domain: asm.matweb.com

Registered: 1997 (28 years)

Introduction: {“Material”: “AISI Type 303 Stainless Steel”, “Form”: “Cold drawn bar”, “Tested at”: “Room Temperature (RT)”, “Subcategory”: [“Ferrous Metal”, “Heat Resisting”, “Metal”, “Stainless Steel”, “T 300 Series Stainless Steel”], “Close Analogs”: [“AISI Type 303 Se”], “Keywords”: [“T303”, “T 303”, “303SS”, “303 SS”, “AFNOR Z 10 CNF 18.09 (Fr)”, “UNI X 10 CrNiS 18 09”, “SUS 303”, “SS14 2346 (Sweden)”, “B.S…

2. Ezlok – AISI Type 303 Stainless Steel Bar

Domain: ezlok.com

Registered: 1997 (28 years)

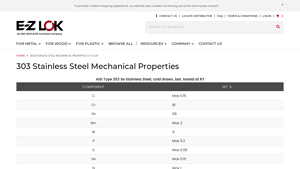

Introduction: {“Material”:”303 Stainless Steel”,”Type”:”AISI Type 303 Se Stainless Steel, cold drawn, bar, tested at RT”,”Chemical Composition”:{“C Max”:”0.15%”,”Cr”:”18%”,”Fe”:”69%”,”Mn Max”:”2%”,”Ni”:”9%”,”P Max”:”0.2%”,”S Max”:”0.06%”,”Se Max”:”0.15%”,”Si Max”:”1%”},”Physical Properties”:{“Density”:{“Metric”:”8 g/cc”,”English”:”0.289 lb/in³”}},”Mechanical Properties”:{“Hardness”:{“Brinell”:”228″,”Knoop”:”251…

3. AZOM – Grade 303 Stainless Steel

Domain: azom.com

Registered: 1999 (26 years)

Introduction: Grade 303 Stainless Steel (1.4305) is known for its excellent machinability due to the presence of Sulphur in its composition. It has lower corrosion resistance compared to Grade 304 and is not suitable for marine environments. Key properties include:

– **Chemical Composition:**

– Carbon (C): 0-0.10%

– Manganese (Mn): 0-2.0%

– Silicon (Si): 0-1.0%

– Phosphorus (P): 0-0.4%

– Sulphur (S):…

4. Vegas Fastener – Stainless Steel 303

Domain: vegasfastener.com

Registered: 2001 (24 years)

Introduction: {“Product Name”: “Stainless Steel 303”, “Type”: “AISI Type 303 Stainless Steel”, “Form”: “Annealed bar”, “Subcategory”: [“Heat Resisting”, “Metal”, “Stainless Steel”, “T 300 Series Stainless Steel”], “Close Analogs”: [“AISI Type 303 Se”], “Keywords”: [“T303”, “T 303”, “303SS”, “303 SS”, “AFNOR Z 10 CNF 18.09 (Fr)”, “UNI X 10 CrNiS 18 09”, “SUS 303”, “SS14 2346 (Sweden)”, “B.S. 303 S 21”, “UNS S303…

5. Steel Pro Group – 303 Stainless Steel

Domain: steelprogroup.com

Registered: 2024 (1 years)

Introduction: 303 Stainless Steel is known for its excellent machinability and is often used in applications requiring high corrosion resistance. It contains a higher sulfur content than other stainless steels, which enhances its machinability but may reduce its corrosion resistance slightly. Common uses include fasteners, fittings, and components in the food processing and chemical industries. Its advantages i…

6. ProtoXYZ – Stainless Steel 303

Domain: protoxyz.com

Registered: 2020 (5 years)

Introduction: {“Material Type”:”Metals”,”Material Sub-Type”:”Stainless Steels”,”Material Name”:”Stainless Steel 303″,”Mechanical Properties”:{“Yield Tensile Strength”:”-“,”Ultimate Tensile Strength”:”-“,”Tensile Modulus”:”-“,”Shear Strength”:”-“,”Shear Modulus”:”-“,”Fatigue Strength”:”-“,”Elongation At Break”:”-“,”Poisson’s Ratio”:”-“,”Hardness”:”-“,”Density”:”-“,”Impact Strength (ASTM)”:”-“},”Electrical/Magnet…

7. Aircraft Materials – Stainless Steel 303/303Se/303Sulf

Domain: aircraftmaterials.com

Registered: 2002 (23 years)

Introduction: {“Product Name”: “Stainless Steel 303 / 303Se / 303Sulf”, “Type”: “Free machining stainless steel”, “Applications”: [“Screw machine industry”, “Shafts”, “Valves”, “Fittings”], “Not Recommended For”: “Vessels containing gases or liquids under high pressure”, “Chemical Composition Limits”: {“C”: “0.15 max”, “Mn”: “2 max”, “Si”: “1 max”, “P”: “0.12-0.17”, “S”: “0.04 max”, “Cr”: “17-18”, “Ni”: “8-10”,…

8. Key Metals – 303 Stainless Steel

Domain: keymetals.com

Registered: 2005 (20 years)

Introduction: This company, Key Metals – 303 Stainless Steel, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

9. MatWeb – Material Properties Database

Domain: matweb.com

Registered: 1997 (28 years)

Introduction: This company, MatWeb – Material Properties Database, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for ss 303 hardness

In summary, the strategic sourcing of AISI Type 303 stainless steel is crucial for international buyers, particularly those in Africa, South America, the Middle East, and Europe. This material offers excellent machinability, corrosion resistance, and mechanical properties, making it ideal for various applications in fasteners, fittings, and components. With a hardness rating that allows for enhanced durability, ss 303 remains a preferred choice for manufacturers seeking reliable and high-quality materials.

As global supply chains evolve, the importance of sourcing strategies that emphasize quality, cost-effectiveness, and supplier reliability cannot be overstated. Buyers should leverage partnerships with reputable suppliers who understand regional market dynamics and can provide tailored solutions to meet specific needs.

Looking ahead, the demand for stainless steel, especially the 303 grade, is expected to rise as industries prioritize sustainability and efficiency. By staying informed on market trends and fostering strong supplier relationships, businesses can navigate the complexities of sourcing effectively. Take action now to ensure your supply chain is robust and prepared for future challenges.