Contents

Manufacturing Insight: Spell Machining

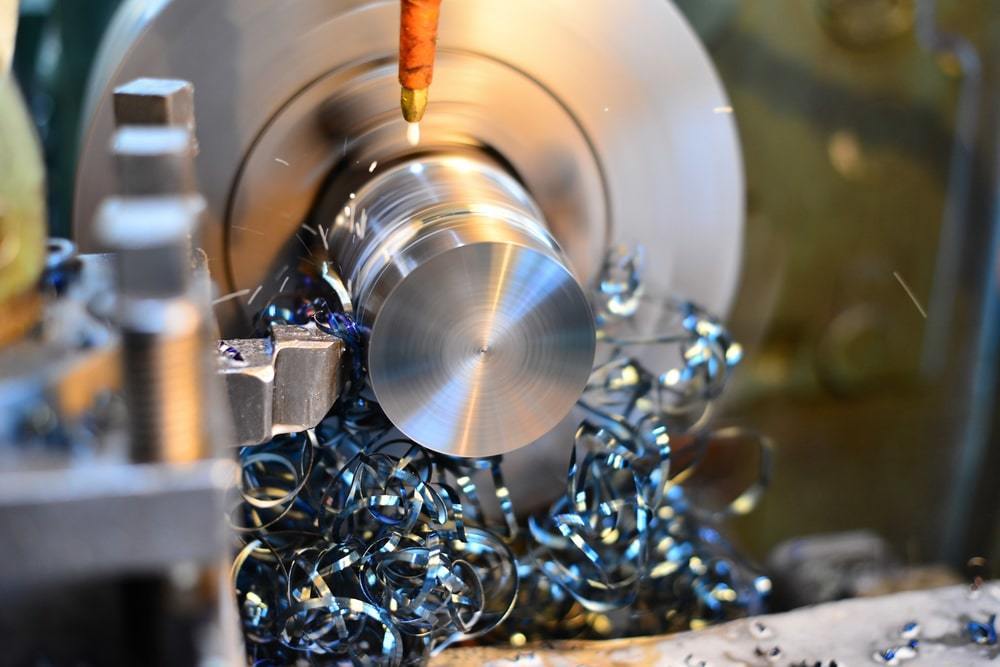

Precision CNC Machining Solutions for Accelerated Prototyping and Production

Honyo Prototype delivers industry-leading CNC machining services engineered to transform complex designs into high-precision components with exceptional speed and repeatability. Our advanced 3-, 4-, and 5-axis milling and turning capabilities support tight tolerances down to ±0.0002 inches across an extensive range of materials including aerospace-grade aluminum alloys, medical stainless steels, titanium, engineering plastics, and exotic composites. Every component undergoes rigorous in-process and final inspection using calibrated CMMs and optical comparators to ensure compliance with AS9100 and ISO 9001 standards, eliminating costly rework and accelerating time-to-market for critical applications.

Leveraging state-of-the-art HAAS and DMG MORI equipment paired with optimized toolpath strategies, we achieve superior surface finishes and geometric accuracy for everything from single-part prototypes to low-volume production runs. Our engineering team collaborates closely with clients during DFM analysis to identify manufacturability improvements that reduce lead times without compromising functionality. This proactive approach, combined with streamlined workflows in our climate-controlled facility, consistently delivers 20-30% faster turnaround versus industry benchmarks for precision-machined parts.

Accelerate your project timeline immediately with Honyo’s Online Instant Quote system. Upload your STEP or IGES file to receive a detailed, real-time cost analysis and manufacturability feedback within minutes—no callbacks or email delays. Experience how our technical expertise and digital quoting efficiency turn design challenges into deliverable solutions.

Technical Capabilities

Honyo Prototype provides high-precision spell machining services, encompassing 3-axis, 4-axis, and 5-axis CNC milling along with CNC turning, optimized for tight tolerance components across a range of engineering materials. Our processes are designed for complex geometries, superior surface finishes, and repeatability within ±0.005 mm (±0.0002″) for critical features. Below are the technical specifications for our spell machining capabilities:

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|---|---|---|---|---|

| Axis Configuration | X, Y, Z | X, Y, Z, A (rotary) | X, Y, Z, A, B (dual rotary) | X, Z (radial & axial) |

| Max Work Envelope (mm) | 760 x 460 x 350 | 600 x 500 x 400 | 500 x 400 x 300 | Ø300 x 500 length |

| Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.005 mm | ±0.005 mm |

| Repeatability | ±0.003 mm | ±0.003 mm | ±0.003 mm | ±0.003 mm |

| Typical Surface Finish | Ra 0.8 – 3.2 µm | Ra 0.8 – 1.6 µm | Ra 0.4 – 1.6 µm | Ra 0.8 – 1.6 µm |

| Minimum Feature Size | 0.5 mm (end mill dependent) | 0.5 mm | 0.5 mm | Ø0.8 mm (turning tool) |

| Max Spindle Speed | 24,000 rpm | 20,000 rpm | 20,000 rpm | 6,000 rpm |

| Tool Change (ATC) | Up to 24 tools | Up to 24 tools | Up to 30 tools | 12-station turret |

Material Compatibility and Machinability:

| Material | Machinability Notes | Typical Applications | Max Tolerance Achievable |

|---|---|---|---|

| Aluminum (6061, 7075) | Excellent machinability, high MRR, low tool wear | Aerospace, enclosures, heat sinks | ±0.010 mm |

| Steel (1018, 4140, Stainless 303/316) | Moderate to difficult; requires rigid setup and appropriate tooling | Industrial components, shafts, fixtures | ±0.008 mm |

| ABS | Easy to machine, low melting point; requires sharp tools and light cuts | Prototypes, housings, jigs | ±0.025 mm |

| Nylon (6, 66, GF-filled) | Can be challenging due to elasticity; needs sharp tooling and stable clamping | Gears, bushings, insulators | ±0.020 mm |

All spell machining operations are supported by in-process metrology, CAD/CAM programming (using Mastercam and Fusion 360), and first-article inspection reports (FAIR) when required. Tight tolerance features are verified using CMM, optical comparators, and laser micrometers to ensure compliance with ISO 2768-mK or customer-specific GD&T requirements.

From CAD to Part: The Process

Honyo Prototype utilizes a streamlined digital manufacturing workflow for CNC machining services, which clients may colloquially refer to as “spell machining” though the correct technical term is CNC machining. Our integrated process eliminates traditional quoting bottlenecks and ensures manufacturability from the initial design stage. Below is the precise sequence of operations:

CAD File Upload and Initial Processing

Clients submit 3D CAD models (STEP, IGES, Parasolid, or native formats) via our secure customer portal. Our system automatically validates file integrity, checks for unit consistency, and performs preliminary geometry analysis. This step ensures the design is machine-readable and identifies obvious anomalies such as non-manifold edges or missing surfaces before proceeding to quoting.

AI-Powered Instant Quoting Engine

Uploaded files trigger our proprietary AI quoting system, which analyzes over 200 geometric and material parameters within seconds. Unlike manual quoting, this engine cross-references real-time machine availability, material stock levels, and historical production data from our 120+ CNC assets. The output is a binding quote with precise lead time, cost breakdown, and material utilization efficiency metrics. Typical quote generation time is under 90 seconds for standard parts.

Automated DFM Analysis with Engineering Oversight

Every design undergoes mandatory Design for Manufacturability (DFM) assessment using our rule-based algorithm calibrated to ISO 2768-mK tolerances. The system flags high-risk features requiring engineering review:

| DFM Check Category | Common Issues Detected | Resolution Path |

|——————-|————————|—————-|

| Geometric Complexity | Deep cavities > 8:1 aspect ratio, thin walls < 0.5mm | Suggest draft angles or wall thickness adjustment |

| Tolerance Stack-up | Interdependent GD&T callouts | Propose simplified tolerance zones |

| Material Constraints | Non-standard alloys, excessive stock removal | Recommend cost-effective alternatives |

| Tool Access | Undercuts without clearance | Propose EDM or multi-axis solution |

Critical findings trigger direct engineer-to-client collaboration via our portal. 87% of designs require only automated suggestions with no human intervention.

Production Execution with Real-Time Tracking

Approved orders enter our production scheduling system, which dynamically allocates work to optimal machines based on:

Current spindle load across 3-axis, 5-axis, and mill-turn centers

Verified tooling availability (over 15,000 tool configurations pre-staged)

Material lot traceability from certified suppliers

Each part receives a unique QR code for full production traceability. In-process inspections occur at critical stages using calibrated CMMs and optical comparators, with real-time SPC data visible to clients via the portal.

Quality-Controlled Delivery

Final inspection follows AS9102 First Article Inspection protocols for aerospace-grade work or ISO 10360-8 for general precision parts. All deliverables include:

Dimensional inspection reports with deviation heatmaps

Material certification and lot traceability documentation

Surface finish verification per ISO 1302

Vacuum-sealed packaging with humidity indicators for critical components

Standard lead time from CAD upload to shipment is 5-7 business days for quantities under 50 pieces, with expedited options available. All shipments include digital twin data matching physical part characteristics to the original CAD model. This closed-loop process reduces time-to-prototype by 63% compared to industry averages while maintaining 99.2% first-pass yield rates.

Start Your Project

Discover precision with Spell Machining — advanced manufacturing solutions engineered for performance and reliability.

Located in Shenzhen, our state-of-the-art factory delivers high-quality machining services with fast turnaround times, supporting prototyping and low-volume production across industries.

For inquiries or project consultations, contact Susan Leo at [email protected]. Let’s build your next innovation together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.