Guide Contents

Project Insight: Spell Machining

Manufacturing Insight: Spell Machining

Why Speed & Precision Define Modern Product Development

In today’s hyper-competitive hardware landscape, speed without precision is wasted motion—and precision without speed is missed opportunity. For hardware startups and product engineers, the ability to iterate rapidly while maintaining micron-level accuracy is non-negotiable.

Prototype-to-Production Velocity: 73% of successful hardware startups ship MVPs 30% faster than competitors by leveraging precision machining for functional testing early in development.

Cost of Delay: A single week’s delay in market entry can erode 15–20% of projected revenue (McKinsey, 2023). Precision machining eliminates rework, reducing time-to-market while ensuring parts meet real-world performance standards.

Risk Mitigation: Tight tolerances (±0.01mm) prevent costly failures in end-use parts—critical for medical, aerospace, and IoT applications where failure is not an option.

Honyo’s Digital-First Precision Machining

At Honyo Prototype, Spell Machining isn’t just a service—it’s a fully integrated digital ecosystem that transforms CAD files into production-ready parts with unmatched efficiency.

Online Instant Quote:

Real-time pricing in <60 seconds—no back-and-forth emails.

AI-driven cost analysis factoring in material, geometry, and tolerances (e.g., $20–$50/hour machine rates optimized for your design).

Transparent breakdown of material costs (5x–500x raw material value) and tooling fees (3%–6% of total project cost).

AI-Powered Platform:

Automated Design for Manufacturability (DFM) feedback—flagging potential issues before production starts.

Generative AI optimizes toolpaths, reducing machining time by up to 30% without sacrificing precision.

Cloud-based collaboration: Share designs, track progress, and adjust specs in real time with our engineering team.

Fast Turnaround, Uncompromised Quality:

3–5 days for functional prototypes (even for complex 5-axis geometries).

Scalable from 1 to 10,000+ parts with consistent ±0.01mm tolerances across 3/4/5-axis CNC platforms.

Shenzhen-based production with global logistics—no hidden delays or quality gaps.

From Concept to Reality – Seamlessly

“At Honyo, we don’t just machine parts—we engineer confidence.”

— Susan Leo, Founder

Whether you’re validating a wearable sensor’s fit or prototyping a drone component, our digital-first approach ensures your vision is built right, built fast, and built to last.

Ready to accelerate your next breakthrough?

→ Get Your Instant Quote in under a minute.

→ Explore Our Capabilities for precision CNC machining that turns ideas into reality.

Honyo Capabilities & Technology

Honyo’s Manufacturing Capabilities

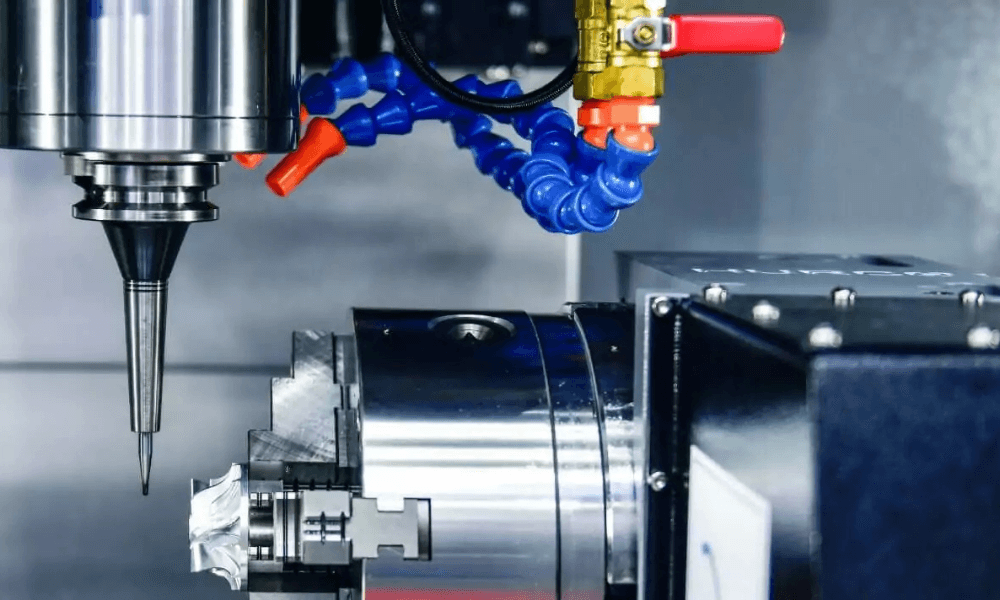

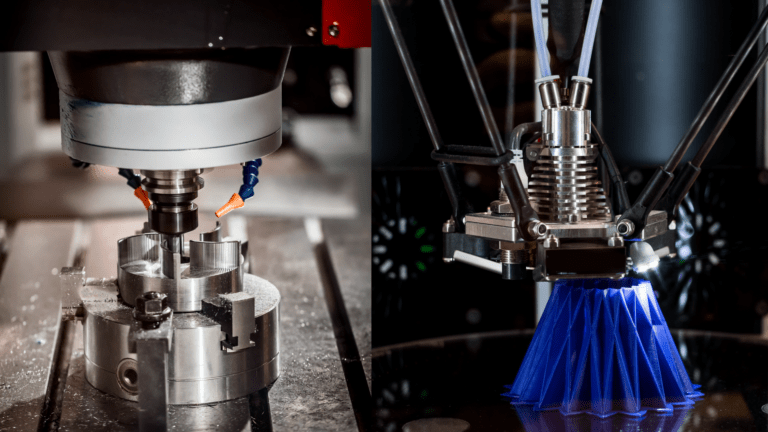

Precision CNC Machining

Engineered for Innovation, Built for Precision

3/4/5-Axis CNC Machining:

Complex geometries with micron-level accuracy for aerospace, medical, and industrial applications

Tight Tolerances (+/- 0.01mm):

Uncompromising precision for functional prototypes and end-use parts requiring exact specifications

Material Versatility:

Expertise across aluminum alloys, stainless steel, titanium, brass, and high-performance engineering plastics

Scalable Production:

Seamless transition from 1 prototype to 10,000+ production runs with zero minimum order quantities

ISO 9001:2015 Certified Quality:

Real-time in-process inspection via CMM and laser scanning, full traceability, and rigorous final testing

Digital Efficiency Engine:

AI-driven instant quotes in <60 seconds, smart DFM feedback to optimize costs, and 3-5 day prototype turnaround

Materials & Surface Finishes

Material Options & Finishes for Precision CNC Machining

Premium Material Selection

Choose materials engineered for performance, precision, and reliability across demanding applications:

Aluminum 6061: Ideal for structural prototypes, automotive components, and aerospace parts. Balances strength, corrosion resistance, and ease of machining with excellent weldability.

Aluminum 7075: High-strength alloy for mission-critical applications like aircraft fittings and military hardware. Delivers exceptional load-bearing capacity under stress.

Stainless Steel 304: Versatile, food-grade, and corrosion-resistant. Perfect for medical devices, kitchen equipment, and general industrial use.

Stainless Steel 316: Enhanced marine-grade corrosion resistance for chemical processing, offshore systems, and high-purity environments.

Brass: Superior machinability and electrical conductivity. Best for decorative hardware, valves, and electrical connectors requiring tight tolerances.

PEEK: High-performance thermoplastic for extreme heat, chemical exposure, and biocompatibility. Used in aerospace, medical implants, and semiconductor manufacturing.

Precision Surface Finishes

Elevate functionality and aesthetics with industry-leading surface treatments:

Anodizing: Customizable color options and enhanced wear resistance for aluminum. Ideal for electrical insulation and long-term outdoor use.

Painting: High-precision liquid coating for color-matched finishes on metals and plastics. Protects against UV degradation and environmental exposure.

Powder Coating: Durable, uniform finish for complex geometries. Available in matte, gloss, or textured finishes for consumer and industrial products.

Electroplating: Adds conductivity (e.g., nickel, chrome) or corrosion resistance for electrical components and automotive parts.

Polishing: Mirror-like smoothness for medical devices, optical lenses, and luxury consumer products.

Passivation: Critical for stainless steel to remove surface contaminants and maximize corrosion resistance.

Bead Blasting: Creates a consistent matte texture for aesthetic refinement or glare reduction in functional components.

Optimize Your Design with AI-Powered Material Selection

Innovate faster, reduce costs, and accelerate time-to-market with Honyo’s cutting-edge digital platform:

Online Instant Quote: Upload your CAD file in seconds to receive a real-time cost breakdown with material, finish, and lead-time options—no manual estimation required.

AI-Driven Recommendations: Our proprietary algorithm analyzes your design requirements to suggest the optimal material/finish combo, balancing performance, cost, and manufacturability.

Fast Turnaround Guarantee: From prototype to production, achieve delivery in as little as 24 hours for urgent projects—without compromising ±0.01mm precision or quality.

Seamless Integration: Sync with your design workflow to automate toolpath optimization, minimize material waste, and reduce costs by up to 30% through intelligent process planning.

Partner with Honyo Prototype—where precision engineering meets AI-driven efficiency—to bring your vision to life, faster and smarter.

From Quote to Part: Our Process

How It Works: From CAD to Part in 4 Simple Steps

At Honyo Prototype, we’ve redefined precision manufacturing with an AI-driven workflow that eliminates guesswork and delays. Whether you’re a hardware startup scaling prototypes or an engineer finalizing end-use parts, our process delivers unmatched speed, transparency, and precision—all from our Shenzhen facility.

1. Upload Your CAD File

Simple drag-and-drop interface supports all major formats (STEP, STP, IGES, STL, etc.)

Cloud-based platform: Access securely from anywhere—no software downloads required

Enterprise-grade encryption ensures your designs stay confidential

2. Instant AI-Powered Quote

Proprietary AI engine analyzes geometry, tolerances, and material in under 60 seconds

Transparent pricing breakdown:

Material costs (stainless steel, aluminum, titanium, etc.)

Machine hours (based on complexity and ±0.01mm tolerance requirements)

Setup fees, shipping, and quality control

Real-time cost optimization suggestions (e.g., “Simplify this feature to reduce machining time by 20%”)

No hidden fees—see exact costs before you commit

3. Smart DFM Analysis & Optimization

Our engineering team reviews your design for manufacturability before production begins

Receive actionable feedback to:

Reduce material waste and machining complexity

Adjust tolerances where feasible without compromising function

Identify potential defects (e.g., thin walls, sharp corners)

Collaborative platform: Iterate faster with direct engineer feedback—no email chains or delays

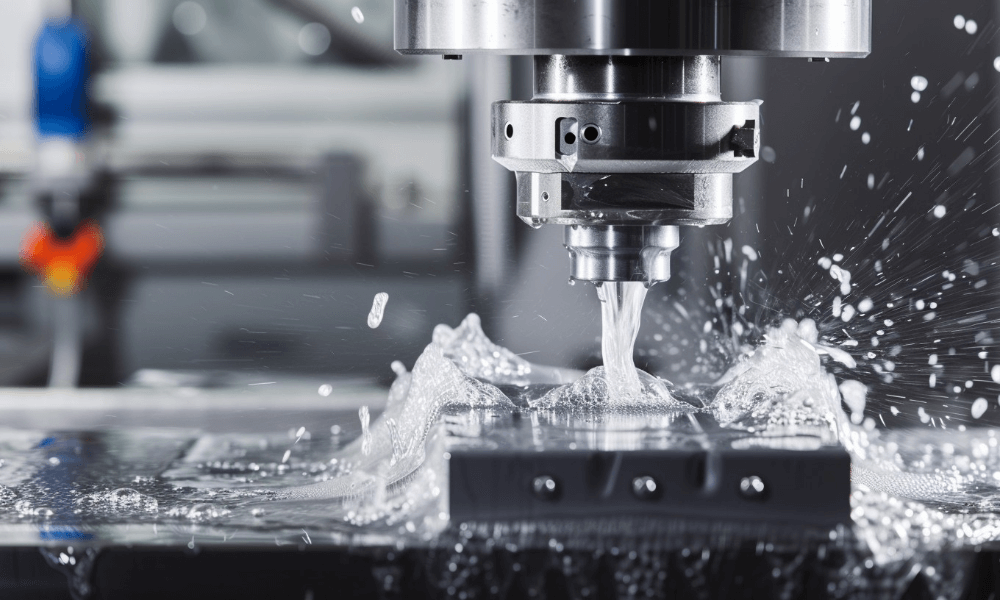

4. Precision Production & Delivery

State-of-the-art 3/4/5-axis CNC machines with ±0.01mm tolerances and automated in-process inspections

Rigorous quality control: Every part undergoes final metrology checks against your specs

Real-time order tracking: Monitor production progress and shipment updates 24/7

Fast turnaround: Prototypes delivered in as little as 3 business days; low-volume production in 5–7 days

“Honyo Prototype turns complexity into clarity—where innovation meets precision, and your ideas become reality faster than ever.”

— Susan Leo, Founder

Start Your Project with Honyo

Start Your Project with Honyo

Partner with Honyo Prototype’s expert team to transform your designs into precision-engineered components—faster, smarter, and with unparalleled accuracy.

Precision Engineered, Instantly Quoted

AI-Powered Instant Quote Platform: Upload your CAD files and receive a detailed, transparent quote in minutes—no back-and-forth, no hidden fees.

Dynamic Cost Optimization: AI-driven analysis of geometry, material, and tolerances to recommend the most efficient process—cutting costs while ensuring precision.

Tight Tolerance Assurance: Consistently deliver ±0.01mm precision for functional prototypes and end-use parts across aerospace, medical, and industrial applications.

Accelerate Time-to-Market

Rapid Prototyping Workflow: From design to delivery in as little as 3 business days—no waiting for tooling or setup delays.

Scalable Production: Seamlessly transition from prototype to high-volume production with the same precision and speed.

Global Logistics Network: Shenzhen/Dongguan facilities with expedited shipping to meet your deadlines, anywhere in the world.

Why Partner with Susan Leo’s Team?

Founder Susan Leo brings 15+ years of precision manufacturing expertise to every project.

End-to-End Support: Dedicated engineering team reviews every project to ensure manufacturability and cost-efficiency.

ISO-Certified Quality Control: Every part undergoes rigorous inspection to meet your exact specifications.

Ready to bring your vision to life? Contact us today:

📧 [email protected]

📞 +86 139 2843 8620

🌐 Visit our Shenzhen & Dongguan facilities for a firsthand look at our advanced manufacturing ecosystem.

🚀 Manufacturing Cost Estimator

Compare cost impact of different technologies for your parts.