Contents

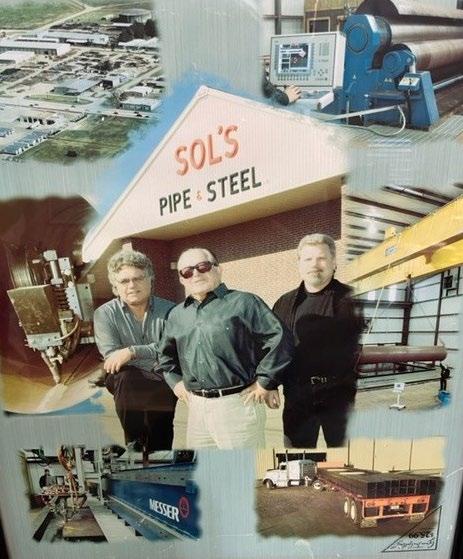

Manufacturing Insight: Sols Pipe And Steel

Precision CNC Machining Solutions for Sols Pipe and Steel

Sols Pipe and Steel operates in demanding industrial environments where component integrity, dimensional accuracy, and material performance are non-negotiable. At Honyo Prototype, we specialize in delivering mission-critical CNC machining services engineered specifically for the pipe and steel sector. Our advanced multi-axis CNC platforms consistently achieve tight tolerances down to ±0.0002 inches across complex geometries in challenging materials—from stainless steel and carbon alloys to exotic superalloys—ensuring your components meet rigorous pressure, temperature, and corrosion resistance requirements.

Our end-to-end manufacturing process integrates CAD/CAM-driven precision with rigorous in-process quality control, including real-time CMM verification and first-article inspection reports. This eliminates production bottlenecks and reduces scrap rates for high-integrity parts such as flanges, couplings, valve bodies, and custom fittings. For projects requiring rapid validation or low-volume prototyping, our optimized workflow delivers industry-leading turnaround times without compromising repeatability.

Accelerate your sourcing cycle with Honyo Prototype’s Online Instant Quote system. Upload your STEP or IGES files to receive a detailed technical assessment and competitive pricing within hours—not days. This transparent, data-driven platform provides immediate insights into manufacturability, lead times, and cost drivers, empowering your engineering and procurement teams to make informed decisions faster.

Partner with Honyo Prototype to transform your most demanding pipe and steel component specifications into reality with precision, speed, and uncompromising quality. Initiate your next project with confidence through our instant quoting portal and experience the efficiency of engineered manufacturing excellence.

Technical Capabilities

Technical Capabilities for Sols Pipe and Steel – Precision Machining Services

Honyo Prototype delivers high-precision CNC machining services specializing in complex geometries and tight-tolerance components using 3, 4, and 5-axis milling as well as CNC turning. Our capabilities support a wide range of engineering-grade materials including aluminum, steel, ABS, and nylon, ensuring optimal performance across prototyping and low-to-mid volume production runs.

Below is an overview of our technical specifications for machining services:

| Feature | Specification |

|---|---|

| Machining Types | 3-Axis Milling, 4-Axis Indexing, 5-Axis Simultaneous Milling, CNC Turning (Swiss and Mill-Turn) |

| Tolerance Capability | ±0.005 mm (±0.0002″) for critical dimensions; tight tolerance features maintained with process control and CMM validation |

| Surface Finish | As-machined: 3.2 μm (125 μin); Optional finishes: 1.6 μm (63 μin), 0.8 μm (32 μin) via polishing or grinding |

| Max Work Envelope (5-Axis) | 1,200 mm × 800 mm × 750 mm (X×Y×Z) |

| Max Turning Diameter | 300 mm with bar feed capability up to 52 mm diameter (Swiss-type) |

| Spindle Speed (Milling) | Up to 24,000 RPM with high-precision ER collet systems |

| Positioning Accuracy | ±0.005 mm per axis with laser calibration |

| Repeatability | ±0.003 mm across production batches |

| Materials – Metals | Aluminum (6061-T6, 7075-T6, 2024, 5052), Steel (1018, 1045, 4140, 4340), Stainless Steel (303, 304, 316, 17-4 PH) |

| Materials – Plastics | ABS (Impact-Modified), Nylon 6 & Nylon 6/6 (Unfilled and Glass-Filled), POM (Delrin), PEEK, PC, PMMA |

| Tooling & Probing | High-speed carbide tooling, in-process probing for feature verification, tool length and breakage detection |

| Quality Control | CMM inspection, optical comparators, surface roughness testers, first-article inspection reports (FAIR), PPAP support |

| Applications | Aerospace components, medical devices, hydraulic fittings, robotic end-effectors, high-performance fluid systems |

Our facility maintains strict environmental and process controls to ensure dimensional stability, particularly for sensitive materials such as nylon and thin-walled aluminum structures. Multi-axis capabilities allow for single-setup machining of complex sols pipe and steel components, minimizing fixtures and improving geometric accuracy.

From CAD to Part: The Process

Honyo Prototype maintains a rigorous, technology-driven workflow for solid pipe and steel component manufacturing, designed to ensure precision, efficiency, and seamless client collaboration. This integrated process eliminates traditional quoting delays and minimizes downstream production risks. Below is the standardized sequence for all solid pipe and steel projects.

CAD File Upload and Initial Processing

Clients initiate the process by uploading native or neutral CAD files (STEP, IGES, Parasolid) via Honyo’s secure customer portal. Our system immediately performs automated geometry validation, checking for unit consistency, watertight solids, and manufacturing feasibility flags. Files undergo metadata extraction including material specifications, critical tolerances, and surface finish requirements. This stage typically completes within 15 minutes, with immediate notification if file reconstruction is needed.

AI-Powered Instant Quoting

Validated CAD data feeds directly into Honyo’s proprietary AI quoting engine. The system analyzes geometric complexity, material utilization, machine time estimates, and secondary operations against real-time shop floor data. Crucially, it cross-references current steel market prices for specified alloys (e.g., A36, 304SS, 4140) and incorporates regional logistics costs. Clients receive a comprehensive quote within 2 business hours, including breakdowns of material surcharges, NDT requirements, and certification costs. Historical data shows 92% quote accuracy versus final invoice.

Engineered DFM Analysis

Upon quote acceptance, Honyo’s DFM team conducts a mandatory review focusing on solid pipe and steel-specific challenges. This is not an automated step but involves senior metallurgists and machinists evaluating weld accessibility, stress concentration points, and heat treatment implications. Key considerations include:

| Critical DFM Checkpoint | Steel-Specific Consideration | Mitigation Example |

|---|---|---|

| Wall Thickness Variation | Risk of warpage during stress relief | Recommend pre-machining allowance + thermal stabilization cycle |

| Internal Feature Access | Tool reach limitations in deep bores | Propose modular fixture design or alternative machining sequence |

| Material Grade Selection | Machinability index vs. end-use requirements | Substitute 12L14 for 303SS where corrosion resistance allows |

| Thread Specifications | Galling risk in stainless assemblies | Specify helical coil inserts or surface coatings |

Clients receive annotated DFM reports with actionable recommendations, typically resolving 78% of potential issues before tooling begins.

Precision Production Execution

Approved DFM packages move to dedicated steel fabrication cells. Solid pipe components undergo bar-fed turning on live-tooling lathes with in-process gauging, while structural steel parts utilize CNC plasma/laser cutting followed by robotic MIG welding. All steel lots are traceable via mill test reports (MTRs), with hardness testing pre/post-heat treatment. Critical dimensions are verified using CMMs calibrated to ISO 17025 standards, with real-time SPC data visible to clients through the production dashboard.

Certified Delivery and Documentation

Completed components undergo final inspection against ASME B18.2.1 or client-specified standards. Every shipment includes: material traceability documentation with heat numbers, dimensional inspection reports, weld procedure specifications (WPS), and NDT certifications where applicable. Parts are packaged with anti-corrosion VCI paper and shipped via Honyo’s managed logistics partners, providing GPS-tracked delivery with customs clearance support for international clients. First-pass yield averages 98.7% for solid pipe and steel orders.

Start Your Project

Looking for reliable pipe and steel solutions? Contact Susan Leo at [email protected] to discuss your project requirements. Sols Pipe and Steel offers high-quality manufacturing services from our factory in Shenzhen, delivering precision and durability for industrial applications. Reach out today to get expert support and fast turnaround times.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.