Contents

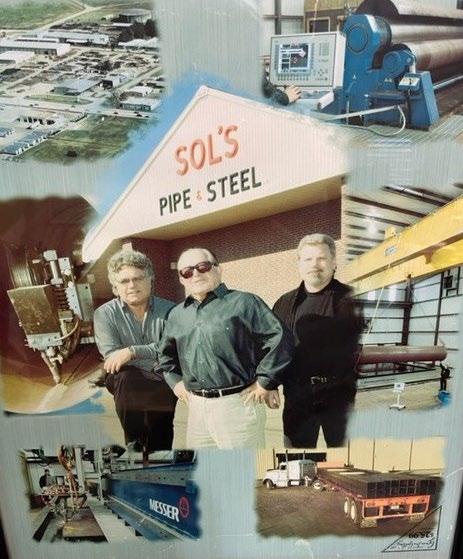

Manufacturing Insight: Sol’S Pipe And Steel

Introduction for Sol’s Pipe and Steel

Sol’s Pipe and Steel operates at the forefront of industrial fluid handling and structural systems, where component integrity directly impacts system performance and safety. As your manufacturing partner, Honyo Prototype delivers precision CNC Machining services engineered to meet the rigorous demands of pipe, valve, and structural steel applications. We specialize in transforming complex designs into mission-critical components with unwavering adherence to tight-tolerance specifications, material certifications, and industry standards such as ASME and ASTM.

Our advanced CNC capabilities include 5-axis milling, precision turning, and multi-tasking machining for materials ranging from carbon and stainless steels to exotic alloys like Inconel and titanium. Each process is supported by in-house metrology, including CMM and optical inspection, ensuring dimensional accuracy down to ±0.0002 inches. For Sol’s Pipe and Steel, this translates to leak-proof fittings, high-pressure valve bodies, and structural interfaces that perform reliably under extreme thermal and mechanical stress—eliminating field failures and reducing lifecycle costs.

Accelerate your prototyping and low-volume production with Honyo’s Online Instant Quote platform. Submit CAD files in STEP, IGES, or native formats to receive a detailed manufacturing assessment and competitive pricing within hours—not days. This seamless integration of engineering expertise and digital efficiency ensures Sol’s Pipe and Steel maintains agility in project timelines while upholding uncompromising quality benchmarks. Partner with Honyo Prototype to convert design intent into precision-engineered reality.

Technical Capabilities

Honyo Prototype delivers precision machining services through advanced 3, 4, and 5-axis CNC milling and turning capabilities, specializing in tight-tolerance components for demanding industrial, aerospace, and medical applications. Our technical expertise ensures consistent accuracy and surface integrity across a range of engineering materials including aluminum, steel, ABS, and nylon. Below are the key technical specifications for our machining services:

| Parameter | Specification Detail |

|---|---|

| Machining Capabilities | 3-Axis, 4-Axis, and 5-Axis CNC Milling; CNC Turning (including multi-axis turning) |

| Tolerance Range | ±0.005 mm (±0.0002″) typical; tight-tolerance work down to ±0.001 mm (±0.00004″) |

| Positioning Accuracy | ±0.002 mm per axis |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope | Milling: 1000 mm × 600 mm × 500 mm; Turning: Ø300 mm × 500 mm (diameter × length) |

| Spindle Speed (Milling) | Up to 24,000 RPM |

| Spindle Speed (Turning) | Up to 6,000 RPM (varies by part diameter) |

| Feed Rates | Up to 15,000 mm/min (programmable with high-speed machining options) |

| Materials Supported | Aluminum (6061, 7075, 2024), Steel (1018, 4140, Stainless 303, 304, 316), ABS, Nylon (6, 66, GF-reinforced variants) |

| Surface Finish | As-machined: 1.6–3.2 µm Ra; post-processed finishes down to 0.4 µm Ra available |

| Coolant & Lubrication | High-pressure through-spindle coolant (metals); air cooling and specialized tooling for plastics |

| Inspection & Metrology | On-site CMM, optical comparators, micrometers, and digital height gauges; full FAI and PPAP support |

| Fixturing | Custom soft jaws, vacuum and mechanical clamping, tombstone fixturing for batch runs |

Our process control systems ensure material-specific parameters are optimized—for example, high-speed cutting strategies for aluminum and nylon, and rigid, low-vibration setups for hardened steels. All components undergo in-process and final inspection to meet tight-tolerance requirements, with full traceability and documentation available per customer specifications.

From CAD to Part: The Process

Honyo Prototype’s Sheet Metal Pipe and Steel Fabrication Process

Honyo Prototype executes a streamlined, technology-driven workflow for sheet metal pipe and steel components, ensuring precision, cost efficiency, and rapid turnaround. The process begins with secure CAD file submission via our client portal, accepting industry-standard formats including STEP, IGES, and native SOLIDWORKS files. All uploads undergo automated validation for geometry integrity and unit consistency, with immediate feedback provided if corrections are required. This foundational step eliminates upstream errors and establishes a digital twin for the entire production chain.

The AI Quote engine then processes the validated CAD data, leveraging Honyo’s proprietary material database and real-time shop floor analytics. Unlike generic quoting tools, our system factors in material grade-specific properties (e.g., SS304 bend allowances, A36 steel shear rates), geometric complexity penalties for tubular sections, and secondary operation costs like welding or coating. The output is a granular cost breakdown with lead time estimates, delivered within 4 business hours. Crucially, this phase includes AI-driven material optimization suggestions—such as nestable flat patterns for pipes—to reduce waste by 12–18% on average.

Design for Manufacturability (DFM) follows, where Honyo’s senior manufacturing engineers conduct a human-led technical review. This phase focuses on steel-specific feasibility: verifying bend radii against material ductility, assessing weld accessibility for enclosed pipe joints, and validating tolerances per ASME Y14.5 standards. Clients receive a formal DFM report with actionable recommendations, such as modifying flange thickness to prevent warpage during heat treatment. Only after client sign-off on the DFM report does production commence, ensuring zero rework cycles.

Production utilizes Honyo’s integrated digital workflow. Laser cutters (e.g., Bystronic 8kW) process flat blanks with ±0.1mm accuracy, followed by CNC press brakes for precision bending of pipes and structural sections. All steel components undergo in-process CMM verification at critical stages, with real-time SPC data logged against the original CAD model. For welded assemblies, our robotic cells (FANUC ARC Mate) execute pre-programmed sequences with traceable weld parameters, while powder coating or anodizing occurs in climate-controlled booths meeting ISO 12944 corrosion standards.

Final delivery includes comprehensive documentation: First Article Inspection reports per AS9102, material certs (MTRs) with heat numbers, and a digital quality dossier accessible via our client portal. Components ship in custom anti-corrosion packaging with serialized barcodes for full supply chain visibility. Typical lead times from CAD upload to delivery are 7–12 business days for low-volume prototypes, as validated in our production analytics:

| Production Stage | Avg. Duration | Key Performance Metric |

|---|---|---|

| CAD Validation | < 2 hours | 99.2% first-pass validation rate |

| AI Quote + Optimization | 4 hours | 15.7% avg. material cost reduction |

| DFM Review | 24–48 hours | 92% client approval on first submission |

| Production | 5–8 days | 98.4% on-time completion rate |

| Delivery | 1–2 days | 100% traceable logistics tracking |

This closed-loop process integrates AI efficiency with deep manufacturing expertise, specifically optimized for the geometric and material challenges inherent in pipe and steel fabrication. Clients maintain full visibility at every phase through our secure portal, with engineering support available for real-time issue resolution.

Start Your Project

Looking for high-quality pipe and steel solutions? Contact Susan Leo at [email protected] to discuss your project requirements. Sol’s Pipe and Steel, with its manufacturing base in Shenzhen, offers reliable production capabilities and precision engineering to meet demanding industrial standards. Reach out today to streamline your supply chain with a trusted manufacturing partner.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.