Introduction: Navigating the Global Market for solidworks tolerance stack

In today’s competitive manufacturing landscape, sourcing effective solutions for SolidWorks tolerance stack analysis is crucial for ensuring product quality and minimizing defects. International B2B buyers face the challenge of navigating a diverse market filled with various tools and software options that promise to enhance design accuracy and streamline production processes. This guide delves into the complexities of tolerance stack analysis, providing insights into the different types of tools available, their applications across industries, and strategies for supplier vetting.

We explore the intricacies of leading software options like 3DCS Variation Analyst and SOLIDWORKS TolAnalyst, highlighting their capabilities in simulating assembly processes and managing dimensional variations. By understanding the nuances of each tool, buyers can make informed decisions that align with their specific operational needs. Additionally, this guide addresses cost considerations, enabling businesses in Africa, South America, the Middle East, and Europe—regions known for their dynamic industrial sectors—to optimize their investments.

With a comprehensive approach to tolerance stack analysis, this guide empowers international B2B buyers to enhance their product quality, reduce rework, and ultimately drive profitability. By leveraging the insights provided, companies can confidently navigate the global market, ensuring they select the best tools to meet their engineering and manufacturing challenges.

Understanding solidworks tolerance stack Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Worst-Case Tolerance Stack-Up | Calculates maximum and minimum variations for worst-case scenarios. | Aerospace, Automotive, Medical Devices | Pros: Comprehensive risk assessment; Cons: Can be overly conservative, leading to tighter tolerances. |

| Root Sum Square (RSS) | Uses statistical methods to calculate the overall variation. | Consumer Products, Electronics, Machinery | Pros: More realistic; considers multiple variables; Cons: Requires understanding of statistical principles. |

| Monte Carlo Simulation | Employs random sampling to predict variation outcomes. | Heavy Equipment, Construction, Energy | Pros: Provides a visual representation of potential outcomes; Cons: Computationally intensive and time-consuming. |

| Geometric Dimensioning & Tolerancing (GD&T) | Focuses on the function of parts and their relationships. | All industries focusing on precision engineering | Pros: Enhances communication; Cons: Complexity in implementation and understanding. |

| DimXpert Tolerance Analysis | Automates the application of tolerances directly from CAD models. | Rapid Prototyping, Custom Manufacturing | Pros: Streamlines workflow; Cons: Limited to SOLIDWORKS users. |

What are the Characteristics of Worst-Case Tolerance Stack-Up?

Worst-Case Tolerance Stack-Up is characterized by its conservative approach, calculating the maximum and minimum dimensions that could occur during assembly. This method is particularly useful in industries where safety and reliability are paramount, such as aerospace and medical devices. Buyers should consider this method if they prioritize a comprehensive risk assessment, although they may find that it leads to tighter tolerances, potentially increasing manufacturing costs.

How Does Root Sum Square (RSS) Differ from Other Methods?

Root Sum Square (RSS) utilizes statistical analysis to determine overall part variation by summing the squares of individual tolerances. This method is suitable for industries like consumer products and electronics, where understanding the cumulative effect of variations is crucial. Buyers should weigh the benefits of a more realistic approach against the need for a solid grasp of statistical principles, which may require additional training or expertise.

Why Choose Monte Carlo Simulation for Tolerance Analysis?

Monte Carlo Simulation stands out for its ability to visualize potential outcomes through random sampling techniques. This method is particularly advantageous in sectors like heavy equipment and construction, where complex interactions between parts can lead to significant variations. Although it provides detailed insights, buyers must be prepared for the computational demands and time investment associated with this approach.

What is the Importance of Geometric Dimensioning & Tolerancing (GD&T)?

GD&T emphasizes the functional relationships between parts, providing a framework for ensuring that components fit together as intended. This method is applicable across various industries, particularly in precision engineering. While it enhances communication among design and manufacturing teams, buyers should be aware of the complexity involved in implementation and the need for thorough training for effective use.

How Does DimXpert Tolerance Analysis Streamline the Tolerance Process?

DimXpert Tolerance Analysis automates the application of tolerances directly from CAD models, significantly speeding up the design process. This method is particularly beneficial in rapid prototyping and custom manufacturing environments, where time is of the essence. However, it is limited to users of SOLIDWORKS software, so buyers should consider their existing tools and the potential need for software upgrades.

Key Industrial Applications of solidworks tolerance stack

| Industry/Sector | Specific Application of solidworks tolerance stack | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Optimizing assembly tolerances in vehicle manufacturing | Reduces defects, improves fit, and enhances vehicle performance | Supplier capabilities in advanced tolerance analysis and GD&T |

| Aerospace & Defense | Ensuring precision in component assembly for aircraft | Increases safety, compliance, and reduces costly reworks | Certifications for compliance with aerospace standards |

| Medical Device | Validating tolerances in the design of surgical instruments | Enhances product reliability and patient safety | Regulatory compliance expertise and material sourcing |

| Electronics | Managing tolerances in complex circuit board assemblies | Minimizes production costs and enhances product reliability | Supplier’s experience with high-precision electronic components |

| Construction & Heavy Equipment | Streamlining tolerance analysis for machinery parts | Improves operational efficiency and reduces maintenance costs | Availability of robust engineering support and local sourcing |

How is SolidWorks Tolerance Stack Applied in the Automotive Sector?

In the automotive industry, SolidWorks tolerance stack is crucial for optimizing assembly tolerances during vehicle manufacturing. By simulating various tolerances, manufacturers can identify potential fit issues before production begins, thereby reducing defects and enhancing overall vehicle performance. International buyers, particularly from regions like South America and Africa, should consider suppliers that offer robust tolerance analysis capabilities, as these can significantly impact the quality and reliability of automotive components.

What Role Does Tolerance Stack Play in Aerospace & Defense?

In aerospace and defense, precision is paramount. SolidWorks tolerance stack analysis ensures that components fit together correctly, which is vital for safety and compliance with stringent industry standards. This application minimizes the risk of costly reworks and enhances the reliability of critical systems. Buyers from the Middle East and Europe should prioritize suppliers who understand aerospace regulations and can demonstrate a history of compliance and quality assurance.

How Does Tolerance Stack Benefit the Medical Device Industry?

The medical device industry relies on SolidWorks tolerance stack to validate the tolerances of surgical instruments and implants. This analysis helps ensure that products meet stringent reliability and safety standards, ultimately protecting patient health. For international buyers, especially in emerging markets, sourcing from suppliers who have a deep understanding of regulatory compliance is essential to ensure that products can be safely used in medical environments.

Why is Tolerance Stack Important in Electronics Manufacturing?

In the electronics sector, managing tolerances in complex circuit board assemblies is critical. SolidWorks tolerance stack allows manufacturers to minimize production costs while enhancing product reliability by identifying potential issues in assembly before they occur. Buyers from regions like Vietnam and Saudi Arabia should focus on suppliers with experience in high-precision electronic components, as this expertise can lead to better product outcomes and fewer production delays.

How Can Tolerance Stack Improve Construction & Heavy Equipment Manufacturing?

In construction and heavy equipment manufacturing, SolidWorks tolerance stack is utilized to streamline the tolerance analysis of machinery parts. This application helps improve operational efficiency by ensuring components fit together properly, which in turn reduces maintenance costs and downtime. For B2B buyers in Africa and South America, sourcing from suppliers who provide robust engineering support and local sourcing options can enhance the overall efficiency and reliability of construction machinery.

3 Common User Pain Points for ‘solidworks tolerance stack’ & Their Solutions

Scenario 1: Inconsistent Product Quality Across Manufacturing Locations

The Problem: B2B buyers often face the challenge of inconsistent product quality, especially when manufacturing occurs across multiple locations in regions like Africa and South America. Variability in assembly processes and differences in tolerancing standards can lead to significant discrepancies in product quality. For instance, a company might produce parts in one country that fit perfectly, while the same parts manufactured elsewhere might fail to meet specifications, resulting in increased rework and customer dissatisfaction.

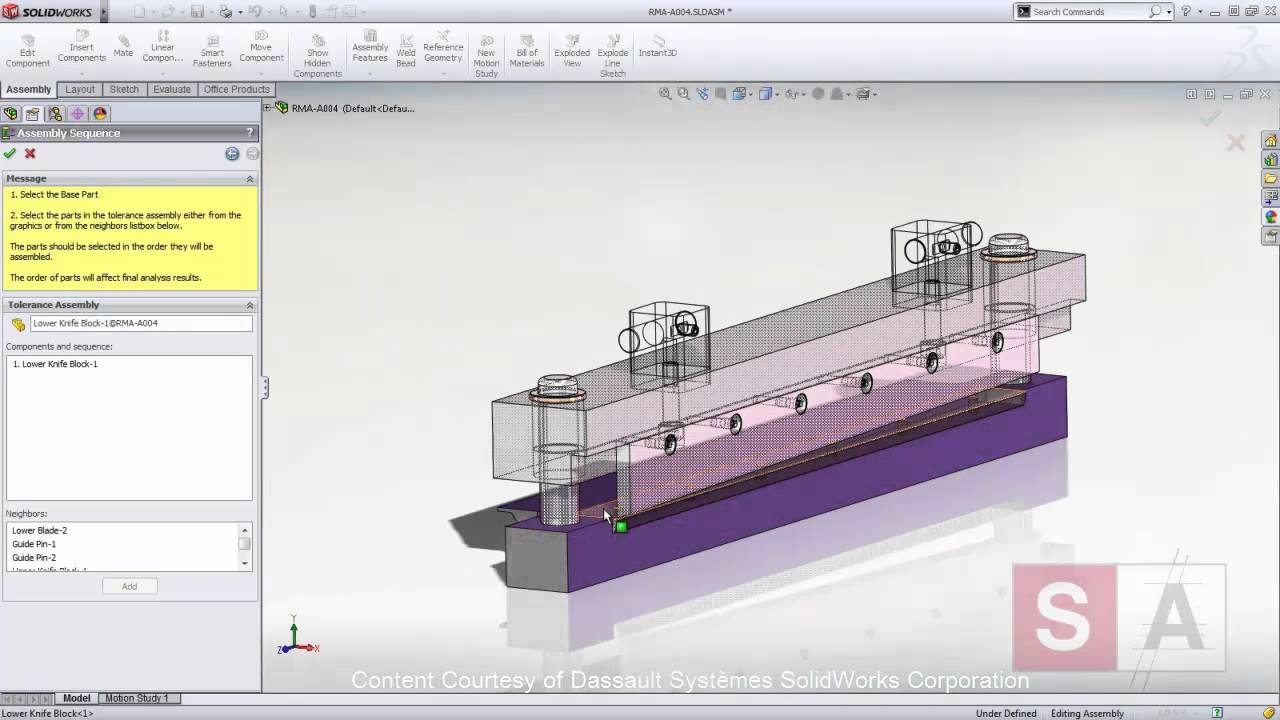

The Solution: To mitigate these quality control issues, leveraging SOLIDWORKS Tolerance Stack-Up with integrated tools like TolAnalyst can be invaluable. By utilizing this add-in, buyers can perform comprehensive tolerance analysis directly within the SOLIDWORKS environment, ensuring that all manufacturing locations adhere to consistent tolerancing practices. It is crucial to standardize the GD&T (Geometric Dimensioning and Tolerancing) specifications across all production sites. Implementing a robust training program for all engineers and assembly staff on the importance of tolerancing can further help in aligning processes. This proactive approach not only reduces variability but also enhances overall product quality.

Scenario 2: High Costs Due to Excessive Tolerances

The Problem: Many B2B buyers struggle with high manufacturing costs stemming from overly tight tolerances. In industries such as aerospace and automotive, where precision is critical, companies often impose stringent tolerances on parts. However, this can lead to unnecessary expenses, as manufacturers may need to invest in specialized machinery or processes to meet these requirements. Overly conservative tolerances can also result in increased scrap rates and rework, further inflating costs.

The Solution: To address this issue, buyers should conduct a thorough tolerance analysis using SOLIDWORKS tools like 3DCS Variation Analyst. This software allows users to simulate the effects of various tolerances on assembly fit, enabling them to identify which tolerances can be relaxed without compromising product quality. By utilizing Monte Carlo simulations or sensitivity analysis, companies can make data-driven decisions about which tolerances are essential and which can be adjusted. Furthermore, engaging in a collaborative review of design specifications with engineers can uncover opportunities to optimize tolerances while maintaining necessary quality standards, ultimately leading to cost savings.

Scenario 3: Difficulty in Communicating Tolerance Requirements

The Problem: Effective communication of tolerance requirements is a common pain point for B2B buyers, particularly when dealing with international suppliers. Misunderstandings or misinterpretations of tolerance specifications can lead to parts that do not fit correctly, resulting in costly delays and strained supplier relationships. For example, if a supplier in the Middle East misinterprets a GD&T specification due to language barriers or differing standards, it could lead to significant production setbacks.

The Solution: To enhance communication around tolerance requirements, buyers should leverage SOLIDWORKS’ capabilities to create clear, precise documentation that includes visual representations of tolerances. Utilizing tools such as DimXpert within SOLIDWORKS can help in automatically applying GD&T to models, ensuring that the specifications are easily understandable and unambiguous. Additionally, establishing a standard operating procedure (SOP) for communicating tolerances, including visual aids and detailed annotations, can significantly reduce the risk of miscommunication. Regular training sessions for both internal teams and external suppliers on GD&T standards and best practices can further bridge any gaps, fostering better collaboration and reducing the likelihood of errors in production.

Strategic Material Selection Guide for solidworks tolerance stack

What Are the Key Properties of Common Materials Used in SOLIDWORKS Tolerance Stack Analysis?

When selecting materials for tolerance stack analysis in SOLIDWORKS, it is essential to consider properties that directly impact performance and application suitability. Below, we analyze four commonly used materials: Aluminum, Steel, Plastic (ABS), and Composite materials.

Aluminum: Lightweight and Versatile

Aluminum is known for its excellent strength-to-weight ratio, making it an ideal choice for various applications, especially in the automotive and aerospace industries. Key properties include good corrosion resistance and thermal conductivity, with a temperature rating of up to 150°C.

Pros: Aluminum is lightweight, easy to machine, and offers good thermal properties. It is also recyclable, which can be a significant advantage for companies focusing on sustainability.

Cons: While generally durable, aluminum can be more expensive than some alternatives, particularly high-strength alloys. It may also have limitations in high-stress applications compared to steel.

Impact on Application: Aluminum’s compatibility with various media makes it suitable for components exposed to moisture or corrosive environments.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM B221 or EN 573. In regions like the Middle East and Africa, where heat and corrosion are concerns, selecting anodized aluminum can enhance longevity.

Steel: Strength and Durability

Steel is a widely used material known for its high strength and durability. It has a temperature rating that can exceed 300°C, depending on the alloy. Steel also exhibits excellent wear resistance and can be treated for enhanced performance.

Pros: Steel is cost-effective and can be used in various applications, from construction to automotive parts. Its strength allows for tighter tolerances in designs.

Cons: Steel is heavier than aluminum and can be prone to corrosion if not properly treated. Additionally, manufacturing complexity can increase with certain alloys.

Impact on Application: Steel’s robustness makes it suitable for high-stress applications, but its weight may be a disadvantage in lightweight design scenarios.

Considerations for International Buyers: Compliance with standards like ASTM A36 or DIN 17100 is crucial. In South America and Europe, buyers should be aware of local regulations regarding material sourcing and environmental impact.

Plastic (ABS): Cost-Effective and Lightweight

Acrylonitrile Butadiene Styrene (ABS) is a thermoplastic known for its impact resistance and ease of manufacturing. It can withstand temperatures up to 80°C, making it suitable for a variety of consumer products and prototypes.

Pros: ABS is lightweight, cost-effective, and easy to mold, allowing for complex geometries. It also offers good chemical resistance, making it suitable for various applications.

Cons: While it is durable, ABS is less heat-resistant than metals and may deform under high temperatures. Its mechanical properties can also vary significantly based on the manufacturing process.

Impact on Application: ABS is ideal for applications that require lightweight components but may not be suitable for high-stress environments.

Considerations for International Buyers: Buyers should check for compliance with standards such as ISO 1043. In regions like Africa and the Middle East, where heat can be a concern, ensuring proper application of ABS in high-temperature environments is critical.

Composite Materials: Advanced Performance

Composite materials, such as carbon fiber reinforced plastics, offer high strength-to-weight ratios and excellent fatigue resistance. They can withstand temperatures up to 200°C, depending on the resin used.

Pros: Composites are lightweight and can be tailored for specific applications, providing excellent mechanical properties and corrosion resistance.

Cons: The cost of composite materials is generally high, and manufacturing can be complex, requiring specialized techniques and equipment.

Impact on Application: Composites are ideal for high-performance applications, such as aerospace and automotive components, where weight savings are critical.

Considerations for International Buyers: Compliance with standards like ASTM D3039 for tensile properties is essential. Buyers in Europe and the Middle East should also consider the environmental impact of composite disposal.

Summary Table

| Material | Typical Use Case for SOLIDWORKS Tolerance Stack | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and good corrosion resistance | Higher cost than some alternatives | Medium |

| Steel | Structural components, machinery parts | High strength and cost-effective | Heavier and prone to corrosion | Low |

| Plastic (ABS) | Consumer products, prototypes | Cost-effective and easy to mold | Less heat-resistant than metals | Low |

| Composite | Aerospace, high-performance automotive parts | High strength-to-weight ratio | High cost and complex manufacturing | High |

This strategic material selection guide provides valuable insights for international B2B buyers looking to optimize their tolerance stack analysis in SOLIDWORKS, considering both performance and compliance factors relevant to their specific markets.

In-depth Look: Manufacturing Processes and Quality Assurance for solidworks tolerance stack

What Are the Key Stages in the Manufacturing Process for SolidWorks Tolerance Stacks?

The manufacturing process for products designed with SolidWorks tolerance stacks involves several critical stages, each essential for ensuring that final products meet the required specifications and tolerances.

Material Preparation: How Is It Done?

The first step in the manufacturing process is material preparation. This involves selecting the appropriate raw materials based on the design requirements and specifications. Common materials include metals, plastics, and composites, which are chosen for their mechanical properties, cost-effectiveness, and compatibility with the intended application.

Once the materials are selected, they undergo processes such as cutting, machining, or molding to achieve the desired shapes and sizes. This stage is crucial because the quality of the raw materials directly impacts the overall performance and durability of the final product.

What Techniques Are Used in Forming and Assembly?

The next stage is forming, which can involve various methods like stamping, bending, and welding, depending on the product requirements. For example, in the automotive industry, components might be stamped from sheet metal, while in electronics, injection molding might be used for plastic housings.

After forming, the assembly process begins, where individual components are combined to create the final product. This stage often utilizes automated assembly lines or manual assembly techniques, depending on the complexity of the assembly and production volume. Tools like SolidWorks can aid in simulating assembly processes, helping manufacturers identify potential issues before production begins.

How Does Finishing Impact the Quality of Tolerance Stacks?

Finishing is the final stage in the manufacturing process, which involves additional treatments such as painting, coating, or polishing. These finishing touches not only enhance the aesthetic appeal of the product but also improve its resistance to wear and corrosion.

The finishing processes must be closely monitored, as they can affect the dimensions and tolerances of the product. Any deviations at this stage can lead to misalignments or failures in assembly, making it essential to integrate finishing processes into the overall tolerance stack analysis.

What Quality Control (QC) Measures Are Essential for SolidWorks Tolerance Stacks?

Quality control is a vital aspect of the manufacturing process, ensuring that products meet both international standards and specific industry regulations.

Which International Standards Should Buyers Consider?

For B2B buyers, understanding relevant international standards is crucial. ISO 9001 is a widely recognized standard that outlines the requirements for a quality management system. This standard emphasizes customer satisfaction, process improvement, and compliance with regulations, making it essential for manufacturers operating in international markets.

In addition to ISO 9001, industry-specific certifications may also be applicable. For example, the CE mark is crucial for products sold in the European market, while API standards are vital for manufacturers in the oil and gas sector. Buyers should ensure that their suppliers adhere to these standards to guarantee product safety and reliability.

What Are the Key QC Checkpoints in Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to identify and rectify issues early. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, periodic checks are conducted to monitor the production process and identify defects in real-time.

-

Final Quality Control (FQC): Once production is complete, final inspections are performed to verify that the finished product meets all specifications and tolerances.

These checkpoints help reduce scrap rates and ensure that products meet quality standards before they reach the market.

How Can B2B Buyers Verify Supplier QC Processes?

For B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for minimizing risk.

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is a crucial step in assessing a manufacturer’s QC processes. These audits should evaluate the supplier’s adherence to international standards, their QC checkpoints, and the effectiveness of their quality management systems.

Buyers can implement a structured audit process that includes:

- Documentation Review: Assessing quality manuals, inspection reports, and certifications.

- Site Visits: Physically inspecting the manufacturing facilities and observing processes in action.

- Interviews: Engaging with quality assurance personnel to understand their methodologies and practices.

How Do Third-Party Inspections Enhance Confidence?

Engaging third-party inspection services can further enhance the reliability of the QC process. These independent organizations offer unbiased assessments of manufacturing practices and product quality. Buyers can request detailed reports from these inspections to gain insights into the supplier’s adherence to quality standards.

What QC and Certification Nuances Should International Buyers Be Aware Of?

International buyers must navigate various QC and certification nuances that can affect their procurement strategies. Different regions may have varying regulations regarding product safety and quality.

How Do Regional Standards Impact Product Compliance?

For instance, manufacturers exporting to the European market must comply with the CE marking requirements, which necessitate thorough testing and documentation. Similarly, products intended for the Middle Eastern market may need to adhere to specific local standards, such as those set by the Gulf Cooperation Council (GCC).

Buyers should conduct thorough research into the regulatory requirements of their target markets and ensure that their suppliers are compliant with these standards.

Conclusion: Ensuring Quality in SolidWorks Tolerance Stacks

Understanding the manufacturing processes and quality assurance measures associated with SolidWorks tolerance stacks is critical for B2B buyers. By focusing on material preparation, forming, assembly, and finishing processes, along with robust QC measures aligned with international standards, businesses can ensure the production of high-quality, reliable products. As global trade continues to expand, maintaining strict oversight on supplier practices and compliance will be paramount for success in diverse markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘solidworks tolerance stack’

To effectively procure SOLIDWORKS tolerance stack solutions, it is essential to follow a structured approach that ensures the selection of the best tools and suppliers for your specific needs. This guide provides a step-by-step checklist designed for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Begin by outlining the specific technical requirements your organization needs from a SOLIDWORKS tolerance stack solution. This includes identifying the types of assemblies you will analyze, the level of precision required, and any industry standards you must comply with. Clearly defined specifications help suppliers understand your needs, ensuring you receive appropriate solutions.

Step 2: Research Available Tools and Software

Investigate the various tolerance analysis tools compatible with SOLIDWORKS, such as 3DCS Variation Analyst and TolAnalyst. Compare features, pricing, and user reviews to evaluate which tools best meet your requirements. Look for software that offers integration capabilities, as this can enhance workflow efficiency by streamlining processes.

Step 3: Evaluate Potential Suppliers

Before making a commitment, conduct thorough evaluations of potential suppliers. Request detailed company profiles, case studies, and references from buyers in similar industries or regions. It’s crucial to assess their experience with SOLIDWORKS and tolerance stack solutions to gauge their ability to meet your specific needs.

- Consider the following:

- Years of experience in the industry

- Client testimonials and satisfaction ratings

- Support and training services offered

Step 4: Verify Certifications and Compliance

Ensure that the suppliers you consider hold relevant certifications and adhere to industry standards. This includes ISO certifications or any specific compliance relevant to your industry, such as automotive or aerospace standards. Verified certifications indicate a commitment to quality and reliability, minimizing the risk of non-compliance in your projects.

Step 5: Request Demonstrations and Trials

Before finalizing your choice, request demonstrations or trial versions of the software to assess usability and functionality. This hands-on experience is invaluable in determining whether the software aligns with your team’s workflow and meets your performance expectations. Pay attention to user interface, ease of integration, and support for GD&T (Geometric Dimensioning and Tolerancing).

Step 6: Assess Training and Support Options

Evaluate the training and support options provided by suppliers. Comprehensive training is crucial for maximizing the capabilities of SOLIDWORKS tolerance stack solutions. Look for suppliers that offer ongoing support, tutorials, and resources to help your team effectively use the tools over time.

Step 7: Negotiate Terms and Finalize Contracts

Once you’ve selected a supplier, engage in negotiations to ensure favorable terms regarding pricing, licensing, and support. Clearly outline expectations in the contract, including delivery timelines and service level agreements. A well-negotiated contract can provide additional protections and ensure accountability from the supplier.

By following this checklist, B2B buyers can confidently navigate the procurement process for SOLIDWORKS tolerance stack solutions, ensuring they select the best tools and partners for their specific needs.

Comprehensive Cost and Pricing Analysis for solidworks tolerance stack Sourcing

What Are the Key Cost Components in SolidWorks Tolerance Stack Sourcing?

Understanding the cost structure of SolidWorks tolerance stack sourcing is essential for B2B buyers looking to optimize their budgets. The main cost components include:

-

Materials: The choice of materials significantly impacts costs. High-quality materials that meet specific tolerances tend to be more expensive but can enhance product durability and performance. Buyers should evaluate material specifications carefully to balance cost and quality.

-

Labor: Skilled labor is necessary for accurate tolerance stack analysis and implementation. Training staff on tools like TolAnalyst or 3DCS can incur additional costs but ultimately leads to better efficiency and fewer errors.

-

Manufacturing Overhead: This encompasses utilities, facilities, and administrative costs associated with production. Efficient manufacturing processes can help lower overhead costs, which is particularly important for international buyers facing varying operational costs across regions.

-

Tooling: Custom tooling may be required for specific designs, adding to the initial investment. However, investing in versatile tooling can reduce long-term costs by enabling the production of a wider range of components.

-

Quality Control (QC): Implementing rigorous QC processes ensures that products meet tolerance specifications. While this can increase upfront costs, it can lead to significant savings by reducing defects and rework.

-

Logistics: Shipping and handling costs, especially for international transactions, can affect pricing. Understanding Incoterms and choosing the right logistics partners can help mitigate these expenses.

-

Margin: Supplier margins vary widely and can be influenced by factors such as brand reputation, supply chain efficiency, and market demand. Buyers should benchmark supplier quotes against industry standards to ensure competitiveness.

How Do Price Influencers Affect SolidWorks Tolerance Stack Costs?

Several factors can influence pricing in the context of SolidWorks tolerance stack sourcing:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs and negotiate minimum order quantities (MOQs) that align with their production schedules.

-

Specifications and Customization: Customized solutions tailored to specific project requirements can increase costs. Buyers should clarify their needs upfront to avoid unexpected expenses later in the project.

-

Materials: The choice of materials significantly affects pricing. Higher-grade materials may yield better performance but come at a premium. Buyers should balance material quality with cost-effectiveness.

-

Quality Certifications: Suppliers with recognized quality certifications may charge higher prices, but the assurance of quality can lead to lower long-term costs. Buyers should weigh the benefits of quality assurance against initial expenditures.

-

Supplier Factors: The reliability and reputation of suppliers can impact pricing. Established suppliers may command higher prices but often provide better service and lower risk.

-

Incoterms: Understanding shipping terms is crucial for international buyers. Incoterms dictate who is responsible for shipping costs, insurance, and tariffs, influencing the overall cost structure.

What Are the Best Buyer Tips for Cost-Efficient SolidWorks Tolerance Stack Sourcing?

To maximize cost efficiency in SolidWorks tolerance stack sourcing, consider the following strategies:

-

Negotiate Wisely: Engage in discussions with suppliers about pricing, especially when placing bulk orders. Leverage your position as a B2B buyer to negotiate better terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Assess maintenance, operational costs, and potential savings from reduced defects or rework to determine the true cost of sourcing.

-

Research Pricing Nuances for International Transactions: Different regions may have varying pricing structures due to labor costs, material availability, and regulatory standards. Familiarize yourself with these factors to make informed purchasing decisions.

-

Invest in Training and Tools: Providing your team with adequate training on SolidWorks tools like TolAnalyst can lead to more accurate designs and less costly mistakes.

-

Build Long-Term Relationships with Suppliers: Establishing strong partnerships with reliable suppliers can yield better pricing and terms over time, as they become more invested in your success.

By understanding the complexities of cost components, price influencers, and strategic buying practices, B2B buyers can navigate the sourcing of SolidWorks tolerance stacks effectively, ensuring optimal financial outcomes.

Alternatives Analysis: Comparing solidworks tolerance stack With Other Solutions

When evaluating tolerance analysis solutions, it is essential for B2B buyers to consider various alternatives to the Solidworks Tolerance Stack. Each option comes with its unique features and benefits, catering to different organizational needs and operational contexts. Below, we compare Solidworks Tolerance Stack with two viable alternatives: 3DCS Variation Analyst and TolAnalyst.

| Comparison Aspect | Solidworks Tolerance Stack | 3DCS Variation Analyst | TolAnalyst |

|---|---|---|---|

| Performance | Integrated with CAD for real-time analysis | Advanced simulations with Monte Carlo methods | Quick worst-case calculations with GD&T data |

| Cost | Requires SOLIDWORKS Professional/Premium license | Subscription-based pricing, potential for higher costs | Included with SOLIDWORKS Professional/Premium |

| Ease of Implementation | Requires familiarity with SOLIDWORKS tools | Integrated but may require training for advanced features | User-friendly for basic GD&T analysis |

| Maintenance | Regular updates included in SOLIDWORKS | Ongoing updates and support from 3DCS | Updates aligned with SOLIDWORKS versions |

| Best Use Case | Ideal for standard design environments | Best for complex assemblies and high-precision industries | Suitable for quick tolerance checks in simple assemblies |

What Are the Pros and Cons of 3DCS Variation Analyst?

3DCS Variation Analyst is a powerful alternative that specializes in advanced tolerance analysis. It employs techniques such as Monte Carlo simulation, which allows for a more comprehensive understanding of product variation and quality risks. The software integrates seamlessly with SOLIDWORKS, enabling users to manage their CAD models while conducting tolerance analyses. However, the complexity of its features may necessitate a steeper learning curve and ongoing training, potentially increasing overall costs for businesses that require extensive use of its advanced functionalities.

How Does TolAnalyst Compare in Terms of Functionality?

TolAnalyst, an add-in for SOLIDWORKS, provides a more straightforward approach to tolerance stack-up analysis. It simplifies the process of verifying dimensioning and tolerancing schemes by automating calculations and generating contributor lists for tolerance impacts. This solution is particularly beneficial for users who need to conduct quick assessments without delving into complex simulations. On the downside, its capabilities may be limited compared to the more sophisticated analyses offered by 3DCS, making it less suitable for industries requiring high precision and detailed analysis.

How to Choose the Right Solution for Your Organization?

When selecting a tolerance analysis solution, B2B buyers should assess their specific needs, including the complexity of their products and the level of precision required. For organizations with standard design processes, Solidworks Tolerance Stack or TolAnalyst may suffice. However, for those dealing with intricate assemblies and stringent quality requirements, 3DCS Variation Analyst could provide the necessary depth and insight. Additionally, cost considerations and the potential need for ongoing training should also inform the decision-making process. Ultimately, aligning the chosen solution with the company’s operational goals and resources will yield the best long-term results.

Essential Technical Properties and Trade Terminology for solidworks tolerance stack

What are the Essential Technical Properties in SOLIDWORKS Tolerance Stack?

When working with SOLIDWORKS for tolerance stack analysis, understanding key technical properties is crucial for ensuring product quality and manufacturability. Here are some of the most critical specifications:

-

Material Grade: This refers to the specific type of material used in manufacturing a component, which can significantly affect its mechanical properties and performance. Material grade influences tolerance stack outcomes, as different materials exhibit varying levels of thermal expansion, stiffness, and strength. For B2B buyers, selecting the right material grade is vital for ensuring that products meet durability and performance standards while also adhering to cost constraints.

-

Tolerance: Tolerance specifies the permissible limit of variation in a physical dimension. In SOLIDWORKS, tolerances can be defined using Geometric Dimensioning and Tolerancing (GD&T) standards. Properly set tolerances are essential for fitting parts together correctly in assembly processes. For businesses, maintaining optimal tolerances helps reduce manufacturing costs by minimizing scrap and rework.

-

Assembly Variation: This property assesses how different components fit together during the assembly process, taking into account their individual tolerances. Understanding assembly variation helps identify potential issues before production, reducing the risk of costly errors. In a B2B context, this is crucial for manufacturers aiming to streamline their processes and enhance product quality.

-

GD&T (Geometric Dimensioning and Tolerancing): GD&T is a system for defining and communicating engineering tolerances. It provides a clear and concise way to specify the allowable limits of variation for features on a part. This system is essential for ensuring that parts manufactured in different locations or times will fit together as intended. For companies, implementing GD&T can lead to improved communication and fewer misunderstandings in the manufacturing process.

-

Worst-Case Scenario Analysis: This analysis estimates the maximum possible variation in part dimensions and how it affects assembly fit. By conducting worst-case scenario analysis, engineers can identify the most critical tolerances that impact product functionality. For B2B buyers, this insight is crucial for making informed decisions about design adjustments and manufacturing processes.

-

Monte Carlo Simulation: This statistical technique is used to understand the impact of risk and uncertainty in prediction and forecasting models. In the context of tolerance stack analysis, it helps predict how variations in part dimensions will affect the final product. For businesses, Monte Carlo simulations provide a data-driven approach to risk management, allowing for better strategic planning.

What are the Common Trade Terms Used in SOLIDWORKS Tolerance Stack?

In the realm of SOLIDWORKS tolerance stack analysis, familiarity with industry terminology can facilitate better communication and decision-making. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer): This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In tolerance stack analysis, understanding the role of OEMs is vital for ensuring compatibility and compliance with specifications.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to manage inventory costs effectively and negotiate better deals with suppliers.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to solicit price quotes for a specific quantity of goods or services. It is a critical step in the procurement process that helps businesses understand costs associated with manufacturing tolerance stacks.

-

Incoterms (International Commercial Terms): These are predefined commercial terms published by the International Chamber of Commerce that delineate responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to clarify shipping, insurance, and duty obligations, thereby minimizing risks in global trade.

-

PLM (Product Lifecycle Management): PLM refers to the process of managing the entire lifecycle of a product from inception, through engineering design and manufacturing, to service and disposal. Implementing PLM systems helps companies streamline processes and improve collaboration, especially in tolerance stack analysis.

-

DFA (Design for Assembly): This principle emphasizes designing products in a way that simplifies the assembly process. In the context of tolerance stacks, DFA can help reduce the complexity and cost of manufacturing, making it a key consideration for engineers and decision-makers.

By grasping these essential properties and terminology, B2B buyers can better navigate the complexities of SOLIDWORKS tolerance stack analysis, leading to improved product quality and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the solidworks tolerance stack Sector

What Are the Current Market Dynamics and Key Trends in the SolidWorks Tolerance Stack Sector?

The global SolidWorks tolerance stack market is increasingly influenced by several key drivers. One of the most significant is the rising demand for precision engineering across industries such as aerospace, automotive, and medical devices. As competition intensifies, manufacturers are compelled to minimize defects and enhance product quality, leading to a surge in the adoption of tolerance analysis tools like 3DCS and TolAnalyst. These tools facilitate advanced simulations that help engineers identify potential variances and improve design processes.

Emerging technologies, including artificial intelligence (AI) and machine learning, are also shaping the landscape of tolerance analysis. Companies are leveraging these technologies for predictive analytics, allowing them to foresee potential issues in the design phase and make informed decisions to mitigate risks. This trend is particularly relevant for B2B buyers in regions such as Africa and South America, where the integration of advanced tech can significantly enhance operational efficiencies.

Another notable trend is the increasing focus on integrated software solutions. Tools that seamlessly integrate with existing CAD platforms, such as SOLIDWORKS, provide users with streamlined workflows, enhancing the overall design and analysis process. This is crucial for international buyers, especially in Europe and the Middle East, where companies are looking for solutions that offer scalability and adaptability to changing market demands.

How Does Sustainability and Ethical Sourcing Impact B2B Buyers in the SolidWorks Tolerance Stack Sector?

Sustainability has become a pivotal concern for B2B buyers in the SolidWorks tolerance stack sector. The environmental impact of manufacturing processes is under scrutiny, compelling companies to adopt greener practices. This shift is not only driven by regulatory requirements but also by consumer preferences for sustainable products. As a result, manufacturers are increasingly prioritizing the use of environmentally friendly materials and processes, which is essential for maintaining competitiveness in the global market.

Ethical sourcing is equally important, as buyers seek suppliers who demonstrate a commitment to responsible practices. Transparency in the supply chain, along with certifications for green materials, is becoming a critical factor in vendor selection. B2B buyers should prioritize suppliers who have robust sustainability initiatives and can provide documentation or certifications that validate their practices. This focus on ethical sourcing not only helps companies comply with regulations but also enhances their brand reputation and fosters customer loyalty.

What Is the Brief Evolution of Tolerance Analysis in SolidWorks?

The evolution of tolerance analysis within SolidWorks has been marked by significant technological advancements. Initially, tolerance stack-ups were calculated manually, often leading to errors and inefficiencies. The introduction of integrated tools like the TolAnalyst add-in revolutionized this process, allowing engineers to automate calculations and quickly verify dimensioning and tolerancing schemes.

As the market evolved, the integration of advanced simulation techniques such as Monte Carlo analysis and sensitivity analysis further enhanced the capabilities of tolerance analysis tools. These innovations have enabled manufacturers to simulate complex assembly processes, thus minimizing risks associated with design variations. Today, with the growing emphasis on digital transformation and Industry 4.0, tolerance analysis continues to adapt, focusing on real-time data integration and analytics, which are essential for modern manufacturing environments.

By understanding these market dynamics and trends, B2B buyers can make informed decisions that align with their strategic goals and enhance their operational efficiencies in the SolidWorks tolerance stack sector.

Frequently Asked Questions (FAQs) for B2B Buyers of solidworks tolerance stack

-

1. How do I solve tolerance stack-up issues in my designs?

To address tolerance stack-up issues, utilize tools like SOLIDWORKS TolAnalyst or 3DCS Variation Analyst. These software solutions allow for advanced tolerance analysis by simulating part assembly and evaluating variations through methods such as Monte Carlo simulation. Begin by defining your design’s GD&T (Geometric Dimensioning and Tolerancing) and apply it within the software. The analysis will help identify critical tolerances affecting assembly, enabling you to make informed adjustments that enhance product quality while minimizing costs. -

2. What is the best software for tolerance stack analysis in SOLIDWORKS?

The best software for tolerance stack analysis within the SOLIDWORKS environment includes 3DCS Variation Analyst and the TolAnalyst add-in. Both provide integrated solutions for performing comprehensive tolerance analysis. 3DCS offers advanced features like Monte Carlo simulations and sensitivity analysis, making it ideal for complex assemblies. TolAnalyst simplifies the process by directly reading GD&T data from SOLIDWORKS models, allowing for quick calculations of maximum and minimum tolerances, which is beneficial for ensuring proper fit and function. -

3. How can I ensure compliance with international quality standards when sourcing tolerance analysis software?

To ensure compliance with international quality standards, select software providers that hold relevant certifications such as ISO 9001. Additionally, verify if the software supports GD&T, which is critical for maintaining industry standards. Research the provider’s reputation, customer reviews, and case studies in your industry to assess their expertise. Engaging with suppliers who offer robust support and training can also enhance your implementation process, ensuring that your team can effectively utilize the software to meet compliance requirements. -

4. What are the typical minimum order quantities (MOQs) for tolerance stack software?

Minimum order quantities for tolerance stack software can vary based on the supplier and the licensing model. Typically, companies might offer single licenses for individual users or bulk licenses for teams. If you are considering a large-scale deployment across multiple departments or locations, inquire about volume discounts or enterprise licensing options that can reduce overall costs. Always clarify the terms with the supplier, as some may provide flexible pricing based on your specific needs. -

5. How do payment terms work for international software purchases?

Payment terms for international software purchases can differ significantly by supplier. Common terms include upfront payment, partial payments during implementation, or subscription-based models. It’s crucial to discuss and agree upon payment methods, such as credit cards, bank transfers, or digital payment platforms, considering any currency exchange implications. Ensure that the supplier provides a detailed invoice outlining the services included, as this will help in managing your budget and ensuring compliance with your financial policies. -

6. What logistics considerations should I be aware of when sourcing software internationally?

When sourcing software internationally, consider factors such as delivery timelines, installation support, and potential customs issues. Ensure that the supplier provides electronic delivery options to expedite access to software. Additionally, inquire about the availability of localized support and training, which can be vital for successful implementation. Understanding the time zone differences for support can also help in planning your project timelines effectively. -

7. How can I vet potential suppliers for tolerance stack software?

To vet potential suppliers for tolerance stack software, start by reviewing their industry experience, customer testimonials, and case studies relevant to your sector. Ask for references from existing clients and assess their level of customer support and training offerings. It may also be beneficial to request a demo or trial period to evaluate the software’s functionality and ease of use. Finally, ensure that the supplier has a clear roadmap for updates and ongoing support to align with your long-term needs. -

8. Can I customize the software to fit specific project needs?

Yes, many tolerance stack analysis software solutions, including those integrated with SOLIDWORKS, offer customization options to cater to specific project requirements. You can often adjust settings related to tolerancing parameters, simulation methods, and reporting formats. Discuss your customization needs with the supplier to understand the extent of modifications possible and any associated costs. Additionally, consider whether the supplier provides support for creating custom templates or workflows that align with your operational processes.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Solidworks Tolerance Stack Manufacturers & Suppliers List

1. SolidWorks – TolAnalyst™

Domain: help.solidworks.com

Registered: 1995 (30 years)

Introduction: TolAnalyst™ is a tolerance analysis tool used to study the effects tolerances and assembly methods have on dimensional stack-up between two features of an assembly. The result of each study includes a minimum and maximum tolerance stack, a minimum and maximum root sum squared (RSS) tolerance stack, and a list of contributing features and tolerances. The study is created using a four-step procedure…

2. Solid Solutions – TolAnalyst™ Tool

Domain: solidsolutions.co.uk

Registered: 1999 (26 years)

Introduction: Tolerance Stack-Up Analysis in SOLIDWORKS includes the TolAnalyst™ tool for automated tolerance analysis of parts and assemblies. It allows users to assess manufacturability by checking dimensions and tolerances early in the design process, which helps in saving time and development costs. Key capabilities include: assessing min/max tolerances, performing root-sum-squared (RSS) tolerance analysis,…

3. Reddit – Tolerance Stack Management Tools

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Tolerance stacks are used in high volume manufacturing to manage gaps and ensure product specifications are met. Engineers often utilize tools like Excel and PowerPoint for organization and analysis, while CAD software such as NX and Solidworks can integrate tolerances and provide statistical analysis for manufacturing processes.

4. 3DCS – Variation Analyst for SOLIDWORKS

Domain: 3dcs.com

Registered: 1997 (28 years)

Introduction: 3DCS Variation Analyst for SOLIDWORKS is an integrated tolerance analysis software that simulates product assembly and part tolerance stack-ups using Monte Carlo Analysis, Equation-Based, and High-Low-Median (Sensitivity) Analysis. It helps manufacturers reduce defects and improve product quality by providing insights into product variation and risk of failure. Key features include:

1. Integrated…

Strategic Sourcing Conclusion and Outlook for solidworks tolerance stack

How Can Strategic Sourcing Enhance Your SolidWorks Tolerance Stack Process?

In conclusion, strategic sourcing plays a pivotal role in optimizing the SolidWorks tolerance stack process, enabling organizations to mitigate risks, reduce costs, and enhance product quality. By leveraging advanced tools such as 3DCS Variation Analyst and TolAnalyst, companies can perform precise tolerance analysis, ensuring that parts fit and function correctly while minimizing rework and scrap rates. This not only streamlines the design and manufacturing processes but also fosters a culture of continuous improvement across teams.

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the integration of robust tolerance stack solutions can drive significant competitive advantages. As industries evolve and demand for quality escalates, investing in these strategic tools will empower businesses to meet stringent global standards and customer expectations.

We encourage you to explore the latest advancements in tolerance analysis software and consider how they can be integrated into your operations. By embracing these innovative solutions, you position your organization for future growth and success in an increasingly complex marketplace. Take the next step in your journey toward excellence in product design and manufacturing today.