Introduction: Navigating the Global Market for smt company

In today’s rapidly evolving global market, sourcing high-quality SMT (Surface Mount Technology) components can be a daunting challenge for B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. The complexities of varying supplier capabilities, fluctuating costs, and the need for stringent quality assurance make informed purchasing decisions critical. This comprehensive guide serves as a vital resource for international buyers seeking to navigate the intricate landscape of SMT companies, offering insights into the types of services available, applications across industries, and essential supplier vetting processes.

Throughout this guide, we will delve into the myriad aspects of SMT sourcing, including detailed evaluations of supplier capabilities, cost considerations, and the importance of establishing robust quality control measures. Additionally, we will explore the latest innovations in SMT technology and how they can enhance operational efficiency and product reliability. By equipping B2B buyers with actionable insights and strategies, this guide aims to empower you to make confident and informed decisions that align with your business needs and objectives.

Whether you are a manufacturer in Nigeria looking for reliable SMT solutions or a tech company in Vietnam seeking cutting-edge electronic components, this guide will serve as your roadmap to successfully navigating the global SMT market. Embrace the opportunity to enhance your sourcing strategies and build long-lasting supplier relationships that drive your business forward.

Understanding smt company Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electronic Manufacturing Services (EMS) | Focus on high-volume, complex PCB assemblies and custom integrations. | Consumer electronics, automotive, medical devices. | Pros: Scalability, rapid prototyping. Cons: Potentially high costs for low-volume runs. |

| Machine Tool Suppliers | Provide a range of machining and fabrication equipment. | Manufacturing, construction, and mining. | Pros: Diverse machinery options, strong support services. Cons: Initial investment can be substantial. |

| Sports Technology Providers | Specialize in data visualization and real-time analytics for sports. | Sports broadcasting, event management. | Pros: Enhanced fan engagement, innovative solutions. Cons: Niche market, may require technical expertise. |

| Counterfeit Electronics Mitigation | Focus on ensuring supply chain integrity and component authentication. | Defense, aerospace, and electronics sectors. | Pros: Reduces risk of counterfeit parts, comprehensive testing. Cons: Can be resource-intensive and complex. |

| Medical Device Manufacturers | Develop minimally invasive devices for healthcare applications. | Hospitals, clinics, and medical research. | Pros: Innovation in patient care, compliance with regulations. Cons: Regulatory hurdles and lengthy development cycles. |

What are Electronic Manufacturing Services (EMS) and Their B2B Relevance?

Electronic Manufacturing Services (EMS) companies provide essential support in the production of electronic components, focusing on high-volume and complex PCB assemblies. They are particularly suitable for businesses looking to scale production rapidly or launch new products. When considering an EMS partner, B2B buyers should evaluate the company’s capabilities in rapid prototyping, quality control standards, and the flexibility to adapt to changing market demands. The ability to deliver high-quality products quickly can significantly enhance a buyer’s competitive edge.

How Do Machine Tool Suppliers Support Manufacturing Industries?

Machine tool suppliers are pivotal in providing the machinery needed for various manufacturing processes, including turning, milling, and fabricating. These suppliers cater to industries such as construction and mining by offering a wide array of equipment. B2B buyers must consider the supplier’s range of products, after-sales service, and support when making purchasing decisions. While the initial investment can be high, the right machine tools can greatly enhance production efficiency and product quality.

What Role Do Sports Technology Providers Play in Enhancing Fan Engagement?

Sports technology providers leverage data visualization and real-time analytics to enhance the fan experience during sporting events. Their solutions are increasingly vital for broadcasters and event organizers aiming to engage audiences. B2B buyers should assess the provider’s track record, technology integration capabilities, and the uniqueness of their offerings. While these services can significantly enhance viewer engagement, they often require a level of technical understanding and investment in infrastructure.

Why is Counterfeit Electronics Mitigation Critical for B2B Buyers?

Counterfeit electronics mitigation companies focus on safeguarding supply chains by authenticating components and ensuring compliance with industry standards. This is crucial for sectors like defense and aerospace, where the integrity of components is paramount. Buyers should consider the company’s experience, testing methodologies, and the comprehensiveness of their supply chain assurance services. Although these services can add complexity and cost, they are essential for reducing risks associated with counterfeit parts.

What Innovations are Offered by Medical Device Manufacturers?

Medical device manufacturers specialize in developing cutting-edge healthcare solutions, such as minimally invasive devices. Their products are vital for hospitals and clinics looking to improve patient outcomes. B2B buyers in the healthcare sector should evaluate the manufacturer’s commitment to innovation, compliance with regulatory standards, and ability to provide ongoing support. While the development cycles can be lengthy and regulatory hurdles significant, the potential for improved patient care makes these partnerships highly valuable.

Key Industrial Applications of smt company

| Industry/Sector | Specific Application of smt company | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Electronics Manufacturing | High-Mix PCB Assembly | Quick turnaround for diverse product lines, reducing time-to-market | Quality control standards, component authenticity, scalability |

| Aerospace & Defense | Counterfeit Electronics Mitigation | Assurance of component integrity, enhancing operational reliability | Accreditation standards, supply chain transparency |

| Healthcare & Medical Devices | Development of Minimally Invasive Cardiovascular Devices | Innovation in patient care, improved outcomes, and market competitiveness | Regulatory compliance, material sourcing, and testing protocols |

| Sports Technology | Real-Time Data Visualization for Fan Engagement | Enhanced viewer experience, increased audience engagement | Integration capabilities, data accuracy, and system compatibility |

| Construction & Mining Equipment | Tooling and Fabrication Solutions | Improved operational efficiency, cost savings through optimized processes | Equipment durability, service support, and local availability |

How Does SMT Company Serve the Electronics Manufacturing Sector?

In the electronics manufacturing sector, SMT Company specializes in high-mix PCB assembly, addressing the need for rapid prototyping and production. This capability allows businesses to launch diverse product lines with quick turnarounds, thus reducing time-to-market significantly. For international buyers, especially those from Africa and South America, quality control standards and component authenticity are paramount, as they seek reliability in their supply chains amidst fluctuating market conditions.

What Role Does SMT Company Play in Aerospace and Defense?

SMT Company is recognized for its expertise in counterfeit electronics mitigation, particularly within the aerospace and defense industries. By providing assurance of component integrity, SMT helps businesses maintain operational reliability and compliance with stringent industry regulations. For buyers in the Middle East and Europe, understanding accreditation standards and ensuring supply chain transparency are critical when sourcing components that meet military specifications.

How Does SMT Company Contribute to Healthcare Innovations?

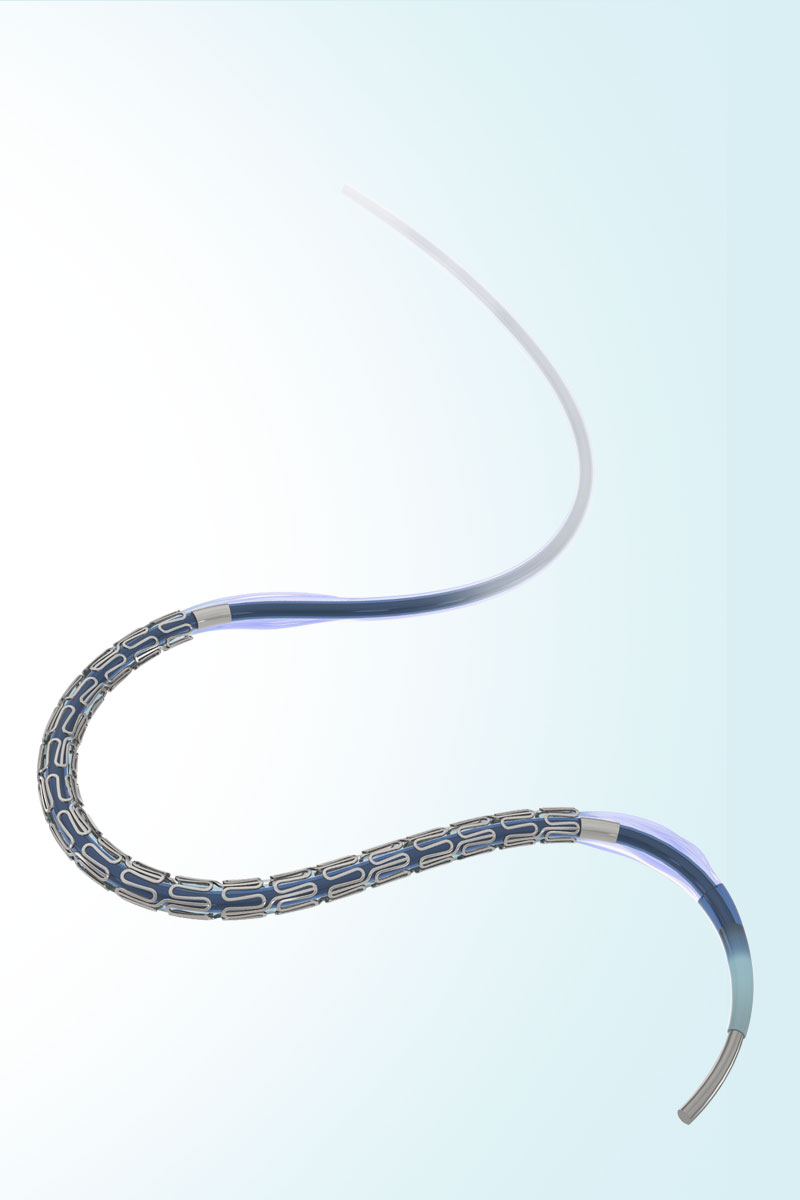

In the healthcare sector, SMT Company develops minimally invasive cardiovascular devices, focusing on innovation to improve patient care. This commitment not only enhances clinical outcomes but also strengthens market competitiveness for healthcare providers. For international B2B buyers, particularly from regions like Nigeria and Vietnam, compliance with regulatory standards and sourcing high-quality materials are essential factors to consider during the procurement process.

In What Ways Does SMT Company Enhance Sports Technology?

SMT Company plays a pivotal role in sports technology by offering real-time data visualization tools that significantly enhance fan engagement. This application is vital for sports organizations aiming to improve viewer experiences and increase audience interaction. Buyers, particularly in Europe and South America, should prioritize integration capabilities and data accuracy when sourcing these technologies, ensuring they align with existing systems and deliver impactful results.

How Does SMT Company Support Construction and Mining Equipment Industries?

In the construction and mining equipment sectors, SMT Company provides tooling and fabrication solutions that enhance operational efficiency. By optimizing processes, businesses can achieve significant cost savings. For international buyers, especially in Africa, considering equipment durability, service support, and local availability are key factors in ensuring long-term operational success and minimizing downtime.

3 Common User Pain Points for ‘smt company’ & Their Solutions

Scenario 1: Navigating Complex Supply Chains in Electronics Manufacturing

The Problem: B2B buyers in electronics manufacturing often face significant challenges when dealing with complex supply chains, particularly when sourcing components. Issues such as component shortages, long lead times, and the risk of counterfeit parts can jeopardize production schedules and inflate costs. For buyers in regions like Africa and South America, where reliable sourcing can be further complicated by local market conditions, the stakes are even higher. This scenario can lead to delays in product launches, increased operational costs, and ultimately, lost revenue.

The Solution: To navigate these complexities, buyers should consider partnering with SMT Company, known for its robust supply chain assurance and counterfeit mitigation strategies. Buyers should initiate the procurement process by leveraging SMT’s extensive whitelist supplier network, which features over 200 approved suppliers. This network not only reduces the risk of counterfeit components but also enhances the reliability of sourcing. Additionally, engaging SMT’s onsite authentication labs for electrical and environmental testing can ensure that the components meet industry standards before they enter the production line. Buyers should also take advantage of SMT’s 24/7 secure web portal to track inventory and manage supply chain logistics effectively, ensuring that they have real-time visibility into their component sourcing.

Scenario 2: Struggling with Rapid Prototyping Timelines

The Problem: In today’s fast-paced market, B2B buyers often find themselves under pressure to accelerate product development cycles. When launching new electronic products, delays in prototyping can result in missed market opportunities. Buyers may struggle with traditional prototyping methods that are not agile enough to meet the increasing demands for speed and efficiency, particularly when working with complex PCB assemblies.

The Solution: SMT Company offers a Rapid Prototyping Solutions Center that is designed to address these specific challenges. Buyers should engage SMT early in the product development process to benefit from real-time Design for Manufacturing (DFM) feedback, which can significantly reduce prototyping timelines. By providing prototypes that are IPC-compliant and designed for quick turnarounds, SMT enables buyers to validate designs faster and move into production without unnecessary delays. Furthermore, buyers should consider utilizing SMT’s integrated approach to New Product Introduction (NPI), which allows for a disciplined yet flexible launch process that adapts to changing requirements and accelerates time-to-market.

Scenario 3: Ensuring Quality Control in High-Volume Production

The Problem: Quality assurance is a critical concern for B2B buyers, especially when scaling production in high-volume environments. The risk of defects increases as production volumes rise, leading to costly recalls, rework, and potential damage to brand reputation. For companies operating in competitive markets, such as those in Europe and the Middle East, maintaining consistent quality while meeting production demands can be a daunting task.

The Solution: SMT Company emphasizes uncompromising quality control standards throughout its manufacturing processes. Buyers should capitalize on SMT’s commitment to quality by leveraging their state-of-the-art technology and individualized customer service. Engaging with SMT to establish a clear quality assurance protocol tailored to specific production needs can mitigate risks. Buyers should also implement traceability measures to ensure that every component can be tracked through the supply chain, enabling quick responses to any quality issues that may arise. Regular audits and reviews of production processes in collaboration with SMT can further enhance quality assurance efforts, providing buyers with the confidence that their products will meet the highest standards before reaching the market.

Strategic Material Selection Guide for smt company

What Are the Key Materials Used in SMT Company Products?

In the context of SMT companies, selecting the right materials is crucial for ensuring product performance and longevity. Here, we analyze four common materials used in SMT applications: Aluminum, Copper, FR-4 (a type of fiberglass), and Stainless Steel. Each material has unique properties, advantages, and disadvantages that can significantly impact the end product and its suitability for various applications.

How Does Aluminum Perform in SMT Applications?

Key Properties: Aluminum is lightweight yet strong, with excellent thermal and electrical conductivity. It typically has a temperature rating of up to 150°C and offers good corrosion resistance, particularly when anodized.

Pros & Cons: The primary advantage of aluminum is its low weight, which can reduce shipping costs and improve product performance in applications requiring mobility. However, it can be more expensive than other metals and may require additional coatings for enhanced corrosion resistance in harsh environments.

Impact on Application: Aluminum is commonly used in heat sinks and enclosures, where thermal management is critical. Its compatibility with various media makes it a versatile choice for different SMT applications.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local availability and import tariffs on aluminum. Compliance with international standards such as ASTM and ISO is also essential to ensure quality and performance.

What Are the Benefits of Using Copper in SMT Manufacturing?

Key Properties: Copper is renowned for its exceptional electrical and thermal conductivity, making it ideal for applications requiring efficient heat dissipation. It has a high melting point (around 1,984°F or 1,085°C) and excellent corrosion resistance when properly treated.

Pros & Cons: The primary advantage of copper is its superior conductivity, which enhances performance in electronic applications. However, it can be relatively expensive and may require protective coatings to prevent oxidation.

Impact on Application: Copper is often used in PCB traces, connectors, and heat sinks, where efficient electrical performance is paramount. Its compatibility with various soldering processes makes it a staple in SMT manufacturing.

Considerations for International Buyers: Buyers should be aware of the fluctuating market prices for copper, which can affect overall project costs. Compliance with standards like JIS for electronic components is also crucial for ensuring product reliability.

Why Is FR-4 a Preferred Material for PCBs?

Key Properties: FR-4 is a composite material made of woven fiberglass and epoxy resin, offering excellent electrical insulation and mechanical strength. It typically withstands temperatures up to 130°C and has good flame resistance.

Pros & Cons: FR-4 is cost-effective and widely used in PCB manufacturing due to its excellent dielectric properties. However, it can be less durable than metals and may not perform well in extreme thermal or mechanical conditions.

Impact on Application: FR-4 is ideal for high-frequency applications and is commonly used in consumer electronics and telecommunications. Its lightweight nature also contributes to reduced overall product weight.

Considerations for International Buyers: Buyers should ensure that FR-4 materials meet local and international standards such as UL and IPC to guarantee safety and performance. Understanding local sourcing options can also help mitigate supply chain challenges.

How Does Stainless Steel Compare in SMT Applications?

Key Properties: Stainless steel is known for its high strength, durability, and excellent corrosion resistance. It can withstand high temperatures (up to 1,500°F or 815°C) and is suitable for harsh environments.

Pros & Cons: The key advantage of stainless steel is its longevity and resistance to wear and tear. However, it is heavier than other materials and can be more expensive, impacting overall production costs.

Impact on Application: Stainless steel is often used in housings, brackets, and components that require high strength and corrosion resistance. Its robustness makes it suitable for industrial applications.

Considerations for International Buyers: Buyers in the Middle East and Europe should consider the specific grades of stainless steel that comply with local regulations and standards, such as EN and ASTM. Understanding the implications of weight on shipping and handling is also essential.

Summary Table of Material Selection for SMT Company

| Material | Typical Use Case for SMT Company | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Heat sinks, enclosures | Lightweight and good thermal conductivity | Higher cost and requires coatings | Medium |

| Copper | PCB traces, connectors, heat sinks | Superior electrical and thermal conductivity | Expensive and oxidation-prone | High |

| FR-4 | PCBs in consumer electronics | Cost-effective with excellent insulation | Less durable in extreme conditions | Low |

| Stainless Steel | Housings, brackets, industrial parts | High strength and corrosion resistance | Heavier and can be more expensive | High |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, helping them make informed decisions based on specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for smt company

What Are the Main Stages of Manufacturing Processes in SMT Companies?

The manufacturing processes in SMT (Surface Mount Technology) companies involve several critical stages that ensure high-quality electronic products. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation

The first step in the manufacturing process is the preparation of materials. This involves sourcing high-quality raw materials, including printed circuit boards (PCBs), electronic components, and solder paste. SMT companies often rely on a network of trusted suppliers to ensure the integrity and reliability of these materials. Effective inventory management systems are also employed to track material quality and availability. -

Forming

In the forming stage, components are prepared for assembly onto the PCBs. Techniques such as stencil printing are used to apply solder paste onto the board accurately. This step is crucial, as the precision of solder paste application directly affects the quality of the final product. Advanced equipment such as pick-and-place machines is employed to position components on the boards with high accuracy. -

Assembly

The assembly phase is where the actual integration of components takes place. SMT companies utilize automated assembly lines that enhance speed and efficiency. Robots and machines handle the placement of components, followed by reflow soldering, where the solder paste is melted to create permanent connections. The use of automated Optical Inspection (AOI) systems during this stage ensures that any defects are identified early in the process. -

Finishing

The finishing stage encompasses a variety of processes aimed at enhancing the product’s durability and functionality. This includes encapsulation, coating, and additional testing. Finishing processes are tailored to meet specific customer requirements and can include surface mount coatings to protect against environmental factors.

How Is Quality Assurance Implemented in SMT Companies?

Quality assurance (QA) is an integral part of the manufacturing process in SMT companies, ensuring that products meet both international standards and customer specifications.

-

International Standards and Certifications

SMT companies typically adhere to international quality management standards, such as ISO 9001. This certification ensures that the company maintains a consistent level of quality across all processes. Other industry-specific certifications may include CE marking for products sold in Europe, and API certifications for companies involved in the aerospace and defense sectors. Compliance with these standards is crucial for international B2B buyers who require assurance of product quality. -

Quality Control Checkpoints

The quality control process in SMT involves several key checkpoints:

- Incoming Quality Control (IQC): This step involves inspecting raw materials and components upon arrival to ensure they meet specified quality standards before they enter the production line.

- In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring takes place to detect any deviations from quality standards. This includes real-time inspections and the use of statistical process control (SPC) to monitor production metrics.

- Final Quality Control (FQC): At the end of the assembly process, a thorough inspection is conducted to ensure the final product meets all specifications. This may involve functional testing, visual inspections, and performance assessments.

- Common Testing Methods

Various testing methods are employed in SMT companies to validate product quality. These methods can include:

- Electrical Testing: This involves checking the electrical integrity of the assembled boards.

- Environmental Testing: Products may be subjected to temperature and humidity tests to ensure they perform under different environmental conditions.

- X-ray Inspection: Used to inspect solder joints and hidden components, ensuring that there are no defects that could lead to product failure.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is essential to ensure a reliable partnership. Here are several actionable strategies:

-

Supplier Audits

Conducting audits of potential suppliers can provide valuable insights into their quality management systems. This includes reviewing their processes, quality control measures, and compliance with international standards. Regular audits help maintain accountability and foster continuous improvement. -

Requesting Quality Reports

Buyers should request detailed quality reports that outline the results of previous inspections and tests. This transparency allows buyers to assess the supplier’s commitment to quality and any past issues that may have arisen. -

Third-Party Inspections

Engaging third-party inspection services can provide an objective assessment of a supplier’s quality control processes. These independent evaluations can validate the supplier’s claims and provide additional assurance of product quality.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

When navigating the complexities of international trade, B2B buyers must be aware of specific nuances related to quality control and certification:

-

Understanding Regional Standards

Different regions may have varying standards and certifications. For instance, products intended for the European market must meet CE requirements, while products for the U.S. market may need to comply with FCC regulations. Buyers should familiarize themselves with these standards to ensure compliance. -

Language and Communication Barriers

Language differences can pose challenges in understanding quality control documentation. Buyers should ensure that they receive all necessary documentation in a language they understand, which can include translations of quality certificates and inspection reports. -

Cultural Considerations

Cultural differences can impact business practices and expectations regarding quality. Building strong relationships with suppliers through open communication can help bridge these gaps and establish a mutual understanding of quality expectations.

By understanding these manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when selecting SMT companies as their partners in electronic manufacturing. This knowledge not only enhances product reliability but also fosters long-term business relationships built on trust and quality.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘smt company’

This guide is designed to assist international B2B buyers in effectively sourcing SMT company services and products. It outlines essential steps to ensure that the procurement process is thorough, efficient, and aligned with your specific business needs. By following this checklist, buyers can mitigate risks and establish strong partnerships with SMT suppliers.

Step 1: Define Your Technical Specifications

Clearly outline your technical requirements before initiating the sourcing process. This includes understanding the types of SMT services needed, such as electronic design, prototyping, or manufacturing capabilities. Having a well-defined specification helps in communicating your needs effectively to potential suppliers and ensures that you receive relevant proposals.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential SMT suppliers that align with your needs. Utilize industry directories, trade shows, and online platforms to create a list of candidates. Pay attention to their areas of expertise, market reputation, and geographical reach, especially if you are sourcing from regions like Africa, South America, or Europe.

Step 3: Evaluate Supplier Certifications

Verify the certifications and standards compliance of potential suppliers. Certifications such as ISO 9001, AS9120B, and others related to quality management systems indicate a commitment to quality and reliability. Suppliers with robust certification profiles are more likely to meet your quality expectations and adhere to industry standards.

Step 4: Request and Analyze Quotations

Once you have shortlisted suppliers, request detailed quotations that outline pricing, lead times, and terms of service. Analyze these quotations not just on cost but also on the value offered, including quality assurance processes and after-sales support. Comparing multiple quotes will give you a clearer picture of the market and help you negotiate better terms.

Step 5: Check References and Case Studies

Request references and review case studies from potential suppliers. Speaking to previous clients can provide insights into the supplier’s reliability, quality of service, and ability to meet deadlines. Look for feedback from companies in similar industries or regions to gauge their performance in contexts similar to yours.

Step 6: Assess Supply Chain Capabilities

Evaluate the supplier’s supply chain management processes. Ensure they have robust systems in place for inventory management, logistics, and order fulfillment. A well-managed supply chain is crucial for timely delivery and can mitigate risks associated with supply chain disruptions, particularly in regions with volatile markets.

Step 7: Negotiate Terms and Agreements

Once you have selected a supplier, engage in negotiations to finalize terms and agreements. Discuss payment terms, delivery schedules, and warranties or guarantees. Ensure that all agreements are documented clearly to protect both parties and establish a framework for future collaboration.

By following this practical sourcing checklist, B2B buyers can enhance their procurement process and establish successful partnerships with SMT companies, ultimately leading to improved operational efficiency and product quality.

Comprehensive Cost and Pricing Analysis for smt company Sourcing

What Are the Key Cost Components in SMT Company Sourcing?

When engaging with SMT companies, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of raw materials significantly affects pricing. High-quality materials that meet specific industry standards may incur higher costs but contribute to product longevity and performance.

-

Labor: Labor costs vary depending on the skill level required for assembly and manufacturing. Countries with lower wage scales may offer competitive pricing, but buyers must consider the trade-off between cost and the quality of workmanship.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, and administrative expenses. Efficient production processes can help minimize these overheads, impacting overall pricing.

-

Tooling: Custom tooling can be a significant upfront investment, especially for specialized projects. Understanding the tooling costs is essential, as they can be amortized over larger production runs.

-

Quality Control (QC): Rigorous QC processes ensure product reliability but also add to costs. For international buyers, certifications like ISO can serve as indicators of a company’s commitment to quality, potentially justifying a higher price.

-

Logistics: Shipping and handling costs can fluctuate based on destination, shipping method, and Incoterms. Buyers should factor in these costs when evaluating total pricing.

-

Margin: This is the profit markup applied by the supplier. Margins can vary widely based on market demand, competition, and perceived value.

How Do Price Influencers Affect SMT Company Pricing?

Several factors can influence pricing strategies for SMT companies:

-

Volume/MOQ: Buying in larger quantities often leads to cost savings. Minimum Order Quantities (MOQ) can affect pricing, so negotiating for a better rate based on volume is advisable.

-

Specifications/Customization: Customized products typically come with higher costs due to the additional design and manufacturing processes involved. Clear specifications can help suppliers provide accurate quotes.

-

Materials: The choice of materials not only affects the cost but also the product’s final quality. Buyers should specify material requirements early to avoid unexpected price changes.

-

Quality/Certifications: Certifications like ISO or specific industry standards can impact pricing. Products that meet higher standards may command a premium, but they often offer greater reliability.

-

Supplier Factors: Supplier reputation and market position can influence pricing. Established suppliers may charge more due to their track record of quality and reliability.

-

Incoterms: The terms of shipping and delivery can significantly affect costs. Understanding the responsibilities and liabilities associated with various Incoterms can help buyers avoid hidden fees.

What Tips Can Buyers Use for Cost-Efficiency in SMT Sourcing?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate Effectively: Use your understanding of the cost components to negotiate better pricing. Presenting a clear picture of your volume needs and specifications can strengthen your position.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the long-term costs associated with maintenance, potential downtime, and quality issues. A higher initial investment in quality may save money in the long run.

-

Leverage Supplier Relationships: Establishing long-term relationships with suppliers can lead to better pricing and priority service. Trust and reliability often yield better terms.

-

Stay Informed on Market Trends: Understanding the market dynamics in your region can help you anticipate price changes and make informed purchasing decisions.

-

Be Aware of Pricing Nuances: International transactions may involve additional tariffs, taxes, or currency fluctuations. Familiarizing yourself with these elements can help you manage costs effectively.

Disclaimer on Indicative Prices

Pricing in the SMT sector is highly variable and influenced by numerous factors. The information provided here serves as a guideline and may not reflect specific quotes or pricing from individual suppliers. Always consult directly with suppliers for the most accurate and up-to-date pricing information tailored to your requirements.

Alternatives Analysis: Comparing smt company With Other Solutions

Understanding Alternative Solutions in the B2B Space

When considering solutions from SMT Company, it is essential to evaluate alternatives that can meet similar needs in the market. This analysis compares SMT Company with two other viable options: XYZ Machining Solutions and ABC Electronics Manufacturing. By examining various aspects such as performance, cost, ease of implementation, maintenance, and best use cases, B2B buyers can make informed decisions that align with their specific operational requirements.

| Comparison Aspect | SMT Company | XYZ Machining Solutions | ABC Electronics Manufacturing |

|---|---|---|---|

| Performance | High precision and reliability | Good precision with faster turnaround | Moderate precision, focus on high volume |

| Cost | Mid-range pricing | Competitive pricing, lower overhead | Higher cost due to advanced technology |

| Ease of Implementation | Requires specialized training | User-friendly with straightforward integration | Moderate complexity, training needed |

| Maintenance | Regular maintenance required | Low maintenance, robust design | High maintenance due to complexity |

| Best Use Case | Custom machining and fabricating | Rapid prototyping and small batch runs | High-volume production with intricate designs |

In-Depth Analysis of Alternatives

XYZ Machining Solutions

XYZ Machining Solutions offers competitive pricing and a user-friendly interface that facilitates quick integration into existing workflows. Their focus on rapid prototyping makes them ideal for businesses needing quick turnaround times for small batch production. However, while they provide good precision, they may not match the high standards set by SMT Company in terms of reliability and customization capabilities. This option is best suited for companies that prioritize cost and speed over the highest precision.

ABC Electronics Manufacturing

ABC Electronics Manufacturing specializes in high-volume production using advanced technology. While they provide excellent performance and intricate designs, their pricing is on the higher end, which may not be feasible for all businesses. The complexity of their systems requires a more significant investment in training and maintenance, making them less suitable for companies with limited resources. However, for businesses focused on large-scale production and willing to invest in quality, ABC could be the right partner.

Choosing the Right Solution for Your Business Needs

When selecting between SMT Company and its alternatives, B2B buyers should consider their specific operational goals and constraints. If precision and reliability are paramount, SMT Company remains a strong contender. For those seeking cost-effective, rapid solutions, XYZ Machining Solutions might be the better choice. Conversely, if high-volume production with sophisticated designs is essential, ABC Electronics Manufacturing would be ideal. Ultimately, the decision should align with the organization’s strategic objectives, budget, and operational capabilities, ensuring long-term success in their respective markets.

Essential Technical Properties and Trade Terminology for smt company

What Are the Key Technical Properties Important for SMT Companies?

In the context of SMT (Surface Mount Technology) companies, understanding key technical specifications is crucial for international B2B buyers looking to procure electronic manufacturing services or machinery. Here are some essential properties to consider:

1. Material Grade

Material grade refers to the specific type of material used in manufacturing, such as metals or plastics, which can significantly impact durability and functionality. In SMT, material selection affects the performance and reliability of electronic components. For buyers, knowing the material grade ensures that the products meet industry standards and application requirements.

2. Tolerance

Tolerance defines the allowable deviation from a specified dimension in manufacturing processes. In SMT, tight tolerances are critical for ensuring that components fit correctly and function properly in assemblies. Understanding tolerance levels helps buyers gauge the precision of the manufacturing process, which is vital for high-performance applications.

3. PCB Layer Count

The layer count of a printed circuit board (PCB) indicates the number of conductive layers that make up the board. Higher layer counts enable more complex designs, which are often necessary for advanced electronic applications. Buyers should be aware of the layer count required for their products to ensure compatibility and functionality.

4. Surface Finish

Surface finish is the treatment applied to the surface of a PCB or electronic component to enhance solderability and overall performance. Common finishes include HASL (Hot Air Solder Leveling) and ENIG (Electroless Nickel Immersion Gold). Choosing the right surface finish is essential for ensuring the longevity and reliability of electronic connections.

5. Thermal Management

Thermal management refers to the techniques used to control the temperature of electronic components during operation. Effective thermal management is crucial for maintaining performance and preventing failure in high-power applications. Buyers should evaluate the thermal management strategies employed by SMT companies to ensure product reliability.

6. Lead-Free Compliance

Lead-free compliance indicates whether the manufacturing processes adhere to environmental regulations regarding the use of lead in electronic components. With increasing global regulations on hazardous materials, understanding a company’s lead-free status is critical for buyers concerned about sustainability and compliance.

What Are Common Trade Terms Used in the SMT Industry?

Familiarity with trade terminology is essential for effective communication and negotiation in B2B transactions. Here are some common terms used in the SMT sector:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the SMT context, an OEM might provide circuit boards that are then integrated into larger systems. Understanding OEM relationships helps buyers navigate sourcing strategies and quality assurances.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers as it affects inventory management and cash flow. Knowing the MOQ can help in planning purchases and managing production schedules effectively.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit quotes from suppliers for specific products or services. This process is vital for comparing pricing and capabilities among different SMT companies. Buyers should prepare detailed RFQs to receive accurate and competitive quotes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms used in international shipping that define the responsibilities of buyers and sellers. These terms clarify who is responsible for shipping, insurance, and tariffs, which is essential for smooth cross-border transactions.

5. NPI (New Product Introduction)

NPI refers to the process of bringing a new product to market, encompassing design, development, and manufacturing. For buyers, understanding the NPI process of an SMT provider is critical for ensuring timely product launches and successful market entry.

6. HLA (Higher-Level Assembly)

HLA involves the assembly of more complex products that may include multiple components and subassemblies. This term is significant for buyers looking to streamline their supply chains and ensure that final products are fully integrated and tested before delivery.

Understanding these technical properties and trade terms equips B2B buyers with the knowledge necessary for informed decision-making in their procurement processes, ultimately leading to better partnerships with SMT companies.

Navigating Market Dynamics and Sourcing Trends in the smt company Sector

What Are the Current Market Dynamics and Key Trends in the SMT Company Sector?

The SMT (Surface-Mount Technology) sector is experiencing significant transformation driven by globalization, technological advancements, and shifting consumer expectations. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly influenced by trends such as automation, digitalization, and demand for customized solutions. The rise of Industry 4.0 has led to a surge in smart manufacturing technologies, which improve efficiency and reduce lead times. As companies seek to enhance their operational capabilities, there is a growing emphasis on integrating IoT and AI into manufacturing processes.

Additionally, component shortages and supply chain disruptions, exacerbated by geopolitical tensions and the pandemic, have compelled buyers to seek reliable sourcing partners who can provide transparency and flexibility. Emerging technologies like blockchain are being adopted to enhance supply chain visibility and mitigate risks associated with counterfeit components, which is particularly critical for high-stakes industries such as aerospace and medical devices.

Sustainability is another crucial driver. Buyers are increasingly prioritizing suppliers who demonstrate commitment to environmental stewardship and ethical practices. This shift is not only about compliance but also about aligning with consumer values, especially in regions where environmental regulations are tightening.

How Can Sustainability and Ethical Sourcing Be Integrated into B2B Strategies?

Sustainability and ethical sourcing have become paramount in the SMT sector, reflecting both environmental concerns and corporate responsibility. The environmental impact of manufacturing processes is significant, with energy consumption and waste generation being critical issues. B2B buyers are now more inclined to partner with SMT companies that implement sustainable practices, such as using energy-efficient machinery, recycling materials, and minimizing waste throughout the production cycle.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers’ sourcing practices to ensure compliance with labor laws and environmental standards. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management are becoming essential in supplier evaluations. Adopting ‘green’ materials and processes not only fosters a positive brand image but also reduces risks associated with regulatory penalties and reputational damage.

For international buyers, particularly those in emerging markets, aligning with suppliers committed to sustainability can provide a competitive edge. It enhances their marketability and helps build trust with end consumers who prioritize ethical considerations in their purchasing decisions.

What Has Been the Evolution of the SMT Company Sector?

The SMT sector has evolved significantly over the past few decades, transitioning from traditional manufacturing methods to highly automated and sophisticated production techniques. Initially focused on simple assembly processes, the industry has embraced advancements in technology, leading to the integration of robotics, AI, and data analytics into manufacturing operations. This evolution has enabled SMT companies to produce complex assemblies with higher precision and lower error rates.

The rise of electronic devices and the Internet of Things (IoT) has further accelerated growth in the SMT sector, as the demand for miniaturization and increased functionality in electronic components has soared. As a result, SMT companies are now positioned as critical players in the global supply chain, catering to a diverse range of industries including automotive, aerospace, and consumer electronics. This historical progression underscores the importance of adaptability and innovation for B2B buyers seeking to stay ahead in a rapidly changing marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of smt company

-

How do I ensure quality when sourcing SMT products internationally?

Ensuring quality starts with thorough supplier vetting. Request certifications like ISO 9001 and other relevant industry standards. Conduct audits, if possible, to assess their manufacturing processes and quality control systems. Additionally, consider requesting samples to evaluate product quality firsthand. Establish clear communication about your quality expectations and utilize performance metrics to monitor ongoing compliance. Engaging third-party inspection services can provide an added layer of assurance. -

What are the common payment terms for international SMT transactions?

Payment terms can vary, but common options include Letter of Credit (LC), advance payment, and net 30/60/90 days. It’s crucial to negotiate terms that align with your cash flow while also ensuring the supplier’s confidence in your commitment. Some suppliers may offer discounts for early payments or require partial upfront payments. Always clarify terms in the contract to avoid misunderstandings and ensure that both parties are protected. -

What customization options are available for SMT products?

Many SMT companies offer customization options to meet specific client needs. This can include alterations in design, material specifications, and functionality. When discussing your requirements, provide detailed specifications and any relevant compliance standards. Early engagement in the design process can facilitate better integration with your existing systems and ensure that the final product meets your operational needs. -

What are the minimum order quantities (MOQs) for SMT products?

Minimum order quantities vary by supplier and product type. Typically, MOQs are set to ensure production efficiency and cost-effectiveness. For specific SMT products, it’s advisable to discuss your needs directly with the supplier to determine if they can accommodate smaller orders or whether there are flexible options available. Understanding the implications of MOQ on your inventory management and cash flow is crucial for effective planning. -

How can I mitigate risks in international logistics for SMT supplies?

Mitigating logistics risks involves selecting reliable shipping partners and understanding the local regulations of your destination countries. Utilize Incoterms to clarify responsibilities for shipping, insurance, and duties. Additionally, consider using logistics services that offer real-time tracking to monitor shipments. Establishing a buffer in delivery timelines can also help manage expectations and ensure continuity in your operations. -

What should I know about international trade regulations when sourcing SMT products?

Familiarize yourself with the trade regulations of both your country and the supplier’s country. This includes understanding tariffs, customs duties, and import/export restrictions. Regulatory compliance is crucial to avoid unexpected costs and delays. Working with a customs broker can streamline the process and ensure that all necessary documentation is accurately completed, reducing the risk of penalties or shipment seizures. -

How do I evaluate the reliability of an SMT supplier?

Evaluate supplier reliability through a combination of factors including industry reputation, customer reviews, and years of experience. Request references from current or previous clients to gauge their experiences. Additionally, assess the supplier’s financial stability and capacity to meet your demands consistently. Engaging in a pilot project can also provide insight into their operational capabilities and responsiveness. -

What quality assurance practices should I expect from an SMT supplier?

A reputable SMT supplier should have robust quality assurance (QA) practices in place. This typically includes regular inspections, testing protocols, and adherence to industry standards. Look for suppliers who implement continuous improvement methodologies, such as Six Sigma or ISO quality management systems. Additionally, inquire about their processes for handling defects and returns, which can indicate their commitment to maintaining high-quality standards.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Smt Company Manufacturers & Suppliers List

1. SMT, Co – Machining and Fabricating Equipment

Domain: smtco.com

Registered: 2003 (22 years)

Introduction: SMT, Co offers a wide range of machining and fabricating equipment including:

1. **Machining Equipment:**

– Horizontal Machining Centers

– Vertical Machining Centers (including 5-Axis or More)

– Multitasking Machining Centers

– Gantry Machining Centers (including Bridge & Double Column)

– CNC Lathes (including 5-Axis or More, Engine Lathes, Oil Field & Hollow Spindle Lathes, …

2. SMT – Electronic Manufacturing Services

Domain: teamsmt.com

Registered: 1998 (27 years)

Introduction: SMT provides solution-driven Electronic Manufacturing Services (EMS) tailored for high-volume, high-mix, and complex PCB assemblies. Key product details include: 1. Electronic Design and Development – from embedded controls to full-system architecture. 2. Rapid Prototyping – fast-turn builds, IPC-compliant, with real-time DFM feedback. 3. New Product Introduction (NPI) – disciplined, scalable laun…

3. SMT North America – ROMCO & Sierra Machinery

Domain: smt.network

Registered: 2017 (8 years)

Introduction: SMT North America offers two main product lines: ROMCO and Sierra Machinery. ROMCO, based in Dallas, serves the Texas construction and mining markets with quality production products and exceptional customer support. Sierra Machinery is a full-service distributor of construction, mining, and industrial equipment, representing major manufacturers such as Volvo CE, Doosan, and Gomaco.

4. SMT Corp – Counterfeit Electronics Mitigation Solutions

Domain: smtcorp.com

Registered: 2002 (23 years)

Introduction: SMT Corp. specializes in counterfeit electronics mitigation, offering a range of services including: 1. Sourcing and Authentication – Recognized expertise in counterfeit electronics mitigation with a best-in-industry component authentication lab since 2007. Global sourcing specialist with over 200 approved suppliers and 1,400 blacklist suppliers. 2. Electrical and Environmental Testing Services – …

5. SMT – Minimally Invasive Cardiovascular Devices

Domain: smtpl.com

Registered: 2004 (21 years)

Introduction: SMT is a leading global developer and manufacturer of minimally invasive cardiovascular devices, including: 1. Coronary Intervention Devices: – Coronary Stents: Supraflex Cruz, Supraflex Tetriflex, Tetrilimus, Supraflex Star, Flexinnium, Everoflex – PTCA Balloon Dilatation Catheters: Wilma SC, Wilma NC, Pipit SC, Pipit NC 2. Structural Heart Devices: – Aortic Valve Occluders: Hydra – Septal Occlud…

6. SMT Manufacturing Group – Electronic Assemblies

Domain: smt-llc.com

Registered: 2006 (19 years)

Introduction: SMT Manufacturing Group, LLC. produces high-quality electronic assemblies for commercial and military markets with 25+ years of experience. They offer electrical/electronic design, assembly, and testing services. Certifications include ISO 9001:2015, IPC-610/620 Class 3, IPC Instructors on Staff, and J-STD-001. They specialize in small-batch, quick-turn assembly jobs, capable of handling under 100…

7. SMT Automation LLC – Automation Machinery Solutions

Domain: smtautomationllc.com

Registered: 2016 (9 years)

Introduction: SMT Automation LLC specializes in automation machinery manufacturing services, offering a range of solutions including design and engineering, hardware selection, control systems implementation, startup support, commissioning, and mechanical design. The company serves various industries such as automotive, food, medical, mining, and metal. SMT Automation is a minority, women-owned business and is …

Strategic Sourcing Conclusion and Outlook for smt company

In the ever-evolving landscape of global manufacturing and technology solutions, strategic sourcing emerges as a cornerstone for businesses aiming to enhance efficiency, reduce costs, and foster innovation. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the diverse offerings of SMT companies is crucial. SMT’s capabilities in areas like electronic manufacturing services, advanced machining, and counterfeit electronics mitigation not only ensure high-quality production but also provide invaluable supply chain assurance.

By leveraging strategic sourcing, businesses can tap into SMT’s extensive expertise and robust supplier networks, ultimately driving competitive advantage in their respective markets. The focus on agile responses to market demands and the commitment to quality and compliance further solidify SMT’s role as a strategic partner.

As you navigate your sourcing strategies, consider SMT as a pivotal ally in achieving your operational goals. The future holds immense potential for collaboration and growth; seize the opportunity to engage with SMT and transform your supply chain into a powerful engine for success. Embrace innovation, and let SMT help you shape the future of your business.