Introduction: Navigating the Global Market for small water jet machine

Navigating the complexities of sourcing a small water jet machine can be a daunting task for international B2B buyers, particularly those operating in emerging markets like Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying machines that meet specific operational needs but also in ensuring that these machines offer precision, reliability, and cost-effectiveness. This guide serves as a comprehensive resource, outlining the diverse types of small water jet machines available, their various applications across industries, and critical factors for supplier vetting.

In an ever-evolving global market, understanding the nuances of water jet technology is essential for informed purchasing decisions. Buyers will gain insights into key specifications, such as cutting capabilities, operational efficiencies, and maintenance considerations, tailored to their unique regional contexts. Additionally, the guide addresses cost implications, providing a breakdown of investment versus potential returns, which is crucial for businesses looking to optimize their budgets.

By equipping buyers with actionable insights and a structured approach to sourcing, this guide empowers them to navigate the competitive landscape of small water jet machines confidently. Whether you are in Germany, Brazil, or any other part of the world, the information herein will facilitate informed decisions, ensuring your business stays ahead in the cutting-edge realm of water jet technology.

Understanding small water jet machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| NanoJet | Fully enclosed, high precision, compact design | Aerospace, automotive, manufacturing | Pros: High accuracy, minimal footprint. Cons: Higher initial investment. |

| WAZER Pro | Affordable, powerful, user-friendly, cuts a variety of materials | Custom fabrication, education, prototyping | Pros: Low maintenance, versatile. Cons: Limited to smaller workpieces. |

| Pure Waterjet | Utilizes pure water stream for cutting soft materials | Art, sign-making, food industry | Pros: Clean cuts, ideal for soft materials. Cons: Not suitable for hard materials. |

| Standard Waterjet | Employs abrasive garnet for cutting hard materials | Metal fabrication, aerospace, construction | Pros: Versatile, can cut various materials. Cons: Higher operating costs due to abrasives. |

| Desktop Waterjet | Compact, entry-level option, designed for small shops | Hobbyists, small businesses, educational institutions | Pros: Affordable, easy to use. Cons: Limited cutting thickness and speed. |

What are the Characteristics of the NanoJet Small Water Jet Machine?

The NanoJet is an advanced small-format waterjet machine designed for high precision and rapid part processing. Its fully enclosed design minimizes noise and enhances safety, making it suitable for environments where space is limited. With a maximum traverse speed of up to 15,000 mm/min and a linear positional accuracy of ±0.02 mm, it excels in cutting highly engineered materials. B2B buyers should consider its suitability for applications requiring intricate designs and tight tolerances, although the initial investment can be significant.

How Does the WAZER Pro Stand Out in the Market?

The WAZER Pro is notable for its balance of power and affordability, making it an attractive option for businesses looking to integrate waterjet technology without excessive costs. It is capable of cutting materials up to 1 inch thick and is designed for ease of use, allowing operators with minimal training to achieve high-quality results. Its versatility makes it ideal for custom fabrication and prototyping across various industries. However, potential buyers should be aware that its compact size may limit the scale of projects.

What are the Advantages of Using Pure Waterjet Technology?

Pure waterjet machines are designed specifically for cutting softer materials, employing a high-velocity water stream to achieve clean cuts without the need for abrasives. This technology is particularly beneficial in industries such as art and food production, where material integrity is crucial. The advantages of using pure waterjet include minimal kerf width and no heat-affected zones, ensuring that sensitive materials remain undamaged. However, businesses should consider that this machine type is not suitable for hard materials, which may limit its application range.

What Makes Standard Waterjet Machines Versatile for B2B Applications?

Standard waterjet machines utilize abrasive garnet mixed with water to cut through a wide variety of materials, including metals and composites. Their versatility makes them a popular choice in sectors like aerospace and construction. With the ability to handle thick materials and complex geometries, these machines are ideal for high-demand environments. However, the operational costs associated with abrasives can be a consideration for businesses looking to manage their budgets effectively.

Why Choose a Desktop Waterjet for Small Businesses?

Desktop waterjets provide an entry-level solution for small businesses, hobbyists, and educational institutions. These machines are designed to be compact and affordable, making them accessible for those new to waterjet cutting. While they are capable of cutting various materials, their limitations in thickness and speed may not meet the demands of larger operations. Buyers should evaluate their specific needs and consider whether a desktop model can fulfill their project requirements effectively.

Key Industrial Applications of small water jet machine

| Industry/Sector | Specific Application of small water jet machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision cutting of complex parts and prototypes | Enables rapid prototyping and reduces lead times in production | High precision requirements, reliability, and support |

| Automotive | Custom parts fabrication for vehicles | Streamlines production processes and allows for material versatility | Compatibility with various materials and thicknesses |

| Manufacturing | On-demand production of components | Reduces waste and improves efficiency in custom orders | Scalability, maintenance costs, and ease of operation |

| Glass Art | Intricate glass cutting and design | Enhances creativity and reduces manual labor in glass production | Safety features, precision, and material compatibility |

| Education | Hands-on training in modern manufacturing techniques | Prepares students for industry demands and practical experience | User-friendly operation and availability of training resources |

How is the Small Water Jet Machine Used in Aerospace Applications?

In the aerospace industry, small water jet machines are utilized for precision cutting of complex parts and prototypes made from high-performance materials. These machines help in creating intricate geometries that are often required in aircraft components, ensuring high accuracy and minimizing material waste. For international buyers, especially from regions like Africa and Europe, sourcing machines that meet stringent aerospace standards and offer reliable support services is crucial to maintain production efficiency and compliance.

What are the Benefits of Using Small Water Jet Machines in Automotive Manufacturing?

The automotive sector leverages small water jet machines for the fabrication of custom parts, including components for electric vehicles and custom builds. The ability to cut various materials, such as aluminum and composites, without thermal distortion is a significant advantage, ensuring the integrity of the parts. Buyers need to consider the machine’s versatility in handling different thicknesses and the availability of maintenance services, especially in emerging markets like South America and the Middle East.

How Do Small Water Jet Machines Enhance Manufacturing Processes?

In manufacturing, small water jet machines facilitate on-demand production of components, enabling businesses to respond quickly to market changes. They help reduce waste by utilizing precise cutting techniques, which is vital for companies looking to improve their sustainability practices. For B2B buyers, understanding the scalability of the machine and its maintenance costs is essential to ensure long-term operational efficiency.

What Role Do Small Water Jet Machines Play in Glass Art?

Small water jet machines are increasingly used in the glass art industry for intricate cutting and design work. They allow artists to create complex patterns and shapes that would be labor-intensive and time-consuming using traditional methods. Buyers in this sector should focus on sourcing machines that offer precision and safety features, ensuring that they can produce high-quality work while minimizing risks associated with glass cutting.

Why are Small Water Jet Machines Important in Educational Institutions?

In educational settings, small water jet machines serve as vital tools for teaching students about modern manufacturing techniques. They provide hands-on experience with advanced technology, preparing students for careers in various industries. When sourcing these machines, educational institutions should prioritize user-friendly operation and the availability of training resources to facilitate effective learning experiences.

3 Common User Pain Points for ‘small water jet machine’ & Their Solutions

Scenario 1: Integrating Small Water Jet Machines into Existing Operations

The Problem: Many B2B buyers encounter significant challenges when trying to integrate small water jet machines into their existing manufacturing processes. These challenges can stem from a lack of understanding of how water jet technology fits within their operational framework, leading to inefficient workflows and unoptimized production schedules. Buyers may also struggle with limited floor space, as small water jet machines often need to be strategically placed to avoid disrupting current operations, which can exacerbate the integration process.

The Solution: To effectively integrate a small water jet machine, buyers should conduct a thorough assessment of their current production workflows. This assessment should identify bottlenecks that the water jet machine can alleviate, such as reducing the time taken for intricate cuts compared to traditional methods. Collaborating with the machine manufacturer to understand the machine’s specifications and capabilities can help in planning the integration. Additionally, consider utilizing software that allows for seamless communication between existing systems and the new water jet technology. This could involve training sessions for staff to familiarize them with the new equipment, ensuring that employees are comfortable and skilled in its operation. Lastly, planning for a trial phase where the machine runs alongside existing operations can help identify any issues without fully committing to a permanent setup.

Scenario 2: Maintenance and Downtime Concerns with Small Water Jet Machines

The Problem: Buyers often worry about the potential for high maintenance costs and unexpected downtimes with small water jet machines. This concern is particularly acute in industries that rely on tight production schedules, where any unplanned interruption can lead to significant financial losses. Buyers may find it challenging to source reliable parts for maintenance or to understand the best practices for keeping the machine in peak operational condition.

The Solution: To mitigate maintenance and downtime concerns, buyers should prioritize purchasing from reputable manufacturers known for their robust support systems. Look for machines that offer comprehensive service contracts, which can include regular maintenance checks, rapid response times for repairs, and easy access to replacement parts. Buyers should also invest in training their maintenance staff on the specific needs of the water jet machine to ensure they can handle minor issues in-house, thus reducing dependency on external service providers. Creating a maintenance schedule based on the machine’s usage and adhering to it can help predict and prevent potential issues before they escalate. Moreover, utilizing predictive maintenance tools that monitor machine performance can offer insights into when components may need replacing, allowing for proactive maintenance instead of reactive repairs.

Scenario 3: Cost Management for Operating a Small Water Jet Machine

The Problem: Managing the costs associated with operating a small water jet machine can be a daunting task for B2B buyers. Expenses can accumulate quickly due to the costs of consumables like abrasives, water, and maintenance, along with electricity consumption and labor costs. This financial pressure can lead buyers to hesitate in making the investment or in fully utilizing the machine’s capabilities, ultimately impacting their competitive edge.

The Solution: To manage costs effectively, buyers should conduct a detailed cost analysis before purchasing a small water jet machine. This analysis should encompass not just the initial purchase price but also the ongoing operational costs, including consumables and energy consumption. When selecting a machine, consider models that offer energy-efficient features and lower abrasive consumption, which can significantly reduce long-term operational costs. Additionally, establishing a strong relationship with suppliers for bulk purchasing of consumables can lead to discounts and savings. Implementing a job costing system that tracks material usage and labor for each project can also help buyers identify areas where they can optimize efficiency and reduce waste. Finally, leveraging the versatility of water jet cutting can open up new business opportunities, allowing buyers to take on a wider range of projects that can justify the investment.

Strategic Material Selection Guide for small water jet machine

What Are the Key Properties of Common Materials for Small Water Jet Machines?

When selecting materials for use with small water jet machines, understanding their properties is crucial for optimizing performance and ensuring suitability for specific applications. Below, we analyze four common materials: aluminum, stainless steel, glass, and composites, focusing on their key properties, advantages, disadvantages, and considerations for international B2B buyers.

Aluminum: A Lightweight and Versatile Choice

Aluminum is a popular choice for various applications due to its lightweight nature and excellent machinability. It typically has a temperature rating of up to 660°C and is resistant to corrosion, making it suitable for both indoor and outdoor applications.

Pros: Aluminum is durable, cost-effective, and easy to cut, allowing for complex geometries. Its lightweight nature makes it ideal for applications where weight reduction is essential, such as in the aerospace and automotive industries.

Cons: While aluminum is generally strong, it can be less durable than other metals under extreme stress. Additionally, it may require surface treatment to enhance its corrosion resistance in certain environments.

Impact on Application: Aluminum is compatible with various media and is often used in manufacturing parts for machinery, automotive components, and structural applications.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is essential, particularly in regions like Europe and Germany, where material quality is strictly regulated.

Stainless Steel: Strength and Corrosion Resistance

Stainless steel is renowned for its strength and corrosion resistance, making it an ideal choice for applications requiring durability. It can withstand temperatures up to 870°C, depending on the grade, and is often used in environments exposed to moisture and chemicals.

Pros: Its high tensile strength and resistance to corrosion make stainless steel suitable for demanding applications, including food processing and medical equipment.

Cons: The cost of stainless steel is higher than aluminum, and it can be more challenging to machine due to its hardness. This can lead to increased manufacturing complexity and time.

Impact on Application: Stainless steel’s compatibility with various cutting media allows it to be used in a wide range of industries, including automotive, aerospace, and construction.

Considerations for International Buyers: Buyers must ensure compliance with international standards and certifications, particularly in regions with stringent regulations, such as Europe.

Glass: A Unique Material for Artistic and Functional Applications

Glass is increasingly being cut using water jet technology due to its ability to achieve intricate designs without chipping. It can withstand high pressure but is sensitive to thermal shock.

Pros: Water jet cutting allows for precise and clean cuts, making it ideal for artistic applications and custom glass installations. It is also non-toxic and environmentally friendly.

Cons: Glass can be fragile and may require special handling during the cutting process. Additionally, the cost of high-quality glass can be significant.

Impact on Application: Glass is commonly used in architectural applications, art installations, and custom designs, where precision is paramount.

Considerations for International Buyers: Compliance with safety standards is crucial, especially in regions with strict building codes, such as Germany and other European countries.

Composites: The Future of Lightweight and Strong Materials

Composite materials, including carbon fiber and fiberglass, offer unique properties such as high strength-to-weight ratios and resistance to corrosion. They can endure temperatures up to 300°C, depending on the resin used.

Pros: Composites are lightweight, durable, and can be tailored for specific applications, making them ideal for aerospace, automotive, and sporting goods.

Cons: The complexity of manufacturing composites can lead to higher costs and longer production times. Additionally, they may require specialized cutting techniques and equipment.

Impact on Application: Composites are increasingly used in high-performance applications where weight and strength are critical factors.

Considerations for International Buyers: Buyers should be aware of the varying standards for composite materials across regions, ensuring compliance with local regulations.

Summary Table of Material Selection for Small Water Jet Machines

| Material | Typical Use Case for small water jet machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive parts, structural components | Lightweight and easy to machine | Less durable under extreme stress | Low |

| Stainless Steel | Food processing, medical equipment | High strength and corrosion resistance | Higher cost and more challenging to machine | High |

| Glass | Architectural applications, art installations | Precise cuts without chipping | Fragile and requires special handling | Medium |

| Composites | Aerospace, sporting goods | High strength-to-weight ratio | Higher manufacturing complexity | High |

This guide provides essential insights for B2B buyers considering small water jet machines, emphasizing the importance of material selection in achieving optimal performance and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for small water jet machine

What Are the Main Stages in the Manufacturing Process of Small Water Jet Machines?

The manufacturing of small water jet machines involves several critical stages, each designed to ensure precision, efficiency, and quality. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Components Selected and Prepared?

The first step in the manufacturing process is the careful selection and preparation of materials. High-quality materials such as stainless steel for the cutting head, aluminum for the frame, and specialized composites for the tank are commonly used.

In this stage, suppliers often perform preliminary checks to ensure materials meet industry standards. This may involve chemical composition analysis and physical property testing. Proper documentation is essential to track the material source and specifications, which is vital for quality assurance later in the process.

Forming: What Techniques Are Employed to Shape the Components?

Once materials are prepared, the next stage is forming. This involves machining techniques such as CNC milling, laser cutting, and water jet cutting itself to create the various components of the water jet machine. Precision is paramount, as the accuracy of the cutting head and the positioning systems directly affects the machine’s performance.

Advanced forming techniques, such as 3D printing for complex geometries, may also be utilized, particularly for custom parts. This flexibility allows manufacturers to respond quickly to varying customer needs while maintaining high precision.

Assembly: How Are the Components Integrated?

After forming, the assembly process begins. This typically involves the integration of the pump, cutting head, control systems, and frame. Technicians follow strict assembly protocols to ensure that every component is correctly aligned and securely fastened.

The assembly process may include the installation of software systems that control the water jet’s operation. Quality checks are often integrated throughout this phase to confirm that each component functions as intended before moving to the final stages.

Finishing: What Steps Ensure a High-Quality End Product?

The final stage is finishing, which includes surface treatment, painting, and final inspections. Surface treatments such as anodizing or powder coating enhance durability and corrosion resistance, which is critical for machines that may operate in diverse environments.

Quality control at this stage is crucial. Manufacturers often perform final inspections to ensure that the machines meet all specified tolerances and performance criteria. This may include operational tests to verify cutting accuracy and reliability.

What International Standards and Quality Assurance Practices Are Relevant for Small Water Jet Machines?

Quality assurance is integral to the manufacturing process of small water jet machines. Adherence to international standards not only ensures product reliability but also enhances marketability, especially for international buyers.

Which International Standards Should Buyers Be Aware Of?

Among the most relevant international standards are:

-

ISO 9001: This standard focuses on quality management systems and is applicable to all organizations, including manufacturers of water jet machines. It emphasizes consistent quality, customer satisfaction, and continuous improvement.

-

CE Certification: For machines sold in Europe, CE marking is essential as it indicates compliance with health, safety, and environmental protection standards.

-

API Standards: For companies involved in oil and gas, adhering to American Petroleum Institute (API) standards can be crucial, particularly for machines used in harsh industrial environments.

What Are the Key Quality Control Checkpoints?

Effective quality control involves various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process is essential to identify and rectify issues promptly.

-

Final Quality Control (FQC): Before shipment, a thorough inspection ensures that the finished product meets all design specifications and quality standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential for ensuring product reliability and compliance with standards. Here are some actionable methods:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request and review quality audit reports from potential suppliers. These reports provide insights into the supplier’s adherence to quality standards and their manufacturing processes. Look for:

-

Accreditation: Confirm that the supplier is certified under relevant international standards (e.g., ISO 9001, CE).

-

Audit Frequency: Understand how often audits are conducted and by whom. Third-party audits can provide an additional layer of credibility.

-

Non-Conformance Reports: Review any instances of non-compliance and how they were addressed, which can indicate the supplier’s commitment to quality improvement.

Are There Third-Party Inspection Services Available?

Engaging third-party inspection services can provide an objective assessment of a supplier’s manufacturing capabilities. These services can include:

-

Factory Inspections: Physical assessments of the manufacturing facility to evaluate capabilities and adherence to quality standards.

-

Product Testing: Verification that products meet specified performance criteria, which can be conducted at various stages of production.

What Nuances Should International Buyers Consider Regarding Quality Control?

When sourcing from suppliers in different regions such as Africa, South America, the Middle East, and Europe, buyers must consider regional nuances in quality control:

-

Regulatory Differences: Understand the local regulations that may impact manufacturing practices and standards compliance.

-

Cultural Variations: Be aware of cultural differences in business practices that may affect communication and expectations regarding quality.

-

Supply Chain Stability: Assess the stability and reliability of the supply chain, particularly in regions where logistics may pose challenges.

By understanding the manufacturing processes and quality assurance practices specific to small water jet machines, international B2B buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘small water jet machine’

The following practical sourcing guide is designed for B2B buyers looking to procure small water jet machines. This checklist will help you navigate the complexities of the buying process, ensuring you select the right equipment for your operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial to ensure that the water jet machine meets your production requirements. Consider factors such as cutting thickness, material types, and precision levels. For example, if you plan to cut aluminum or composites, ensure the machine can handle the necessary thickness and offers the required precision.

Step 2: Assess Your Budget and Total Cost of Ownership

Understanding your budget goes beyond just the initial purchase price. Calculate the total cost of ownership, which includes maintenance, consumables, and operational costs. This will help you identify machines that fit your financial constraints while still meeting your production needs. Be sure to consider financing options or leasing if upfront costs are a concern.

Step 3: Evaluate Supplier Experience and Reputation

Before committing to a supplier, it is essential to assess their experience and reputation in the industry. Look for suppliers with a strong track record and positive testimonials from customers in your region or industry. This can be done by reviewing case studies, seeking references, and checking online reviews to ensure you are partnering with a reliable company.

Step 4: Verify Certification and Compliance

Ensure that the water jet machines comply with relevant industry standards and certifications. This is particularly important for international buyers, as regulations may vary by region. Check for certifications such as ISO, CE, or local compliance documents that ensure the equipment meets safety and performance standards.

Step 5: Inquire About After-Sales Support and Training

After-sales support can significantly impact your operational efficiency. Confirm what kind of support the supplier offers, such as training, maintenance services, and access to spare parts. A supplier that provides comprehensive training can help your team maximize the machine’s potential and minimize downtime.

Step 6: Request Demonstrations and Samples

Before finalizing your decision, ask for demonstrations or samples of the machine in action. This can provide valuable insights into the machine’s performance and ease of use. If possible, visit a facility where the machine is already in operation to see firsthand how it fits into a production environment.

Step 7: Negotiate Terms and Finalize Purchase

Once you have all the necessary information, it’s time to negotiate the terms of purchase. Discuss payment terms, delivery schedules, and warranties. A well-negotiated contract can save you money and ensure you receive the best value for your investment.

By following this checklist, you will be better equipped to select a small water jet machine that aligns with your business goals and operational requirements.

Comprehensive Cost and Pricing Analysis for small water jet machine Sourcing

What Are the Key Cost Components Involved in Sourcing a Small Water Jet Machine?

When sourcing a small water jet machine, buyers must consider several cost components that contribute to the total expenditure. The primary elements include:

-

Materials: The quality and type of materials used in the machine significantly affect costs. High-grade steel and precision components can increase durability and performance but also raise the initial investment.

-

Labor: Skilled labor is essential for the assembly and quality control of water jet machines. Labor costs can vary by region, impacting the overall price of the equipment, especially in markets with higher wage standards.

-

Manufacturing Overhead: This includes expenses associated with facility maintenance, utilities, and administrative costs. Manufacturers often distribute these overhead costs across all products, which can affect the price per unit.

-

Tooling: Custom tooling may be necessary for specific applications, adding to the cost. The complexity of the tooling directly influences the price, particularly for specialized machines that require unique configurations.

-

Quality Control (QC): Investing in rigorous QC processes ensures that machines meet industry standards and certifications. This investment can lead to higher upfront costs but ultimately ensures reliability and performance.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. These costs can fluctuate based on the delivery method, distance, and any applicable tariffs or taxes.

-

Margin: Suppliers typically include a profit margin that reflects their costs and desired profit. Understanding the standard margins in the industry can help buyers gauge whether they are receiving a fair price.

How Do Price Influencers Affect the Cost of Small Water Jet Machines?

Several factors can influence the pricing of small water jet machines, and understanding these can aid buyers in making informed decisions:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often leads to discounts, which can significantly reduce the per-unit cost. Buyers should assess their needs to determine if bulk purchasing is feasible.

-

Specifications and Customization: Custom features or specifications tailored to specific applications can increase costs. Buyers should weigh the necessity of these customizations against their budget constraints.

-

Materials and Quality Certifications: Machines made from higher-quality materials or those with specific industry certifications often come at a premium. While these may represent higher initial costs, they can reduce long-term maintenance and operational expenses.

-

Supplier Factors: Supplier reputation, location, and production capabilities can influence pricing. Engaging with established suppliers may provide additional assurance of quality, albeit often at a higher price point.

-

Incoterms: The terms of international shipping (such as FOB, CIF, etc.) can affect the final cost. Buyers should familiarize themselves with these terms to understand their responsibilities and potential additional costs.

What Negotiation Tips Can Help Buyers Achieve Cost-Efficiency?

To maximize value when sourcing small water jet machines, buyers should consider the following strategies:

-

Thorough Research: Understand the market pricing and be aware of the going rates for similar machines. This knowledge empowers buyers during negotiations.

-

Leverage Volume: If possible, negotiate for discounts based on order volume. Suppliers are often more willing to provide better pricing for larger orders.

-

Request Detailed Quotes: Ask suppliers for a breakdown of costs. This transparency can reveal areas where costs can be minimized, such as logistics or tooling.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but also long-term expenses like maintenance, energy consumption, and parts replacement. A machine with a higher upfront cost may prove more economical over time.

-

Consider Payment Terms: Flexible payment terms can ease cash flow and allow for better financial planning, potentially leading to improved pricing negotiations.

What Pricing Nuances Should International B2B Buyers Be Aware Of?

International buyers, particularly from Africa, South America, the Middle East, and Europe, should be cognizant of the following pricing nuances:

-

Currency Fluctuations: Exchange rate volatility can impact the final price. Consider negotiating in a stable currency to mitigate risks.

-

Import Duties and Taxes: Understand the local regulations regarding import duties and taxes, as these can significantly add to the total cost.

-

Cultural Differences in Negotiation: Be aware of regional negotiation styles, as some cultures may prioritize relationship-building, while others may focus on terms and pricing.

-

Logistics Challenges: International shipping can introduce delays and additional costs. Partnering with suppliers familiar with local logistics can streamline the process.

Disclaimer

Prices for small water jet machines can vary widely based on the aforementioned factors. The information provided serves as a general guideline and should be verified with specific suppliers to obtain accurate and current pricing details.

Alternatives Analysis: Comparing small water jet machine With Other Solutions

When considering a small water jet machine for precision cutting, it is crucial to evaluate its alternatives. Different cutting technologies can offer varied benefits depending on specific project requirements, material types, and production scales. This analysis compares the small water jet machine with laser cutting and plasma cutting, both of which are popular alternatives in the manufacturing and fabrication sectors.

| Comparison Aspect | Small Water Jet Machine | Laser Cutting | Plasma Cutting |

|---|---|---|---|

| Performance | High precision; can cut complex shapes with minimal kerf | Excellent for thin materials; fast cutting speed | Effective for thick metals; less precision |

| Cost | Moderate to high initial investment; low operational costs | Moderate initial costs; higher operational costs due to consumables | Lower initial costs; high operational costs for gas and consumables |

| Ease of Implementation | Requires space and water supply; user-friendly software | Requires alignment and setup; can be complex for beginners | Requires proper ventilation and safety measures; moderate complexity |

| Maintenance | Low maintenance; periodic checks needed | Moderate maintenance; lens and mirrors require cleaning | Higher maintenance; consumable parts need regular replacement |

| Best Use Case | Ideal for intricate designs in various materials | Best for high-speed cutting of thin sheets; metals | Best for cutting thick metals and materials quickly |

What are the Key Advantages and Disadvantages of Laser Cutting?

Laser cutting is known for its speed and precision, making it an excellent choice for projects that require clean cuts in thin materials. It can achieve intricate designs quickly, making it ideal for industries such as electronics and automotive. However, the operational costs can be higher due to the need for consumables like lenses and gases. Additionally, while laser cutting is effective for metals, it may struggle with reflective materials, leading to potential issues during operation.

How Does Plasma Cutting Compare to Water Jet Cutting?

Plasma cutting is another viable alternative, particularly suited for thicker materials. It operates at high temperatures, allowing for rapid cutting speeds, making it effective for heavy-duty applications in shipbuilding and large-scale manufacturing. However, plasma cutting lacks the precision of a small water jet machine, and the resulting cuts may require additional finishing. It also produces heat-affected zones that can compromise the integrity of the material, which is a significant drawback for sensitive applications.

Conclusion: Which Cutting Solution Should B2B Buyers Choose?

Choosing the right cutting solution depends on several factors, including material type, thickness, desired precision, and budget constraints. For projects requiring high precision and versatility across various materials, the small water jet machine stands out as a superior option. Conversely, for high-speed operations on thin metals, laser cutting may be more appropriate. Plasma cutting, while cost-effective for thick materials, may not meet the precision needs of all applications. B2B buyers should carefully assess their specific requirements and consider long-term operational costs alongside initial investments when making their decision.

Essential Technical Properties and Trade Terminology for small water jet machine

What Are the Key Technical Properties of a Small Water Jet Machine?

When investing in a small water jet machine, understanding its technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to consider:

1. Pressure Rating

The pressure rating, typically measured in PSI (pounds per square inch) or bar, indicates the maximum pressure the water jet can achieve. For instance, a pump with a rating of 60,000 PSI offers high cutting power, making it suitable for a variety of materials, including metals and composites. High-pressure capabilities ensure faster cutting speeds and the ability to handle thicker materials, which is critical for businesses needing efficiency and versatility in production.

2. Cutting Accuracy

Cutting accuracy is defined by the machine’s tolerance levels, often expressed in millimeters or inches. A typical tolerance for small water jet machines may be ±0.01 mm. High accuracy is essential for industries such as aerospace and automotive, where precision is paramount. Ensuring that parts meet exact specifications reduces waste and rework, directly impacting profitability.

3. Work Envelope Size

The work envelope size refers to the maximum dimensions of the material that can be processed. For example, a work envelope of 1.2 m x 0.6 m allows for cutting a range of parts without needing to reposition the material frequently. A larger work envelope enhances production efficiency, enabling manufacturers to handle various projects without investment in multiple machines.

4. Z-Axis Travel

The Z-axis travel indicates how deep the cutting head can move, typically measured in millimeters or inches. This specification is vital for cutting thicker materials or creating complex shapes. A Z-axis travel of 150 mm, for instance, allows for versatility in applications, catering to diverse customer needs without sacrificing performance.

5. Repeatability

Repeatability refers to the machine’s ability to produce identical results consistently over multiple cuts. It is usually expressed in millimeters or inches, such as ±0.01 mm. High repeatability is crucial for production runs, ensuring that each part meets quality standards, thereby reducing defects and enhancing customer satisfaction.

6. Acceleration and Traverse Speed

Acceleration measures how quickly the cutting head can reach its maximum speed, while traverse speed indicates the maximum speed at which the head can move across the workpiece. A rapid traverse speed of 15,000 mm/min allows for faster processing times, which is essential in high-demand environments where time is money.

What Are Common Trade Terminologies in the Water Jet Industry?

Understanding industry jargon is vital for effective communication and negotiation with suppliers. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of water jet machines, it is essential to know whether the machine or parts come from an OEM, as this can affect quality, warranty, and service availability.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is important for budgeting and inventory management, especially for businesses looking to scale production without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting price estimates for specific quantities of goods or services. In the water jet industry, submitting RFQs helps buyers gauge market prices and make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in shipping goods. Familiarity with these terms is crucial for international transactions, as they clarify who is responsible for shipping costs, insurance, and risks during transport.

5. CNC (Computer Numerical Control)

CNC technology refers to the automated control of machining tools through computer programming. Understanding CNC is essential for evaluating water jet machines, as it impacts precision, repeatability, and the complexity of cuts that can be achieved.

6. Abrasive

In the context of water jet cutting, an abrasive is a material, often garnet, that is mixed with water to enhance cutting capability. Knowing the type and quality of abrasives used can affect both the efficiency of the cutting process and the overall cost of operation.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions regarding the procurement of small water jet machines, ensuring they align with operational needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the small water jet machine Sector

What Are the Current Market Dynamics and Key Trends Impacting Small Water Jet Machines?

The small water jet machine sector is experiencing robust growth driven by the demand for precision cutting in various industries, including manufacturing, aerospace, automotive, and construction. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to enhance their operational efficiency, the versatility of water jet cutting technology becomes increasingly appealing. Key trends include the integration of advanced automation and software solutions, which streamline operations and improve productivity. Additionally, the rise of compact and affordable water jet machines, like the WAZER Pro, enables smaller businesses to enter the market and leverage this technology without significant capital investment.

Emerging technologies such as IoT (Internet of Things) are also reshaping the landscape, allowing for real-time monitoring and predictive maintenance, thereby reducing downtime and operational costs. Furthermore, sustainability considerations are becoming paramount; buyers are increasingly prioritizing suppliers that demonstrate a commitment to eco-friendly practices, such as using recyclable materials and minimizing waste. As global supply chains evolve, an emphasis on ethical sourcing and transparency is becoming essential, particularly for buyers in regions with stringent regulatory environments.

How Does Sustainability and Ethical Sourcing Influence the Small Water Jet Machine Sector?

Sustainability is a critical concern for today’s international B2B buyers, particularly in the small water jet machine sector. The environmental impact of manufacturing processes, including resource consumption and waste generation, is under scrutiny. As a result, companies are investing in technologies that minimize these impacts. For instance, modern water jet machines utilize high-pressure water streams that reduce the need for harmful chemicals, making them more environmentally friendly than traditional cutting methods.

Moreover, the importance of ethical supply chains cannot be overstated. Buyers are increasingly seeking suppliers who adhere to sustainable practices, including responsible sourcing of materials and transparency in their manufacturing processes. Certifications such as ISO 14001 for environmental management and adherence to green standards are becoming prerequisites for partnership. These certifications not only enhance brand reputation but also align with the growing consumer demand for environmentally responsible products. By prioritizing sustainability, companies can improve their market positioning and appeal to a wider customer base.

What Is the Brief Evolution and History of Small Water Jet Machines in the B2B Context?

The evolution of small water jet machines can be traced back to the 1980s when the technology was first developed for cutting hard materials using high-pressure water streams mixed with abrasive garnet. Initially, water jet machines were large and expensive, primarily used in specialized industries. Over the years, advancements in technology have led to the miniaturization and affordability of these machines, making them accessible to small and medium enterprises.

The introduction of compact models, such as the WAZER and NanoJet, has transformed the market by allowing businesses to perform precision cutting in-house, reducing reliance on outsourcing. This shift not only enhances operational efficiency but also enables companies to respond quickly to market demands. As the technology continues to evolve, the small water jet machine sector is set to expand further, driven by innovation and increasing global demand for sustainable and precise manufacturing solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of small water jet machine

-

How do I choose the right small water jet machine for my business needs?

Choosing the right small water jet machine involves assessing your specific cutting requirements, such as material types, thickness, and complexity of designs. Evaluate the machine’s specifications, including cutting speed, accuracy, and maximum material thickness it can handle. Consider the machine’s footprint, especially if space is a constraint. Additionally, explore the manufacturer’s support services, including training and maintenance options, to ensure you can operate and maintain the machine effectively. -

What are the key features to look for in a small water jet machine?

Key features to consider include cutting accuracy, maximum pressure capability, and the range of materials it can cut. Look for machines with advanced pump technology, as higher pressure can improve cutting efficiency. A fully enclosed design can enhance safety and minimize noise, while user-friendly software can streamline the cutting process. Also, consider the machine’s maintenance requirements and the availability of replacement parts to ensure long-term reliability. -

How can I verify the reliability of a water jet machine supplier?

To verify a supplier’s reliability, research their reputation through customer reviews and testimonials. Request references from previous clients, particularly those in your region, to gauge their experiences. Assess the supplier’s industry experience and the certifications their products hold, such as ISO standards. Engage in direct communication to evaluate their responsiveness and willingness to provide support, including after-sales services and technical assistance. -

What is the typical lead time for ordering a small water jet machine?

Lead times can vary significantly based on the manufacturer, model, and customization requirements. Typically, it ranges from 4 to 12 weeks. For standard machines, lead times may be shorter, while custom configurations could take longer. It’s advisable to discuss lead times upfront with your supplier and factor in additional time for shipping, especially for international orders, to avoid any disruptions in your production schedule. -

What are the payment terms commonly offered by water jet machine suppliers?

Payment terms vary by supplier but often include options such as upfront payment, installment plans, or financing options. Some suppliers may offer favorable terms for bulk purchases or repeat customers. It’s essential to clarify the payment structure, including any deposits required and the timeline for remaining payments. Ensure that the terms are documented in the purchase agreement to avoid misunderstandings. -

What is the minimum order quantity (MOQ) for small water jet machines?

The minimum order quantity for small water jet machines can differ based on the manufacturer and the specific model. Some suppliers may allow single-unit purchases, particularly for standard models, while others might have a MOQ for custom configurations. Always inquire about MOQs during your initial discussions and consider negotiating if you plan to make a larger investment in the future. -

What quality assurance measures should I expect from a water jet machine supplier?

A reputable supplier should have robust quality assurance processes in place, including testing and certification of their machines before shipment. Inquire about their quality control procedures, such as inspection protocols and performance testing. Additionally, request documentation of compliance with international standards to ensure that the machine meets safety and operational requirements, which is crucial for maintaining operational efficiency and safety in your facility. -

How should I handle logistics when importing a small water jet machine?

When importing a small water jet machine, coordinate closely with your supplier to understand shipping options and costs. Determine whether the supplier handles logistics or if you need to arrange this yourself. Research customs regulations in your country to ensure compliance and avoid delays. It’s advisable to work with a freight forwarder familiar with machinery imports to facilitate smooth transportation and delivery, including handling any necessary documentation and tariffs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Small Water Jet Machine Manufacturers & Suppliers List

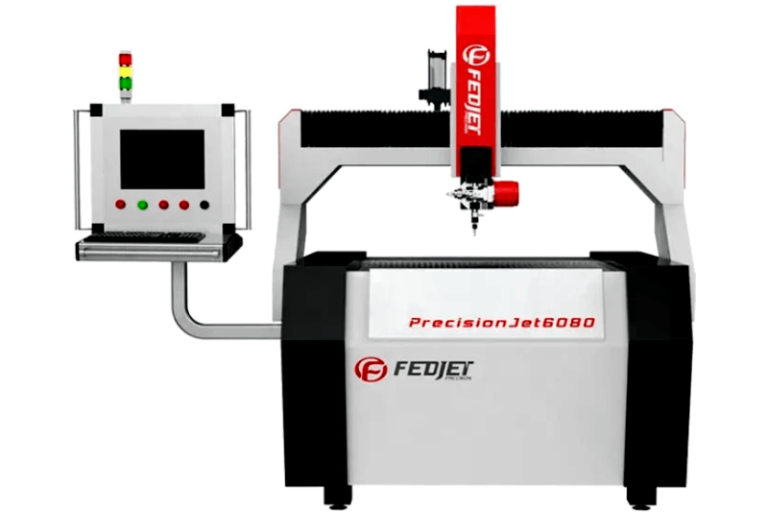

1. Flow Waterjet – NanoJet

Domain: flowwaterjet.com

Registered: 2003 (22 years)

Introduction: NanoJet – A highly accurate, small-format waterjet machining center designed for precise, clean, and quiet cutting. Key features include:

– Fully enclosed, all-in-one solution

– Integrates into high output operations with minimal floor space

– Designed for precise cutting and fast part production

– Equipped for quick and precise motions, maximizing uptime and reliability

– Optional linear mot…

2. Grizzly – Wazer T34212 Benchtop Waterjet Cutter

Domain: grizzly.com

Registered: 1991 (34 years)

Introduction: {“model”:”Wazer T34212″,”type”:”Benchtop Waterjet Cutter”,”power_requirement”:”110V/60Hz”,”price”:”$9,999.00″,”cutting_area”:”12″ x 18″”,”kerf”:”0.044″”,”abrasive_rate”:”0.33 lbs./min.”,”maximum_working_pressure”:”4600 PSI”,”overall_dimensions”:”34″ W x 26″ D x 22″ H”,”included_items”:[“WAZER Desktop”,”WAM software license”,”Two 55-pound abrasive buckets”,”Two cut beds”,”Two water sensors”,”Access…

3. MatterHackers – WAZER Desktop Waterjet Cutter

Domain: matterhackers.com

Registered: 2012 (13 years)

Introduction: WAZER Desktop Waterjet Cutting Machine

– Type: Desktop Waterjet Cutter

– Price: $9,999 (Desktop model)

– Features:

– Digitally-controlled high-velocity jet

– Cuts a wide range of materials including metal, ceramic, plastic, rubber, and carbon fiber

– Compact and contained design

– Easy and safe to use

– Quick learning curve

– Cold cutting process to avoid heat-induced warping

– Enclo…

4. Finepart – Finecut WMC500II

Domain: finepart.com

Registered: 2015 (10 years)

Introduction: Finecut Micro Abrasive Waterjet Machines are high precision cutting machines designed for ultimate precision and productivity. Key models include:

1. **Finecut WMC500II** – Available in 3-axis, 4-axis (Type A), and 5-axis (Types ABX and B4X) configurations.

– **3-Axis**: Cutting width down to 0.2 mm, cutting envelope of 500 mm x 500 mm.

– **4-Axis**: Ultra-high precision with rotating wor…

5. Omax – ProtoMAX Abrasive Waterjet

Domain: omax.com

Registered: 1996 (29 years)

Introduction: { “Product Name”: “ProtoMAX Abrasive Waterjet”, “Description”: “A compact, self-contained cutting system designed for prototyping and low-volume cutting of materials up to approximately 1″ thick.”, “Key Features”: { “Traverse Speed”: “up to 100 in/min (2,540 mm/min)”, “Positional Accuracy”: “±0.005″ (±0.127 mm)”, “Electrical Requirements”: “230-240 VAC single phase, 30A, 50/60 Hz”, “Setup Time”: “…

6. WardJet – A-Series Waterjet

Domain: wardjet.com

Registered: 2000 (25 years)

Introduction: A-Series Waterjet features: 1. Incredibly powerful and compact design. 2. Most power per square foot in its class with a standard 60k psi pump. 3. Cutting enclosure for reduced splash and noise. 4. Intuitive control design with MOVE touchscreen controller. 5. Industrial-grade rack and pinion drive system for accuracy. 6. Capable of cutting materials up to 7″ thick. 7. Built-in water level control …

7. Techniwaterjet – Intec™G2 Series

Domain: techniwaterjet.com

Registered: 2005 (20 years)

Introduction: Intec™G2 Series: i35-G2 (Cutting Area: 915 x 1525 mm, Cantilever Style), i510-G2 (Cutting Area: 1525 x 3050 mm, Cantilever Style), i613-G2 (Cutting Area: 1700 x 3700 mm, Monoblock Style), i713-G2 (Cutting Area: 2000 x 4000 mm, Gantry Style), i815-G2 (Cutting Area: 2350 x 4750 mm, Gantry Style), i1020-G2 (Cutting Area: 3050 x 6100 mm, Gantry Style), i1033-G2 (Cutting Area: 10000 x 3000 mm, Gantry S…

Strategic Sourcing Conclusion and Outlook for small water jet machine

What are the Key Benefits of Investing in Small Water Jet Machines?

In conclusion, the strategic sourcing of small water jet machines presents a multitude of advantages for international B2B buyers. These cutting-edge tools not only offer exceptional precision and versatility, but they also cater to a wide array of materials, making them ideal for diverse industries such as aerospace, automotive, and manufacturing. By integrating solutions like the NanoJet and WAZER Pro into operations, businesses can enhance productivity while minimizing operational costs and maintenance downtime.

The value of strategic sourcing cannot be overstated; it allows businesses to leverage the latest technology, optimize supply chains, and ensure they remain competitive in a rapidly evolving marketplace. As the demand for precision manufacturing continues to rise, investing in small water jet technology will be crucial for companies aiming to stay ahead.

Looking forward, international buyers from Africa, South America, the Middle East, and Europe should seize the opportunity to explore these innovative solutions. Engage with suppliers, request demonstrations, and analyze your specific cutting needs to make informed decisions that can drive your business forward. The future of manufacturing is here—take the leap into precision cutting technology today.