Contents

Manufacturing Insight: Small Cnc Router With Tool Changer

Precision Automation for Prototyping and Low-Volume Production

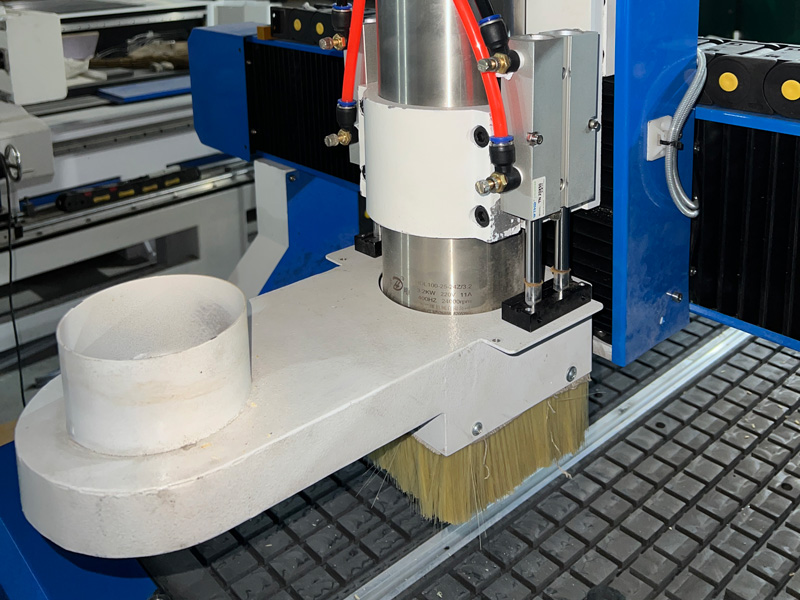

Honyo Prototype delivers advanced CNC machining solutions engineered for demanding prototyping and short-run manufacturing environments. Our small-format CNC routers with integrated automatic tool changers (ATC) eliminate manual intervention, significantly reducing non-cut time while maintaining micron-level accuracy across aluminum, engineering plastics, composites, and wood. These systems feature robust 12-station tool changers, high-speed spindles, and rigid frames designed specifically for shops requiring rapid iteration without sacrificing repeatability. Unlike standard manual-change routers, Honyo’s ATC-enabled platforms enable unattended operation for complex multi-tool workflows, directly addressing bottlenecks in high-mix production where frequent tool swaps traditionally compromise throughput.

Beyond equipment capability, Honyo integrates deep manufacturing expertise with every project. Our engineering team optimizes toolpaths, material selection, and fixturing strategies to maximize machine utilization and part quality—turning your design files into certified components faster. This holistic approach ensures your investment in automation translates to measurable reductions in cost-per-part and accelerated time-to-market.

Accelerate your procurement process with Honyo’s Online Instant Quote system. Upload CAD files to receive detailed, transparent pricing and lead times in under 60 seconds—no forms, no delays. Experience how our precision CNC routing services and digital-first quoting streamline your path from concept to physical part.

Technical Capabilities

Technical Specifications: Small CNC Router with Automatic Tool Changer

The following table outlines the technical specifications for a high-precision small CNC router equipped with an automatic tool changer (ATC), engineered for 3, 4, and 5-axis milling as well as light turning operations. This machine is optimized for tight-tolerance machining across a range of materials including aluminum, steel, ABS, and nylon.

| Parameter | Specification |

|---|---|

| Control System | Fanuc 31i, Siemens 828D, or Heidenhain TNC 640 (optional) |

| Number of Axes | 3-axis standard; optional 4th (rotary B or A axis) and 5th axis (dual rotary) |

| Spindle Speed | 12,000 – 24,000 RPM (HSK-E25 or BT-30 interface) |

| Spindle Power | 5.5 – 8.0 kW (air or liquid cooled) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope | 600 x 400 x 300 mm (X-Y-Z); customizable up to 800 mm in X |

| Tool Changer Type | Automatic Tool Changer (ATC), carousel type |

| Tool Capacity | 8 to 12 tools standard; upgradable to 16 |

| Tool Change Time | < 2.5 seconds (average) |

| Rapid Traverse Rate (XYZ) | 30 m/min |

| Cutting Feed Rate | 1 – 10,000 mm/min (programmable) |

| Linear Guides | High-precision linear roller guides (THK or HIWIN) |

| Ball Screws | Preloaded C3 class, double-nut design with thermal compensation |

| Table Type | T-slots or vacuum with optional indexing rotary table for 4th/5th axis |

| Minimum Increment | 0.001 mm |

| Coolant System | Through-spindle coolant (optional); mist and air blast standard |

| Material Compatibility | Aluminum (6061, 7075), Mild & Stainless Steel (up to 4140), ABS, Nylon, PEEK |

| Max Cutting Tolerance | ±0.01 mm (typical), down to ±0.005 mm under optimized conditions |

| Surface Finish | Ra < 0.8 µm achievable with fine tooling and parameters |

| Machine Frame | Cast iron or mineral casting base with vibration damping |

| Position Feedback | Closed-loop linear encoders (optional for high-precision models) |

| Software Compatibility | Compatible with Mastercam, Fusion 360, SolidCAM, and Heidenhain conversational |

| Dimensions (LxWxH) | Approx. 1,800 x 1,500 x 1,800 mm |

| Weight | 1,200 – 1,600 kg (depending on configuration) |

| Power Requirement | 3-phase 208–230V / 400V, 50/60 Hz, 15–20 kVA |

This compact CNC system is designed for prototyping, precision component manufacturing, and low-volume production in aerospace, automotive, and industrial design sectors. Its rigid construction and high-resolution feedback systems support tight-tolerance machining in both soft materials like ABS and nylon, and harder metals such as aluminum and steel. The integrated tool changer enables unattended operation during complex multi-tool processes, improving throughput and consistency.

From CAD to Part: The Process

Honyo Prototype’s end-to-end manufacturing process for complex assemblies like a small CNC router with automatic tool changer (ATC) follows a rigorously defined workflow to ensure precision, cost efficiency, and on-time delivery. Below is a technical overview of each phase, emphasizing critical engineering controls specific to multi-component electromechanical systems.

Upload CAD

Clients submit complete 3D CAD models (STEP/IGES/Parasolid) with all subassemblies (frame, spindle, linear guides, ATC mechanism, control cabinet interfaces) and 2D technical drawings specifying GD&T, surface finishes, and material certifications. Our system validates file integrity and geometric coherence upon upload. For CNC router projects, mandatory inclusion of ATC interface dimensions (e.g., ISO 30/40 taper specifications, tool magazine pitch) and dynamic load requirements is enforced to prevent downstream rework.

AI-Powered Quoting

Our proprietary AI engine analyzes CAD geometry against a database of 12,000+ historical CNC machining projects. It calculates machine time (including ATC tool change cycles), material utilization, and secondary operations (anodizing, hardening) using physics-based simulations. For a typical small router (e.g., 600x400mm work envelope), the AI generates a preliminary quote within 2 hours with 92% cost accuracy, highlighting high-risk elements like thin-walled aluminum housing or hardened steel guide rails. Critical parameters assessed include:

| Parameter | Typical Tolerance Range | AI Assessment Trigger |

|---|---|---|

| Spindle nose runout | ≤0.005mm TIR | Flag if CAD shows >0.003mm |

| ATC magazine alignment | ±0.02mm positional | Requires manual review |

| Linear rail mounting surfaces | 0.02mm/1000mm flatness | Material grade check |

Engineering-Driven DFM

This phase involves direct collaboration between Honyo’s manufacturing engineers and the client’s design team. We perform a structured DFM review focused on CNC router-specific challenges:

ATC mechanism manufacturability is rigorously evaluated for tool change collision avoidance and repeatability. Spindle housing thermal expansion coefficients are cross-referenced with selected materials. We simulate chip evacuation paths to prevent ATC interference during operation. Typical DFM outcomes include recommending chamfered tool magazine entries to reduce jamming risk or modifying bracket geometries to enable 5-axis simultaneous milling. Clients receive a formal DFM report with actionable suggestions, typically reducing NRE costs by 18-22% through design simplifications like consolidating welded assemblies into single castings.

Precision Production

Machining occurs in climate-controlled cells using DMG MORI 5-axis centers with Renishaw probes for in-process verification. ATC components undergo sequential quality gates:

Tool changer arms: CMM inspection of pivot point concentricity (±0.008mm)

Magazine plates: Laser scanning of tool pocket profiles

Frame assemblies: Gravimetric testing for dynamic balance

All critical surfaces (e.g., linear guide mounting ways) are measured per ISO 230-2 standards before assembly. The ATC system undergoes 500+ automated tool change cycles with load cells monitoring retention force (2,800-3,200N range). Final router calibration includes laser interferometer validation of positioning accuracy (±0.006mm over full travel).

Validated Delivery

Units ship with full traceability documentation including material certs, CMM reports for critical features, and ATC cycle test logs. We conduct pre-shipment operational validation per ISO 10791-7:

8-hour continuous dry-run at 90% max spindle load

Tool change repeatability testing (≤0.015mm positional deviation)

Thermal stability monitoring during extended operation

Delivery includes a digital twin package with calibrated machine parameters and preventive maintenance schedules specific to the ATC system. Typical lead time for a small CNC router with ATC is 14-18 weeks from CAD approval, with 72-hour expedited shipping options for validated designs.

Start Your Project

Upgrade your prototyping and production capabilities with our compact, high-precision small CNC router equipped with an automatic tool changer. Engineered for efficiency and accuracy, this machine is ideal for intricate milling tasks across industries—from electronics to precision components.

Built in our Shenzhen manufacturing facility, each unit undergoes rigorous quality control to ensure durability and peak performance.

For sales inquiries and technical specifications, contact Susan Leo at [email protected]. Let’s build precision together.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.